Dispersion strengthened ceramic composite material and preparation method thereof

A ceramic composite material and dispersion strengthening technology, applied in the field of composite materials and engineering ceramic materials, can solve the problems of poor corrosion resistance and wear resistance, increased production cost, easy to block nozzles, etc., and achieve low porosity and comprehensive mechanical properties. Improved, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

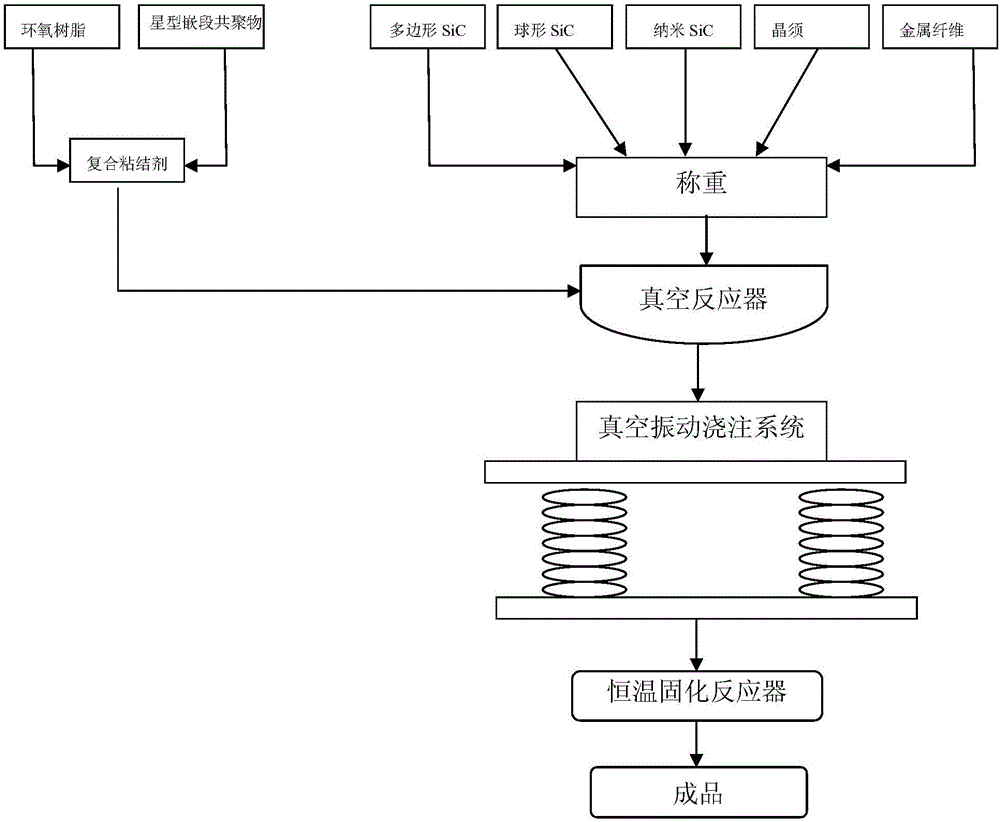

Method used

Image

Examples

Embodiment 1

[0051] A dispersion-strengthened ceramic composite material, which is composed of silicon carbide, calcium sulfate whiskers, metal titanium fibers with a passivation film on the surface, and a composite binder. In the ceramic composite material, silicon carbide particles of different shapes , calcium sulfate whiskers, metal titanium fibers and composite binder interweave and distribute; where:

[0052] According to the mass ratio, 1.5mm ± 0.5mm polyhedral silicon carbide particles: 450 μm ± 50 μm polyhedral silicon carbide particles: 15 μm ± 5 μm spherical silicon carbide: 100nm spherical nano-silicon carbide: calcium sulfate whiskers with an aspect ratio of 100 and a diameter of 1 μm: Metal titanium fibers with a passivation film on the surface of a diameter of 8 μm and a length of 1 mm: composite binder = 30:5:20:5:10:5:15;

[0053] Described composite binder is made up of epoxy resin and star-shaped block copolymer, by mass ratio, epoxy resin: star-shaped block copolymer=99...

Embodiment 2

[0065] A dispersion-strengthened ceramic composite material, which is composed of silicon carbide, calcium sulfate whiskers, metal titanium fibers with a passivation film on the surface, and a composite binder. In the ceramic composite material, silicon carbide particles of different shapes , calcium sulfate whiskers, metal titanium fibers and composite binder interweave and distribute; where:

[0066] According to the mass ratio, 2.5mm ± 0.5mm polyhedral silicon carbide particles: 450 μm ± 50 μm polyhedral silicon carbide particles: 15 μm ± 5 μm spherical silicon carbide: 90 nm spherical nano-silicon carbide: calcium sulfate whiskers with an aspect ratio of 90 and a diameter of 1.5 μm : 10 μm in diameter and 1.2 mm in length, titanium metal fibers with a passivation film on the surface: composite binder = 5: 30: 20: 1: 5: 5: 30;

[0067] Described composite binder is made up of epoxy resin and star-shaped block copolymer, by mass ratio, epoxy resin: star-shaped block copolyme...

Embodiment 3

[0079] A dispersion-strengthened ceramic composite material, which is composed of silicon carbide, calcium sulfate whiskers, metal titanium fibers with a passivation film on the surface, and a composite binder. In the ceramic composite material, silicon carbide particles of different shapes , calcium sulfate whiskers, metal titanium fibers and composite binder interweave and distribute; where:

[0080] According to the mass ratio, 2mm ± 0.5mm polyhedral silicon carbide particles: 450 μm ± 50 μm polyhedral silicon carbide particles: 15 μm ± 5 μm spherical silicon carbide: 90nm spherical nano-silicon carbide: calcium sulfate whiskers with an aspect ratio of 110 and a diameter of 0.5 μm: Metal titanium fibers with a passivation film on the surface of a diameter of 7 μm and a length of 2.4 mm: composite binder = 15: 15: 10: 3: 10: 0.5: 25;

[0081] Described composite binder is made up of epoxy resin and star-shaped block copolymer, by mass ratio, epoxy resin: star-shaped block co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com