Nickel-hydrogen battery pack heat management system

A technology for heat management and battery packs, which is applied to secondary batteries, circuits, electrical components, etc., can solve the problems of nickel-hydrogen battery pack heat that has not yet formed a system, simple management, etc., to improve service life and safety performance, guarantee The effect of service life and good temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

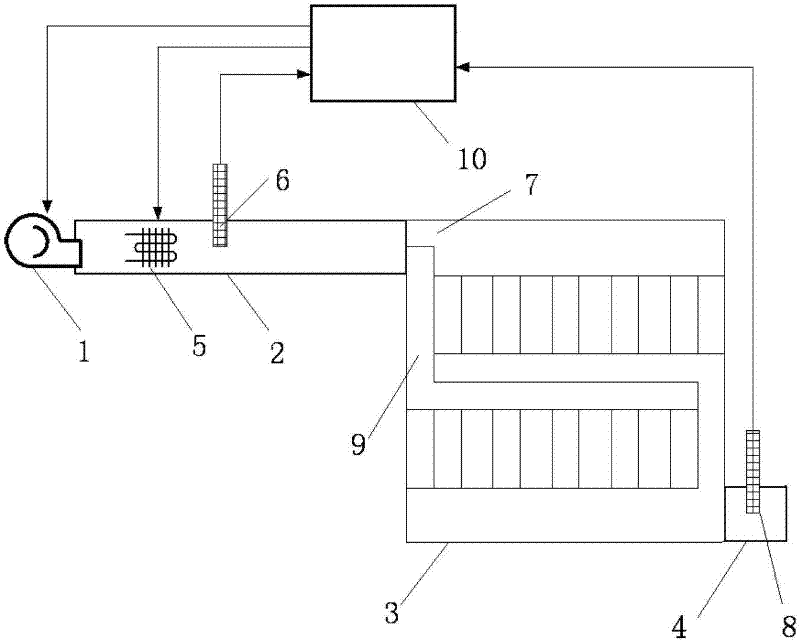

[0024] The heat management system of the nickel-metal hydride battery pack of the present embodiment is as follows: figure 1 As shown, the Ni-MH battery pack 3 is formed by connecting upper and lower electric stacks in series, and the upper and lower electric stacks are formed by connecting several single cells in parallel. The heat management system of the Ni-MH battery pack includes sequentially connected fans 1. Air intake pipe 2, nickel-metal hydride battery pack 3 and air outlet pipe 4; a heater 5 is arranged on the end of the air intake pipe 2 close to the fan 1, between the heater 5 and the nickel-hydrogen battery pack 3 A first temperature sensor 6 is arranged on the air inlet pipe 2 between them, and a second temperature sensor 8 is arranged near the end of the Ni-MH battery pack 3 on the outlet pipe 4; the fan 1, the heater 5, the first The temperature sensor 6 and the second temperature sensor 8 are connected to the controller 10 respectively.

[0025] In this embo...

Embodiment 2

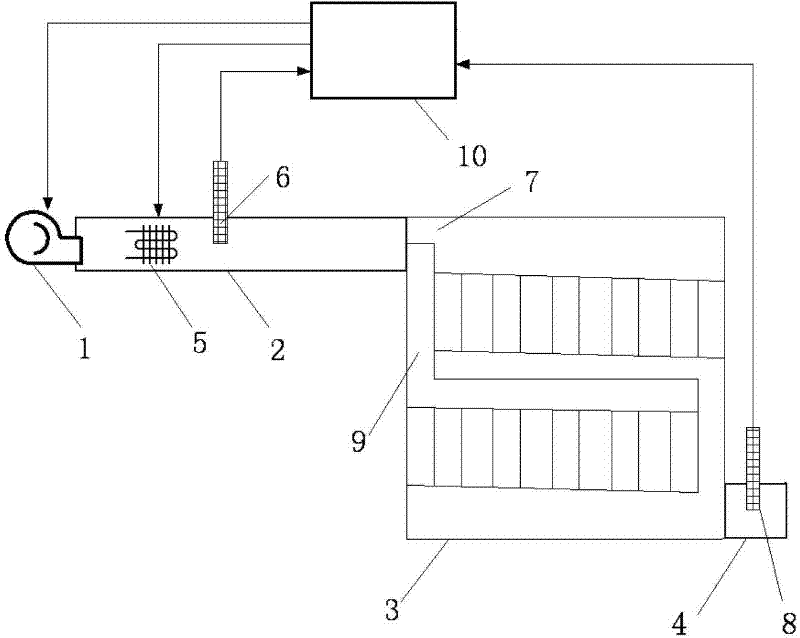

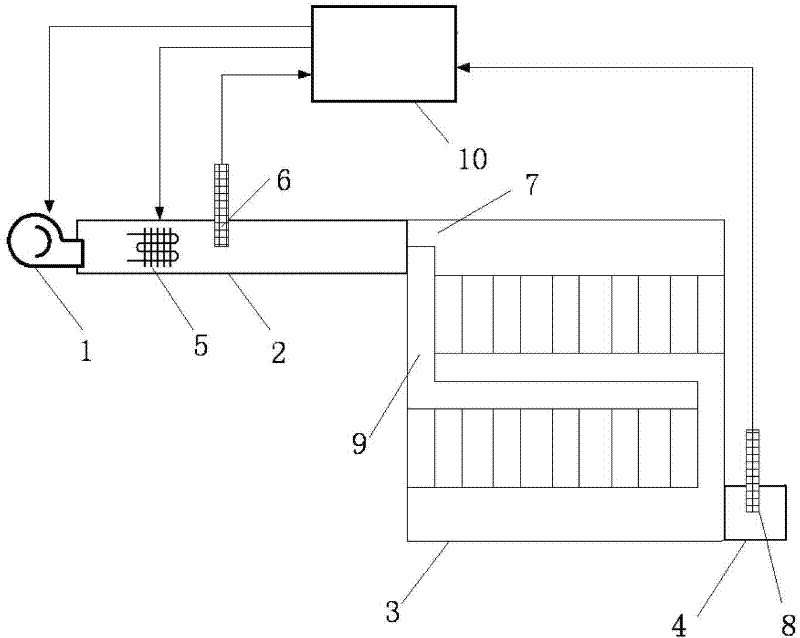

[0029] The heat management system of the nickel-metal hydride battery pack of the present embodiment is as follows: figure 2 As shown, the difference from Example 1 is that the angle between the upper and lower stacks and the horizontal direction is 2.5° (it can be any value between 2° and 3°, and it will never affect the actual value within this range. Use effect); this arrangement makes the heat dissipation effect between the parallel-connected single cells on the upper and lower stacks more consistent, and makes the battery cells have better temperature consistency, thereby better improving the nickel metal hydride Battery life and safety performance.

[0030] To sum up, since the consistency of temperature between battery modules is one of the important factors affecting the performance of the battery pack, even if the consistency of the battery is good when it is first assembled, the consistency will become more and more serious as the use progresses. It's getting worse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com