Test bracket of generator heating test bench

A heating test, generator technology, applied in the direction of the measuring device casing, etc., can solve the problem of surface paint damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

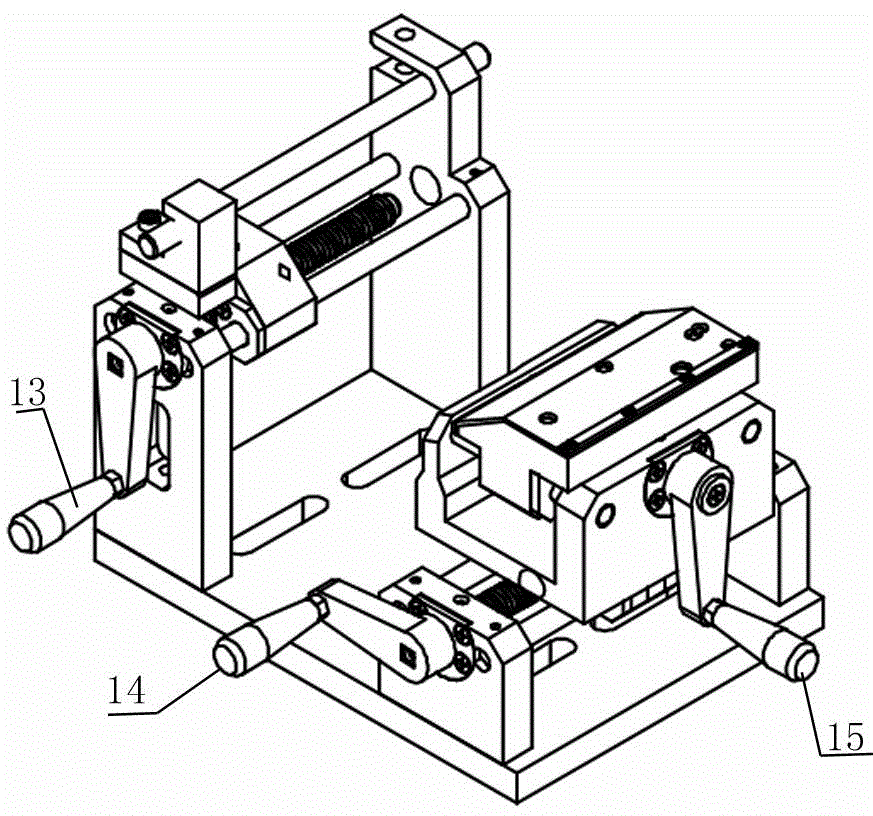

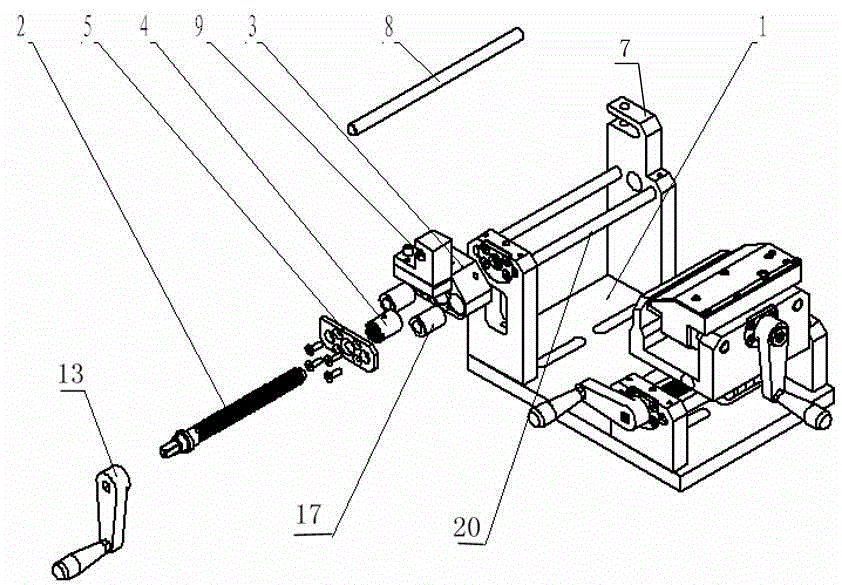

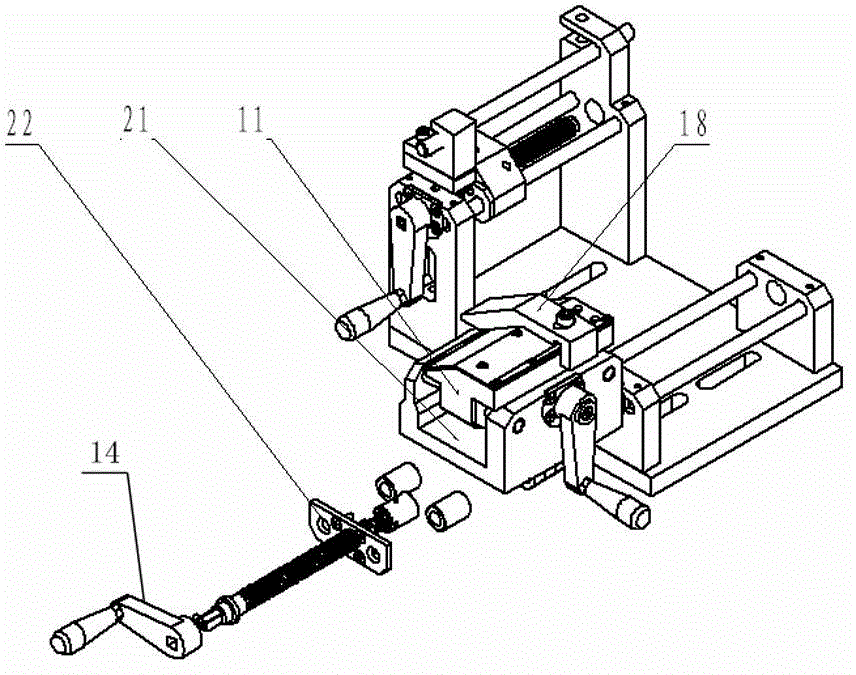

[0026] this invention figure 1 , 2 , 3, 4, 5, 6, and 7.

[0027] Screw mandrel 2 and screw nut 4 are all products of the same structure in the three sets of adjustment devices, so all use the same label to use here.

[0028] The test bracket of the generator heating test bench includes a base 1, on both sides of the base 1 there are upright columns, on one side of the uprights there is a handle assembly 13, and the handle assembly 13 drives the screw nut 4 to move back and forth through the screw rod 2 , the screw nut 4 is provided with a small sliding seat 3, and the side of the small sliding seat 3 fixes the screw rod 2 and the screw nut 4 through a small fixed plate 5 to form the first set of adjustment devices; the handle assembly on the other side of the column Two 14 drives the screw nut 4 to move back and forth through the screw rod 2, and the screw nut 4 is provided with a middle sliding seat 21, and the side of the middle sliding seat 21 fixes the screw rod 2 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com