Temperature supplementing method and device for conveying roller way of magnesium or magnesium alloy plate strip

A technology for conveying roller tables and magnesium alloy plates, which is used in length measuring devices, metal rolling, and temperature control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

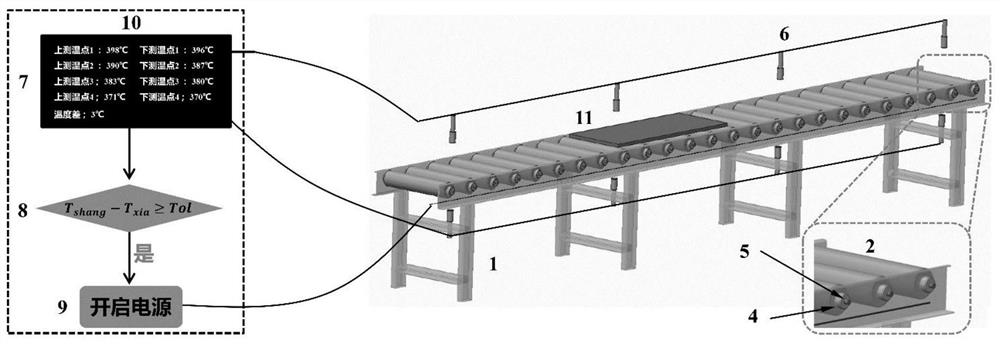

[0036] Embodiment 1, a kind of magnesium or magnesium alloy strip conveying roller table warming device

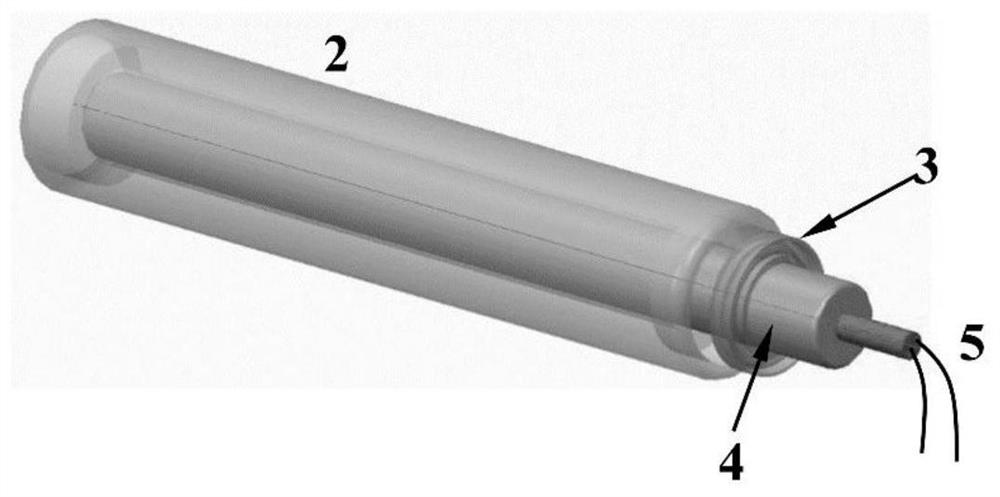

[0037] Such as figure 2 , 3 As shown, the device includes a conveying roller electric heating system and an intelligent control system; the conveying roller electric heating system includes a conveying roller 2 arranged on the conveying roller table frame 1 and an electric heating element 5 located inside the conveying roller; the conveying roller The roller 2 is a hollow roller, and a perforated rotating shaft 4 is arranged inside the roller; the electric heating element 5 is nested in the perforated rotating shaft 4, and the two are connected to the conveying roller 2 through a bearing 3 to form an electric heating conveying roller ( image 3 ); There are multiple electric heating conveying rollers arranged side by side on the conveying roller table frame 1.

[0038] The intelligent control system includes a temperature testing device, a temperature analysis module, a...

Embodiment 2

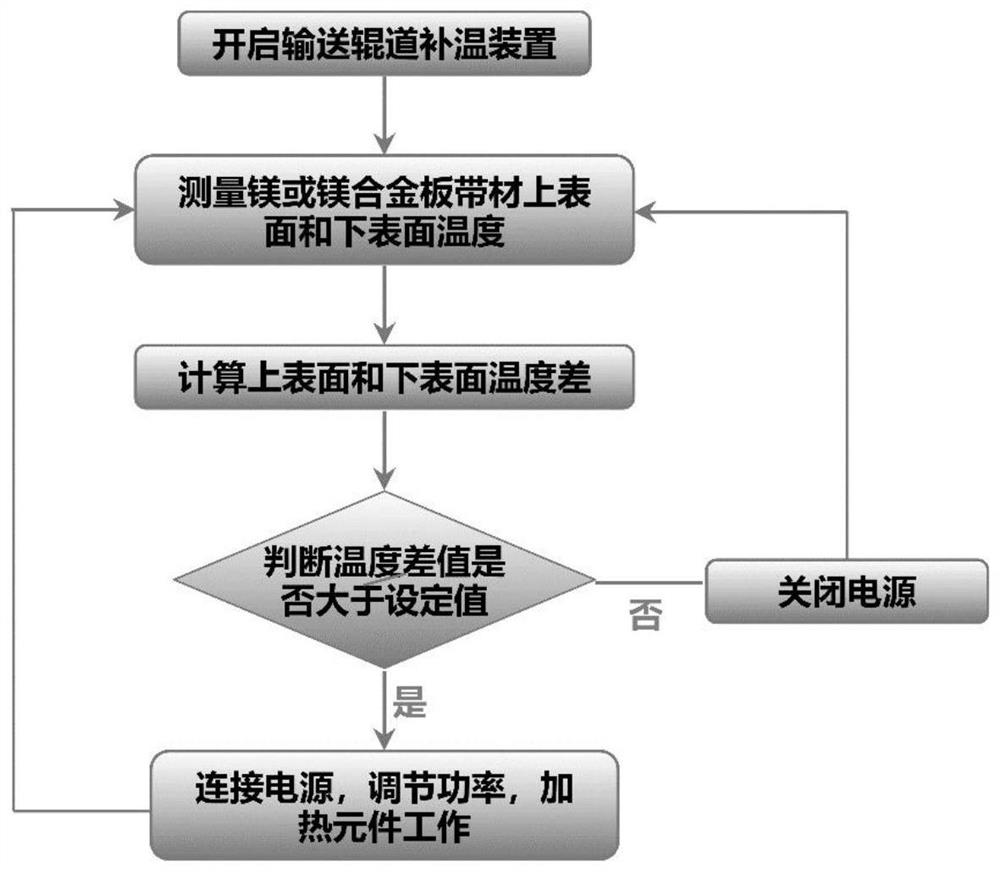

[0040] Embodiment 2, a kind of magnesium or magnesium alloy plate and strip conveying roller table warming method

[0041] workflow such as figure 1 As shown, the specific method steps are as follows:

[0042] (1) adopt embodiment 1 magnesium or magnesium alloy sheet and strip conveying roller table warming device;

[0043] (2) Place the magnesium or magnesium alloy plate and strip to be processed on the conveying roller table; open the conveying roller table and start the warming device;

[0044] (3) The temperature control system tests the initial temperature of the upper surface and the lower surface of the magnesium or magnesium alloy plate and strip to be processed in real time, and continuously tests the temperature of the upper surface and the lower surface of the plate during the transportation process;

[0045] (4) The temperature analysis module in the temperature control system calculates the temperature difference between the upper surface and the lower surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com