Air-cooled battery box

A battery box and air-cooled technology, which is applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve problems such as difficult to meet, corrode battery cells, and reduce the temperature difference of battery cells, so as to ensure temperature balance and high temperature. Lifespan, the effect of increasing lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

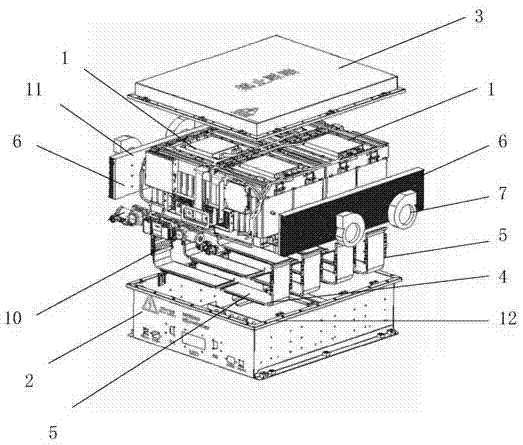

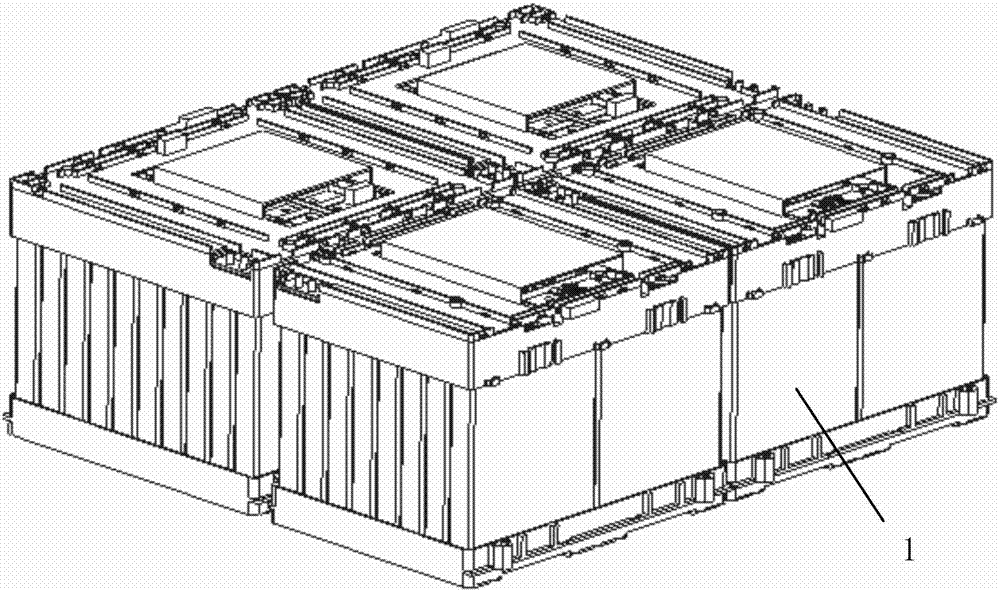

[0021] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. Such as figure 1 As shown, an air-cooled battery box includes a box body and a battery module 1 placed inside the box body, and the box body includes a main box body 2 and a box cover 3 .

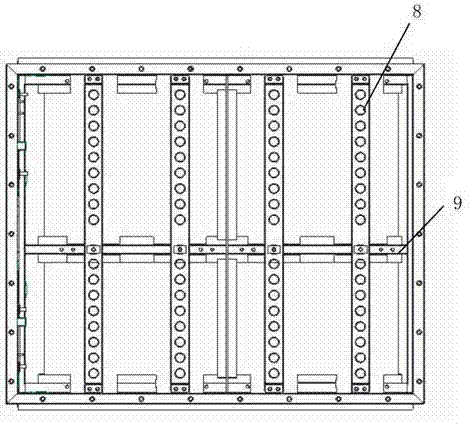

[0022] Such as figure 1 with Figure 4 As shown, a heat conduction component is installed in the main box, and the heat conduction component includes a heat conduction tube 4, a heat conduction silica gel pad 5 and thermal insulation cotton. Correspondingly, the groups are arranged in parallel, and the heat pipes are installed inside the main box. Specifically, buckles are installed on the bottom of the main box to fix the heat pipes. The thermal insulation cotton is pasted on the position corresponding to the heat pipe, the heat conduction silicone pad is bonded to the contact surface between the heat pipe and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com