Method for spreading and drying fermented grains

A technique of drying fermented grains and drying grains, which is applied in the field of brewing, can solve the problems of small ventilation, uneven cooling and uniform mixing of fermented grains with spreading density, and achieves improved cooling uniformity, consistent heat transfer and heat dissipation, and improved cooling. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

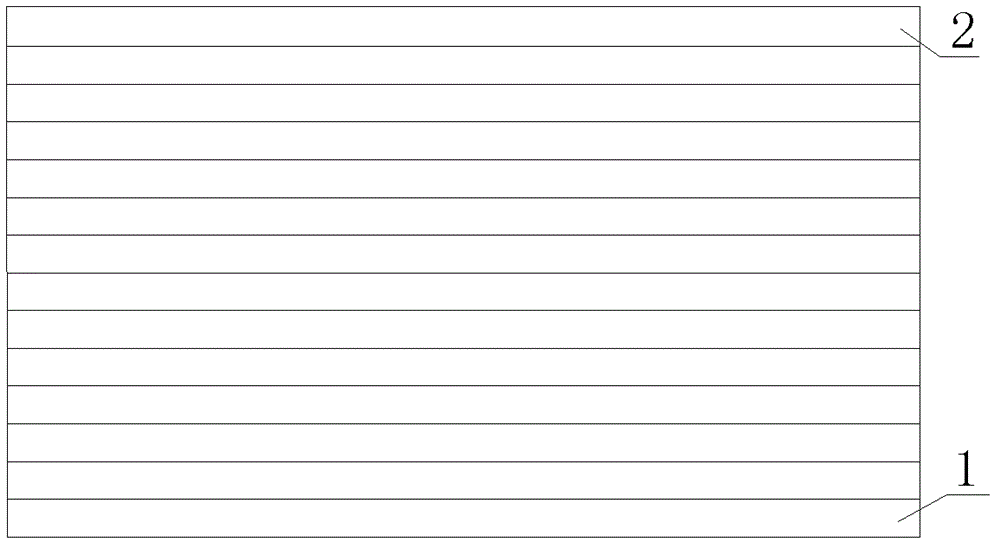

[0031] Put 2000Kg of distilled and gelatinized fermented grains with a temperature of 100°C on the airing shed and spread them evenly to form a layer of fermented grains with a thickness of about 6 cm. Under the condition that the ground temperature is 20°C, turn on the fan of the airing shed. Make the unstrained spirits cool 10 minutes, the temperature of the unstrained spirits drops to about 22 ℃. At this time, if figure 1 As shown, 40Kg koji powder is evenly sprinkled on the surface of the fermented grains layer, and the position of the fermented grains layer is divided into n turning areas with parallel lines, which are 1 area, 1 area, 2 area, 3 area...n-1 area, n Zone 2; first, flip the fermented grains from zone 1 and zone 2 over the fermented grains in the adjacent zone (use a spade to scoop up the fermented grains when flipping, and just turn over and cover the fermented grains in the two front zones, the same below) , and then scrape the fermented grains on the ferme...

Embodiment 2

[0035] Place 2000Kg of distilled and gelatinized fermented grains with a temperature of 100°C on the drying shed and spread them evenly to form a layer of fermented grains with a thickness of about 6 cm, and turn on the fan in the drying shed to cool the fermented grains for 10 minutes. The temperature of unstrained spirits drops to about 22 ℃. At this time, if figure 1 As shown, 40Kg koji powder is evenly sprinkled on the surface of the fermented grains layer, and the fermented grains are divided into n turning areas with parallel lines, which are 1 area 1, 2 area, 3 area...n-1 area, n area 2; First turn the fermented grains in zone 1 and zone 2 onto the fermented grains in the adjacent zone, and then scrape the fermented grains on the fermented grains in the adjacent zone that is higher than the thickness of the original fermented grains layer back to zone 1, zone 1 and zone 2 and spread it evenly; flip the fermented grains in zones 2 and 3 onto the fermented grains in the ...

Embodiment 3

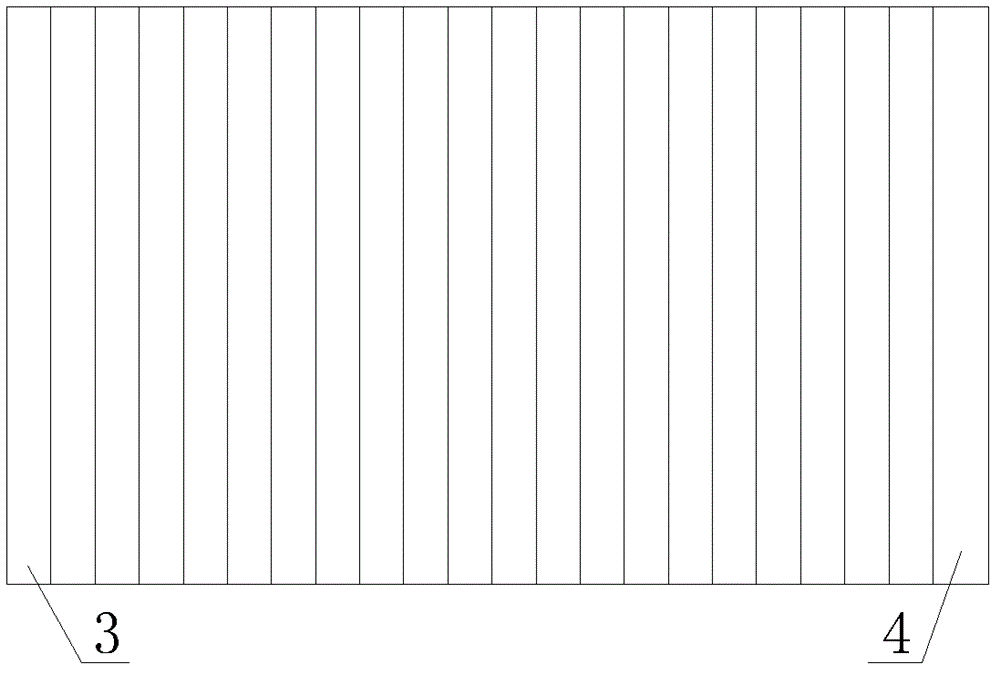

[0039] Place 2000Kg of fermented grains that have been distilled and gelatinized at a temperature of 100°C on the airing shed and spread evenly to form a layer of fermented grains with a thickness of about 6 cm, and turn on the fan of the airing shed. At this time, if figure 2 As shown, use parallel lines to divide the fermented grains into n' turning areas, which are 1' area 3, 2' area, 3' area...n-1' area, n' area 4; first divide 1' area 3 Flip the fermented grains in the 2' area to the fermented grains in the adjacent area, and then scrape the fermented grains on the fermented grains in the adjacent area that is higher than the thickness of the original grains layer back to the 1' area, 3 and 2' areas and spread Spread evenly; turn the fermented grains in the 2' area and the 3' area to the fermented grains in the adjacent area, and then scrape the fermented grains on the fermented grains in the adjacent area that is higher than the thickness of the original grains layer ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com