Patents

Literature

36results about How to "Consistent heat dissipation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

LED light-emitting device and manufacturing method thereof

ActiveCN105097999AImprove light outputLow refractive indexSemiconductor devicesRefractive indexOrganic layer

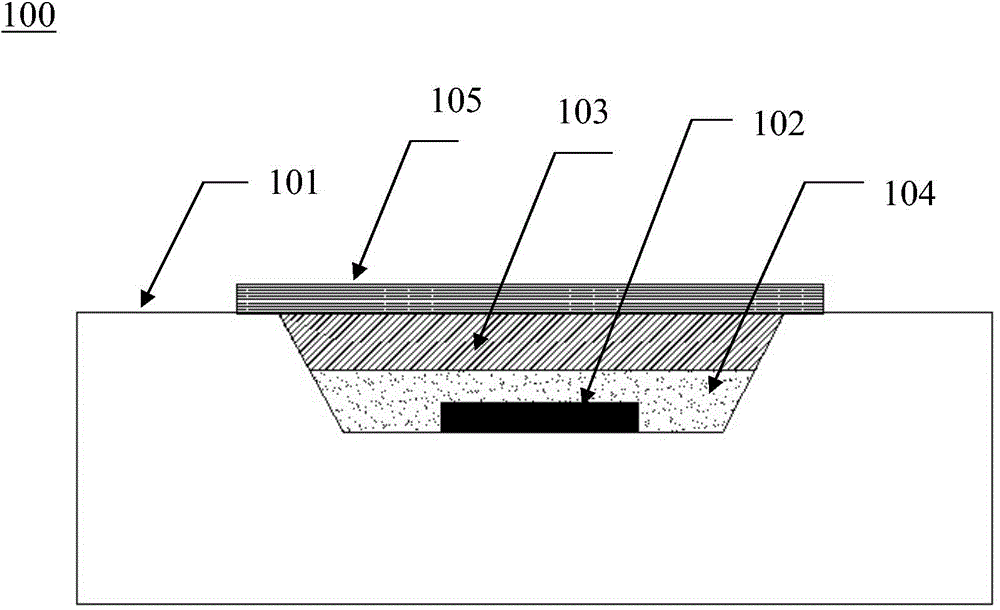

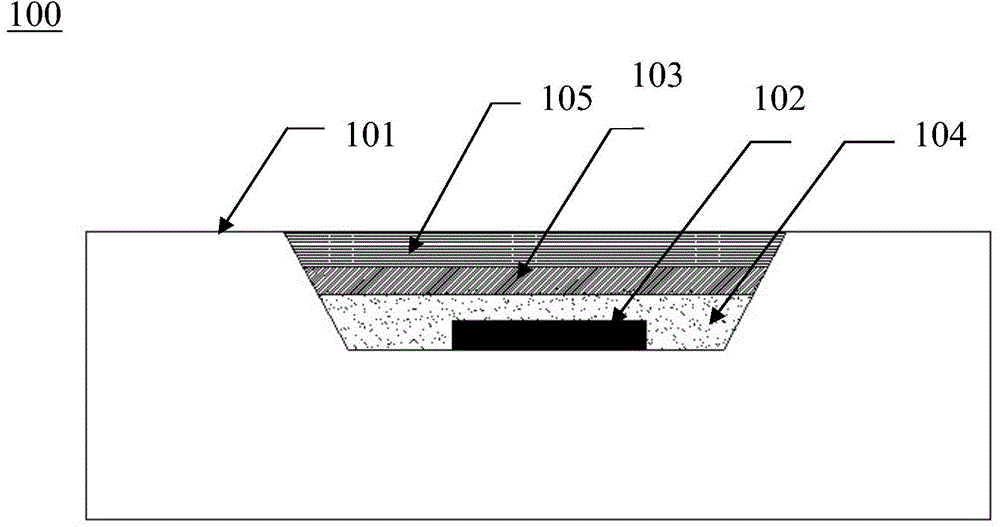

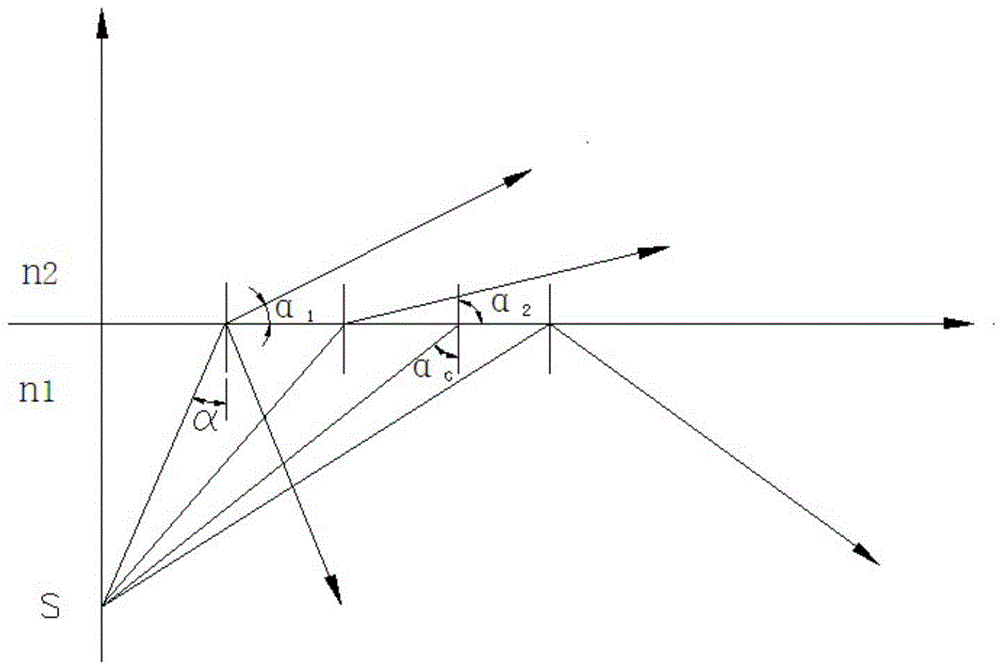

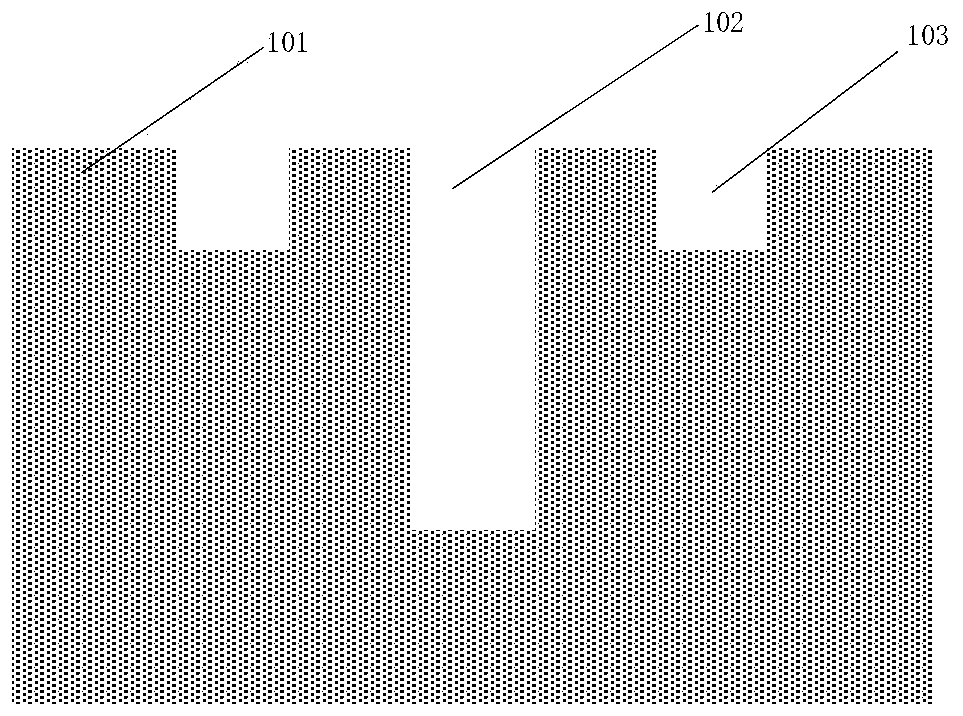

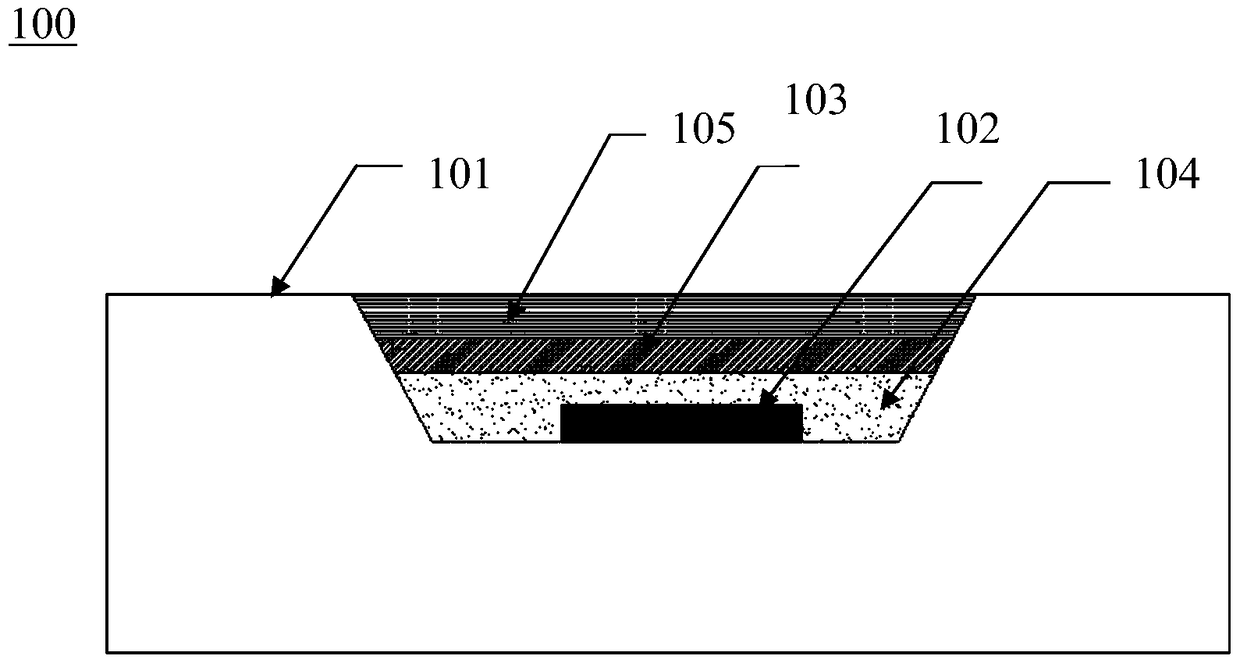

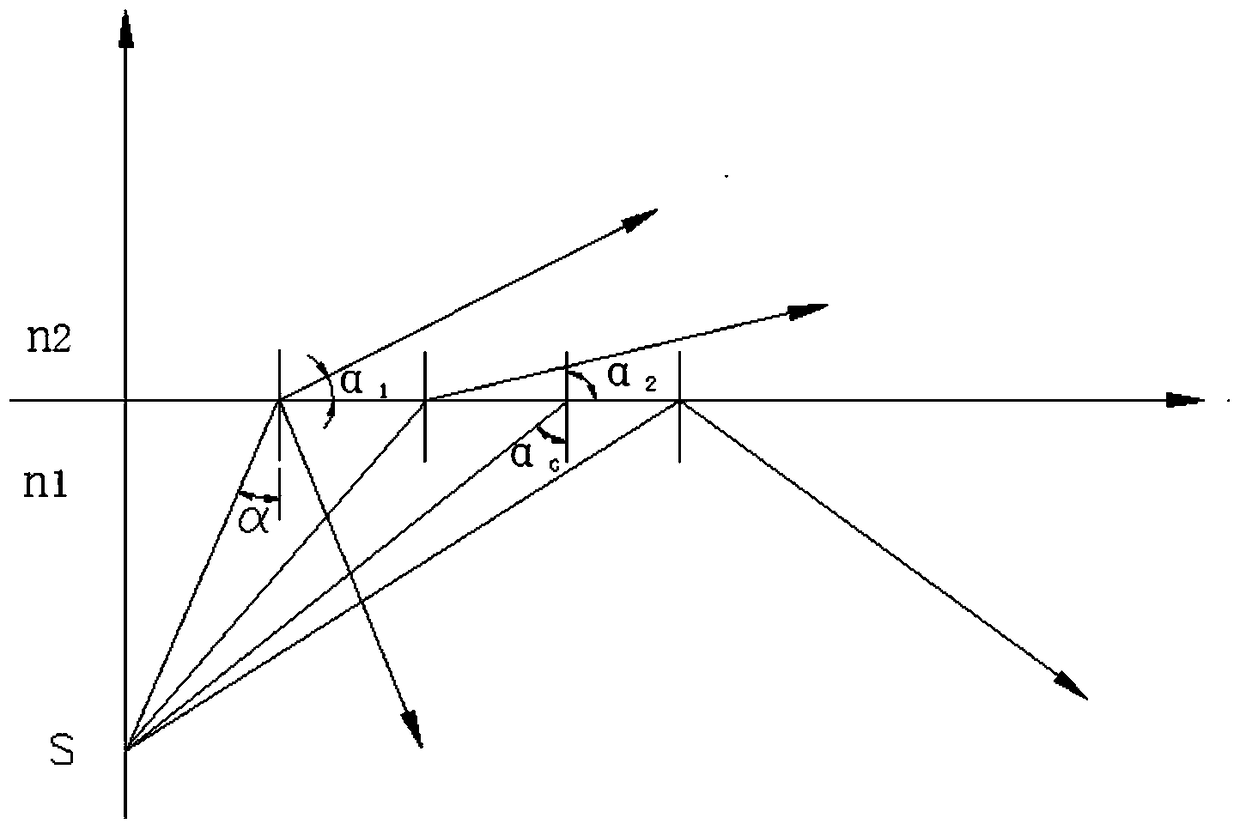

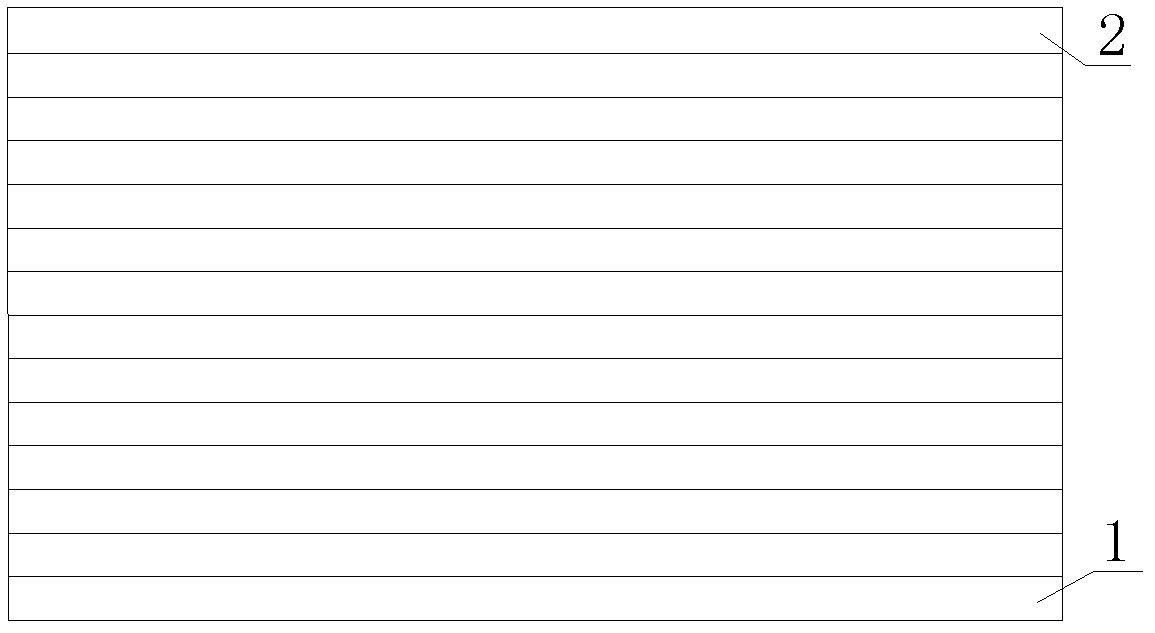

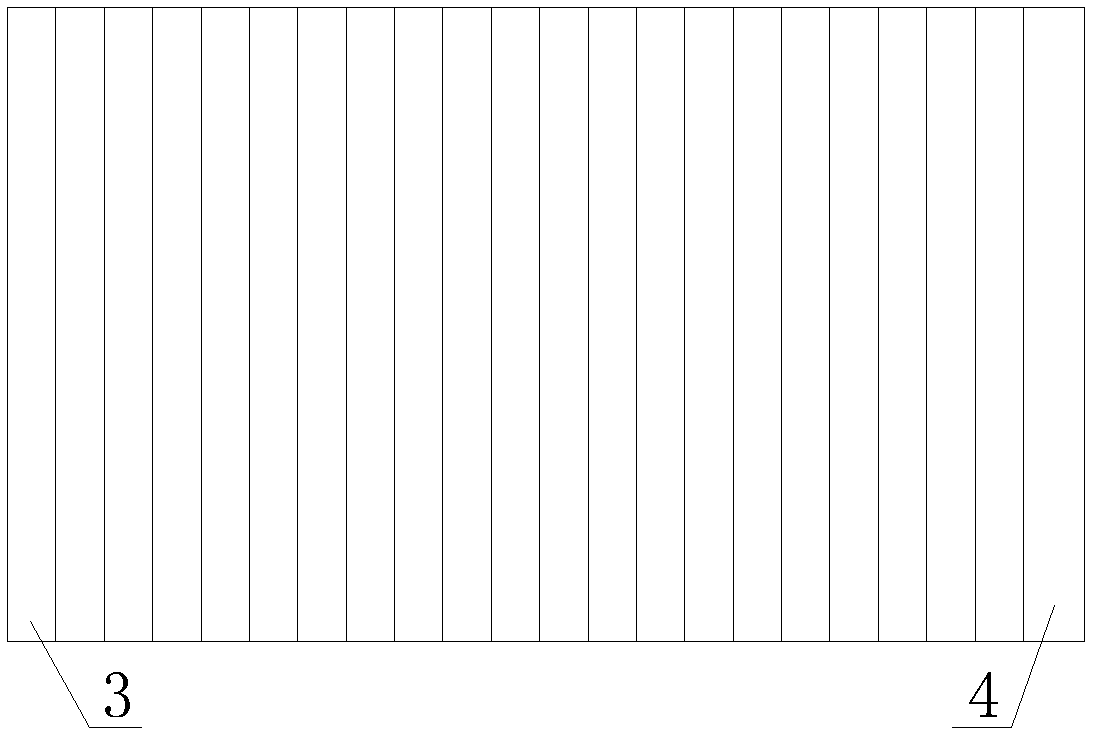

The invention relates to an LED light-emitting device and a manufacturing method thereof. The LED light-emitting device comprises a substrate, an LED chip, and an organic layer, wherein the LED chip and the organic layer are arranged on the substrate. The LED light-emitting device is characterized in that a refractive index buffer layer is arranged between the LED chip and the organic layer and is provided with a refractive index between the refractive index of the LED chip and the refractive index of silica gel; the refractive index buffer layer introduces light emitted by the LED chip into the organic layer in order to more light may pass through the organic layer; the organic layer is covered with a non-uniform luminescent powder layer including at least two luminescent powder layers arranged in a layered manner, wherein the two luminescent powder layers have different types of luminescent powders or the same type of luminescent powders with different particle sizes; the luminescent powders with the same type or same particle sizes of the luminescent powder layers are uniformly arranged; the luminescent powders with different types or different particle sizes are arranged relatively non-uniformly.

Owner:SICHUAN SUNFOR LIGHT

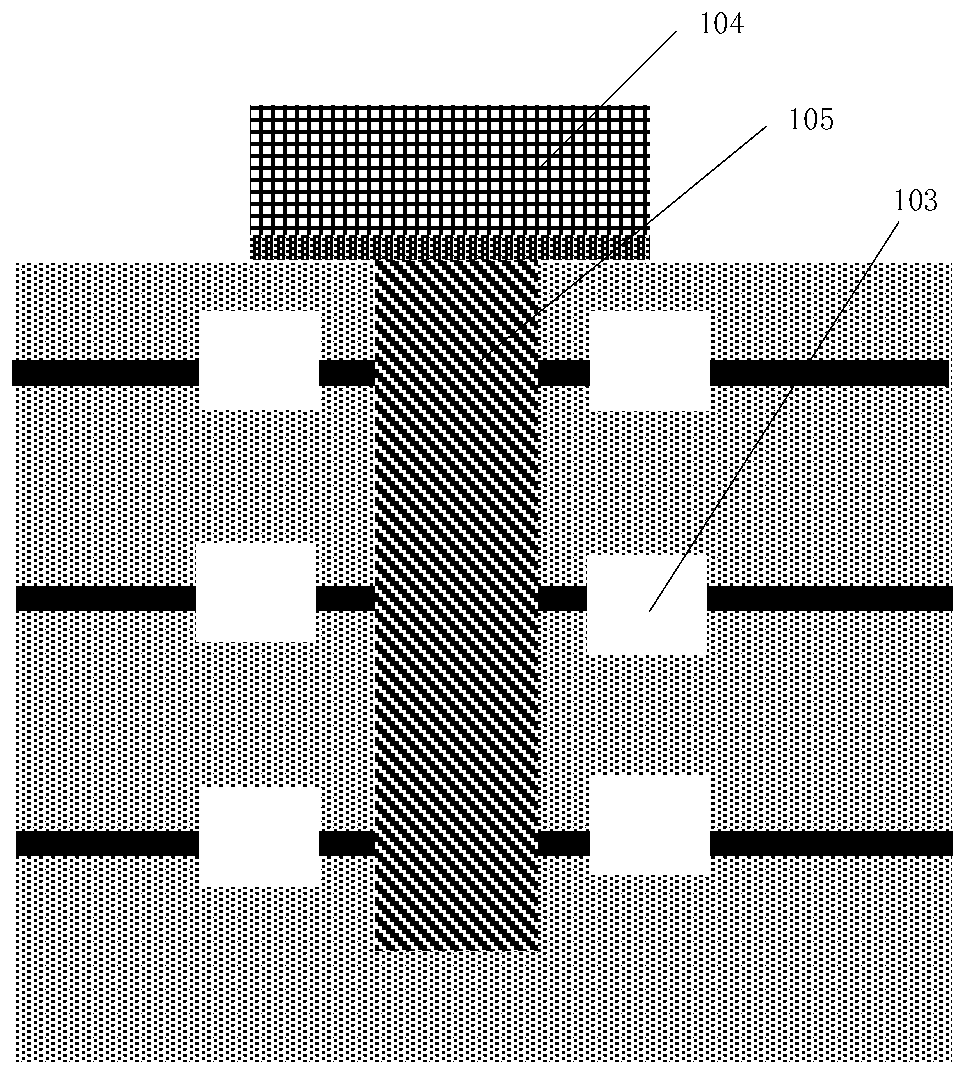

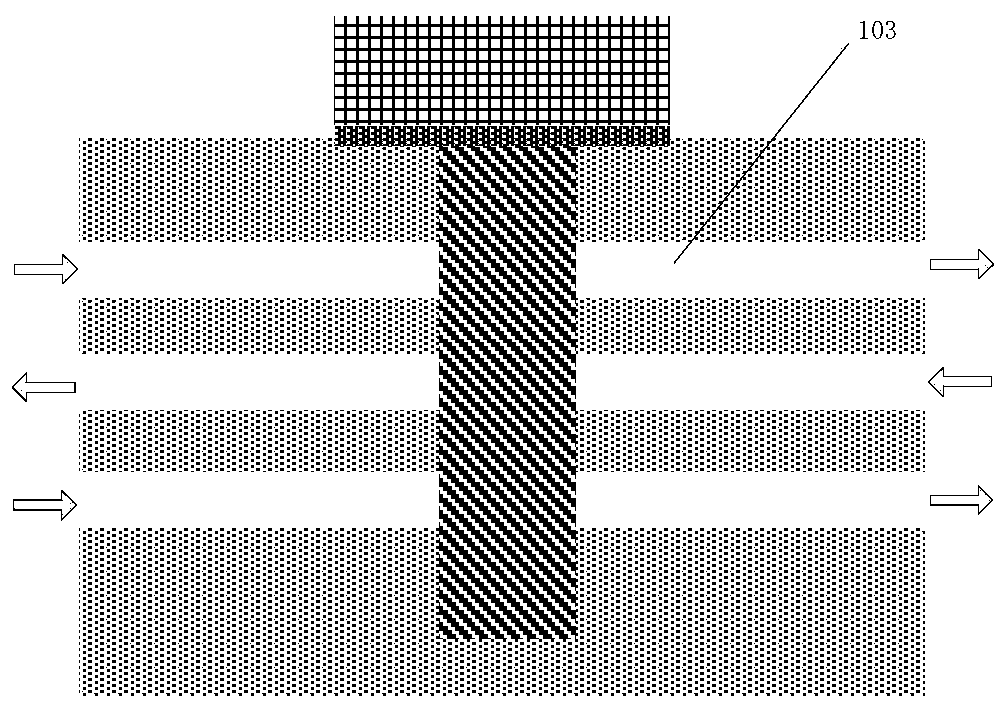

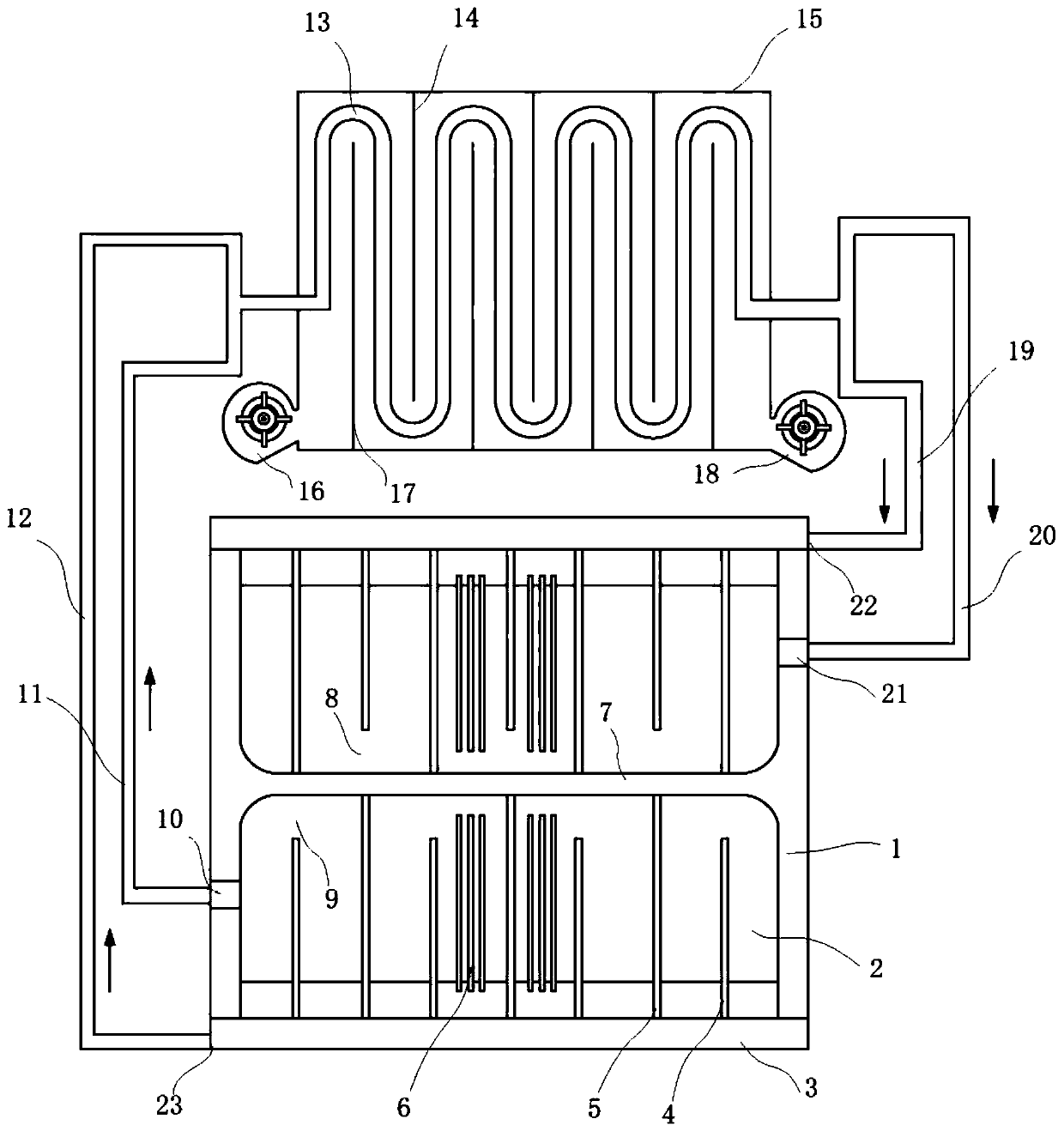

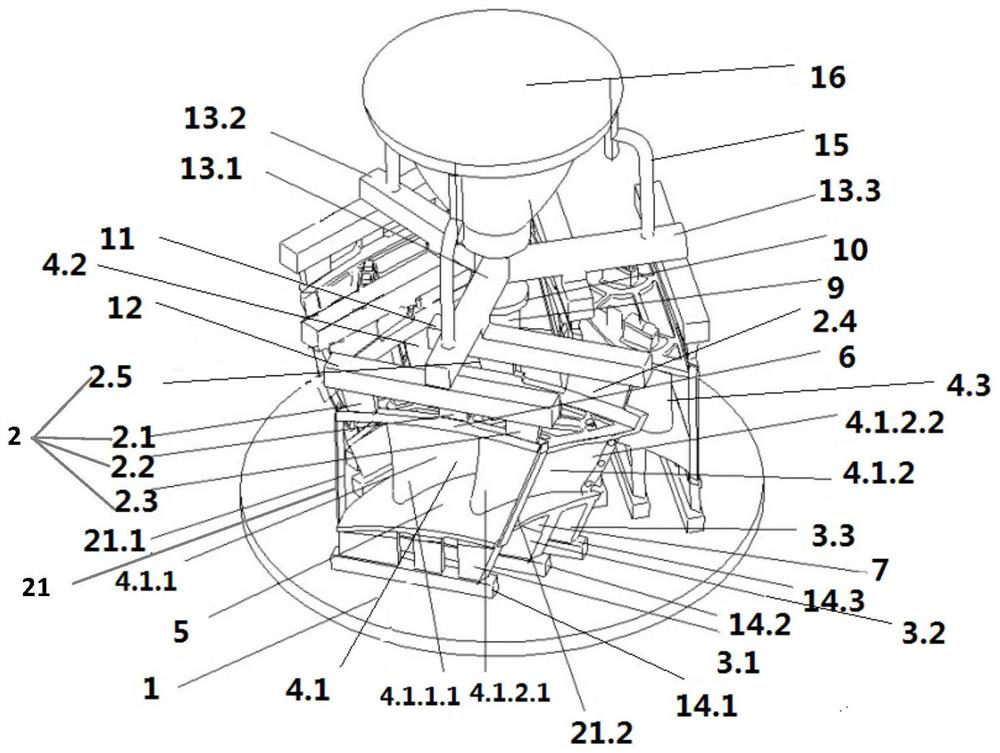

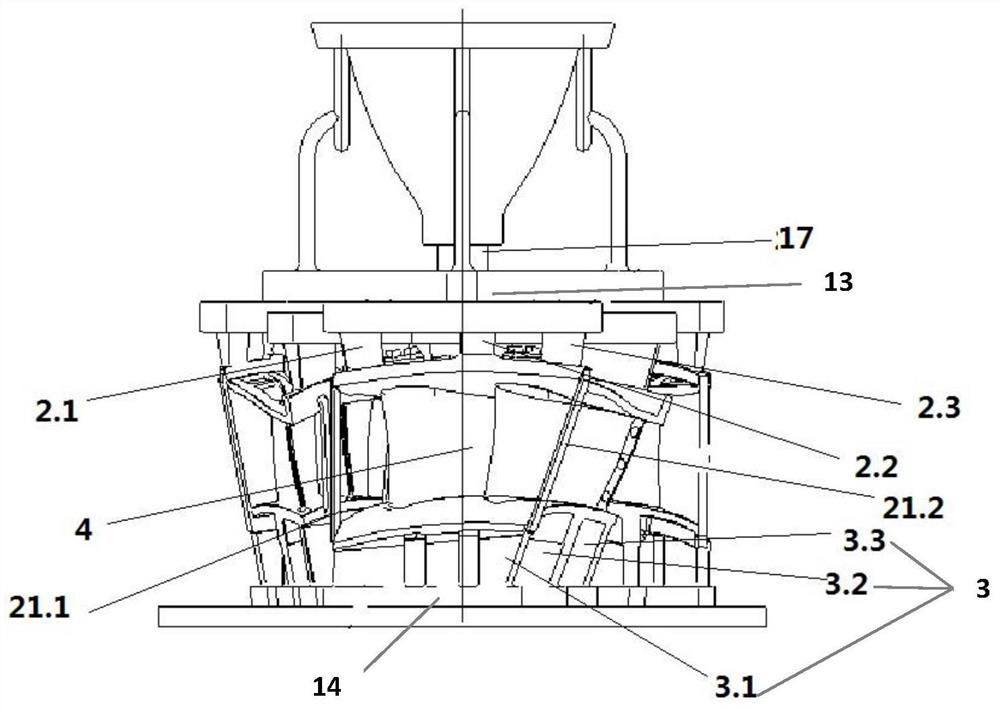

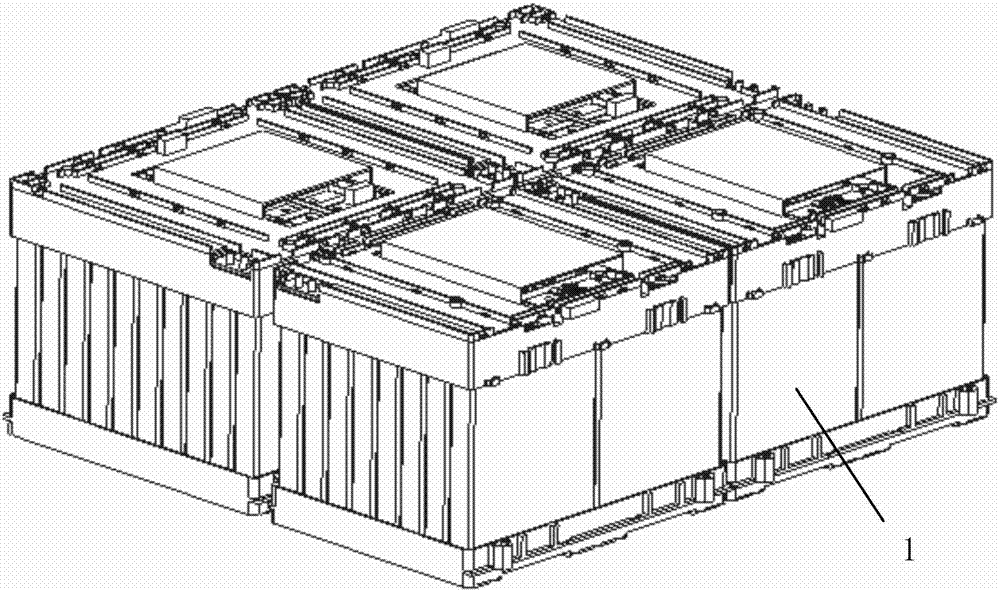

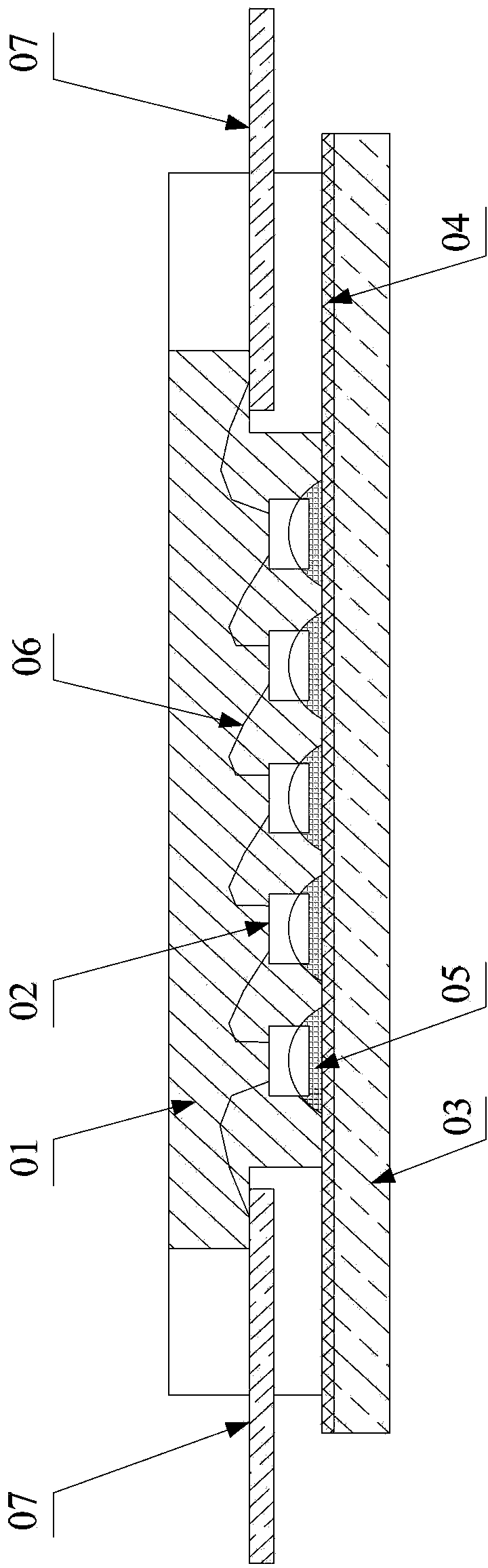

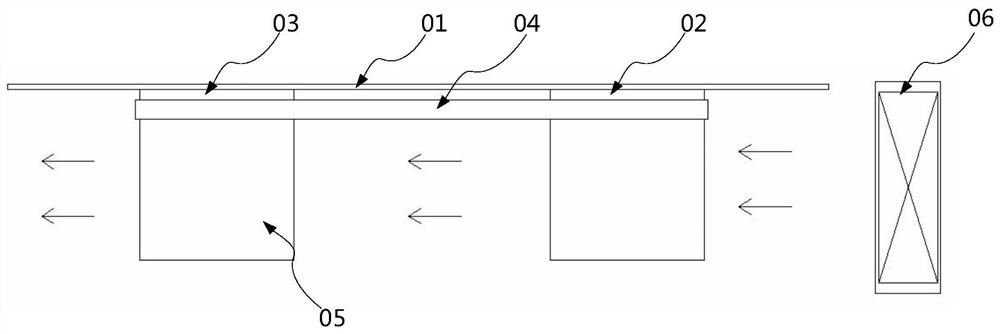

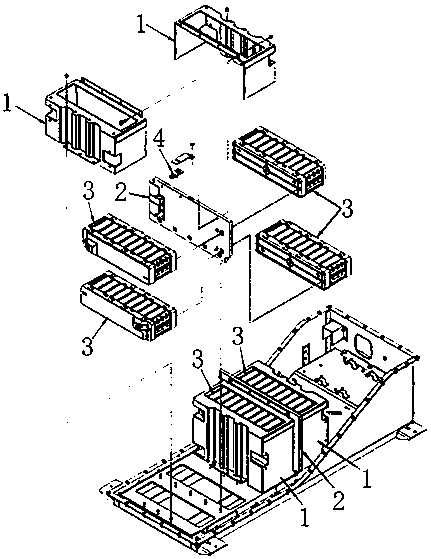

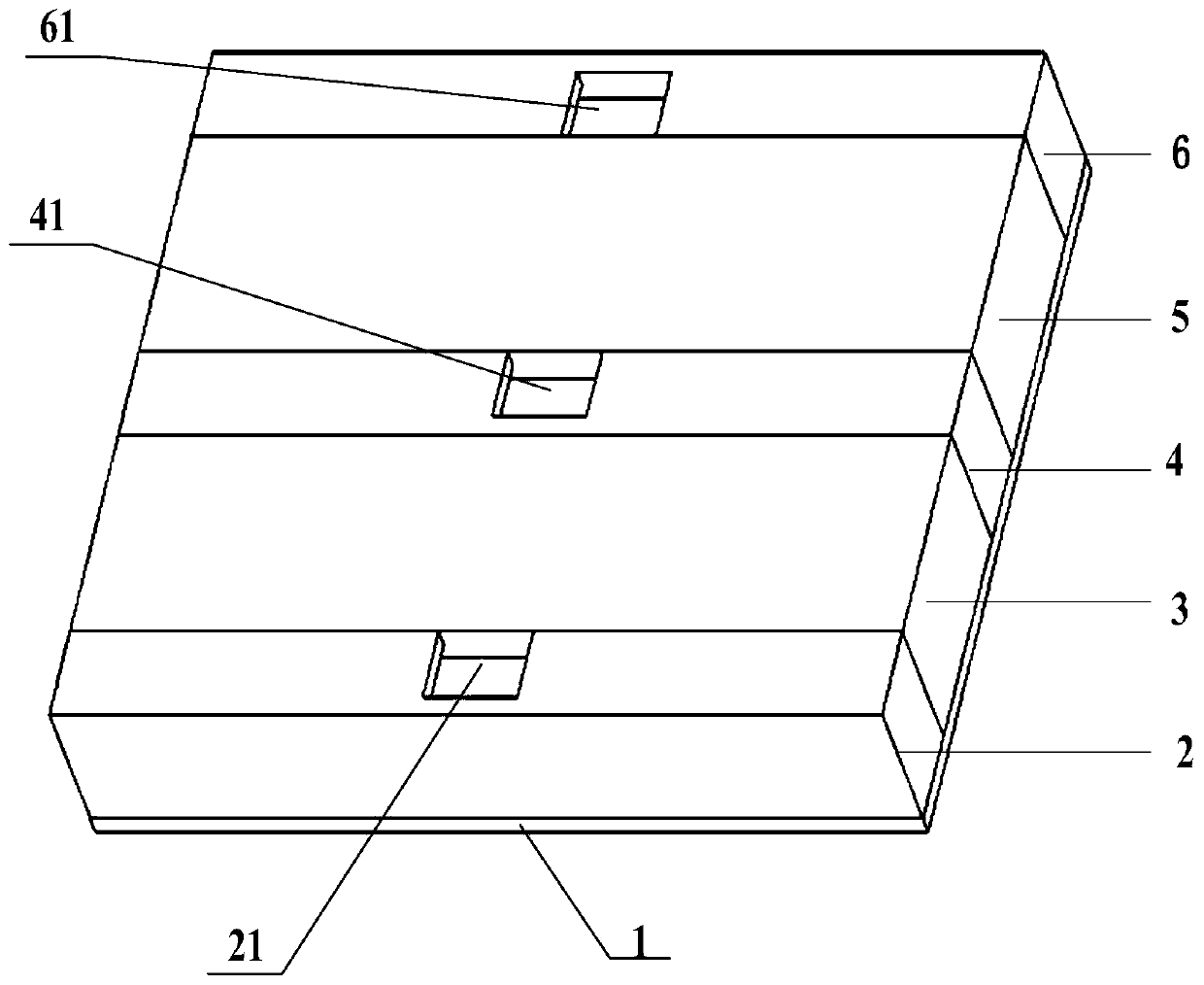

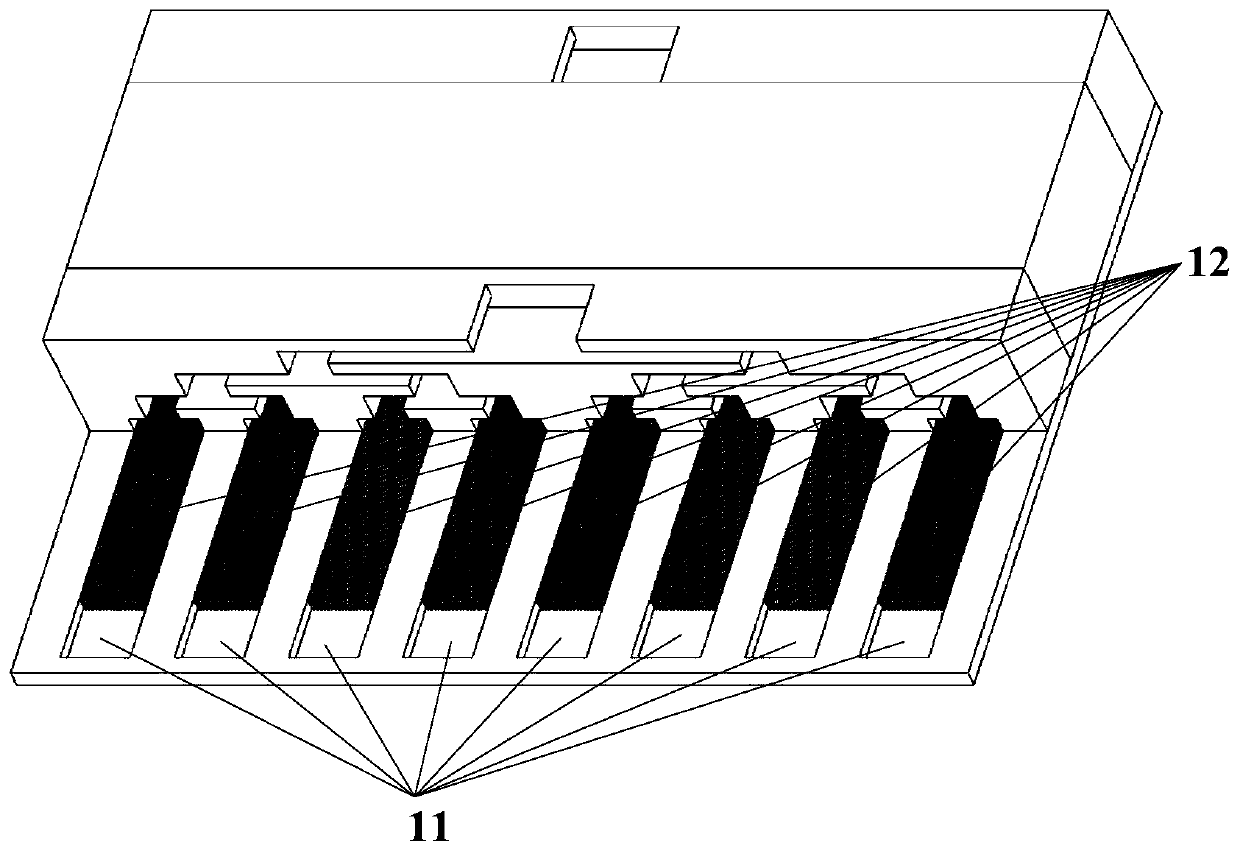

Manufacturing method of multi-layer heat dissipation structure-based three-dimensional radio frequency module

InactiveCN110739226AConsistent heat dissipationSemiconductor/solid-state device detailsSolid-state devicesEngineeringRadio frequency

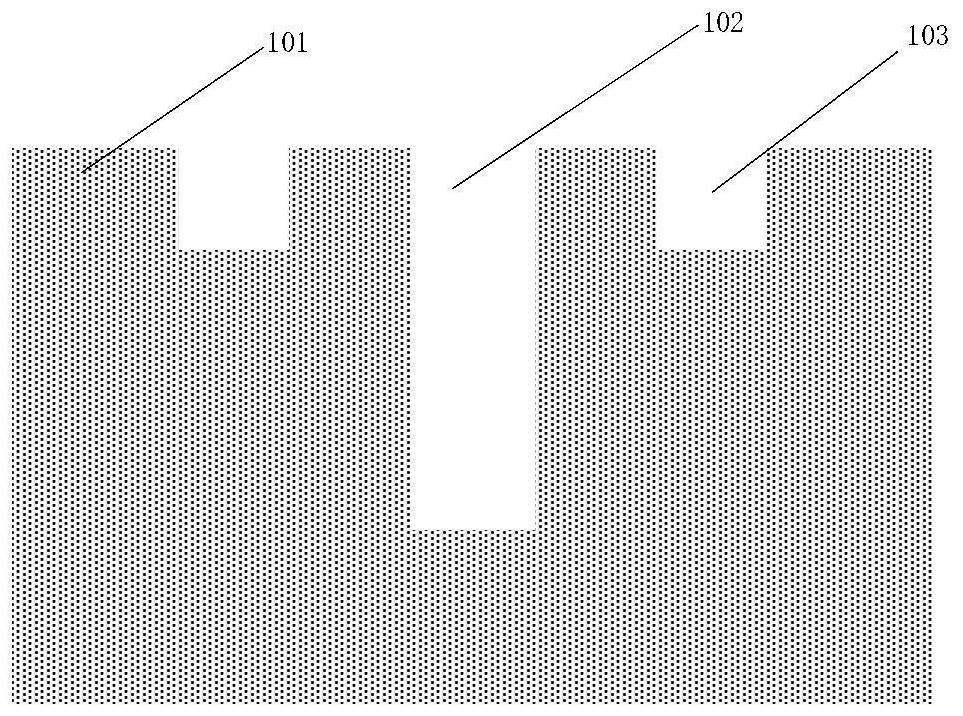

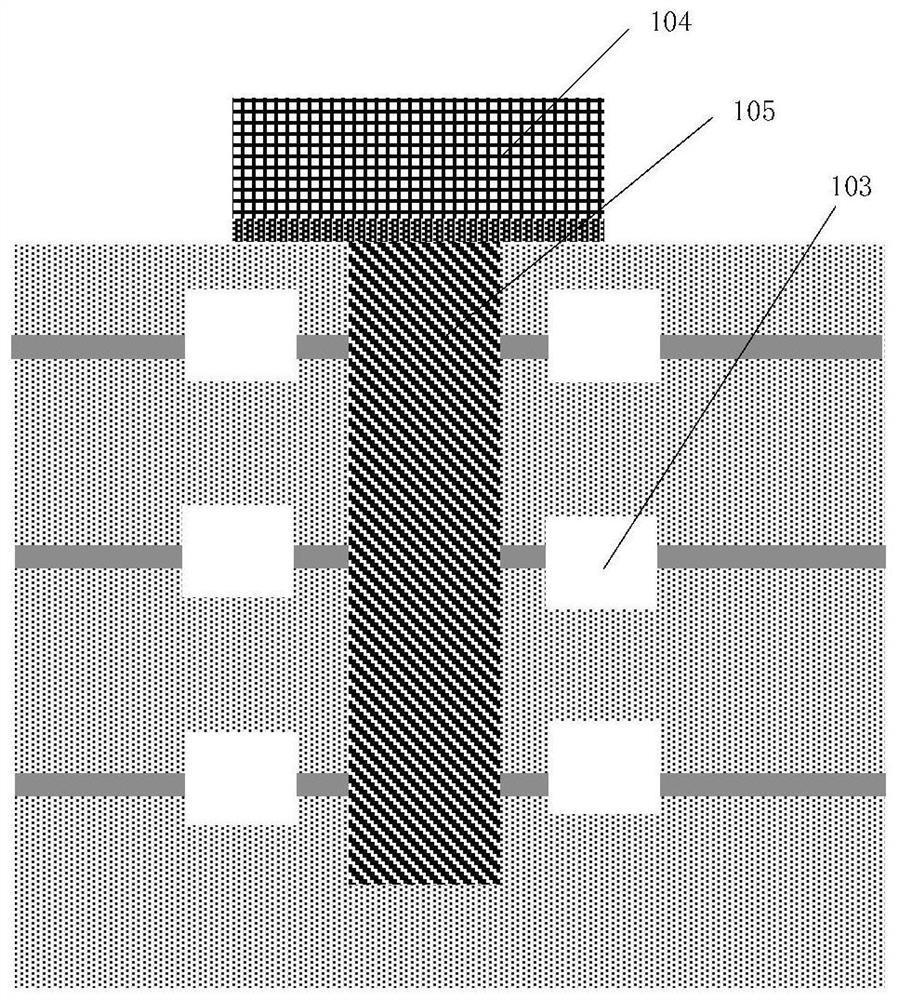

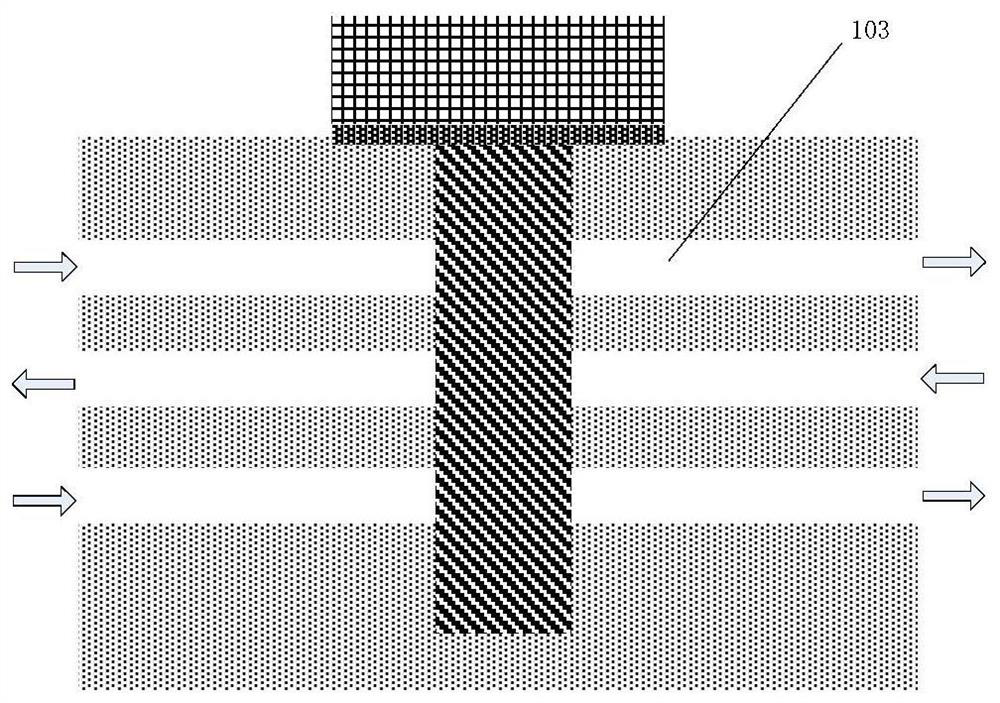

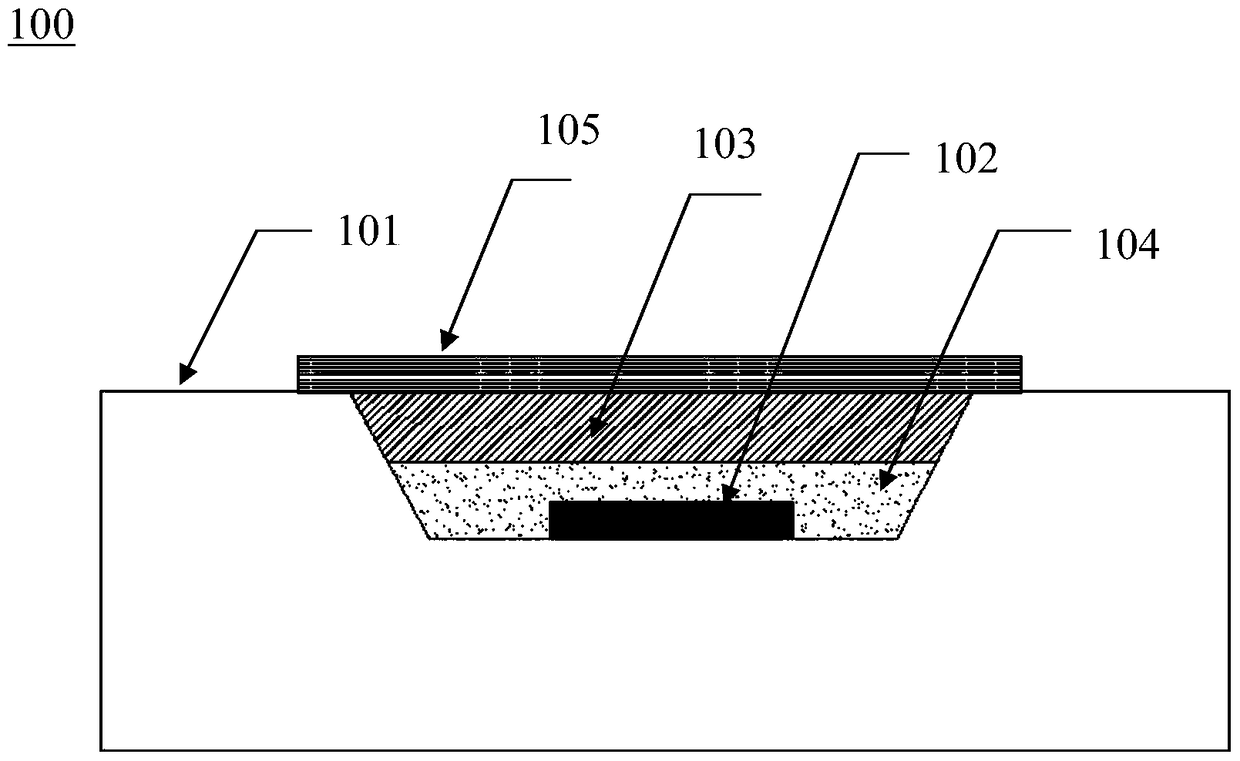

The invention discloses a manufacturing method of a multi-layer heat dissipation structure-based three-dimensional radio frequency module. The method specifically comprises the following steps of: 101) an adapter plate manufacturing step; 102) a bottom plate manufacturing step; 103) a bonding step; and 104) a chip placement step. According to the manufacturing method of the invention, heat conduction metal or a heat conduction pipeline is arranged at the bottom of a chip, so that heat can be quickly conducted into a heat dissipation base; a plurality of layers of micro-channel liquid-phase heat dissipation channels are arranged in the heat dissipation base; cooling liquid in the heat dissipation channels moves in different flowing directions, so that the temperature of the liquid in the micro-flow channels in different layers and on different sides of the chip is balanced, and therefore, the heat dissipation capacity of the micro-flow channels at the bottoms of the chip tends to be consistent.

Owner:GREAT MICROWAVE TECH CO LTD

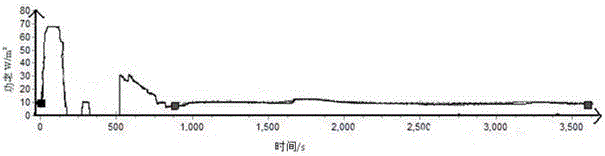

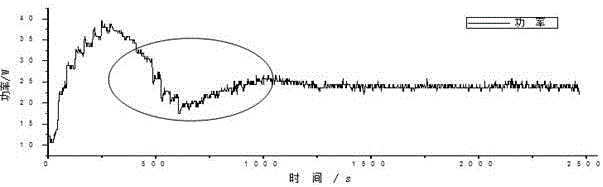

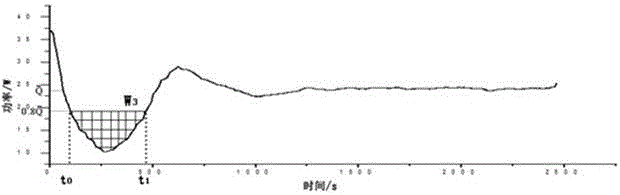

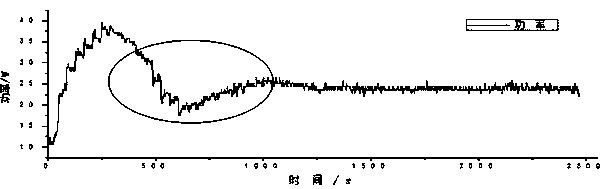

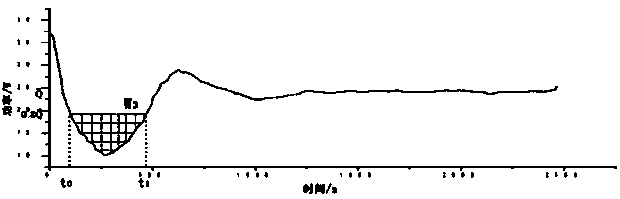

Textile cold and warm feeling test method capable of simulating physiological sensation of human body

InactiveCN106770448AScientific control of heating powerRepresent physical sensationMaterial heat developmentHuman bodyThermal insulation

The invention discloses a textile cold and warm feeling test method capable of simulating physiological sensation of a human body. The method can be realized by using hardware of an existing clothing, bedding and fabric thermal insulation property tester for testing, and the cold and warm feeling of a sample can be analyzed by optimizing the test method and using a signal within an abandon period in thermal insulation property test. The implementation method comprises the steps: controlling a test board temperature and heating power, setting a temperature and humidity of a test environment, judging whether the sample of a textile has cold feeling or warm feeling, and quantitatively analyzing a cold feeling / warm feeling index of the sample of the textile. Compared with the prior art, the test board heating power of a body surface simulating instrument is scientifically controlled to be more consistent with a true heat dissipation rule of the human body, and a measured physical quantity can more effectively represent human physiological sensation. The definitions of the cold feeling index and the warm feeling index with definite physical meaning are provided; the cold feeling index and the warm feeling index of the textile can be scientifically and reasonably detected and analyzed; cold feeling and warm feeling and heat retaining property indexes of the textile can be more accurately detected.

Owner:YANTAI NANSHAN UNIV +1

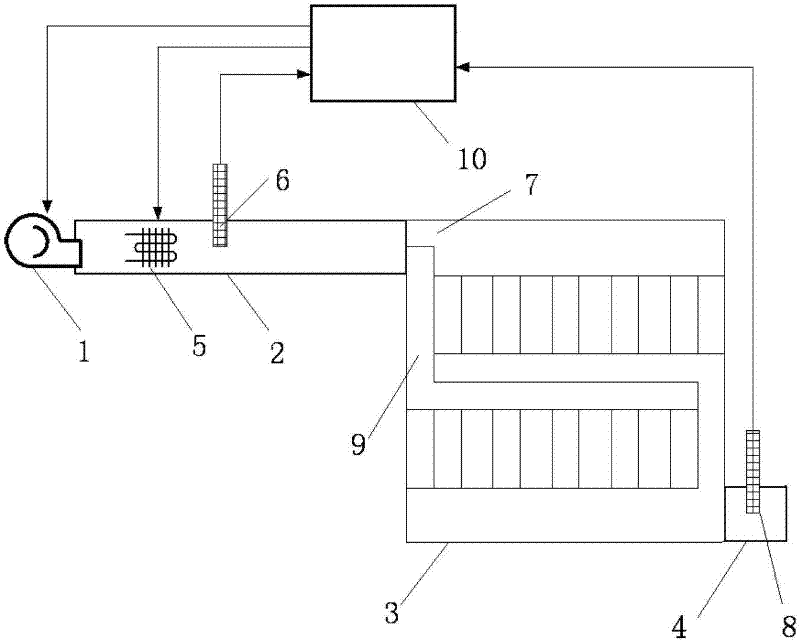

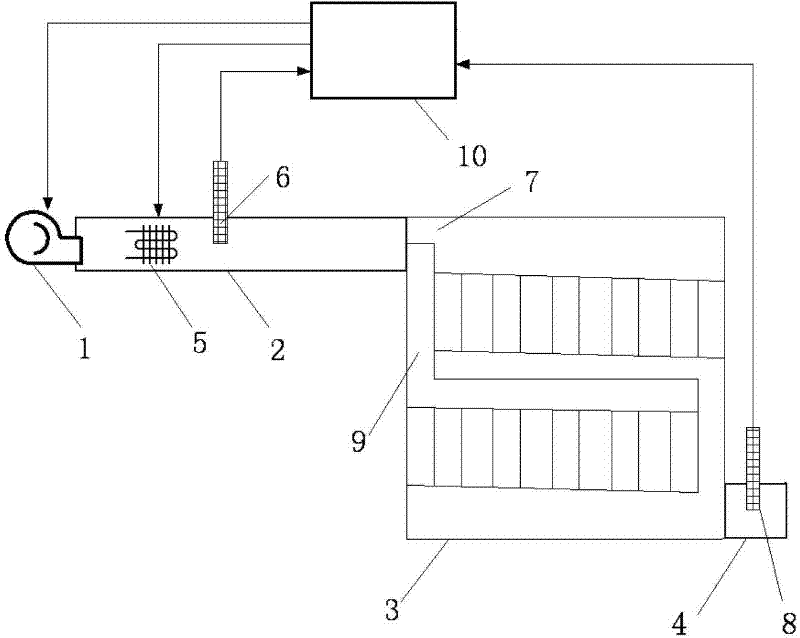

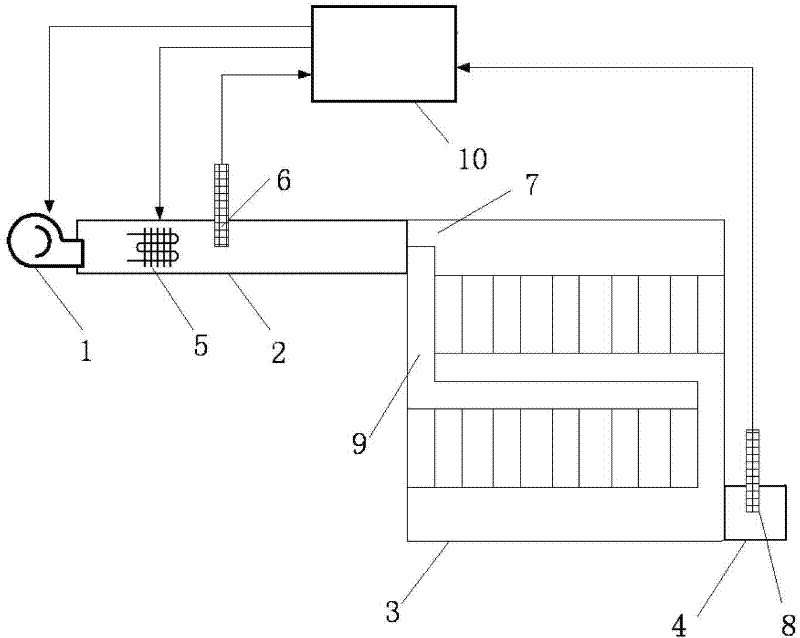

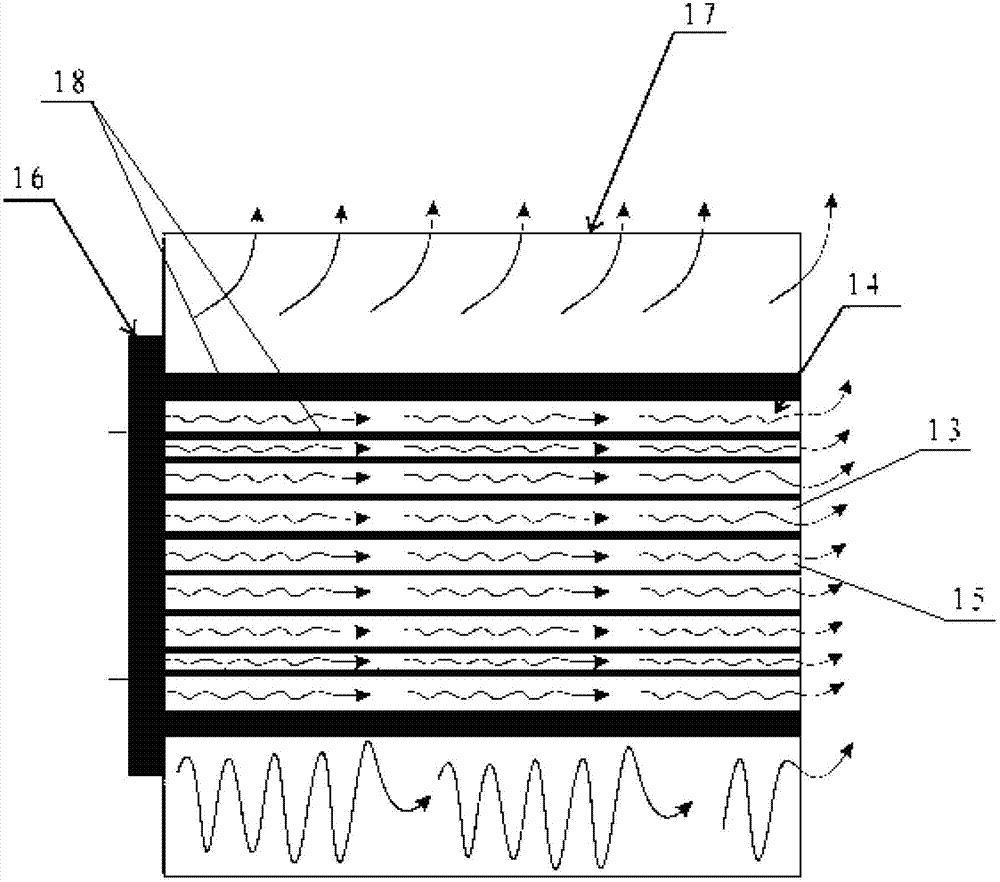

Nickel-hydrogen battery pack heat management system

InactiveCN102694216AGuaranteed service lifeControl working temperatureSecondary cellsHeat managementElectrical battery

The invention discloses a nickel-hydrogen battery pack heat management system. The heat management system comprises a blower fan, an air inlet pipeline, a nickel-hydrogen battery pack, and an air outlet pipeline connected consecutively. A heater is provided at the end portion close to the blower fan in the air inlet pipeline . The air inlet pipeline between the heater and the nickel-hydrogen battery pack is further provided with a first temperature sensor. The air outlet pipeline close to the end portion of the nickel-hydrogen battery pack is provided with a second temperature sensor. The blower fan, the heater, the first temperature sensor, and the second temperature sensor are separately connected to a controller. A preferable scheme comprises: a first and a second air supply channels respectively supplying air for the upper and lower galvanic piles of the nickel-hydrogen battery pack in an independent and parallel way are arranged in the nickel-hydrogen battery pack; both the air inlet end of the first air supply channel and the air inlet end of the second air supply channel are communicated with the air inlet pipeline, and both the air outlet end of the first air supply channel and the air outlet end of the second air supply channel are communicated with the air outlet pipeline. The heat management system of the invention can make the operating temperature of the battery pack within a reasonable scope, and guarantee good temperature consistency among battery monomers, thereby guaranteeing the service life and the safety performance of the nickel-hydrogen battery pack.

Owner:SHANGHAI YAOYU INDAL +1

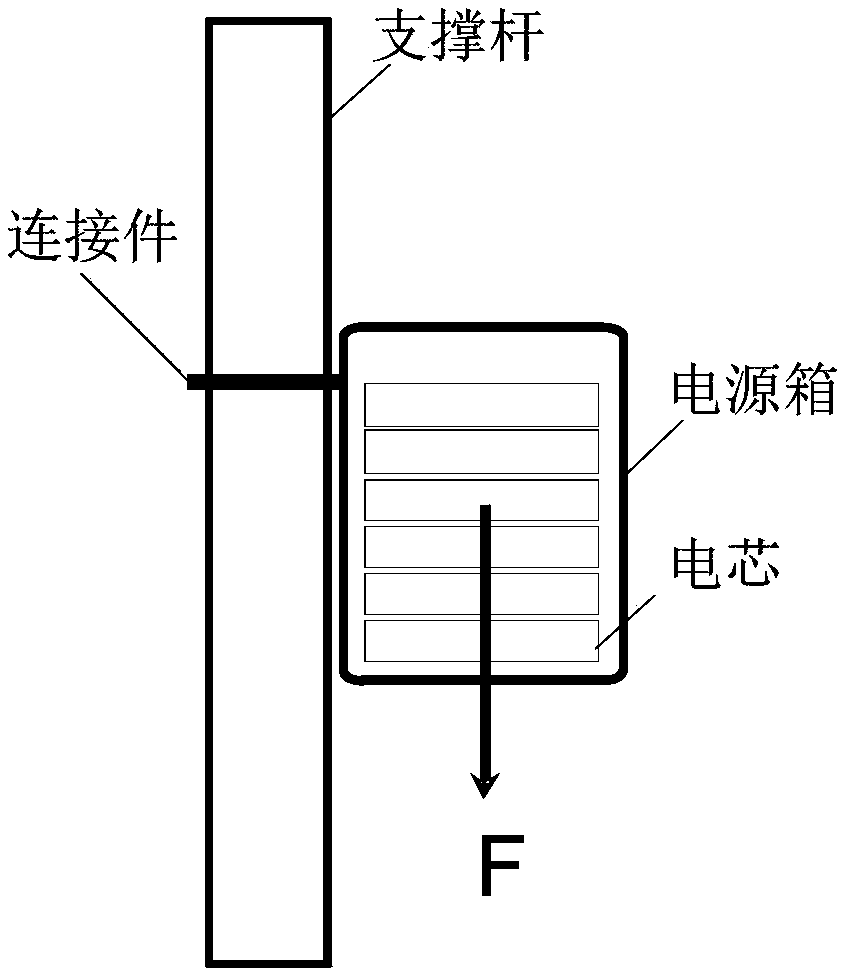

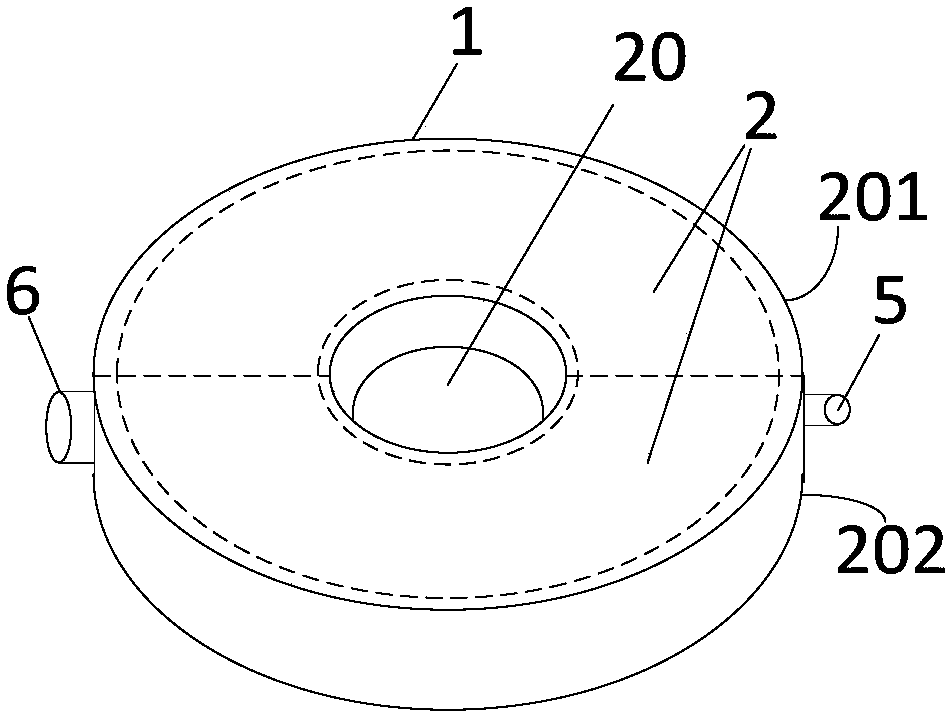

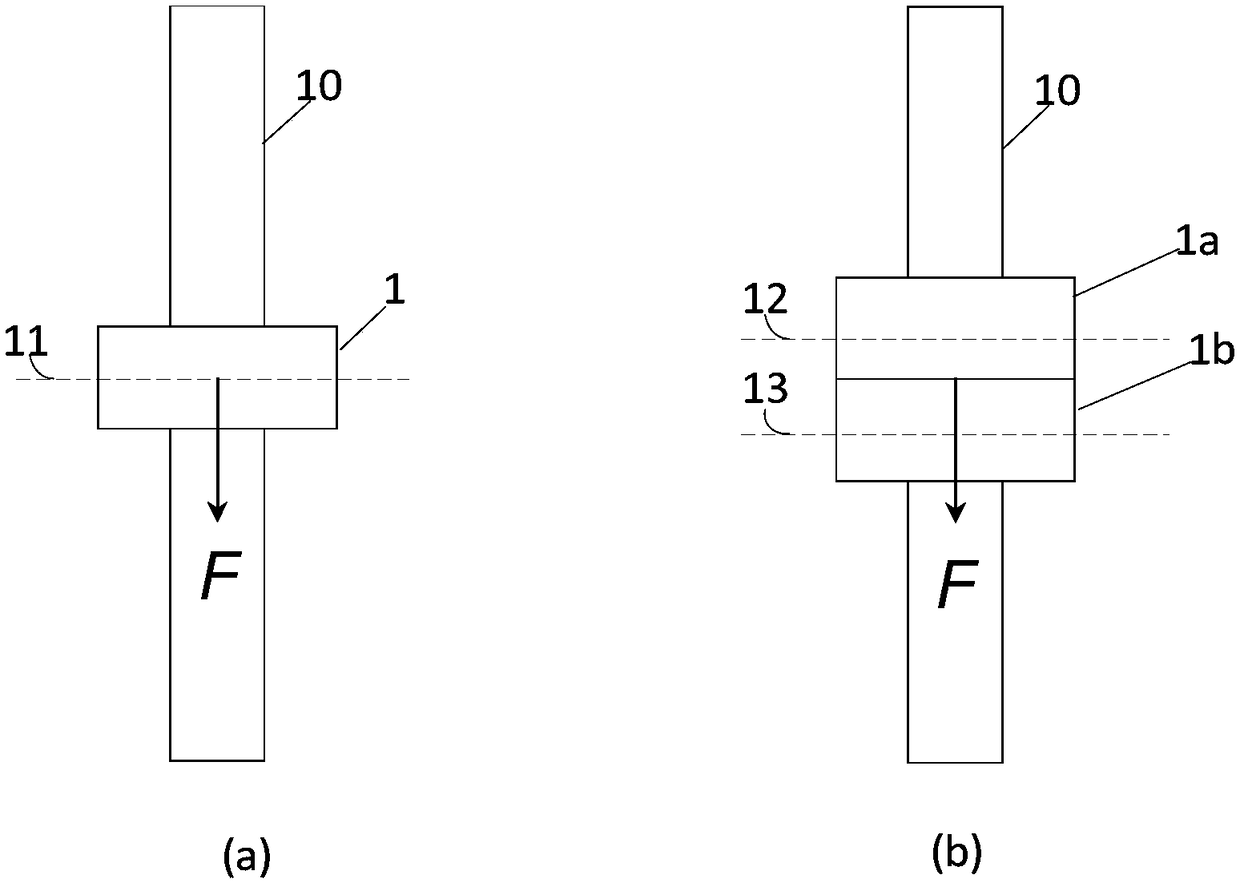

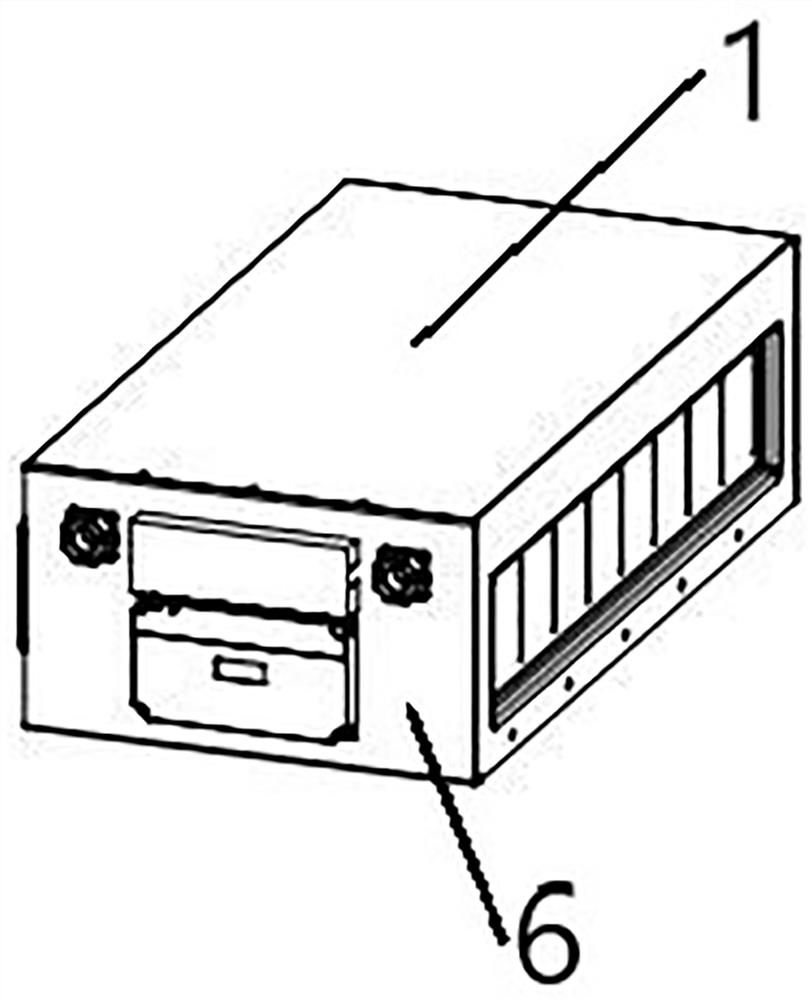

Holding pole power supply

InactiveCN108417746AImprove stabilityExtended service lifeMachine supportsCells structural combinationEngineeringBattery cell

Owner:HUAWEI TECH CO LTD

Circulating cooling type continuous casting crystallizer

The invention relates to a circulating cooling type continuous casting crystallizer. The circulating cooling type continuous casting crystallizer comprises a crystallizer body, an outer layer housingand a cooling box, wherein bosses are arranged at the two ends of the crystallizer body; the bosses are sleeved with the outer layer housing; a closed first cooling channel is formed among the crystallizer body, the bosses and the outer layer housing; the bosses are provided with a first water inlet and a first water outlet which communicate with the first cooling channel; a second cooling channelis arranged in the outer layer housing; the two end faces of the outer layer housing are provided with a second water inlet and a second water outlet which communicate with the second cooling channel; a snakelike heat exchange pipe is arranged in the cooling box; an air blower is arranged on the side, close to a water outlet pipe, of the cooling box; and an exhaust fan is arranged on the side, close to a water inlet pipe, of the cooling box. According to the crystallizer, the two cooling channels are adopted, the heat dissipation efficiency is improved, heat dissipation is more uniform, the crystallization speed of the crystallizer is kept consistent, and the crystallization effect is guaranteed. Cooling water is recycled, water resource utilization is reduced, cost is reduced, and the system integrity and system running stability are improved.

Owner:NANCHANG INST OF TECH

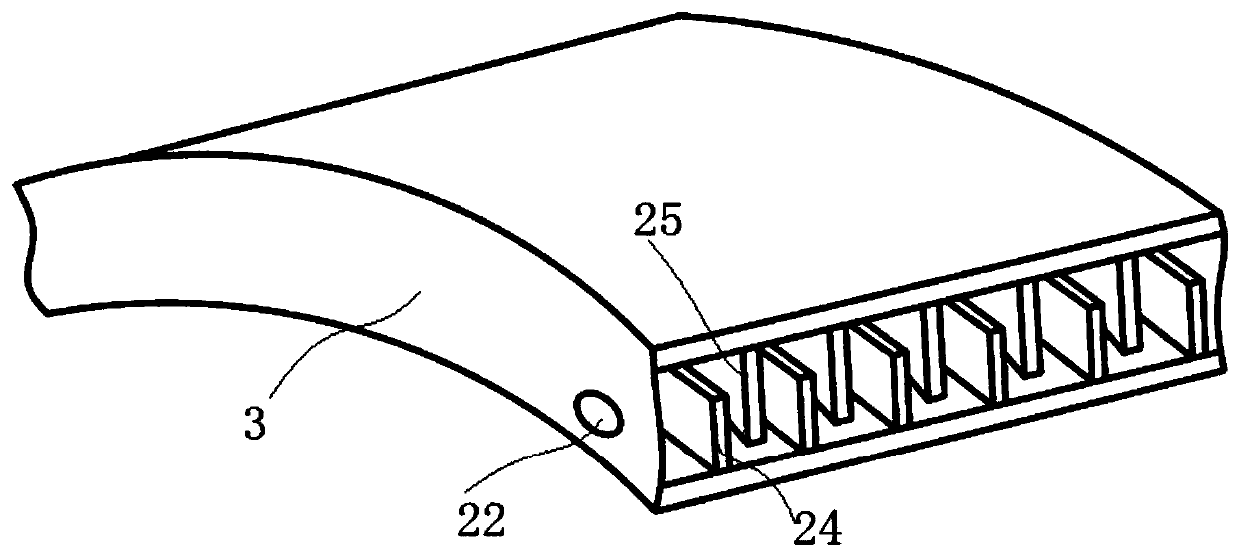

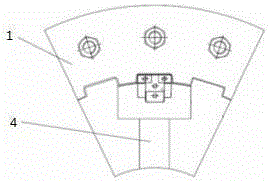

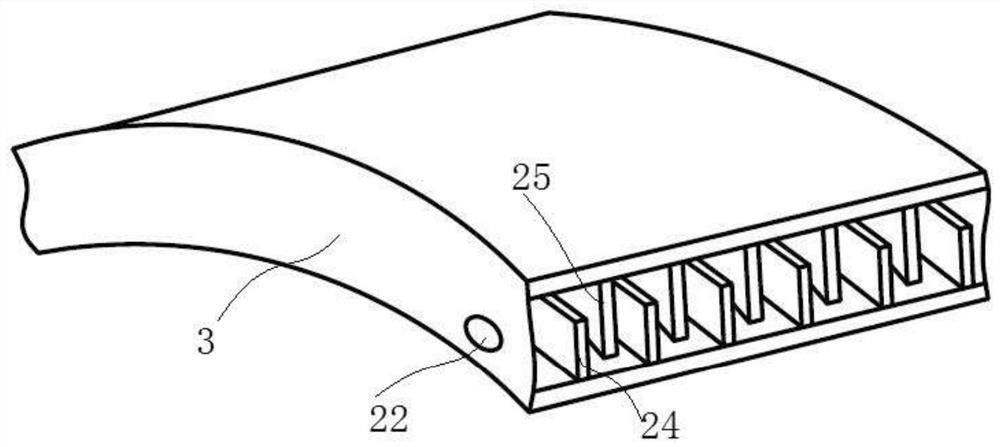

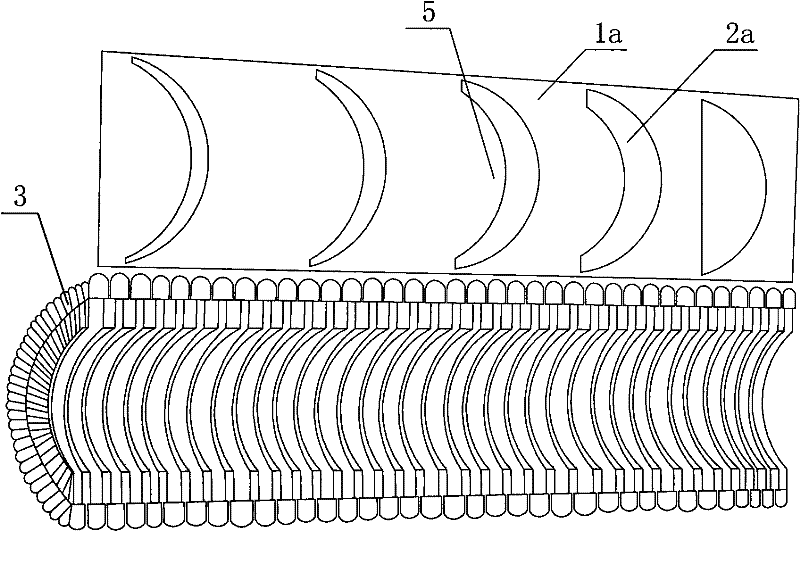

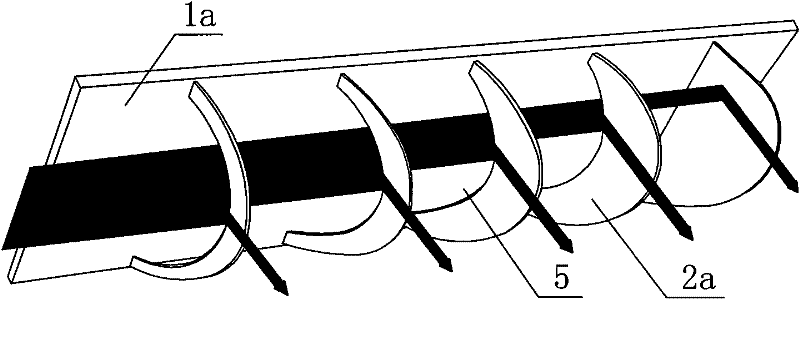

Design method of duplex directional hollow blade casting system

ActiveCN111940679ASolve the problem of orientation deviationImprove casting pass rateFoundry mouldsFoundry coresMold fillingStraight tube

The invention provides a design method of a duplex directional hollow blade casting system. The method comprises the steps: combining casting systems; manufacturing a mold shell of a wax mold module;and putting the mold shell into a three-chamber vacuum furnace to complete casting, wherein the casting temperature of a casting piece is 1480 DEG C, and the crystal pulling speed is 4 mm / min. The combination of the casting systems specifically comprises the steps of determining the diameter of a module chassis; determining the process epitaxy of blades; determining the position of the starting section on the module chassis; determining the height of a middle straight pipe of the module; connecting a casting system mold filling path; arranging a cross gate connected with the middle straight pipe and a pouring cup; and connecting the pouring cup to the upper portion of the middle straight pipe. By designing and optimizing the combination mode of the casting system, the problems of metallurgical defects such as broken crystals, oblique crystals and exposed crystals of columnar crystals at the position of an exhaust edge are successfully solved, and deformation of casting pieces in the casting process is effectively controlled.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

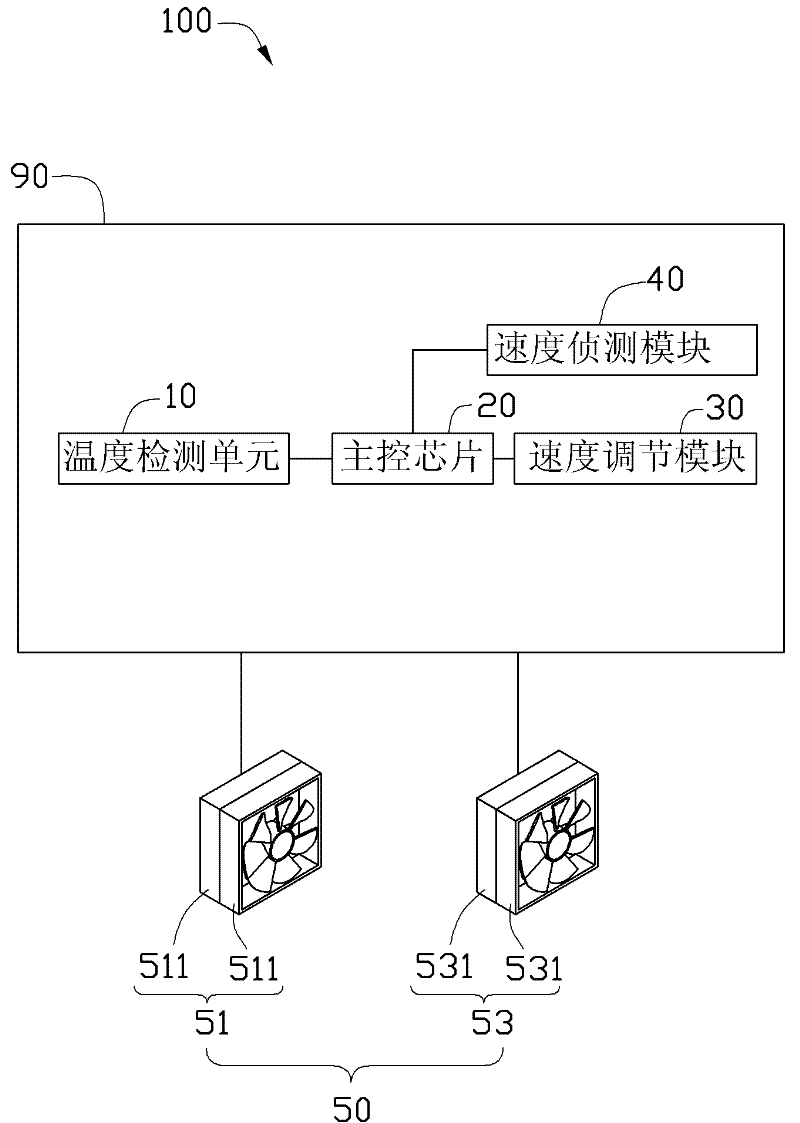

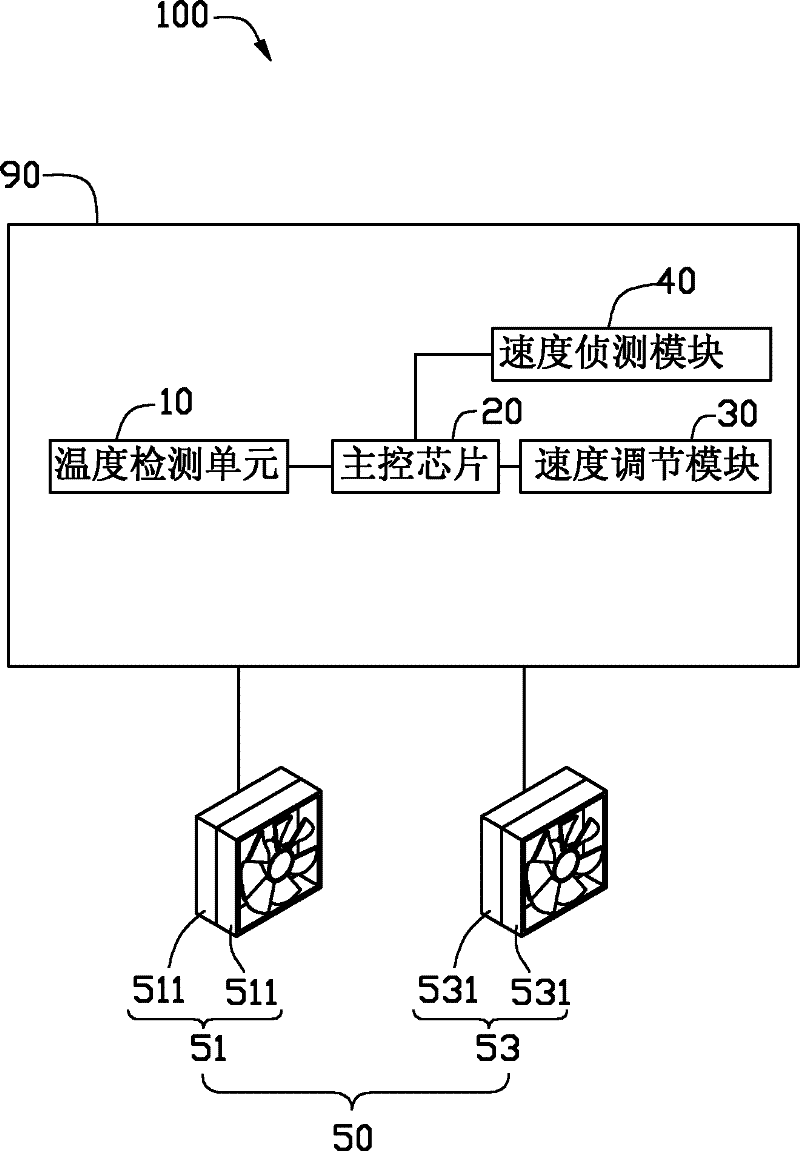

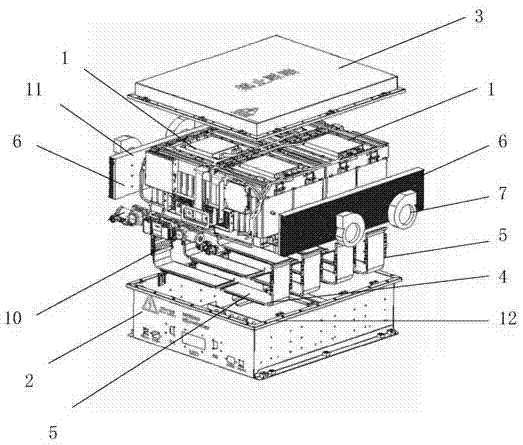

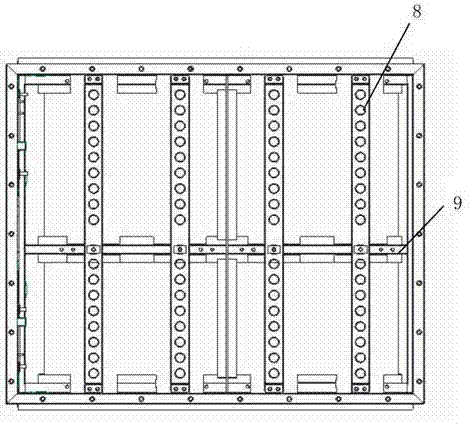

Temperature regulating device for electronic device

InactiveCN102458082AConsistent heat dissipationImprove cooling effectCooling/ventilation/heating modificationsMotor speedEngineering

The invention discloses a temperature regulating device for an electronic device. The temperature regulating device comprises a temperature detection unit, a main control chip and a multi-fan system which are sequentially and electrically connected, wherein the multi-fan system comprises a plurality of fans; each fan comprises a plurality of motors; the temperature detection unit is used for detecting the temperature in the electronic device; the main control chip is used for setting the rotating speeds of the motors of the fans according to the detected temperature and acquiring the rotating speed of the motor of each fan; and if the acquired rotating speed of the motor of one fan is zero, the rotating speeds of the motors of all fans are reset by the main control chip, so that the heat radiating efficiency of all fans is kept consistent.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

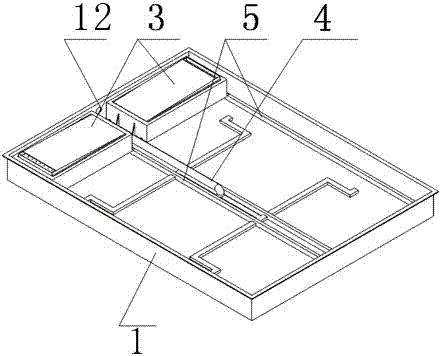

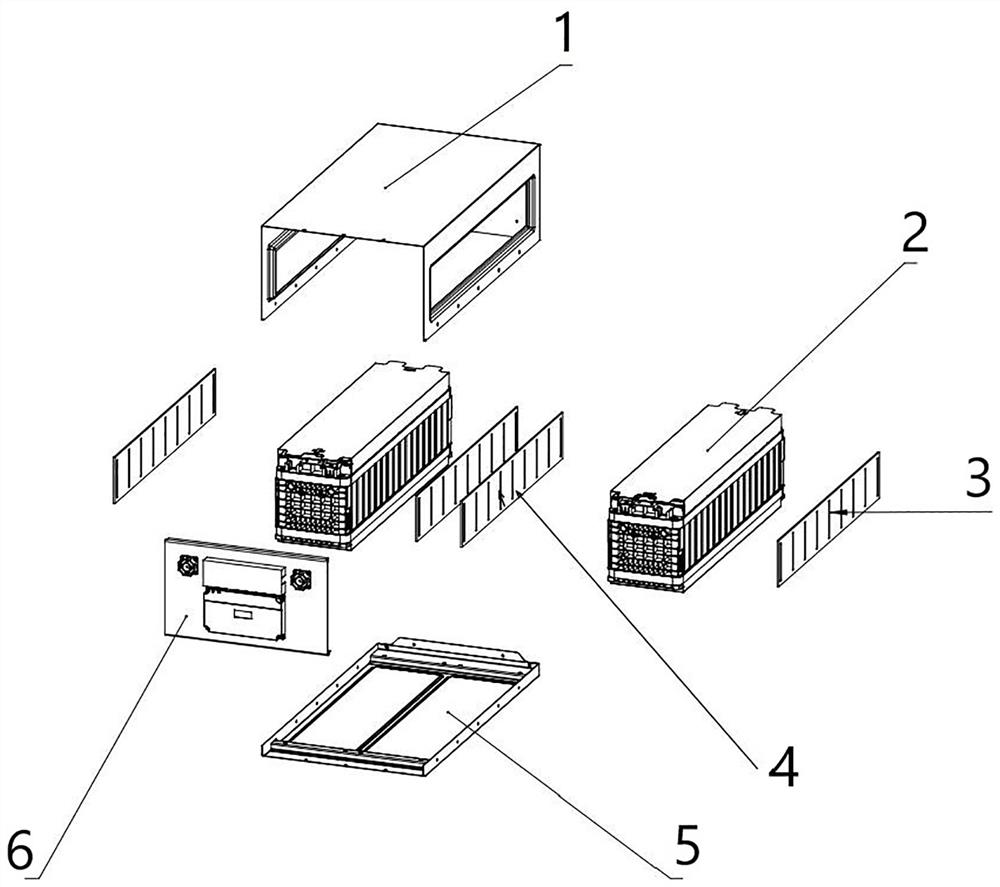

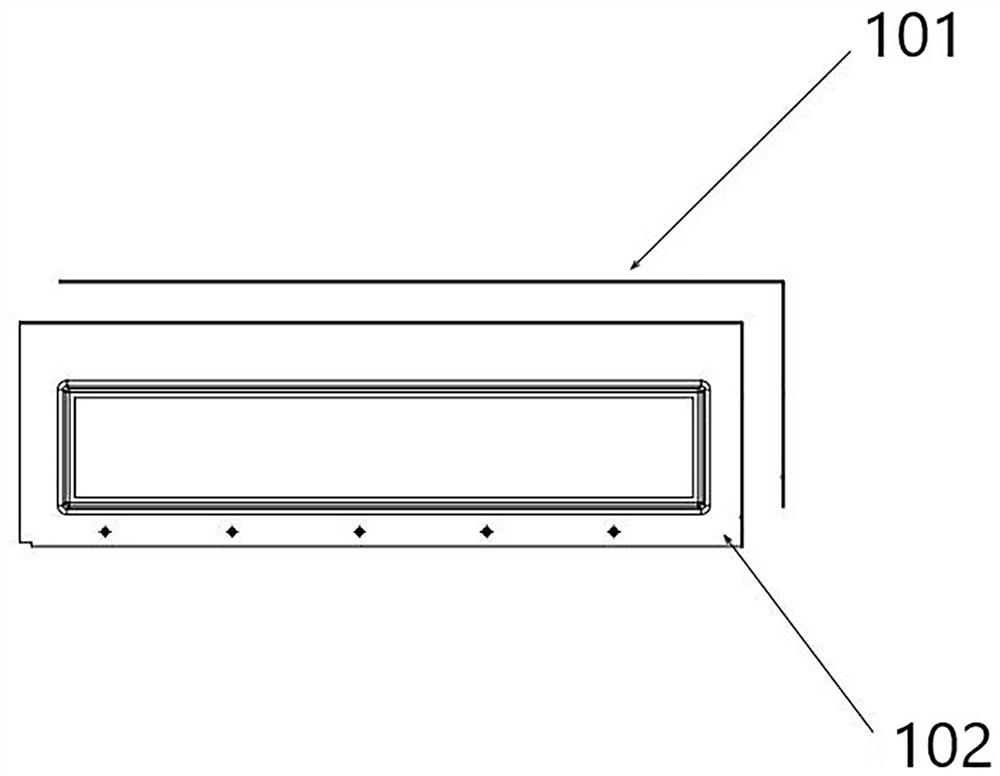

Air-cooled battery box

ActiveCN107482148AUniform temperatureSolve temperature problemsSecondary cellsCell component detailsEngineeringSilica gel

The invention relates to the technical field of lithium ion battery cases, in particular to an air-cooled battery box. The air-cooled battery box comprises a box body and a battery module arranged inside the box body; the box body comprises a main box body and a box cover, a heat conduction assembly is arranged in the main box body and comprises a heat conduction pipe, a heat conduction silicon rubber pad and heat insulation cotton, the heat conduction pipe is arranged inside the main box body, the heat insulation cotton is pasted at a position, corresponding to the heat conduction pipe, on the main box body, the heat conduction silicon rubber pad is bonded on a contact surface of the heat conduction pipe with the side wall of the main box body, and the battery module contacts the heat conduction pipe after being arranged; and a heat dissipation assembly comprises heat dissipation fins and a centrifugal fan, wherein the heat dissipation fins are arranged on the side wall of the main box body through bolts, and the centrifugal fan is arranged on the heat dissipation fins through bolts. The device is simple in process, low in cost and reliable in structure, and improves the reliability and safety of a battery system.

Owner:LISHEN (QINGDAO) NEW ENERGY CO LTD

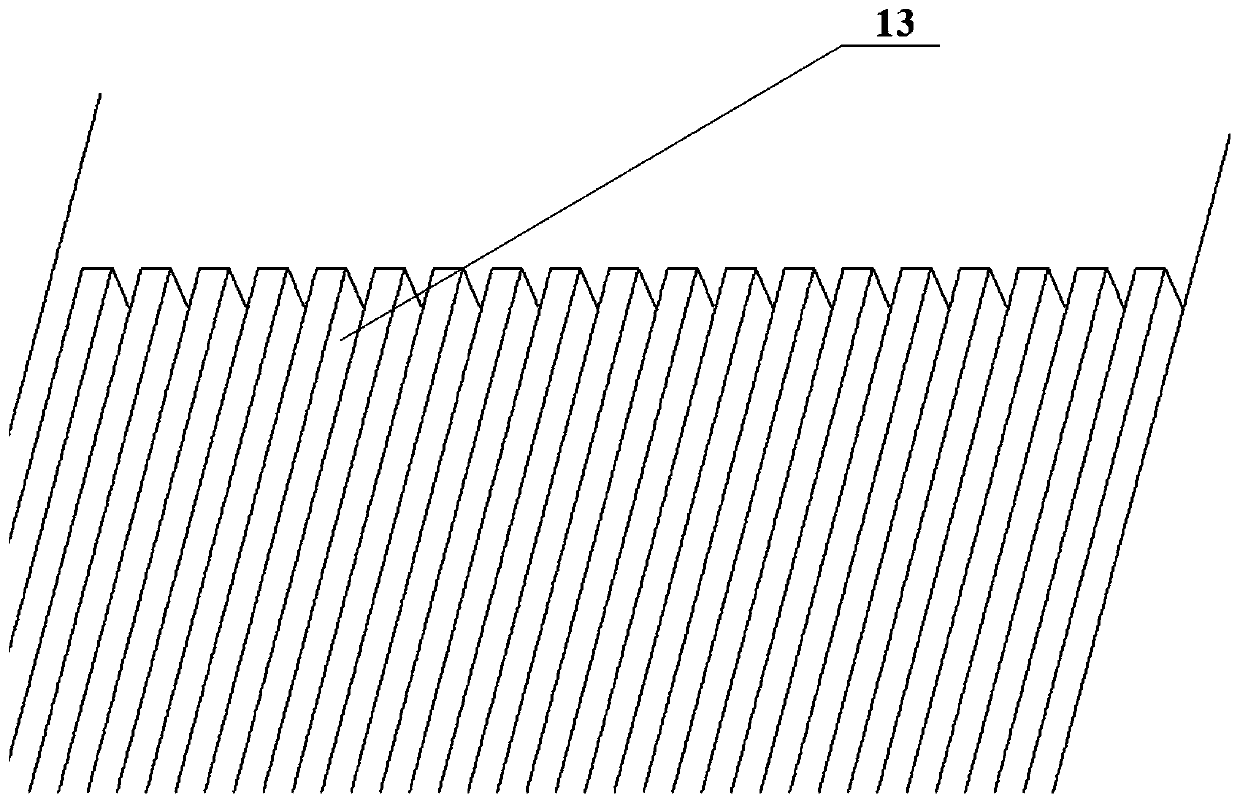

High-power LED (light-emitting diode) lamp radiator

InactiveCN102767810AThermal adaptationIncrease the use of powerPoint-like light sourceLighting heating/cooling arrangementsMortise and tenonAlloy

The invention discloses a high-power light-emitting diode (LED) lamp radiator which comprises a radiating unit with V-shaped cross sections, wherein side views of the two V-shaped faces of the radiating unit are respectively rectangles; a plurality of fins are arranged between the two V-shaped faces; and the direction of the fins is parallel with or coincide with the equally-dividing face of the included angle of the V-shaped faces; the left external side of the V-shaped faces is provided with a tenon, and a mortise is arranged at the position of the external side of the V-shaped faces, which corresponds to the tenon; and a first ornamental engraving structure is arranged near the peaks of the V-shaped faces and comprises a first arc-shaped notch concaving into a left V-shaped face and a crescent protruding block protruding from the right V-shaped face. The radiating unit of the high-power LED lamp radiator is molded and manufactured by extruding aluminum alloy and connected through the mortise and tenon joint, radiating shapes and radiating areas can be combined randomly, thus the high-power LED lamp radiator is good in radiating effect, and adapts to radiating or LED lamps with high powers of 300-500W.

Owner:佑图物理应用科技发展(武汉)有限公司

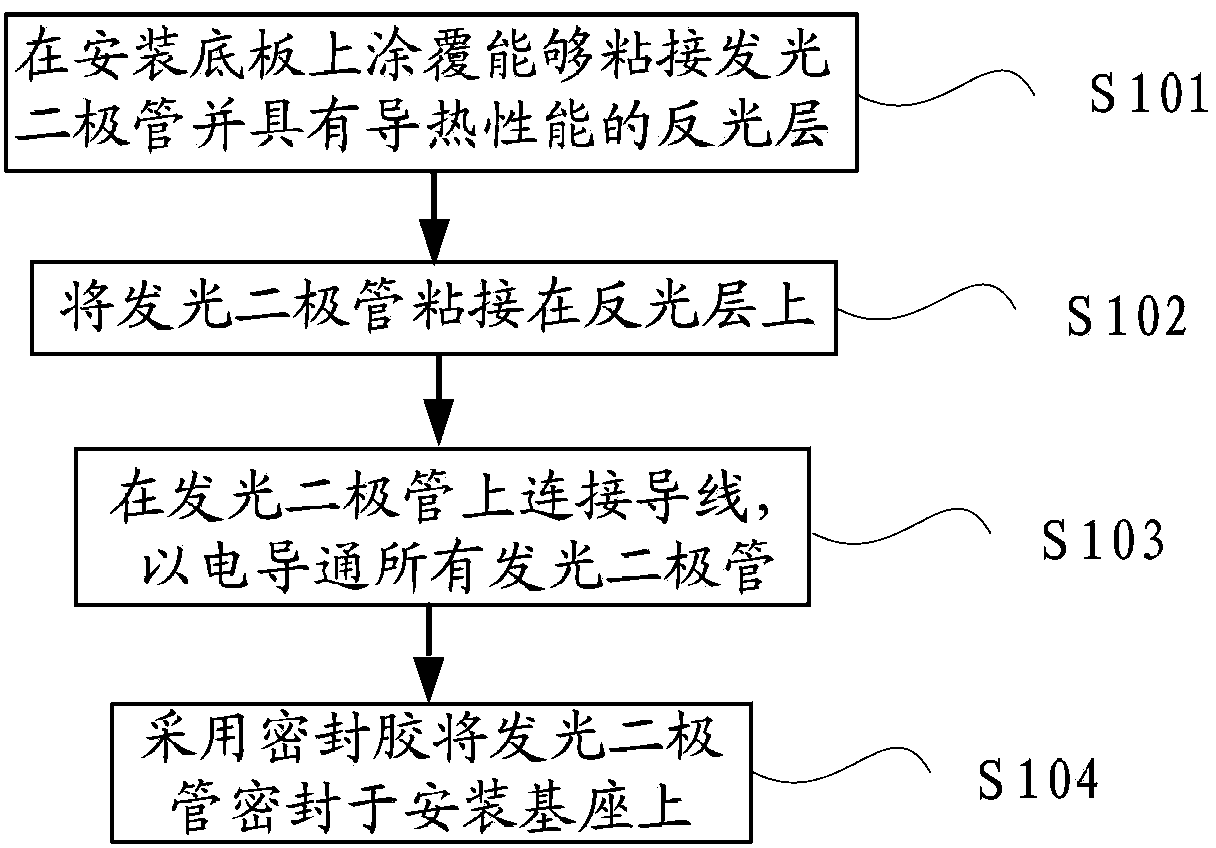

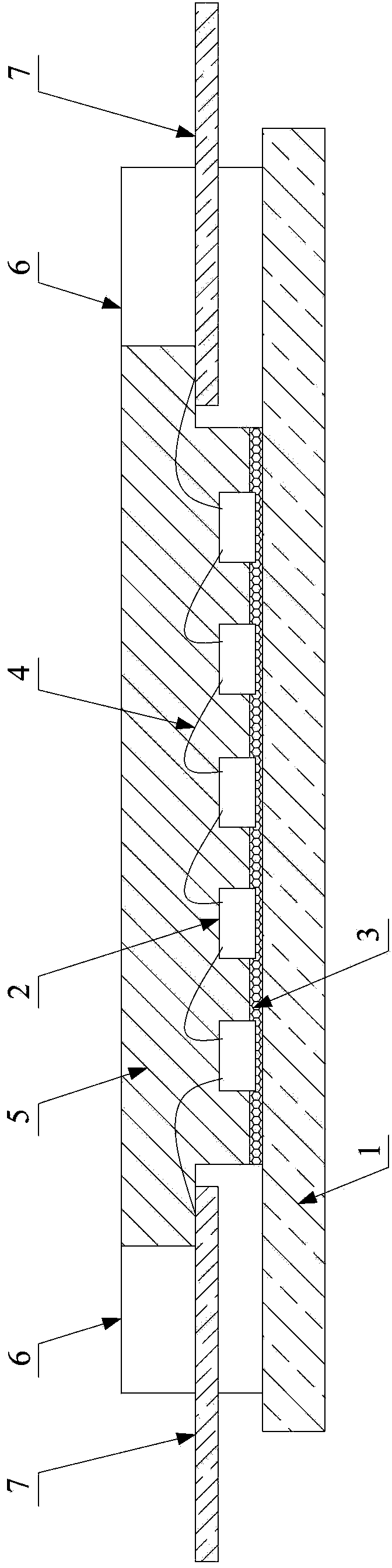

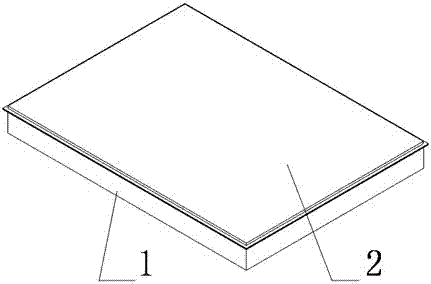

Light-emitting diode packaging process

InactiveCN104347605AGuaranteed uniform conductionConsistent heat dissipationSolid-state devicesSemiconductor devicesAdhesiveMultiple point

The invention provides a light-emitting diode packaging process. The method comprises the following steps that a light-reflecting layer which can be stuck to a light-emitting diode and has heat conductivity is coated on a mounting bottom plate; the light-emitting diode is stuck to the light-reflecting layer; a lead is connected to the light-emitting diode, so that the light-emitting diode is electrified; the light-emitting diode is sealed on the mounting bottom plate by a sealing adhesive. According to the light-emitting diode provided by the invention, an electroplated layer and a crystal solidifying adhesive are substituted by the light-reflecting layer; due to the fact that the top surface and the bottom surface of the light-reflecting layer are planes and are coating layers which are in an integral form, and the coating thickness and the uniformity of the top surface and the bottom surface are more precisely controlled than the crystal solidifying adhesive which are arranged at multiple points and are stacked, the radiating effect of a plurality of light-emitting diodes stuck to different positions and having the same thickness on the light-reflecting layer are consistent by precisely controlling the thickness of the light-reflecting layer, the quality difference of different lamp beads is reduced even avoided, and the quality consistency of different lamp beads is further improved.

Owner:惠州市华阳光电技术有限公司

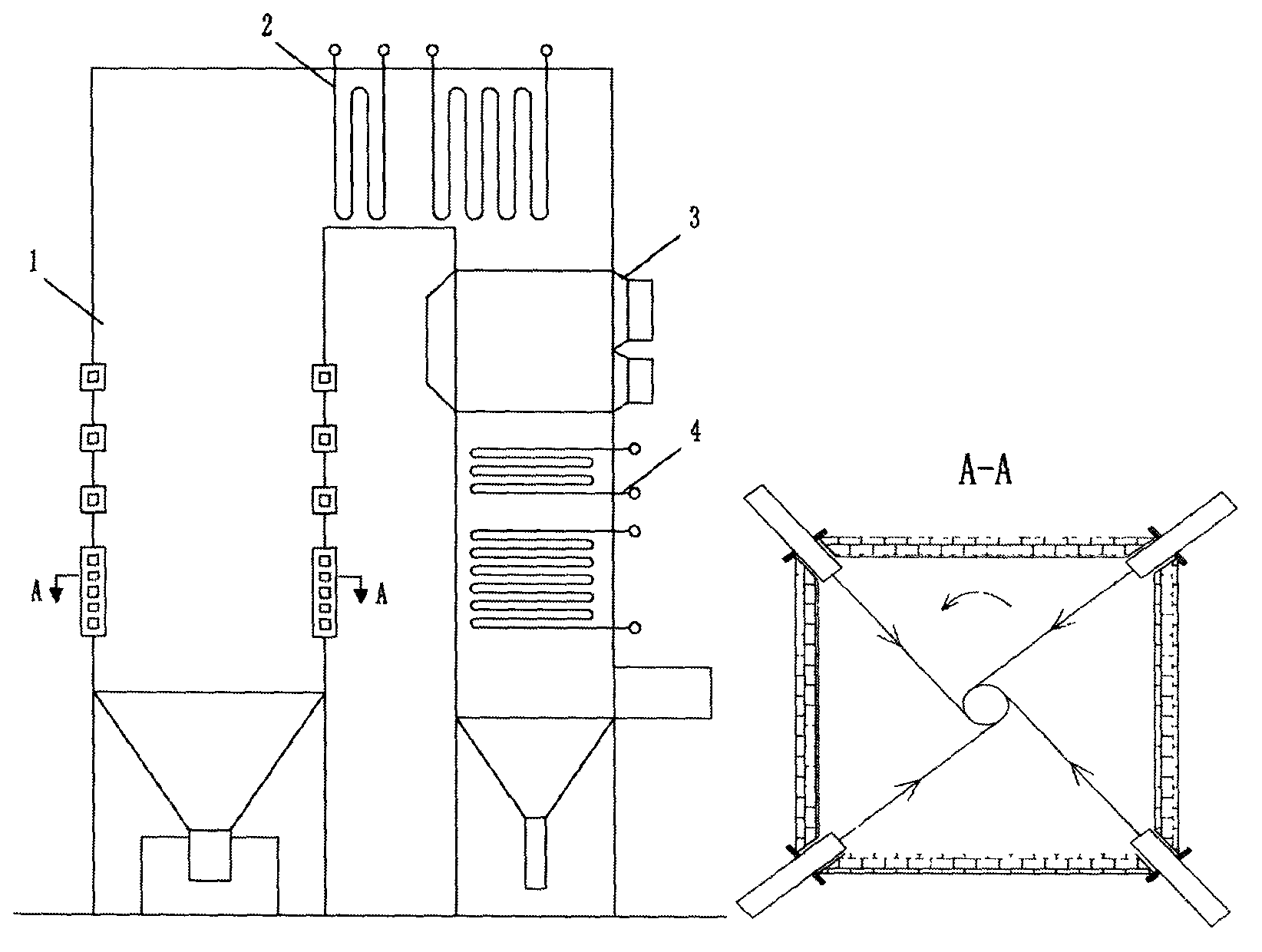

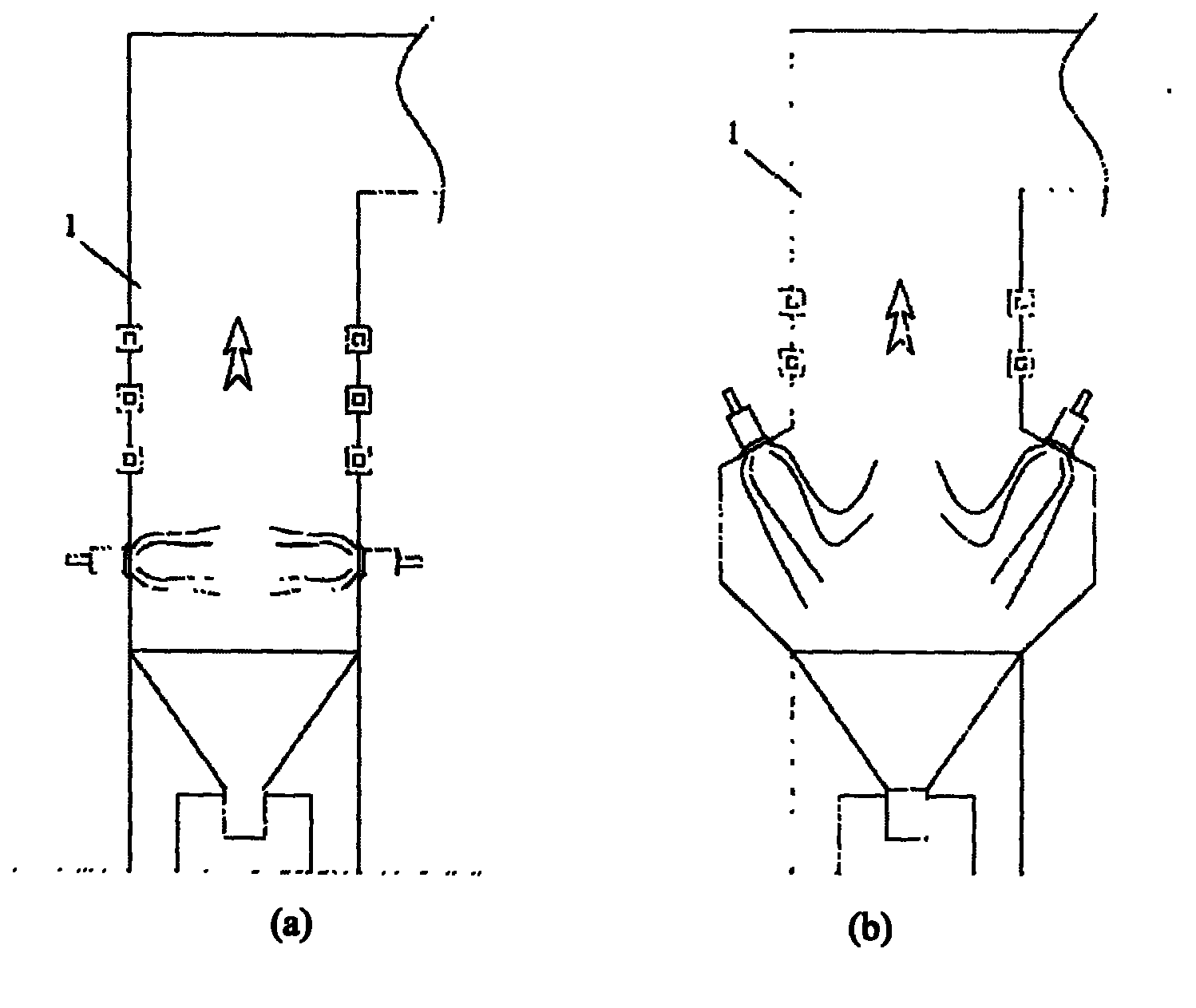

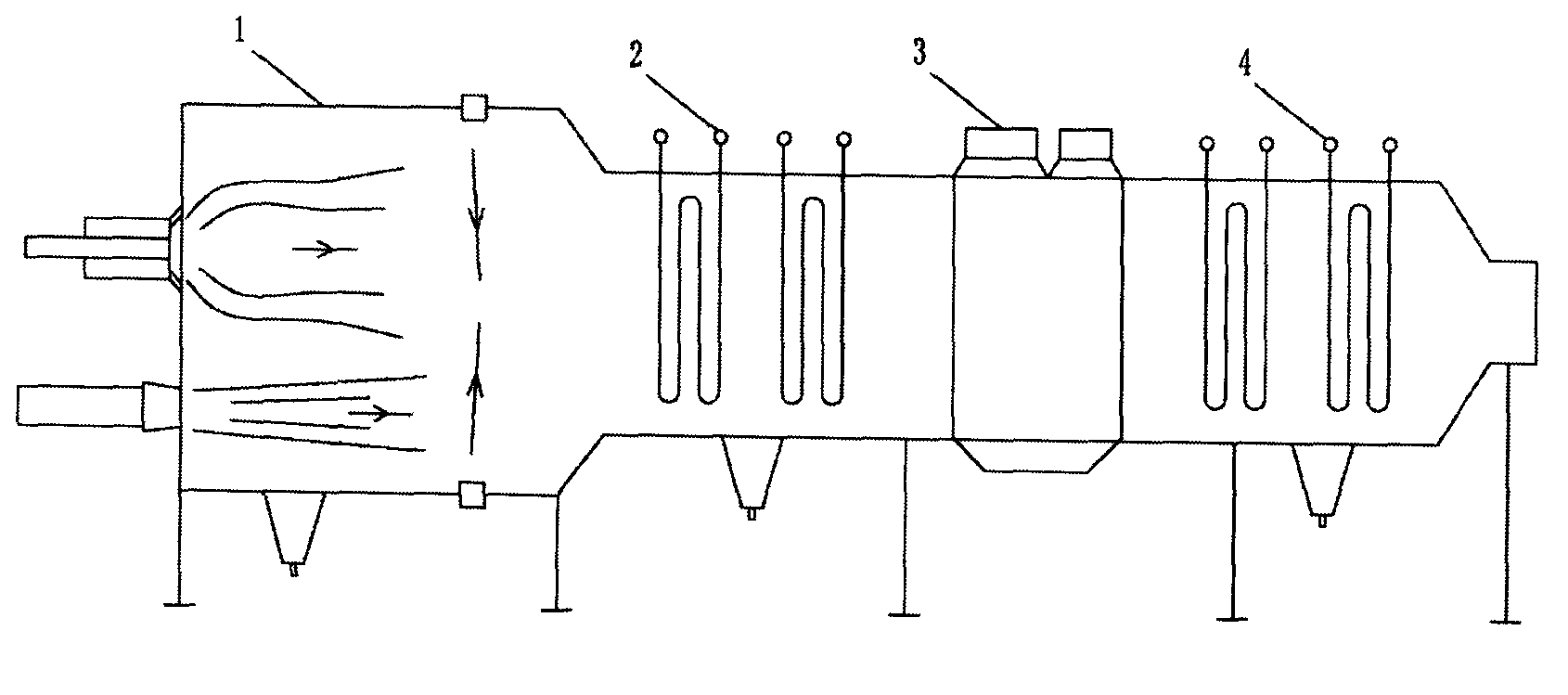

Boiler combustion test furnace

InactiveCN104075745AEnvironmentally friendlyEnvironmentally friendly and scalableMeasurement devicesCoalEngineering

A boiler combustion test furnace is characterized by comprising an interval hearth, a removable classified high-temperature convective heating surface, a high-temperature air pre-heater, and a classified low-temperature coal-saved device. The boiler combustion test furnace provided by the invention creates a test condition of simulating actual power plant boiler combustion for the advanced combustion technology.

Owner:SHANGHAI HEAT ENERGY TECH

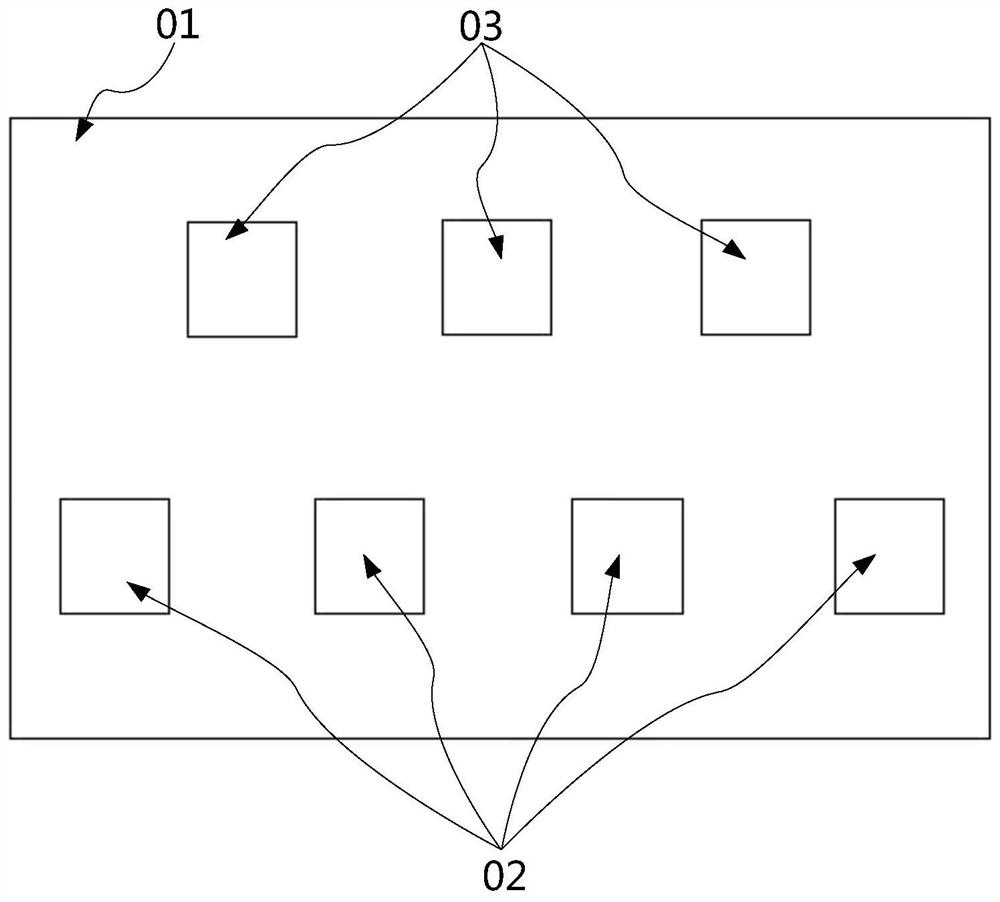

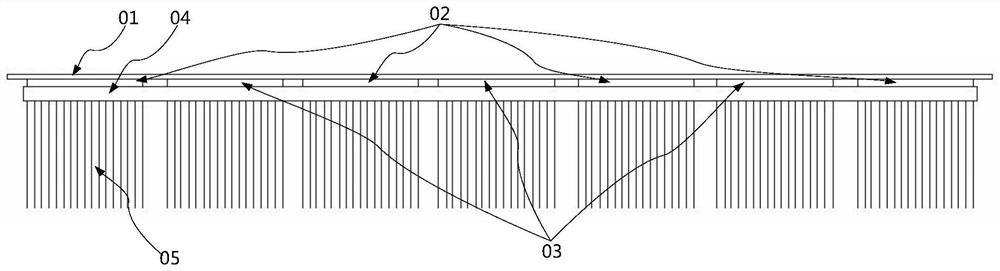

Photovoltaic power station, power equipment and heat dissipation structure thereof

PendingCN113422575AImprove space utilizationImprove cooling effectConversion constructional detailsPhotovoltaicsThermodynamicsMiniaturization

The invention discloses a photovoltaic power station, power equipment and a heat dissipation structure thereof. The heat dissipation structure comprises two groups of heat dissipation components, each heat dissipation component comprises a heat dissipation substrate and a radiator row arranged on the first surface of the heat dissipation substrate, the radiator row comprises a plurality of radiators arranged at intervals, the first surfaces of the two heat dissipation substrates are oppositely arranged, and at least part of the radiators of one radiator row are embedded into the gap of the other radiator row. According to the structure, the distances between the radiators on the two heat dissipation substrates and the fan set are basically consistent, and the radiators on the two heat dissipation substrates can exchange heat with airflow provided by the fan set at the same time, so that the heat dissipation effects of the two tend to be consistent; and meanwhile, the two heat dissipation substrates are oppositely arranged, and the two groups of heat dissipation devices are mutually staggered and embedded, so that the space utilization rate of the heat dissipation structure can be improved, the space occupation of the heat dissipation structure in the width direction is reduced on the premise that the thickness of the heat dissipation structure is not changed basically, and convenience is provided for miniaturization design of power equipment.

Owner:SUNGROW POWER SUPPLY CO LTD

Parallel air-cooled battery box

PendingCN106981592AGuaranteed temperature balanceEnsure consistencySecondary cellsCell component detailsElectric vehicleEngineering

The invention relates to the field of electric vehicles and particularly relates to a parallel air-cooled battery box. The parallel air-cooled battery box comprises a battery box cover, a battery box body, an air inlet pipe and a battery module, wherein the battery box cover covers the battery box body; an installation bracket is arranged at the bottom of the battery box body; an air inlet hole and an air outlet hole are formed in the side wall; the battery module is arranged on the installation bracket; an air inlet chamber is formed among the bottom of the battery box body, the battery module and the installation bracket; an air inlet of the air inlet pipe is connected with the air inlet hole of the battery box body; the air inlet pipe passes through the installation bracket; an air outlet of the air inlet pipe is arranged in the air inlet chamber; the battery module comprises a module box body and a plurality of batteries in the module box body; air guide holes are formed in the upper end surface and the lower end surface of the module box body. The problems of heat dissipation of the batteries in the battery box, internal temperature balance of the battery module and temperature balance among battery modules are effectively solved, thereby prolonging the service life of a battery pack.

Owner:SHANTOU UNIV

Battery box internally provided with independent heat-dissipating channel and battery box body

PendingCN109524582AConsistent heat dissipationImprove cooling efficiencySecondary cellsCell component detailsNew energyAlternative fuel vehicle

The invention relates to the field of new energy automobiles and provides a battery box internally provided with an independent heat-dissipating channel and a battery box body, and solves the problemthat the heat-dissipating efficiency of the battery box in the prior art is low. The battery box internally provided with the independent heat-dissipating channel comprises a battery box body and a battery pack arranged in the battery box body. An air inlet and an air outlet are formed in the battery box body, a battery bracket is arranged in the battery box body, a battery pack mounting cavity and an air flue communicating to the air inlet and the air outlet are separately formed on two sides of the battery bracket, more than two branched tuyeres are formed on the battery bracket, the independent heat-dissipating channels are arranged at the branched buyers, the battery pack is arranged in the independent heat-dissipating channel, and a channel through which an air flow circulates is arranged between the battery pack and the inner wall of the heat-dissipating channel and / or a channel through which an air flow circulates is arranged between the battery units is arranged in the batterypack. The air flow is guided in the channel to dissipate heat of the battery pack in the whole channel, so that the heat-dissipating efficiency is improved.

Owner:ZHENGZHOU YUTONG BUS CO LTD

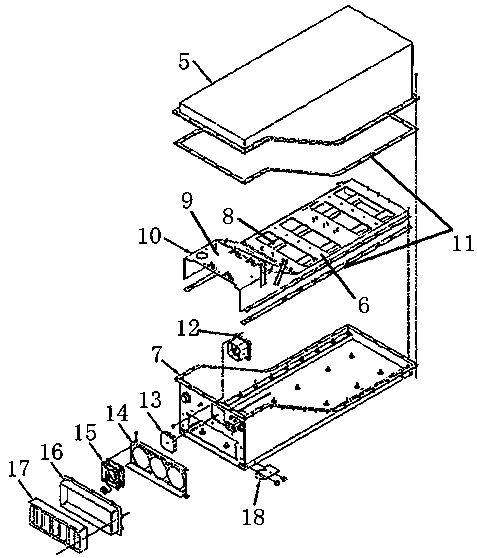

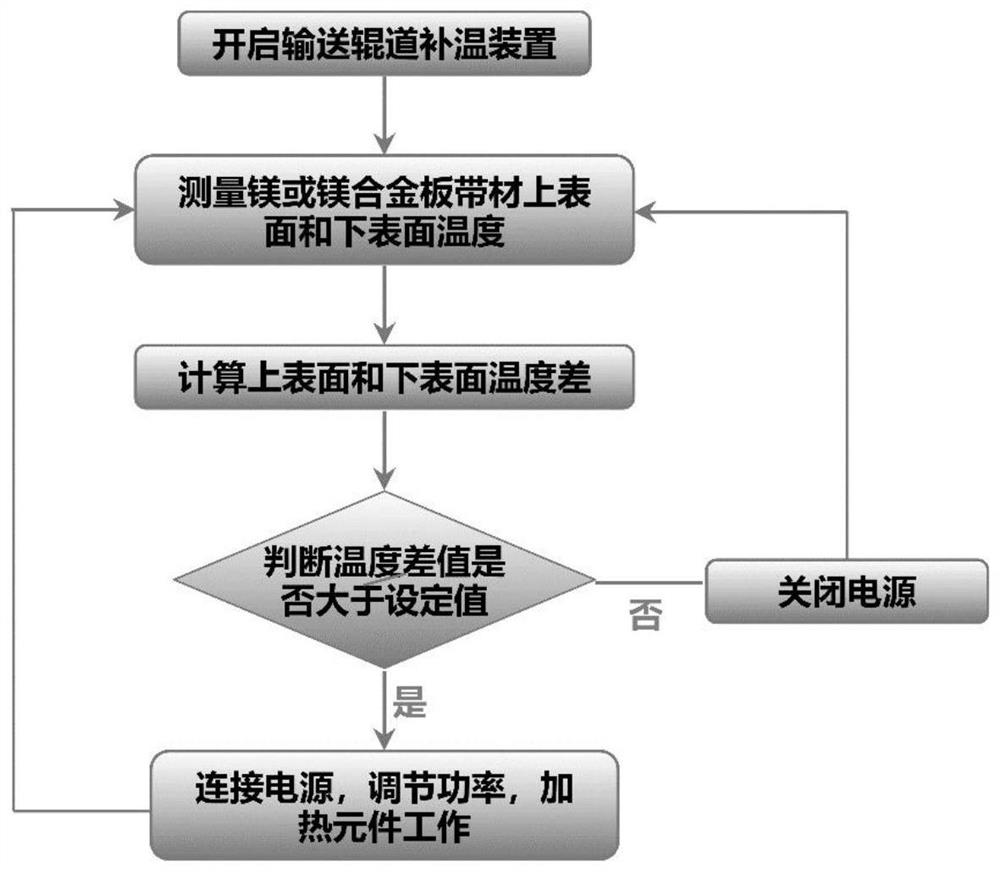

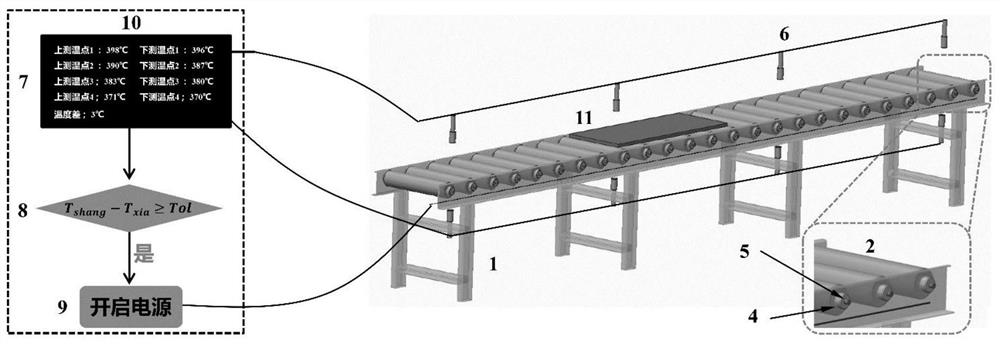

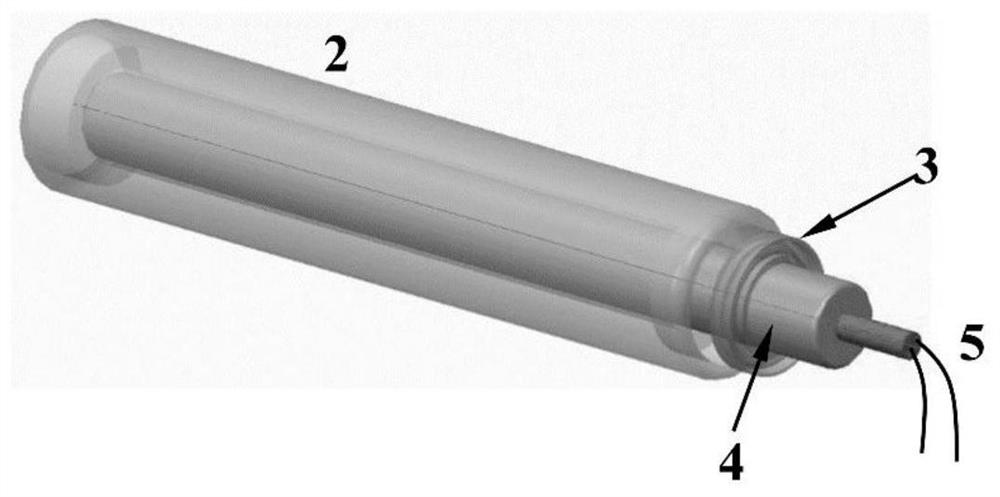

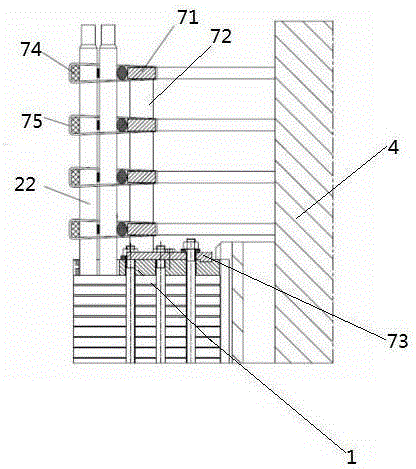

Temperature supplementing method and device for conveying roller way of magnesium or magnesium alloy plate strip

PendingCN112170506AConsistent heat dissipationImprove performanceTemperature control deviceMeasuring devicesTemperature controlMachining

The invention provides a temperature supplementing method and device for a conveying roller way of a magnesium or magnesium alloy plate strip. The invention aims to solve the problem of temperature difference between the upper surface and the lower surface of the magnesium or magnesium alloy plate strip caused by different contact media of the upper surface and the lower surface in the conveying process, and finally the plastic machining capacity of the magnesium alloy plate strip is improved. According to the method, an electric heating conveying roller is adopted, a temperature testing device and a temperature control and feedback system are arranged, the contact environment temperatures of the upper surface and the lower surface of the magnesium or magnesium alloy plate strip are the same in the conveying process by adjusting the temperature of the conveying roller, and the temperature difference between the upper surface and the lower surface of the magnesium or magnesium alloy plate strip is controlled below 5 DEG C in the conveying process on the conveying roller way. According to the method, heat dissipation of the upper surface and the lower surface of the magnesium or magnesium alloy plate strip is consistent in the conveying process, and the purpose of uniform temperature in the thickness direction is achieved; excellent microscopic structures and mechanical properties are obtained after rolling; and the large-scale application of the magnesium or magnesium alloy plate strip in the market can be greatly expanded.

Owner:HARBIN INST OF TECH AT WEIHAI

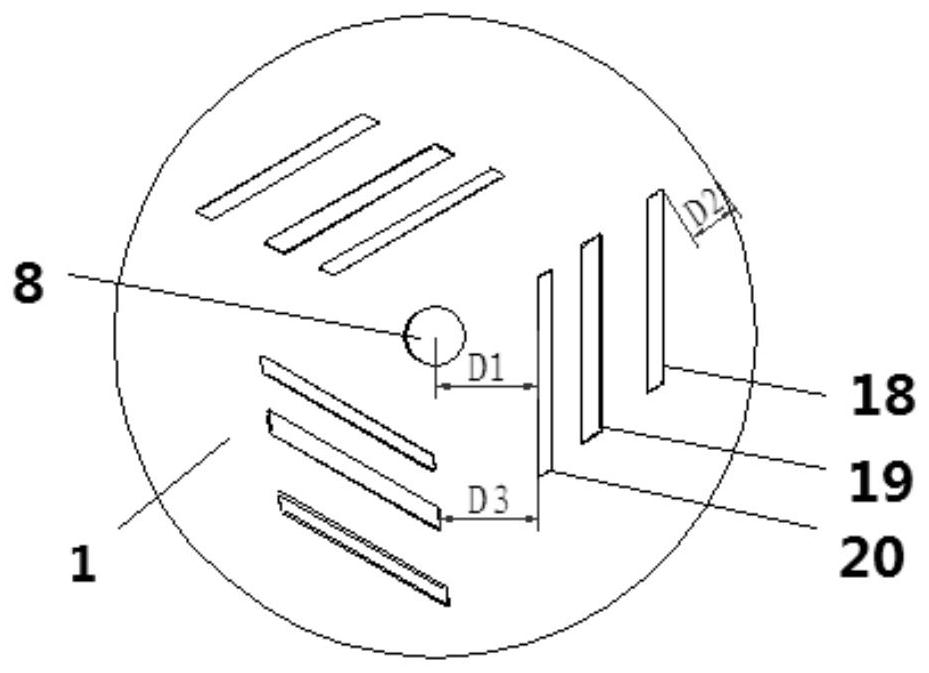

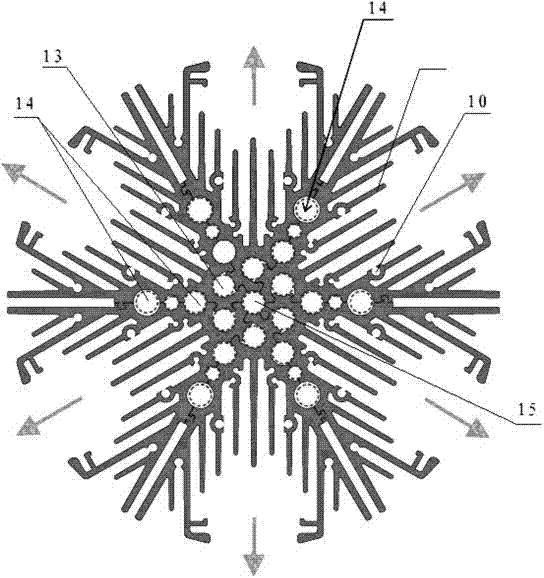

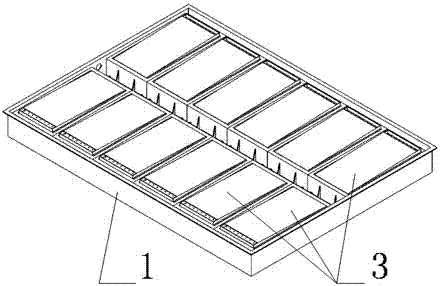

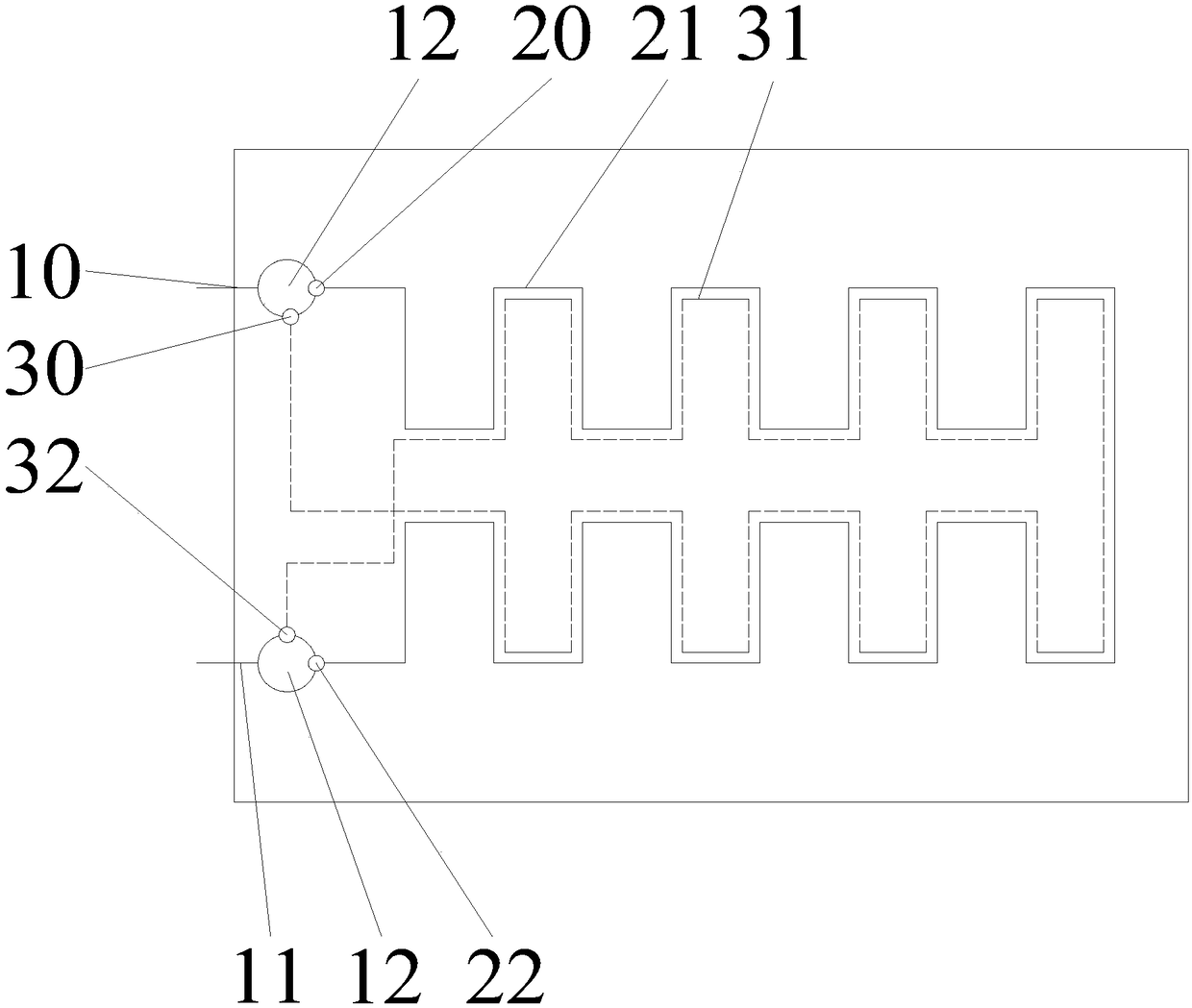

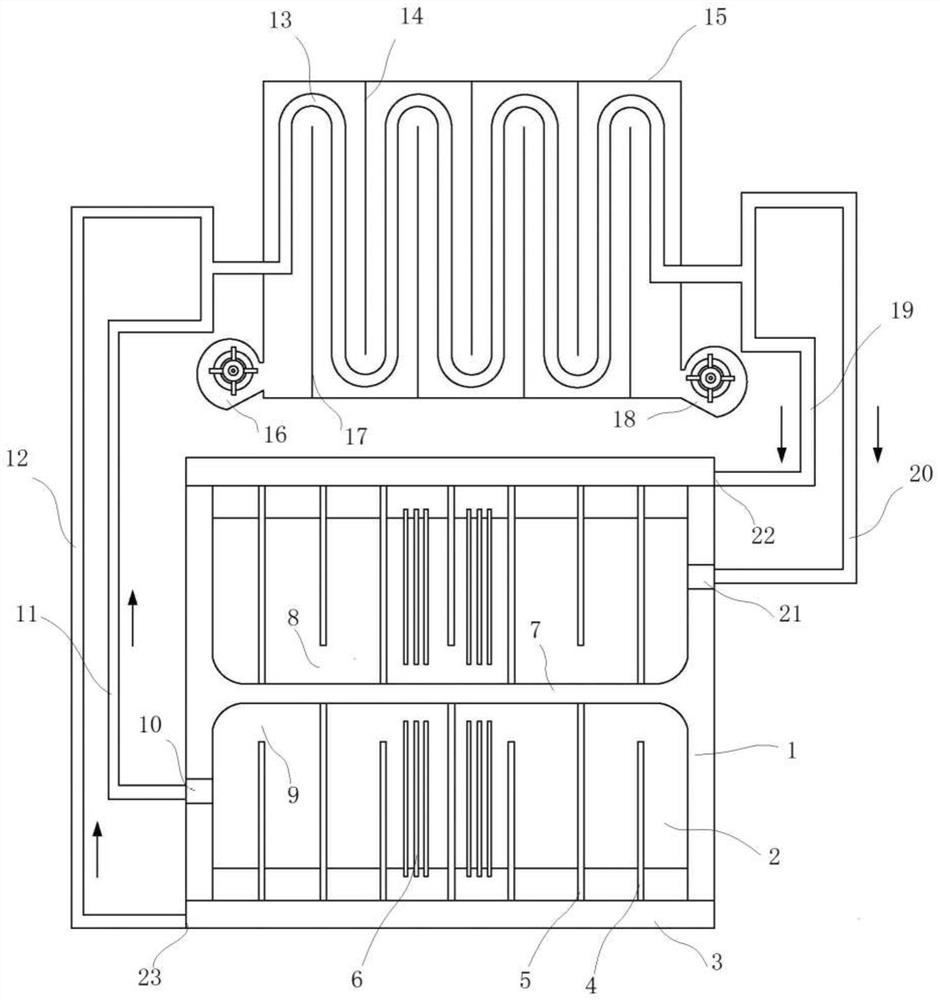

A Microchannel Radiator with Temperature Homogenization

ActiveCN108650848BConsistent heat dissipationImprove temperature consistencyCooling/ventilation/heating modificationsCoolant flowEngineering

The invention discloses a temperature-uniform microchannel heat sink. The temperature-uniform microchannel heat sink comprises a substrate and a coolant distributor, coolant flow concentrators and partition plates which are arranged on the upper surface of the substrate and closely integrated into a whole with the substrate; 2<k> groups of heat dissipating channels are formed in the upper surfaceof the substrate, wherein k is an integer greater than or equal to 1, each group of heat dissipating channels is composed of multiple heat dissipating microchannels, and flow concentration grooves areformed at the two ends of each heat dissipating channel; a coolant inlet is formed in the top face of the coolant distributor, a liquid distribution channel is formed in the coolant distributor and composed of k layers of 2<k>-1 inverted T-shaped flow channels, inlets of the next layer of flow channels are connected with outlets of the previous layer of flow channels, and the outlets of the lastlayer of flow channels correspond to the heat dissipating channels one to one and are located in the middles of the heat dissipating channel groups respectively; and the structure of the coolant flowconcentrators is exactly the same as that of the coolant distributor. The temperature-uniform microchannel heat sink has the advantages of being higher in heat dissipating capacity, better in temperature uniformity and lower in pressure drop and has the excellent comprehensive heat dissipating performance.

Owner:XIDIAN UNIV

A heat dissipation method and a heat dissipation system for an electronically controlled integrated controller

PendingCN108990395AGuaranteed uniformityChurn consistentCooling/ventilation/heating modificationsInlet valveEngineering

The invention discloses a heat dissipation method and heat dissipation system for an electronically controlled integrated controller. The heat dissipation system includes a heat dissipation unit and acontrol unit, The heat dissipation unit comprises a first cooling pipe and a second cooling pipe in which air or liquid can be mutually reversely circulated, wherein the inlet ends of the first cooling pipe and the second cooling pipe are respectively provided with a first inlet valve and a second inlet valve, and the first inlet valve and the second inlet valve are communicatively connected withthe control unit. The heat dissipation effect is uniform and the temperature is controllable, which greatly improves the efficiency and safety of the controller.

Owner:苏州艾思控科技有限公司

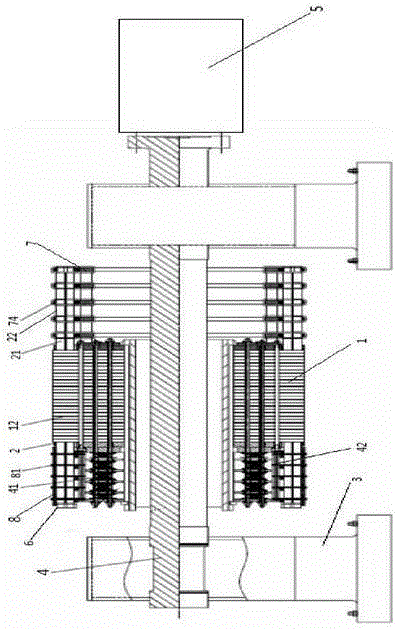

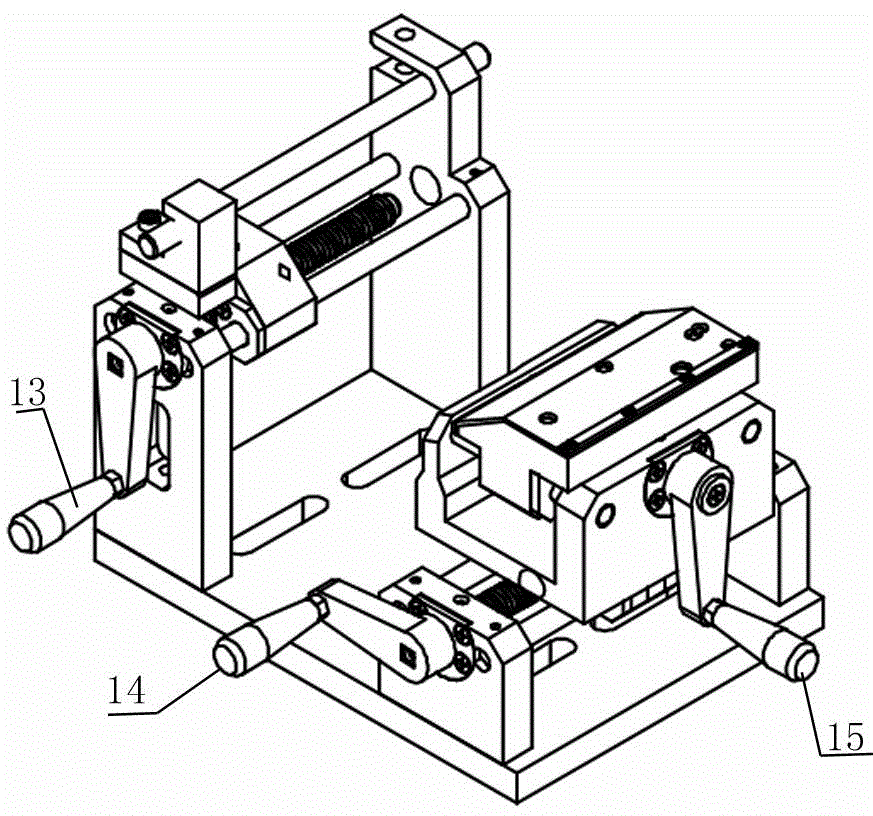

Mechanical model device for rotor of motor

ActiveCN105181325AEasy to operateSimple and fast operationMachine part testingTesting dielectric strengthExperimental researchElectric machine

The invention discloses a mechanical model device for a rotor of a motor and relates to the technical field of test machinery. The mechanical model device comprises a rotor and a rotor winding, wherein an axial winding slot is arranged along an axial direction of the rotor; a winding bar of the rotor winding is inserted into the axial winding slot; a winding tail end of the winding bar exposed from the axial direction of the rotor is formed into an end winding; end fixing devices are fixedly arranged at the two ends of the rotor; the end fixing devices are used for fixing the end winding. The mechanical model device is fit for high-capacity winding type rotor machinery, especially for the experimental research for the fixing mode of the rotor winding end and the detection and test analysis for the safe reliability of the fixing of the winding bar end of the rotor and the electric insulating property of the rotor winding.

Owner:DONGFANG ELECTRIC MACHINERY

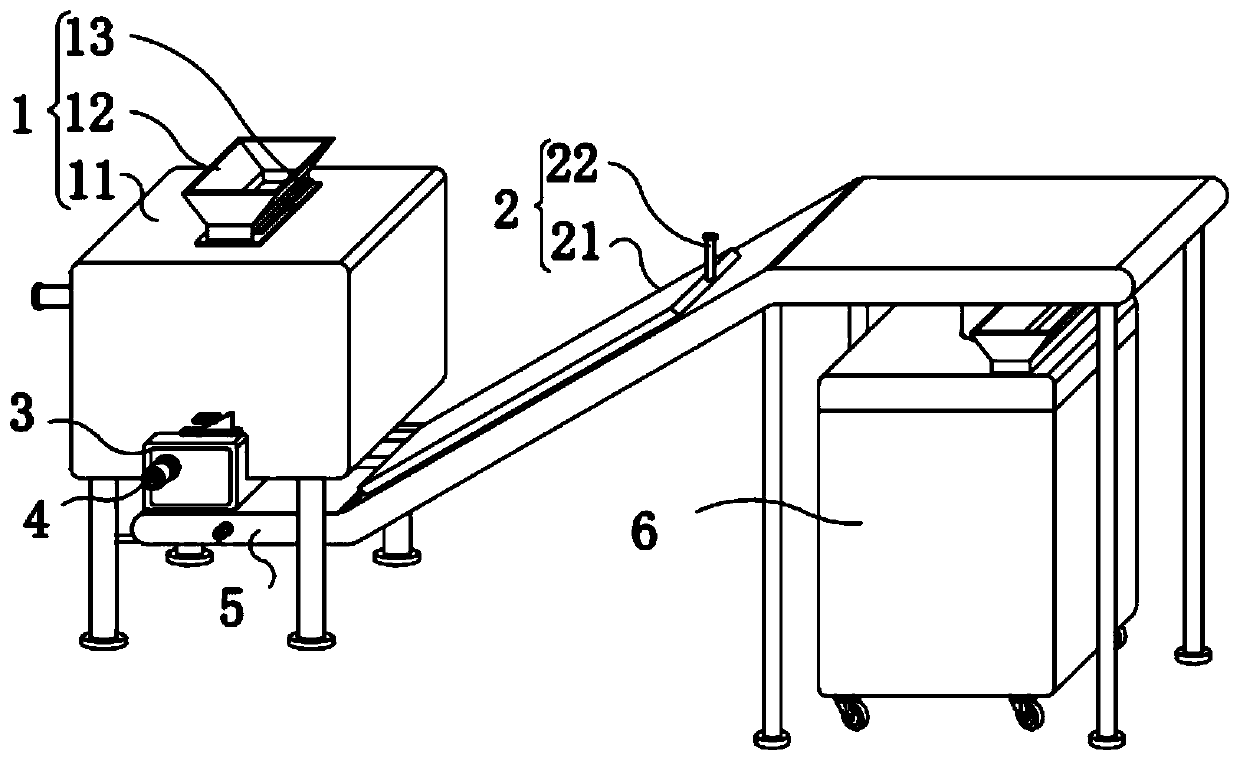

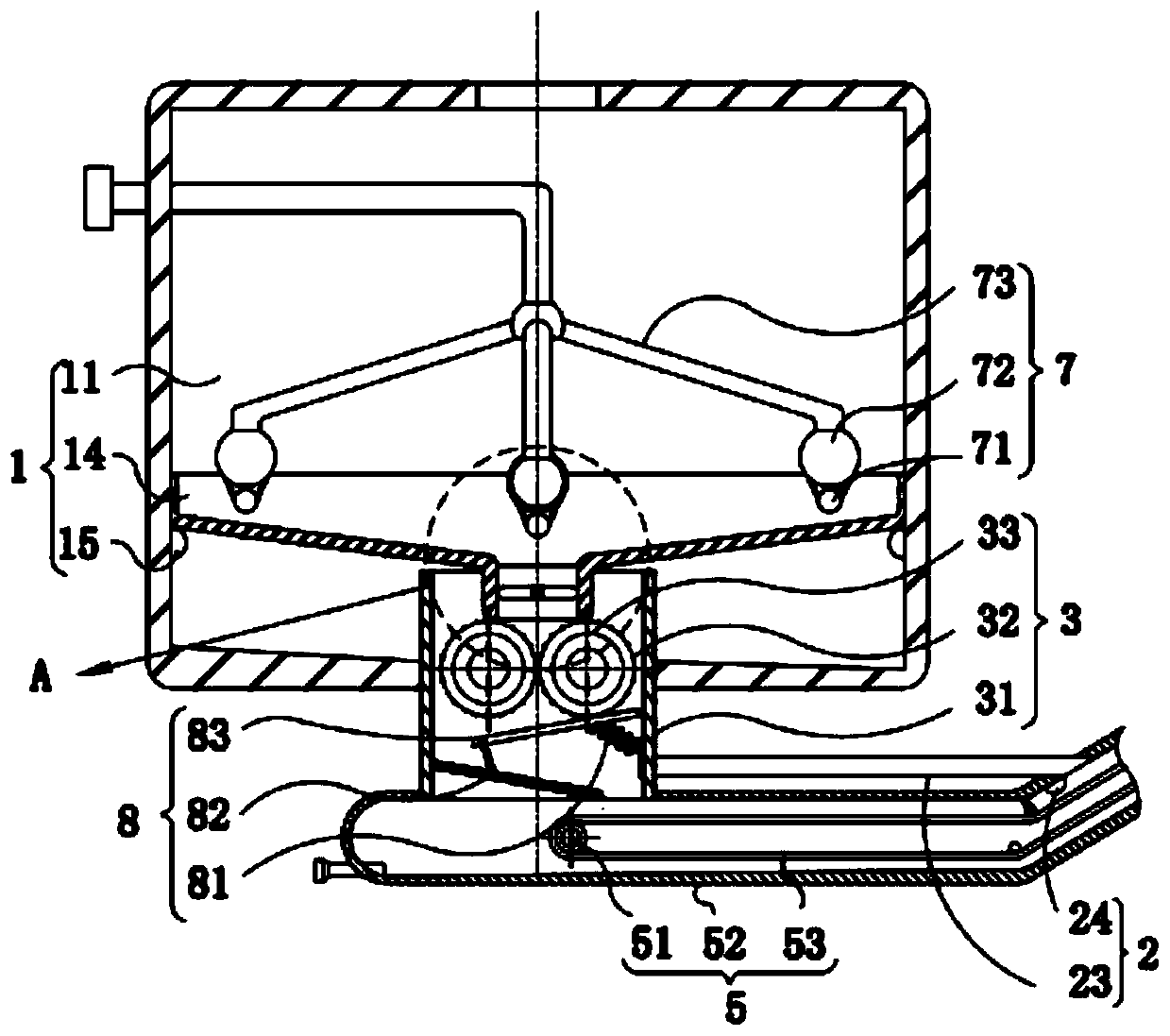

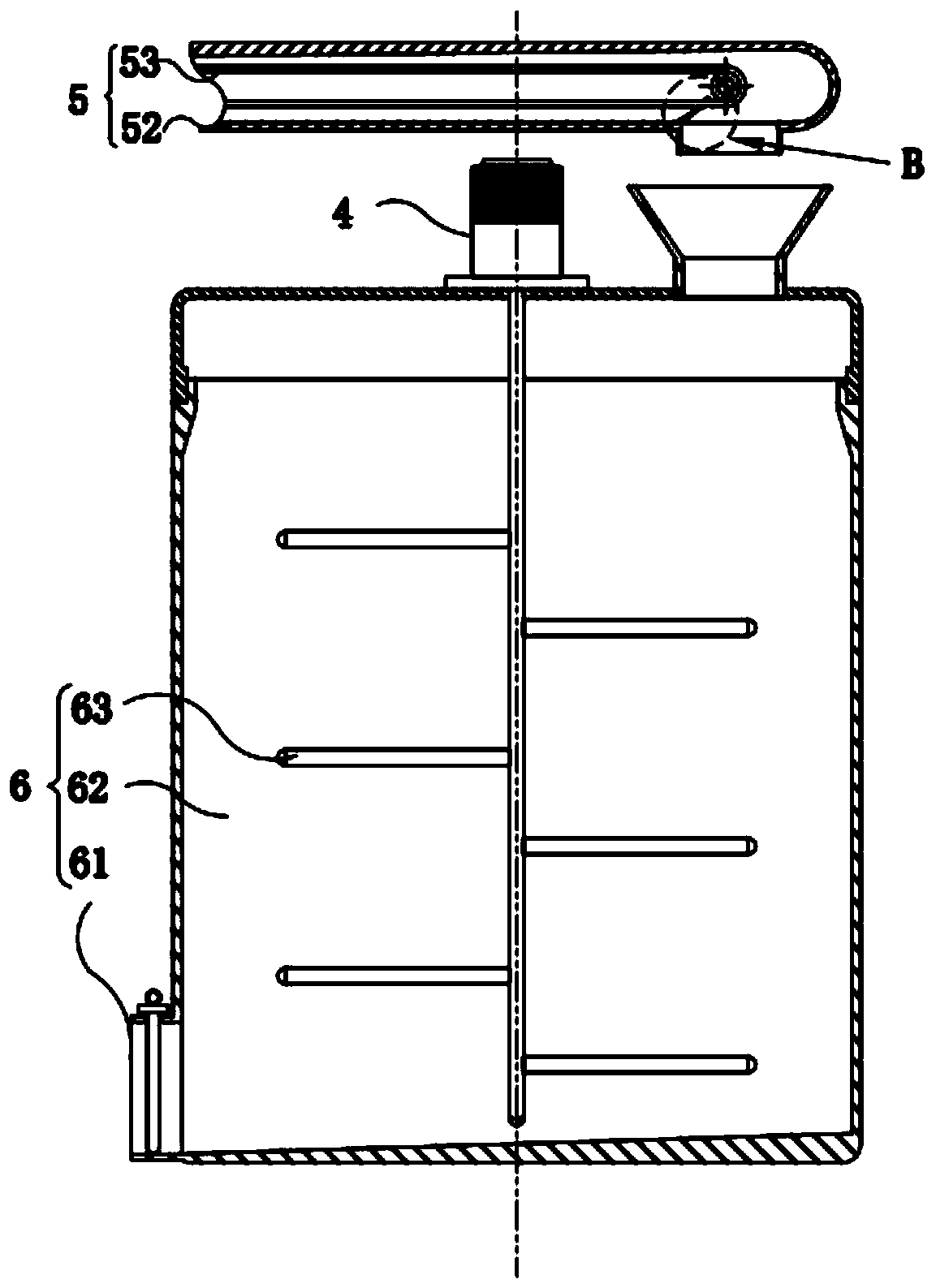

Crushing, cooking and fermenting integrated device for soy sauce processing and production

PendingCN111280433AReduce the temperatureReduce thicknessGrain treatmentsFood scienceChemistryProcess engineering

The invention provides a crushing, cooking and fermenting integrated device for soy sauce processing and production. The crushing, cooking and fermenting integrated device for soy sauce processing andproduction comprises a storage mechanism, an air intake mechanism; a crushing mechanism; a dehumidifying mechanism; a conveying mechanism; a cooling mechanism; a fermentation mechanism; a motor; anda discharging mechanism. The cooling mechanism is installed on the side wall of the conveying mechanism and comprises an installation plate, a cooling pipe, a connecting pipe, a blocking strip and spray heads, the installation plate is fixed to the top end of the conveying mechanism, the cooling pipe with a L-shaped side wall is installed in the installation plate, and the spray heads incline to the side wall of the cooling pipe at equal intervals; the blocking strip and the connecting pipe are installed at the bottom end of the conveying mechanism, the blocking strip with the semicircular section abuts against the bottom end of the connecting pipe, and one end of the connecting pipe extends into the crushing mechanism. According to the crushing, cooking and fermenting integrated device for soy sauce processing and production, soybeans can be conveniently, rapidly and uniformly cooled.

Owner:安徽爱家食品有限公司

Three-dimensional radio frequency module manufacturing method based on multi-layer heat dissipation structure

InactiveCN111653489AConsistent heat dissipationSemiconductor/solid-state device detailsSolid-state devicesRadio frequencyMechanical engineering

Owner:浙江集迈科微电子有限公司

A kind of LED light-emitting device and preparation method thereof

ActiveCN105097999BConsistent heat dissipationAvoid different attenuationSemiconductor devicesOrganic layerRefractive index

The invention relates to an LED light-emitting device and a preparation method thereof. The device comprises a substrate, an LED chip and an organic layer arranged on the substrate. It is characterized in that a refractive index buffer layer with a refractive index between the LED chip and silica gel is provided between the LED chip and the organic layer, and the refractive index buffer layer guides the light emitted by the LED chip into the The organic layer allows more light to pass through the organic layer. The organic layer is covered with a non-uniform luminescent powder layer, and the non-uniform luminescent powder layer includes at least two different types of luminescent powder layers arranged in layers or luminescent powder layers of the same type with different particle sizes. Phosphor powders of the same type or particle size in the layer are uniformly arranged, and phosphor powders of different types or particle sizes are relatively non-uniformly arranged.

Owner:SICHUAN SUNFOR LIGHT

Method for spreading and drying fermented grains

ActiveCN102533490AImprove cooling uniformityConsistent heat transfer and coolingAlcoholic beverage preparationChemistryBrewing

The invention discloses a method for spreading and drying fermented grains for improving uniformity of cooling the fermented grains and the uniformity of mixing the fermented grains and yeast powder, and belongs to the technical field of brewing. The method comprises the following steps of: a. evenly spreading the distillated and pasted fermented grains to form a fermented grain layer with a certain thickness; b. evenly scattering the yeast powder on the surface of the fermented grain layer, and dividing the position on which the fermented grain layer is positioned into n turning regions which are respectively a first region (1), a second region, a third region to a n-1 region and a n region (2); turning and mixing the fermented grains at the first region (1) and the second region, and then evenly spreading the fermented grains on the first region (1) and the second region; turning and mixing the fermented grains at the second region and the third region, and then evenly spreading thefermented grains on the second region and the third region; and orderly turning the fermented grains according to the method till turning and mixing the fermented grains at the n-1 region and the n region, and then evenly spreading the fermented grains on the n-1 region and the n region. The method is simple to operate; the heat dissipation of the fermented grains is consistent; and the fermentedgrains are evenly mixed with the yeast powder.

Owner:LUZHOU PINCHUANG TECH

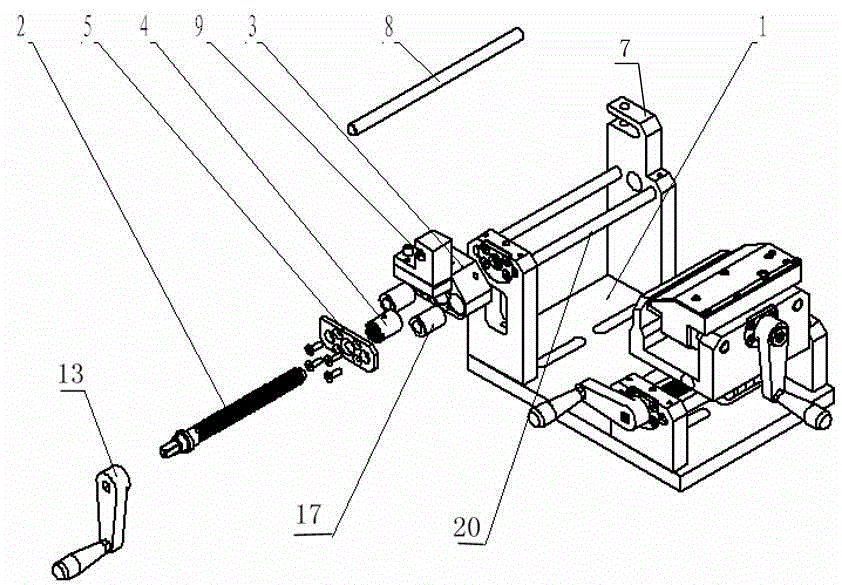

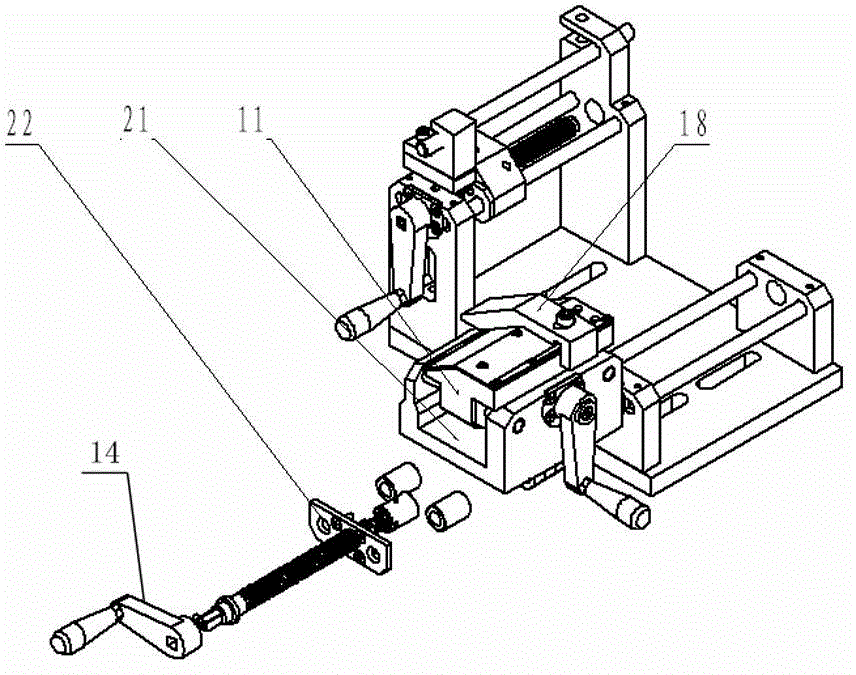

Test bracket of generator heating test bench

InactiveCN105467161ASolve the phenomenon of plastic paint damage on the pressed surfaceMotion track stabilityMeasurement instrument housingType numberTest bench

The invention relates to a test bracket of a generator heating test bench. Two sides of a base are upwardly provided with vertical columns sides, one of the vertical column sides is provided with a first handle assembly, the first handle assembly drives a nut to move back and forth through a lead screw, the nut is externally provided with a small sliding base, and the lead screw and the nut are fixed through a small fixing plate at the side surface of the small sliding base so as to form a first set of adjusting device; a second handle assembly at the other vertical column side drives a nut to move back and forth through a lead screw, the nut is externally provided with a middle sliding base, and the lead screw and the nut are fixed through a middle fixing plate at the side surface of the middle sliding base so as to form a second set of adjusting device; and the upper part of the middle sliding base of the second set of adjusting device is provided with a large sliding base, the side edge of the large sliding base is provided with a third handle assembly through a large fixing plate so as to form a third set of adjusting device, and the third set of adjusting device is vertical with the first set of adjusting device and the second set of adjusting device. The test bracket provided by the invention is formed by three sets of lead screw pairs and linear guide rail pairs, can cover heating tests of general models of generators, and effectively solves problems that the variety of clamps is great and the replacement time is long.

Owner:DONGFENG MOTOR PARTS & COMPONENTS GROUP

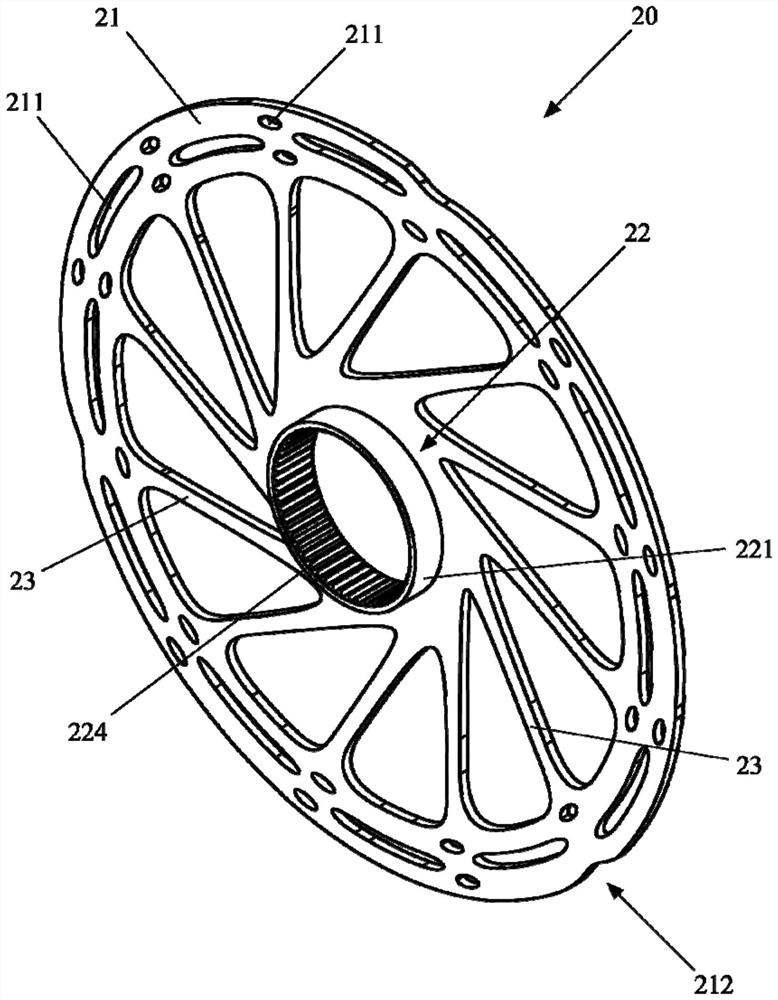

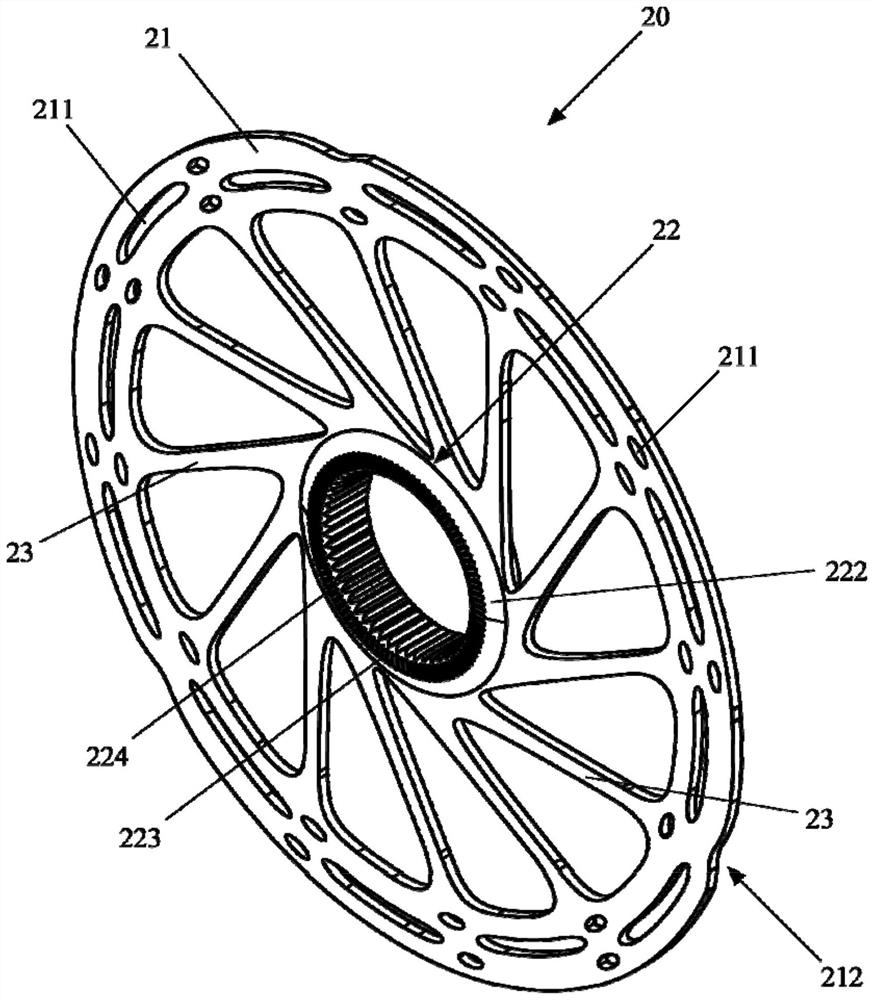

Integrally-formed bicycle brake disc and manufacturing method thereof

InactiveCN112776933AConsistent heat dissipationImproves braking stabilityBraking discsCycle brakesBrakeFilm-coated tablet

The invention relates to an integrally-formed bicycle brake disc and a manufacturing method thereof; the brake disc is integrally formed through the manufacturing procedures of stamping, quenching heat treatment, lathe machining, film coating and local grinding, the brake disc is in butt joint and fixed with an external wheel shaft through a center combination part, and the brake disc is in butt joint with an external locking ring through the center combination part; and an external locking piece is used for locking a disc body on the external wheel shaft and driving the disc body to rotate along with the rotation of the external wheel shaft, so that the technical effects that the brake disc is manufactured through integral forming, the brake disc provides consistent heat dissipation performance, and the brake stability is further improved are achieved.

Owner:SAKYA IND CORP

Method for spreading and drying fermented grains

Owner:LUZHOU PINCHUANG TECH CO LTD

A test method for the cold and warm feeling of textiles simulating the physiological feeling of the human body

InactiveCN106770448BScientific control of heating powerRepresent physical sensationMaterial heat developmentHuman bodyThermal insulation

The invention discloses a textile cold and warm feeling test method capable of simulating physiological sensation of a human body. The method can be realized by using hardware of an existing clothing, bedding and fabric thermal insulation property tester for testing, and the cold and warm feeling of a sample can be analyzed by optimizing the test method and using a signal within an abandon period in thermal insulation property test. The implementation method comprises the steps: controlling a test board temperature and heating power, setting a temperature and humidity of a test environment, judging whether the sample of a textile has cold feeling or warm feeling, and quantitatively analyzing a cold feeling / warm feeling index of the sample of the textile. Compared with the prior art, the test board heating power of a body surface simulating instrument is scientifically controlled to be more consistent with a true heat dissipation rule of the human body, and a measured physical quantity can more effectively represent human physiological sensation. The definitions of the cold feeling index and the warm feeling index with definite physical meaning are provided; the cold feeling index and the warm feeling index of the textile can be scientifically and reasonably detected and analyzed; cold feeling and warm feeling and heat retaining property indexes of the textile can be more accurately detected.

Owner:YANTAI NANSHAN UNIV +1

Battery pack with air duct structure and air cooling method

PendingCN114267902AUniform temperatureEven heat dissipationSecondary cellsEngineeringMechanical engineering

The invention provides a battery pack with an air duct structure and an air cooling method.The battery pack with the air duct structure comprises a box body and battery modules arranged in the box body, the opposite side walls of the box body are each provided with a first air control element, and at least one second air control element is arranged between every two adjacent battery modules; ventilation openings are formed in the first air control element and the second air control element; air enters the box body from the first air control element on one side, flows through the heat dissipation element and the second air control element and is discharged out of the box body from the first air control element on the other side. By arranging the first air control element, the heat dissipation element and the second air control element, the air ducts are optimized, a fan does not need to be installed on the battery pack, the multi-air-duct effect is achieved, and the multi-air-duct battery pack has the advantages of being simple in structure, fully utilizing space, being good in heat dissipation effect and the like.

Owner:SHANGHAI RUIPU ENERGY CO LTD

A circulating cooling type continuous casting crystallizer

The invention relates to a circulating cooling continuous casting crystallizer, which comprises a crystallizer body, an outer shell and a cooling box. Bosses are arranged at both ends of the crystallizer body, and the outer shell is sleeved on the bosses. The crystallizer A closed first cooling channel is formed between the body, the boss and the outer shell, and the boss is respectively provided with a first water inlet and a first water outlet communicating with the first cooling channel; the outer shell is provided with a second Cooling channel, the two ends of the outer casing are respectively provided with a second water inlet and a second water outlet connected to the second cooling channel; a serpentine heat exchange tube is provided in the cooling box; a side of the cooling box near the water outlet pipe is provided There is a blower, and the side of the cooling box near the water inlet pipe is provided with an exhaust fan. The crystallizer of the present invention adopts two cooling passages to improve the heat dissipation efficiency, make the heat dissipation more uniform, keep the crystallization speed of the crystallizer consistent, and ensure the crystallization effect. Cooling water recycling is adopted to reduce the utilization of water resources, reduce costs, and improve the integrity of the system and the stability of system operation.

Owner:NANCHANG INST OF TECH

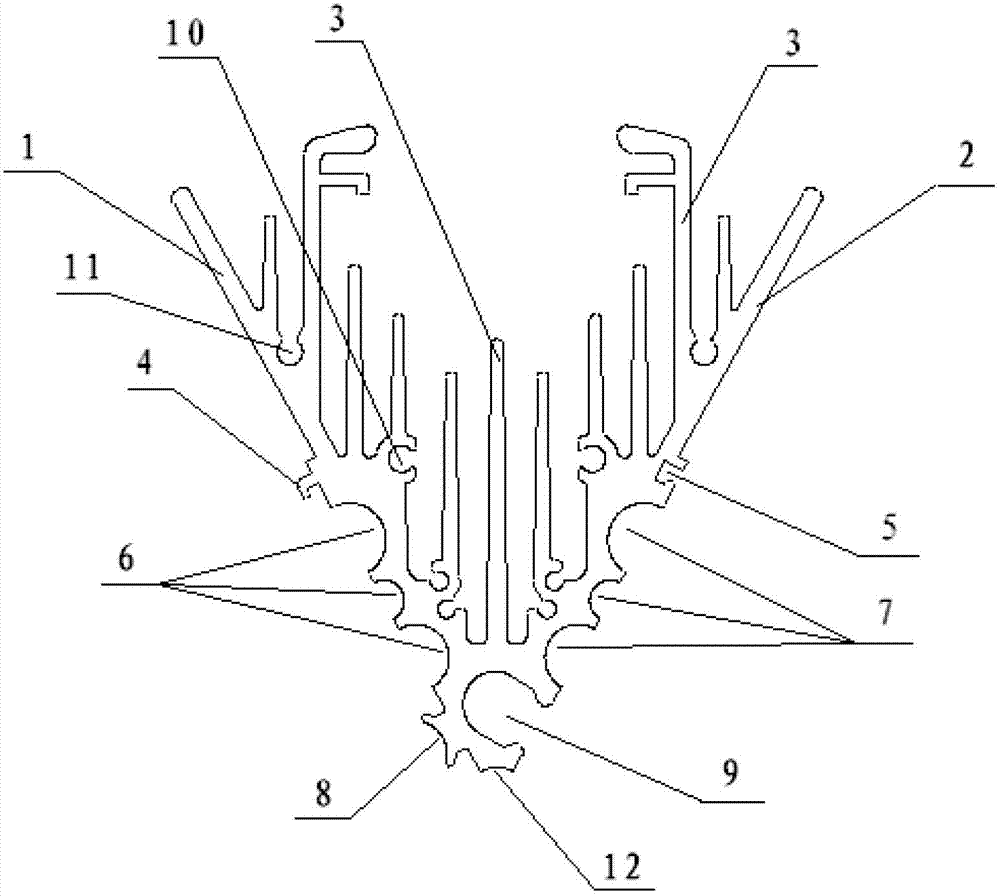

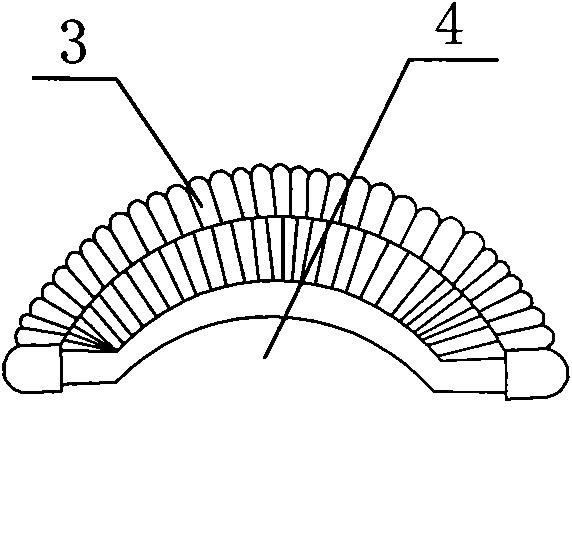

Heat sink built in cavity cylindrical light emitting diode wick

ActiveCN101586796BConsistent heat dissipationReduce heat dissipationPoint-like light sourceSemiconductor/solid-state device detailsHeat sinkLight-emitting diode

The invention discloses a heat sink built in a cavity cylindrical light emitting diode wick, comprising a cylindrical wick with a cavity therein. The cavity of the cylindrical wick therein is provided with a fastener, multiple reflection blades are distantly arranged in the length direction of the fastener, the roots of a first reflection blade to a last but one radiating fin are provided with openings, and the opening areas are decreased in sequence, and the last fin is not provided with an opening. The number of the radiating media needed by the light emitting diodes corresponding to each section of the wick is determined according to the reflecting action of the reflection blades, so as to determine the sizes of the openings at the roots of the radiating media blades and the inclination angle of each blade, such that each light emitting diode of the whole wick obtains relatively uniform radiating effect. As the radiating media blades at each section of the wick are parallel radiating structures, the invention relatively excellently solves the heat superposition and heat internal circulation in the wick, so as to decrease the radiating effect of the wick and improve radiating efficiency.

Owner:广州朗辰伟烨照明科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com