Method for producing rabies vaccine by applying bioreactor and sheet carrier

A bioreactor, rabies vaccine technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of long production cycle, low virus harvest, unsuitable for large-scale production, etc., and achieve production costs Effect of low, high cell density, high viral titer and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

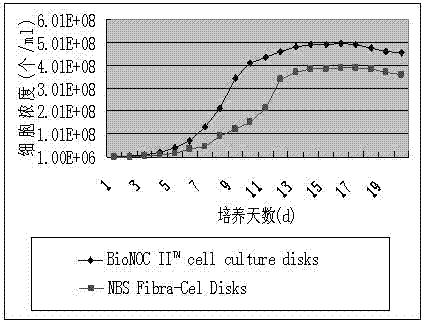

[0039] (1) Sterilize the Celligen 310 14L bioreactor with a fixed bed basket stirring system and assemble it completely, add cell culture medium, add BioNOC II? cell culture disks microcarrier 15g / L, calf serum content in the culture medium is 5 %, adjust the pH to 7.0, temperature at 33°C, and stirring speed at 20rpm overnight; inoculate Vero cells amplified by 3L spinner bottles at a seeding density of 0.5×10 6 cells / ml, adjust CO 2 The pressure is 5%, the pH is 7.2, the temperature is 35°C, the dissolved oxygen is 20%, the glucose concentration is 25uM, and the stirring speed is 20rpm;

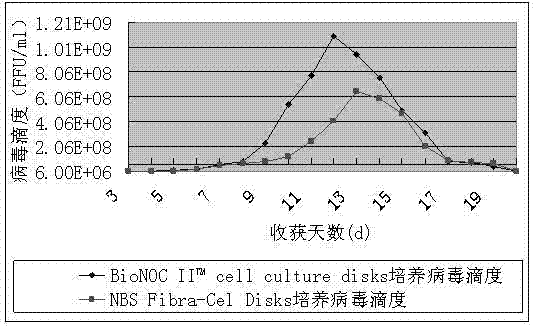

[0040] (2) When the cell density increases to 5×10 7 cells / ml was inoculated with aGV virus, the inoculation ratio was 1:100,

[0041] (3) Detect parameters such as glucose and lactic acid content through a biochemical analyzer, and adjust the reactor control parameters: CO 2 The pressure is 5%, the pH is 7.4, the temperature is 30°C, the dissolved oxygen is 20%, the glucose concentratio...

Embodiment 2

[0044] (1) Sterilize the Celligen 310 14L bioreactor with a fixed bed basket stirring system and assemble it completely, add cell culture medium, add BioNOC II? cell culture disks microcarrier 18g / L, calf serum content in the culture medium is 8 %, adjust the pH to 7.2, temperature 35°C, and stirring speed 35rpm overnight; inoculate Vero cells amplified by 3L spinner bottles, and the inoculation density is 1.3×10 6 cells / ml, adjust CO 2 The pressure is 8%, the pH is 7.3, the temperature is 36°C, the dissolved oxygen is 55%, the glucose concentration is 35uM, and the stirring speed is 60rpm;

[0045] (2) When the cell density increases to 5×10 7 cells / ml was inoculated with aGV virus, the inoculation ratio was 1:300,

[0046] (3) Detect parameters such as glucose and lactic acid content through a biochemical analyzer, and adjust the reactor control parameters: CO 2 The pressure is 8%, the pH is 7.6, the temperature is 33°C, the dissolved oxygen is 55%, the glucose concentrat...

Embodiment 3

[0049] (1) Sterilize the Celligen 310 14L bioreactor with a fixed bed basket stirring system and assemble it completely, add cell culture medium, add BioNOC II? cell culture disks microcarrier 20g / L, calf serum content in the culture medium is 10 %, adjust the pH to 7.4, temperature at 37°C, and stirring speed at 50rpm overnight; inoculate Vero cells amplified by 3L spinner bottles at a seeding density of 2×10 6 cells / ml, adjust CO 2 The pressure is 10%, the pH is 7.4, the temperature is 37°C, the dissolved oxygen is 90%, the glucose concentration is 40uM, and the stirring speed is 100rpm;

[0050] (2) When the cell density increases to 5×10 7 cells / ml was inoculated with aGV virus, the inoculation ratio was 1:500,

[0051] (3) Detect parameters such as glucose and lactic acid content through a biochemical analyzer, and adjust the reactor control parameters: CO 2 The pressure is 10%, the pH is 7.8, the temperature is 35°C, the dissolved oxygen is 90%, the glucose concentrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cell density | aaaaa | aaaaa |

| Titer | aaaaa | aaaaa |

| Titer | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com