A heat dissipation method and a heat dissipation system for an electronically controlled integrated controller

A heat dissipation system and controller technology, which is applied in the direction of electrical components, electrical equipment structural parts, cooling/ventilation/heating transformation, etc., can solve problems such as uneven heat dissipation and uncontrollable temperature, and improve system efficiency and safety. The effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

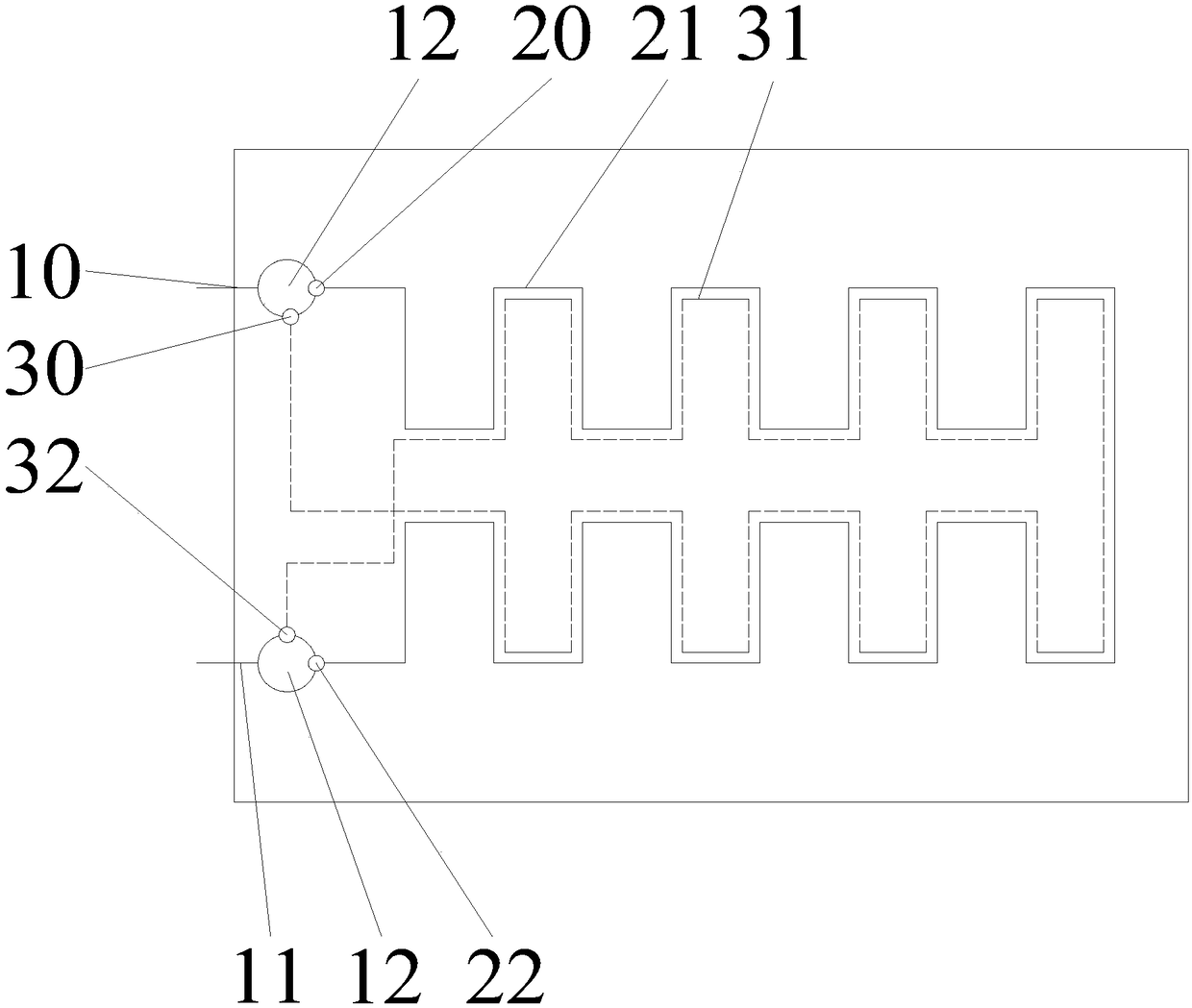

[0032] refer to figure 1 As shown, the present invention discloses a heat dissipation system for an electronic control integrated controller, including a heat dissipation unit and a control unit.

[0033] The above heat dissipation unit includes an inlet port 10 , an outlet port 11 , a transfer cavity 12 , a first cooling pipe 21 and a second cooling pipe 31 .

[0034] The above-mentioned transfer chamber 12 is arranged on the inlet end 10 and the outlet end 11 . The transfer chamber 12 can equalize the pressure of the circulating gas and liquid for cooling, reduce control variables, and improve heat dissipation uniformity and temperature controllability. At the same time, the inlet port 10 and the outlet port 11 can be made unique, so as to reduce the complexity of the system, the cost is low, the maintenance is convenient, and the efficiency is high.

[0035] A first inlet valve 20 and a second inlet valve 30 are disposed on the transfer chamber 12 of the inlet port 10 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com