Patents

Literature

44results about How to "Increase light output power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

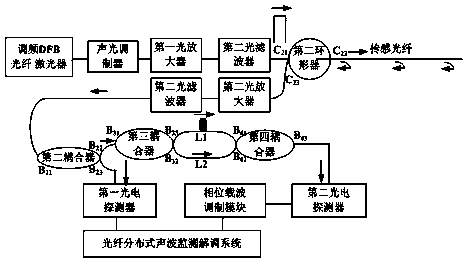

Optical fiber distributed type sound wave monitor system

ActiveCN103411660AIncrease light output powerImprove signal-to-noise ratioSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansOptical modulatorOptical amplifier

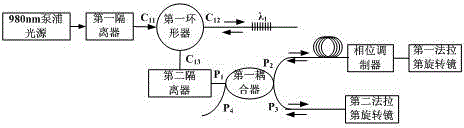

Provided is an optical fiber distributed type sound wave monitor system. Narrow-linewidth frequency-modulated lasers output by a frequency modulation DFB fiber laser are used as the light source of the optical fiber distributed type sound wave monitor system, the lasers output by the frequency modulation DFB fiber laser enter an acoustic optical modulator and are modulated to be pulse lasers through the acoustic optical modulator, the pulse lasers pass through a first optical amplifier and a first optical filter and then enter a second circulator and sensor fibers, the pulse lasers per unit can emit rayleigh scattering light within the range of the passed sensor fibers per unit length, and signals output by the second circulator pass through a second optical amplifier to enter a second optical filter and output backscattering rayleigh signals. The backscattering rayleigh signals between different unit lengths on one sensor fiber are interfered with the method of an interferometer, the interfered signals pass through electrical signals output by a second photoelectric detector and enter the optical fiber distributed type sound wave monitor demodulation system though a phase carrier demodulation module, and the change analysis of the phases of the sensor signals at corresponding positions is achieved.

Owner:LASER RES INST OF SHANDONG ACAD OF SCI

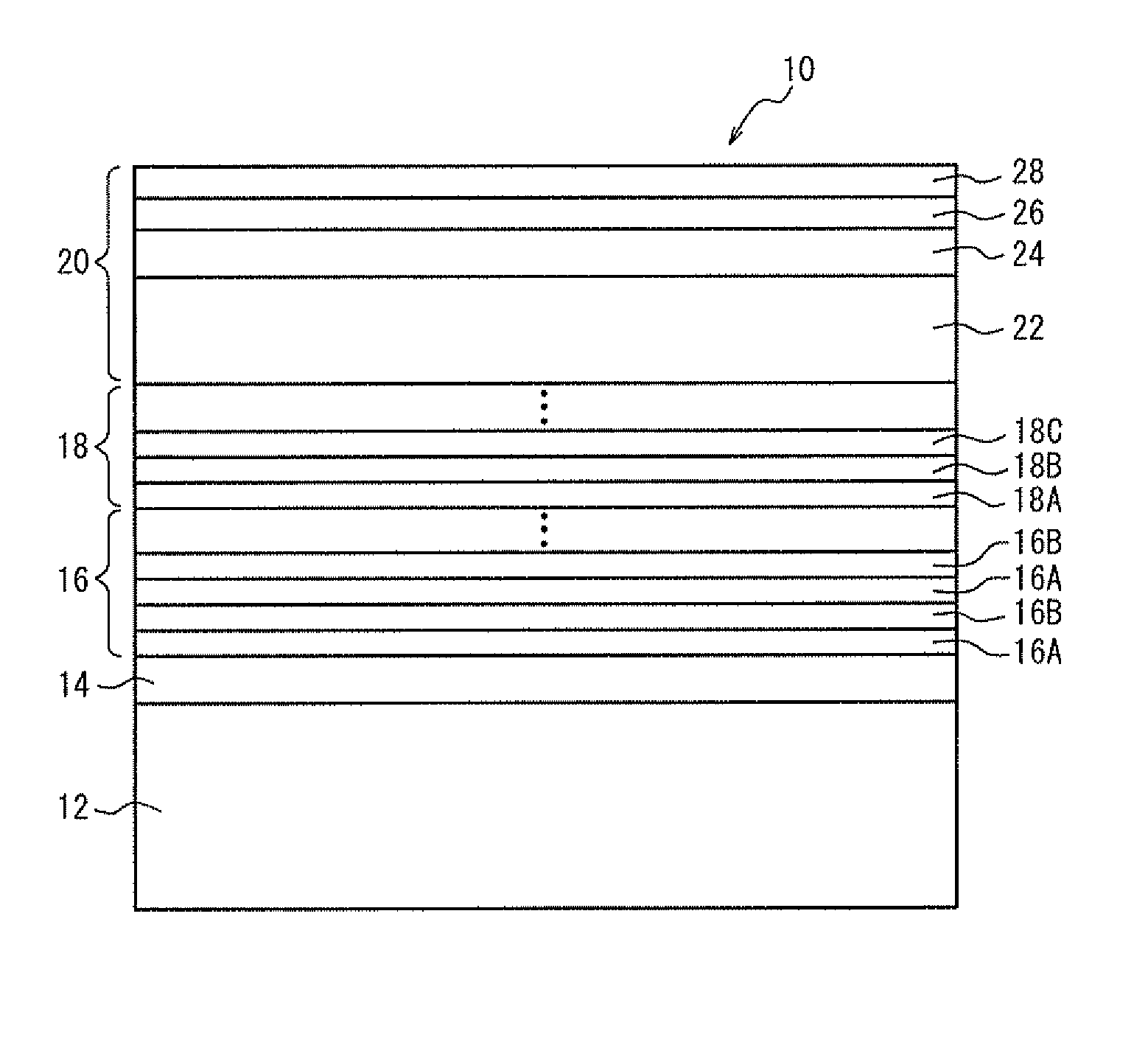

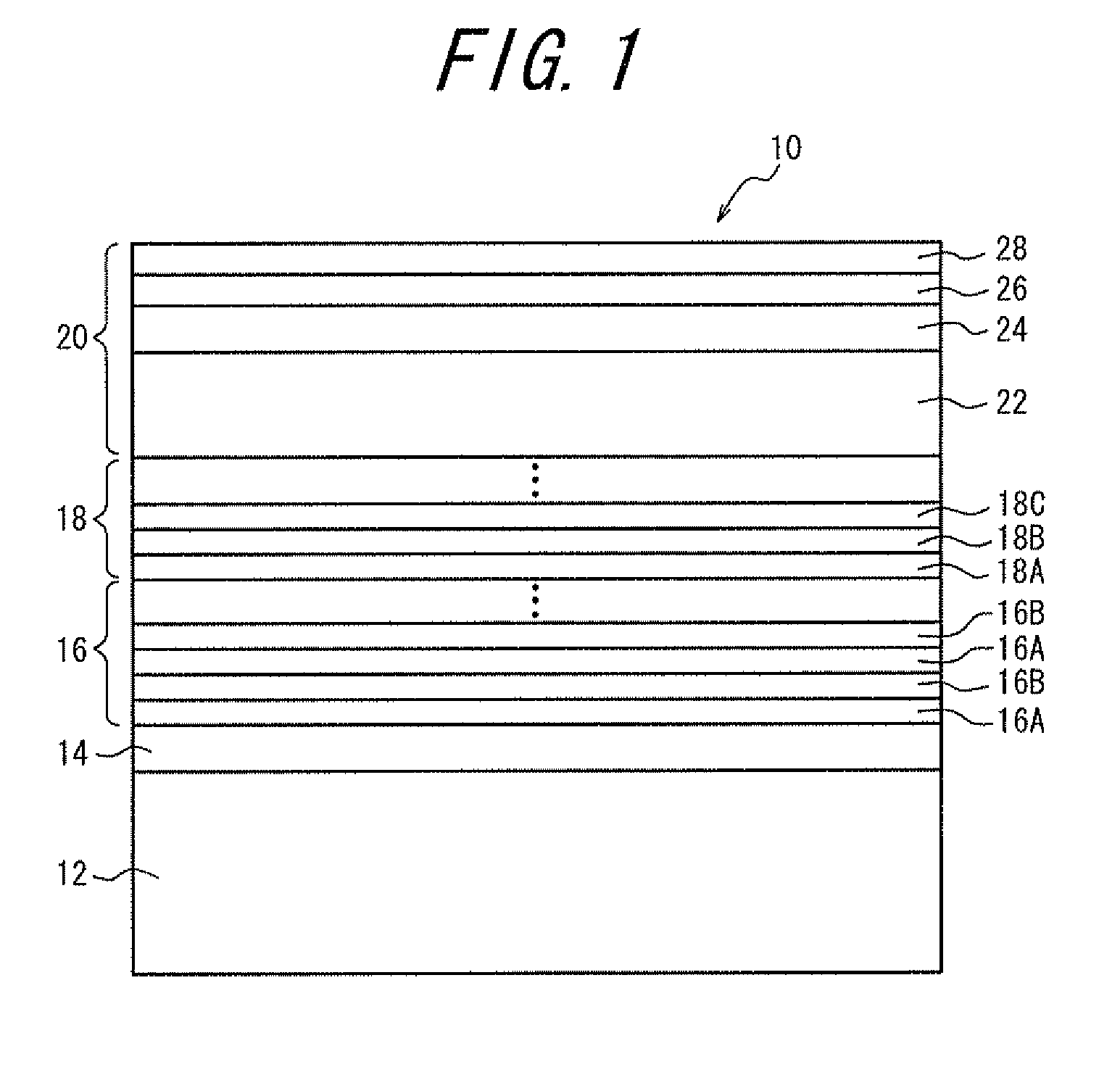

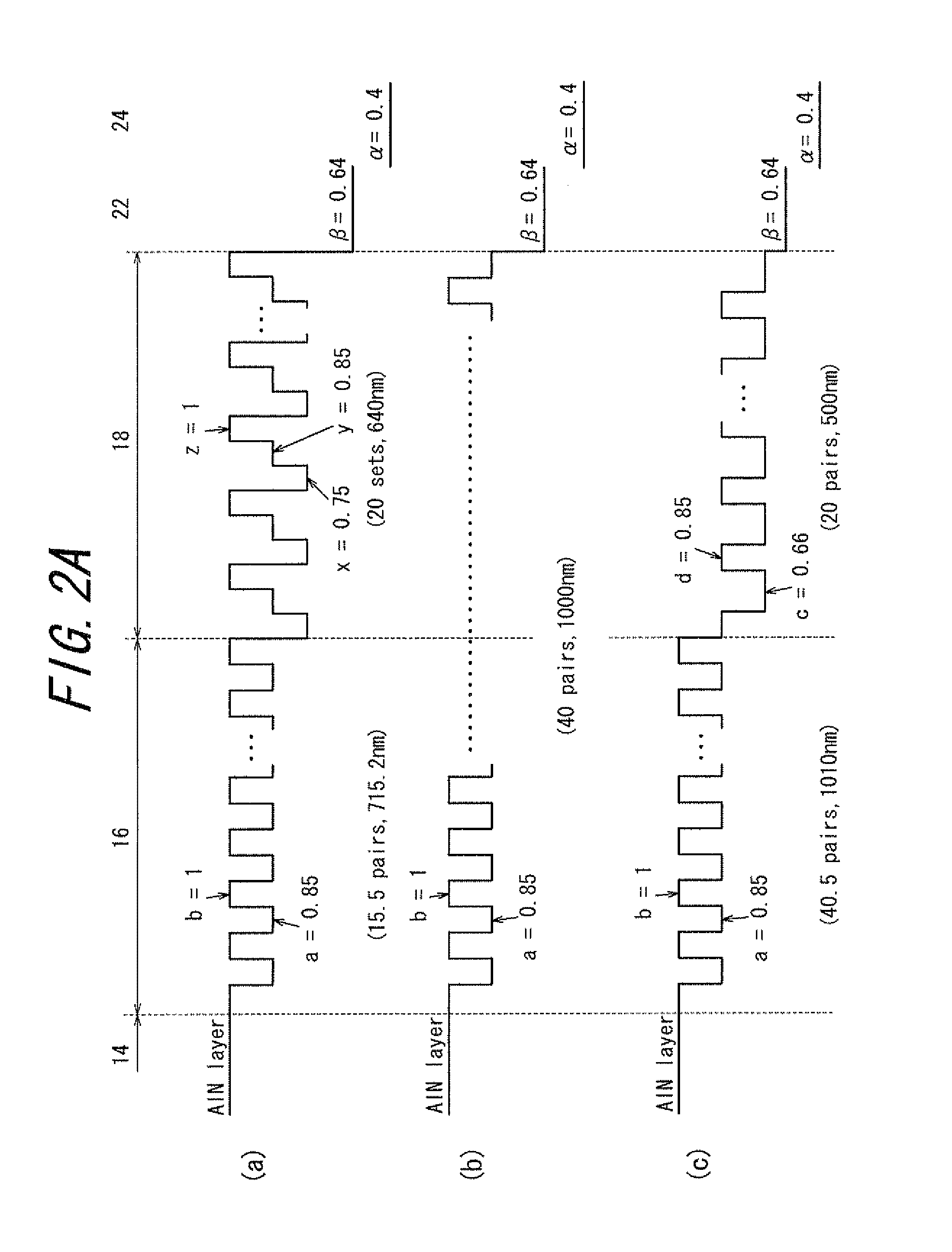

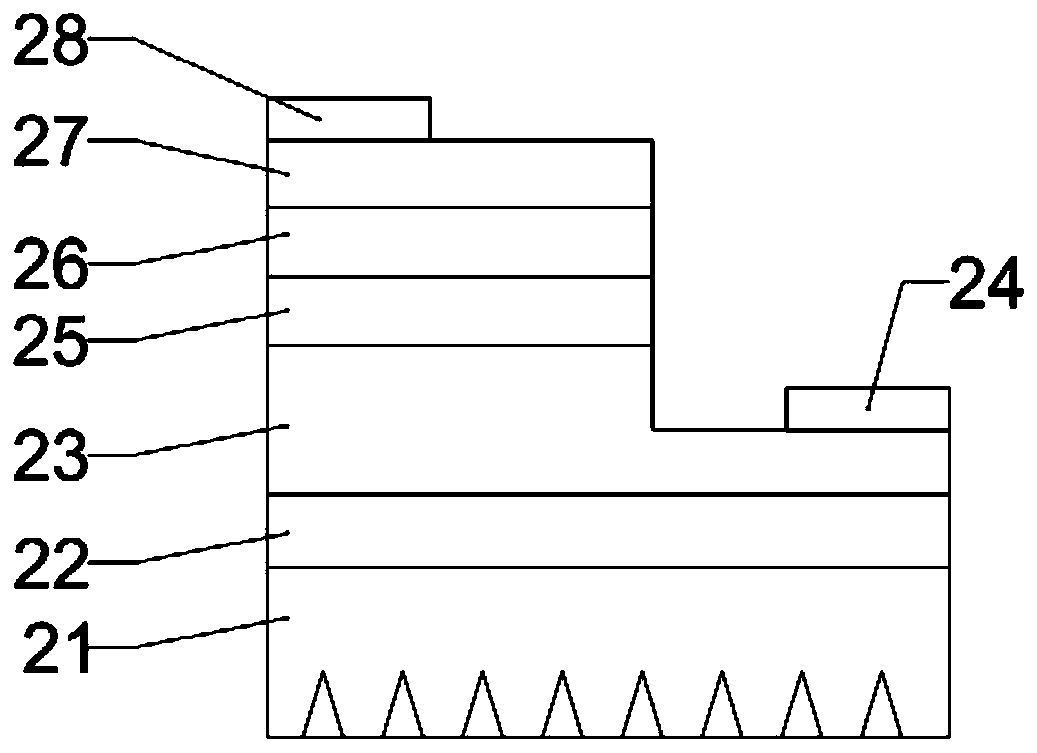

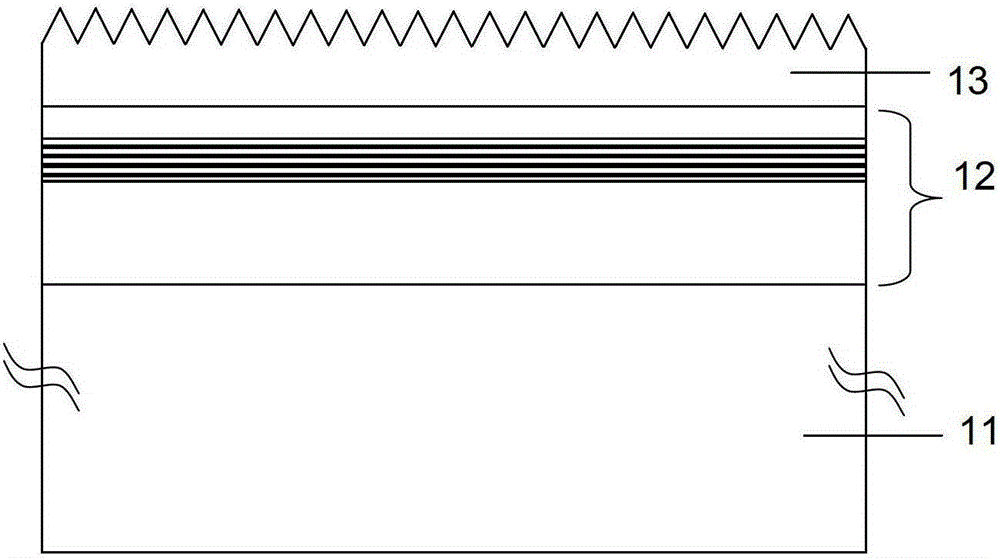

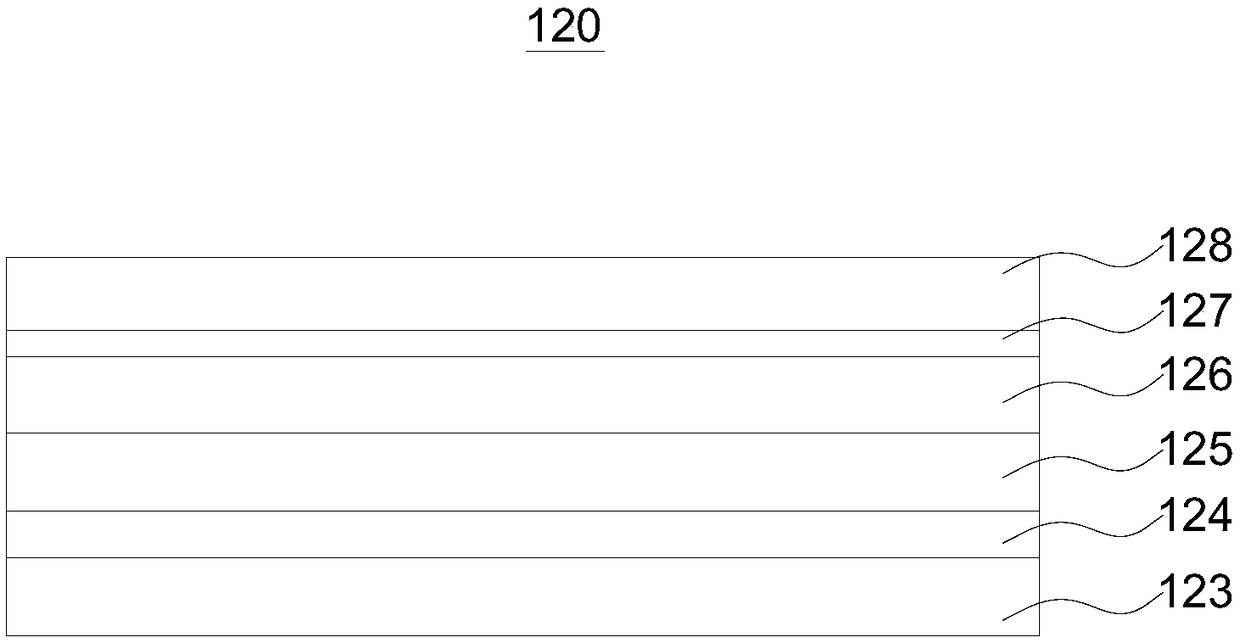

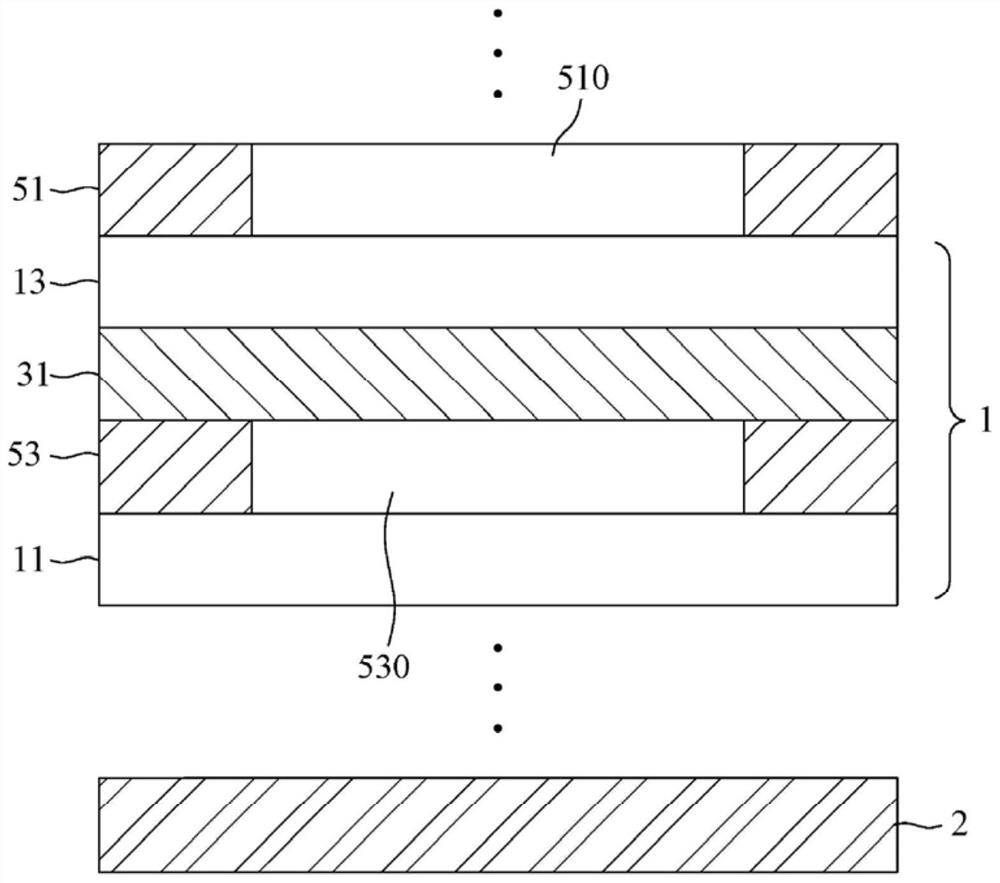

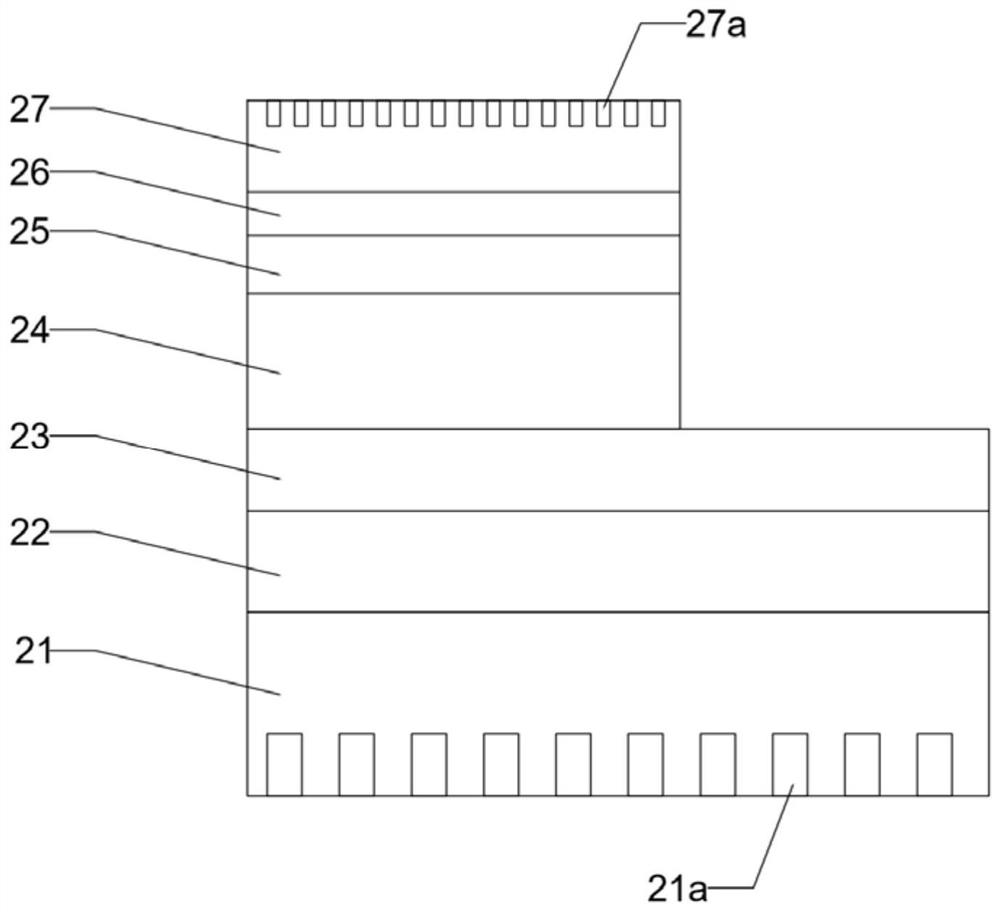

Iii nitride epitaxial substrate and deep ultraviolet light emitting device using the same

ActiveUS20130181188A1Improve optical output powerIncrease light output powerSemiconductor/solid-state device manufacturingSemiconductor devicesUltraviolet lightsActive layer

A III nitride epitaxial substrate which makes it possible to obtain a deep ultraviolet light emitting device with improved light output power is provided. A III nitride epitaxial substrate 10 includes a substrate 12, an AlN buffer layer 14, a first superlattice laminate 16, a second superlattice laminate 18 and a III nitride laminate 20 in this order. The III nitride laminate 20 includes an active layer 24 including an AlαGa1-αN (0.03≦α) layer. The first superlattice laminate 16 includes AlaGa1-aN layers 16A and AlbGa1-bN (0.9<b≦1) layers 16B which are alternately stacked, where α<a and a<b hold. The second superlattice laminate 18 includes repeated layer sets each having an AlxGa1-xN layer 18A, an AlyGa1-yN layer 18B, and an AlzGa1-zN (0.9<z≦1) layer 18C, where α<x and x<y<z hold.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

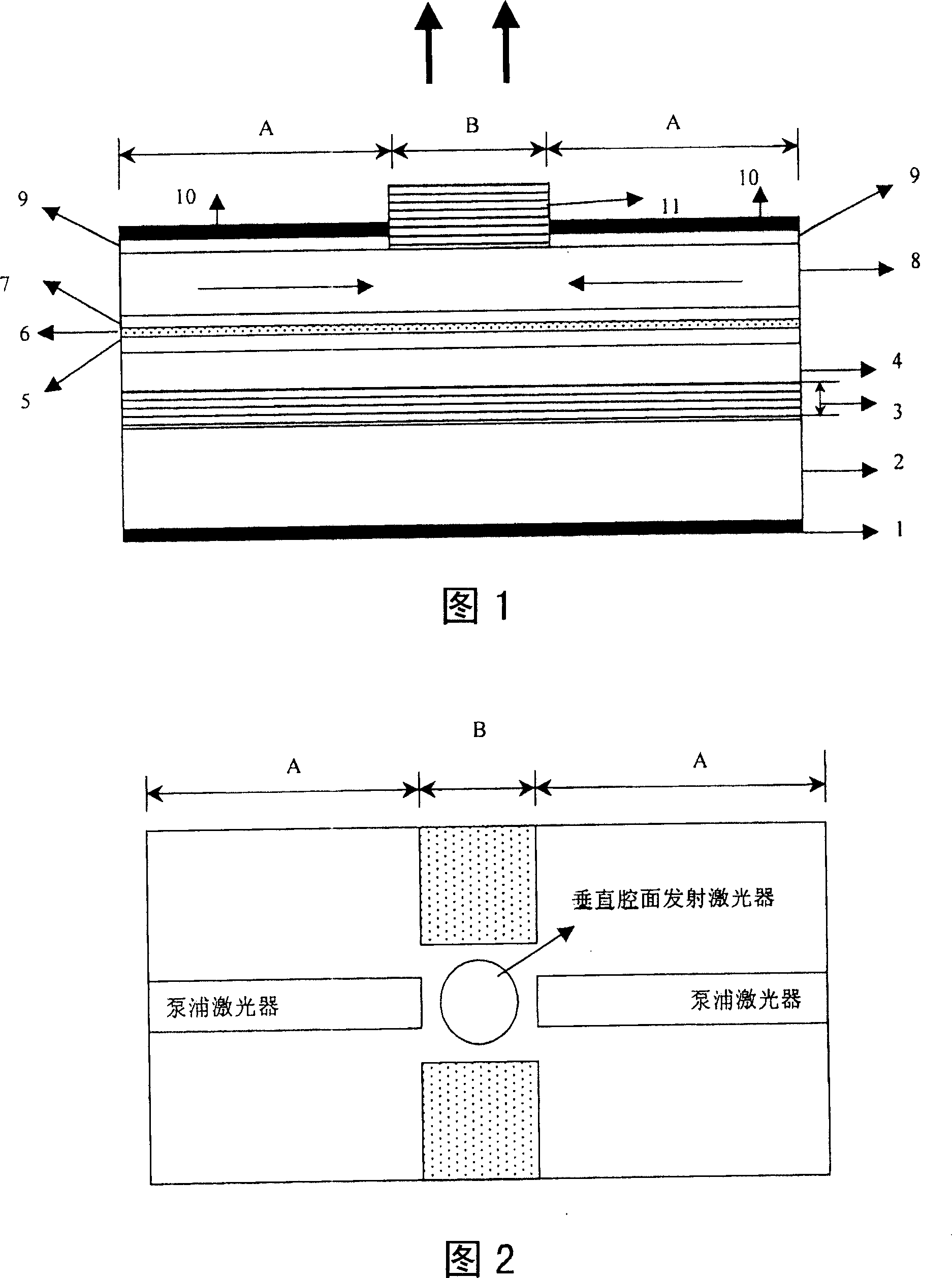

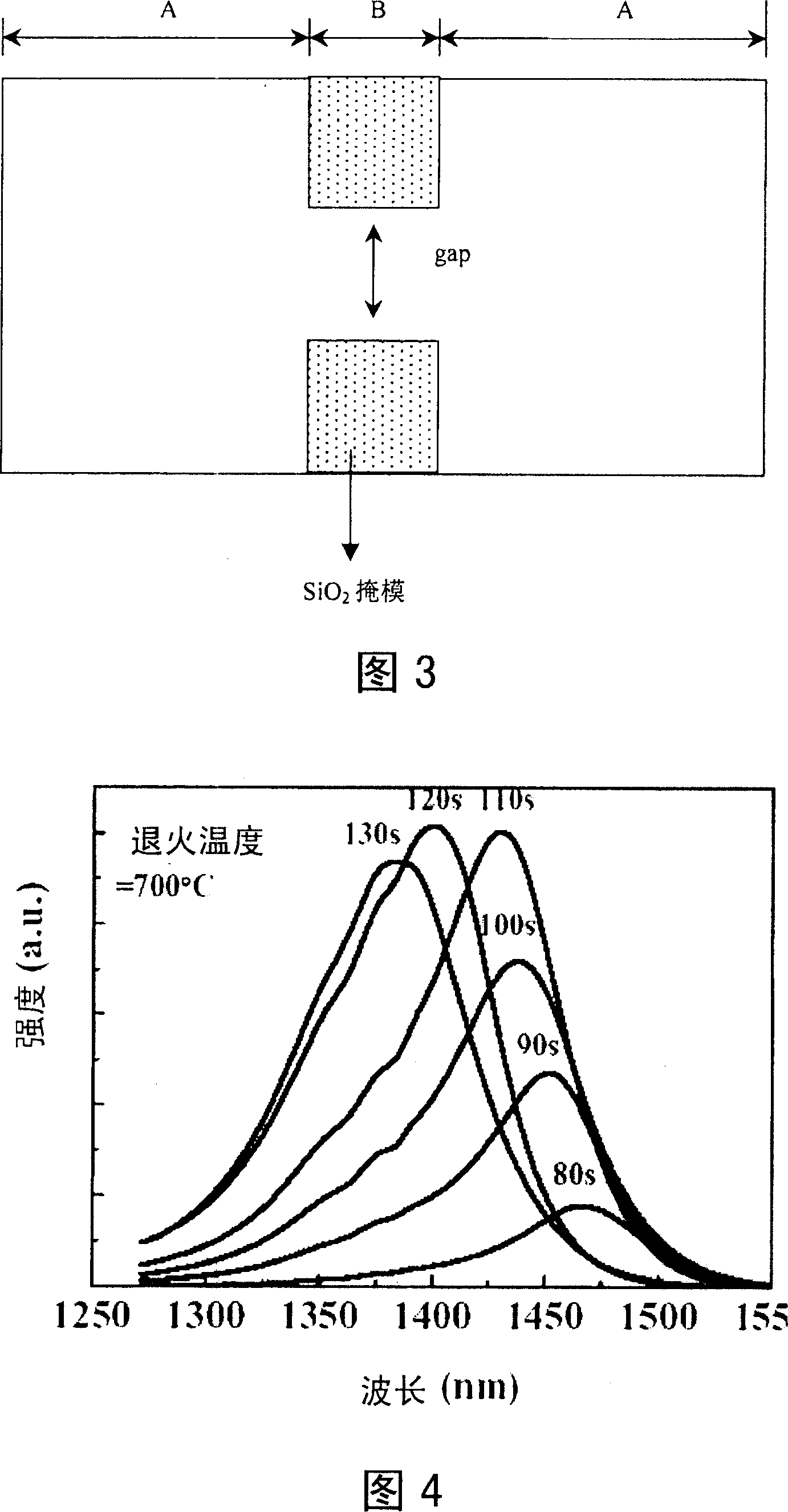

Long wavelength laser transmitted perpendicular to surface of cavity by using integrated pumping light source

InactiveCN101093931ANo reflective interfaceLow costOptical wave guidanceExcitation process/apparatusLower limitOhmic contact

The laser device includes a substrate; a Bragg reflector prepared on the substrate; a low limiting layer prepared on the Bragg reflector; a low waveguide layer prepared on the low limiting layer, and band gap wavelength of the low waveguide layer being as indium-gallium-arsenic-phosphor material in 1.2 micron; an active region prepared on the low waveguide layer; an up waveguide layer prepared on the active region, and band gap wavelength of the up waveguide layer being as indium-gallium-arsenic-phosphor material in 1.2 micron; an up limiting layer prepared on the up waveguide layer; an up Bragg reflector prepared at middle on the up limiting layer; being prepared on the up limiting layer, an ohmic contact layer is located at two sides of the up Bragg reflector; being prepared on the ohmic contact layer, an up electrode is located at two sides of the up Bragg reflector; a low electrode prepared underside of the substrate.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

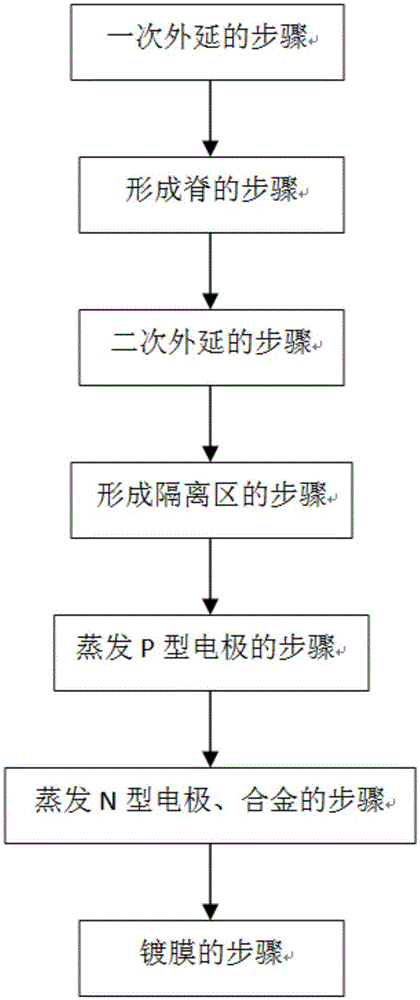

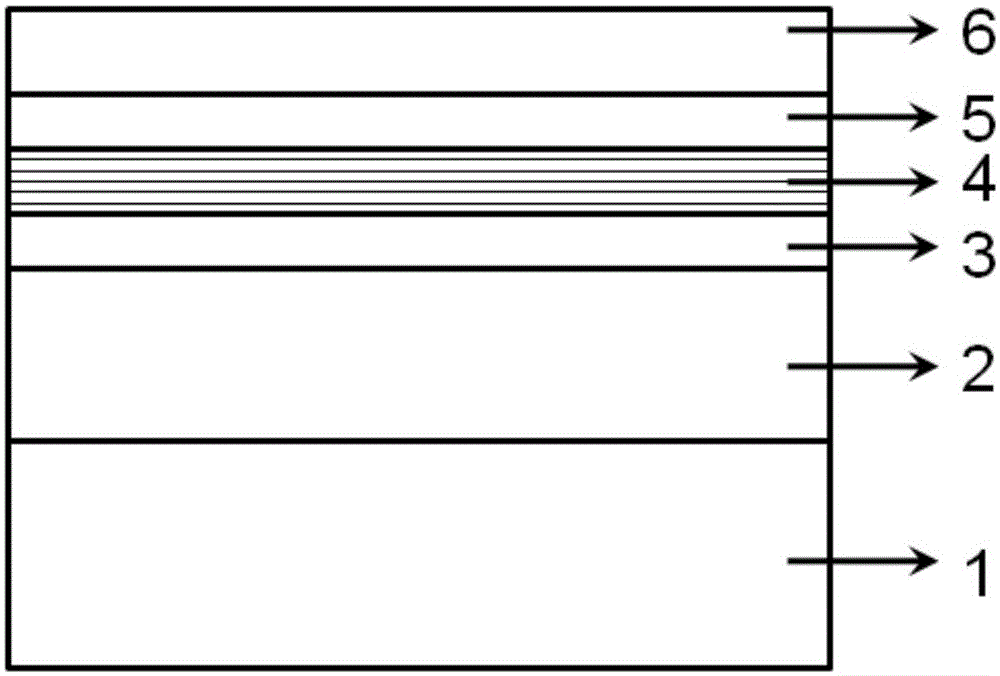

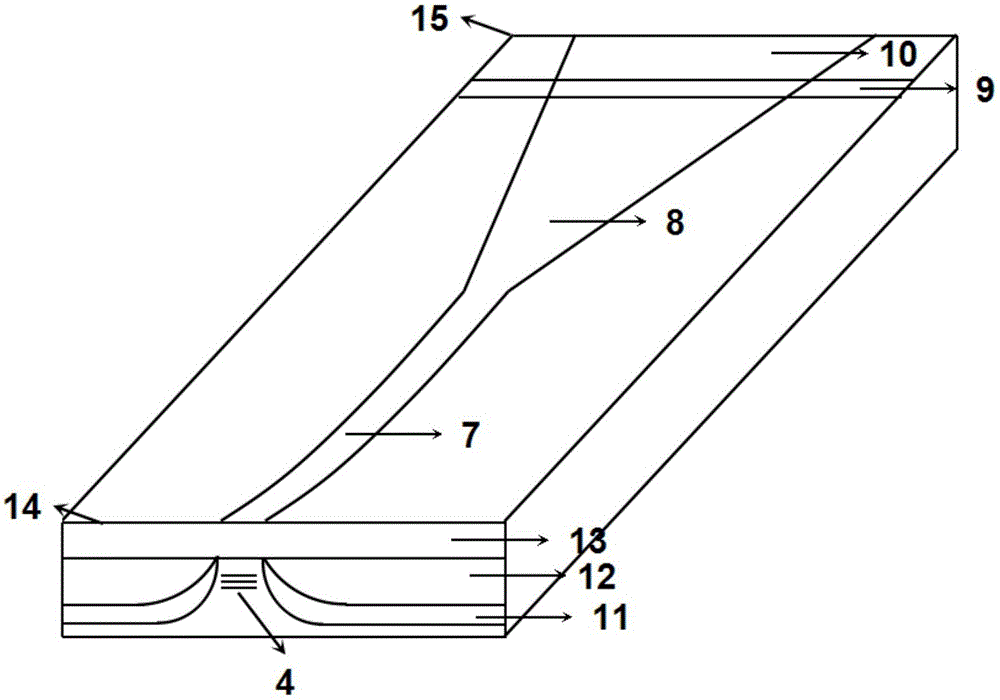

Fabrication method of superluminescent diode chip and fabricated light emitting diode chip

The invention relates to a fabrication method of a superluminescent diode chip. The method comprises the following steps of one-step epitaxy, ridge forming, secondary epitaxy, isolation region forming, P-type electrode evaporation, N-type electrode evaporation, alloy and film coating. The invention also relates to a superluminescent diode chip fabricated according to the fabrication method. The chip fabricated according to the invention has the characteristics of low polarization, high output power and low spectrum corrugation.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

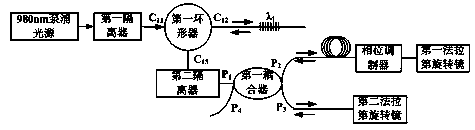

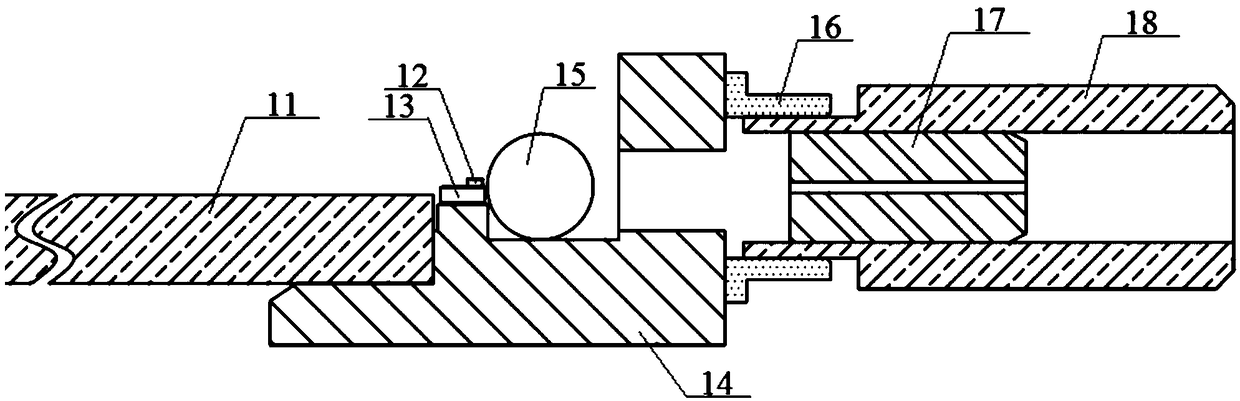

Liquid flow non-immersive measuring device and sensing probe

ActiveCN103344289AEnables non-immersive measurementsRealize measurementCladded optical fibreVolume/mass flow measurementMeasurement deviceGrating

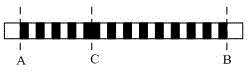

The invention discloses a liquid flow non-immersive measuring device and a sensing probe. The liquid flow non-immersive measuring device comprises the sensing probe and is characterized in that the sensing probe is connected with a circulator through an optical path, light emitted by a pump light source of 980nm is received by the circulator through a separator, optical signals output by the circulator is sent to a coupler through the separator, two optical signals are output by the coupler, one signal is sent to a first Faraday rotary mirror through a phase modulator, and the other signal is directly sent to a second Faraday rotary mirror; the optical signals output by the coupler are sent to a photoelectric detector, electric signals output by the photoelectric detector enter a phase carrier wave demodulating device, weak dynamic variation of the wave length of a DFB optical fiber laser is demodulated, and flow is calculated according to the variation of the wave length; the sensing probe relates to a section of asymmetric phase shifting optical fiber grating fixed on the outer wall of an oil pipe in the circumferential direction.

Owner:LASER RES INST OF SHANDONG ACAD OF SCI

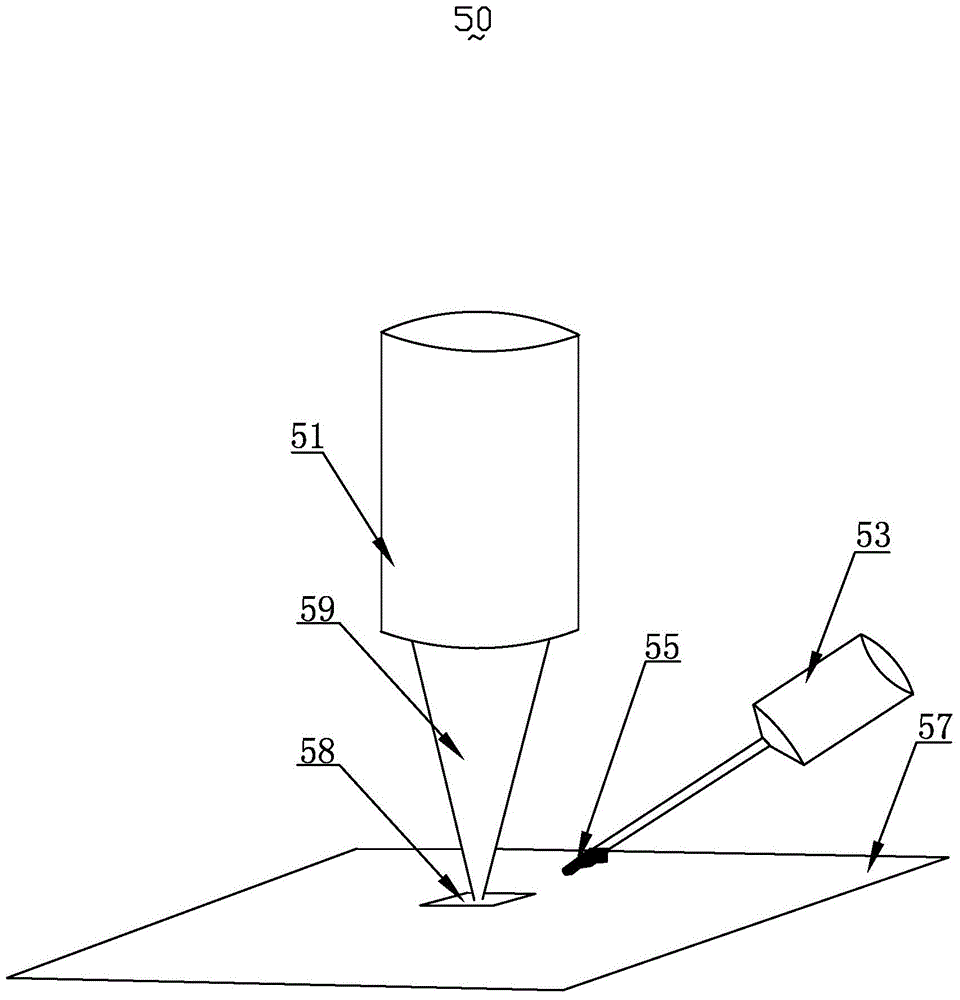

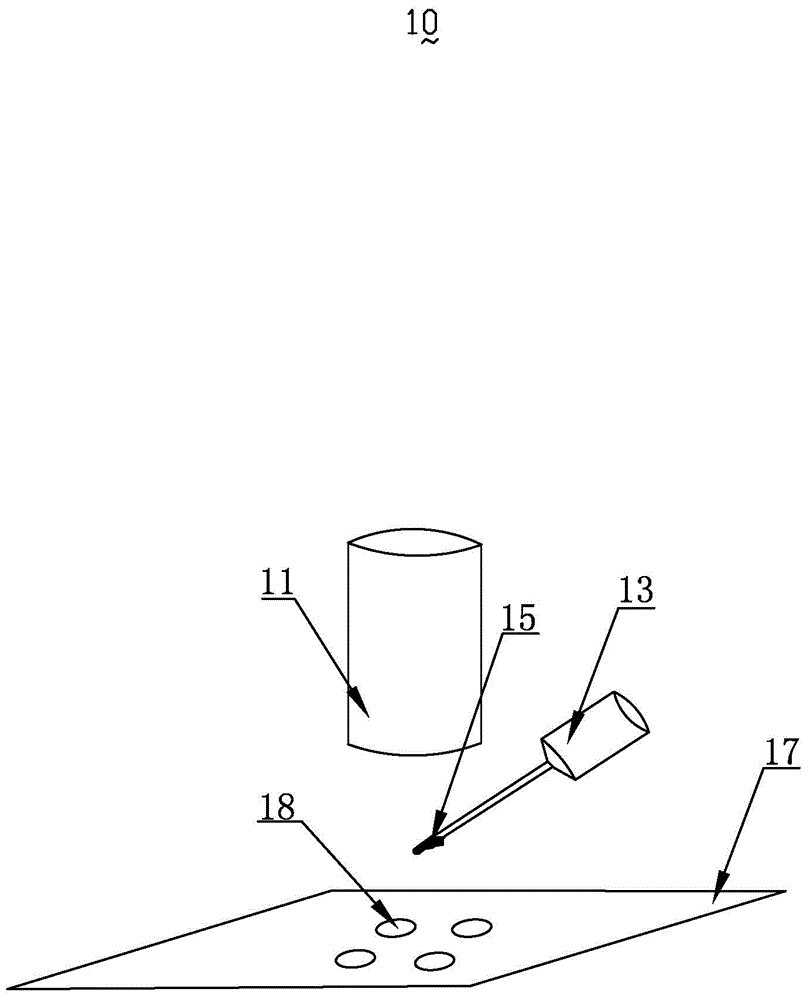

Laser welding method

InactiveCN104439587AImprove laser absorption rateHigh temperature toleranceSoldering apparatusLaser beam welding apparatusControl equipmentLaser

The invention provides a laser welding method. According to the method, a laser welding machine and a circuit board to be welded are provided, a plurality of bonding pads to be welded are arranged on the circuit board, the laser welding machine comprises a focusing head and a tin feeding head, the tin feeding head comprises a tin feeding end, the tin feeding end can feed a tin wire continuously, the tin feeding head is located between the focusing head and the bonding pads, before high-power light of the focusing head exits or while high-power light exits, a section of the tin wire is fed by the tin feeding head, and the tin wire, the focusing head and the bonding pads are located on the same straight line. According to the laser welding method, the welding speed is high, the welding precision is high, the requirement for control equipment is not high, the production cost is low, stability is improved greatly, and the laser welding method has high market value.

Owner:深圳云麟科技有限公司

Method for processing ultraviolet glued crystal

InactiveCN103311796ANot easy to alignMeasurement imaging is clearAfter-treatment detailsVacuum evaporation coatingUltravioletPotassium

The invention discloses a method for processing an ultraviolet glued crystal. The method comprises the following steps of polishing a potassium titanyl phosphate crystal and a neodymium-doped yttrium vanadate crystal, and performing first cleaning; dipping ultraviolet glue on the polished surface of the neodymium-doped yttrium vanadate crystal, uniformly coating the ultraviolet glue on the polished surface of the polishing potassium titanyl phosphate crystal in a contact way; putting onto an optical comparator, adjusting the emission images of the potassium titanyl phosphate crystal and the neodymium-doped yttrium vanadate crystal till superposition; irradiating with an ultraviolet lamp for curing initially; deeply curing; performing second cleaning; coating by adopting a low-temperature cold coating ion sputtering process; testing a coating index after coating; performing third cleaning after qualification; and performing primary bright dipping test, cutting, performing fourth cleaning, assembling, fixing, and packing and sealing after performance testing is qualified. According to the method disclosed by the invention, ultraviolet gluing and a low-temperature plasma coating technology are combined, so that the conventional production process is overturned, the processing period is shortened, the processing efficiency is increased, and the improvement on the product quality is facilitated.

Owner:青岛海泰光电技术有限公司

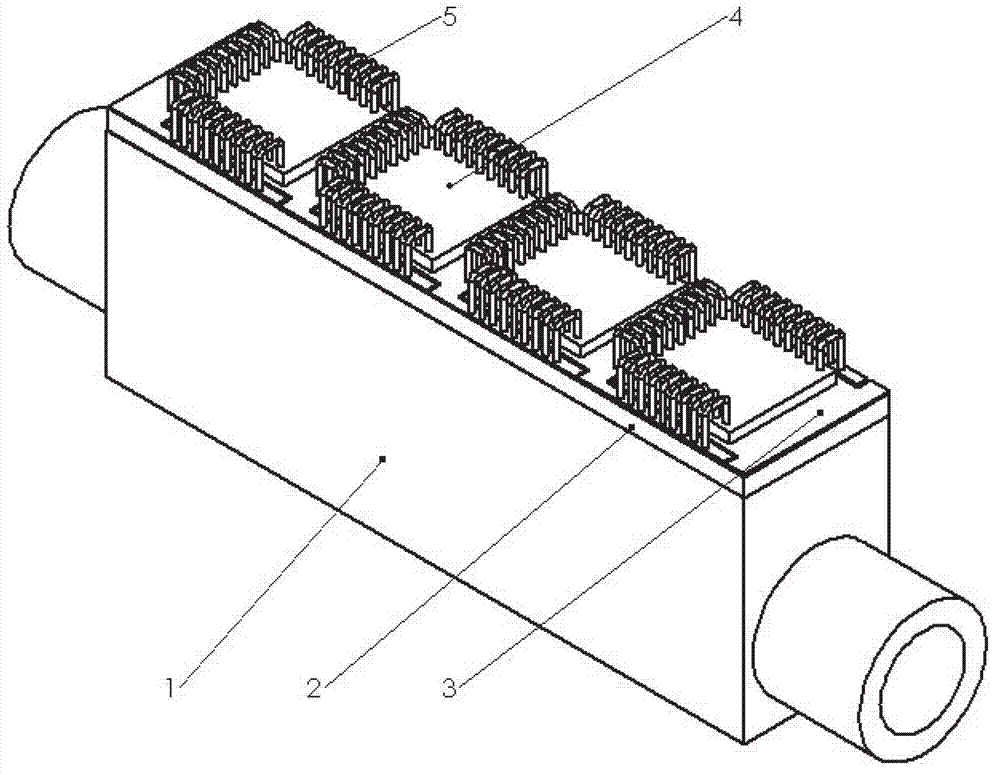

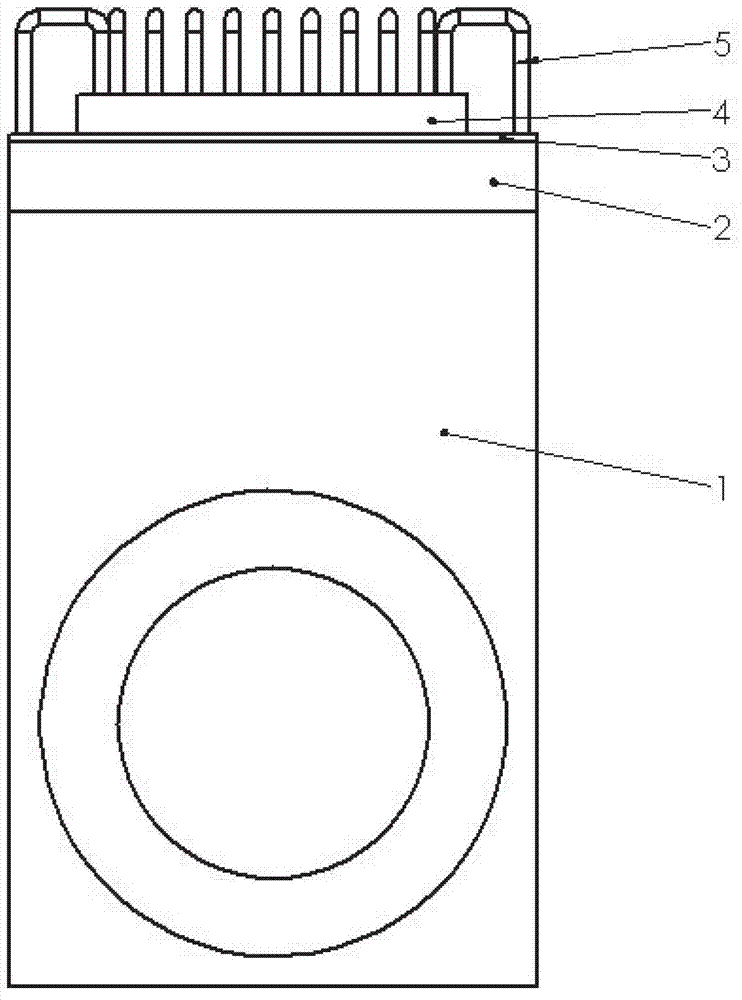

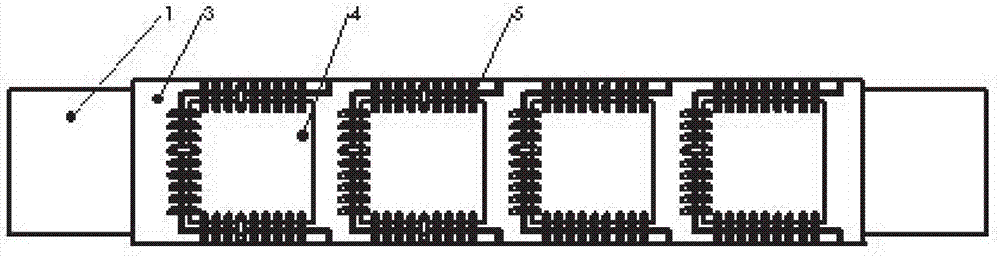

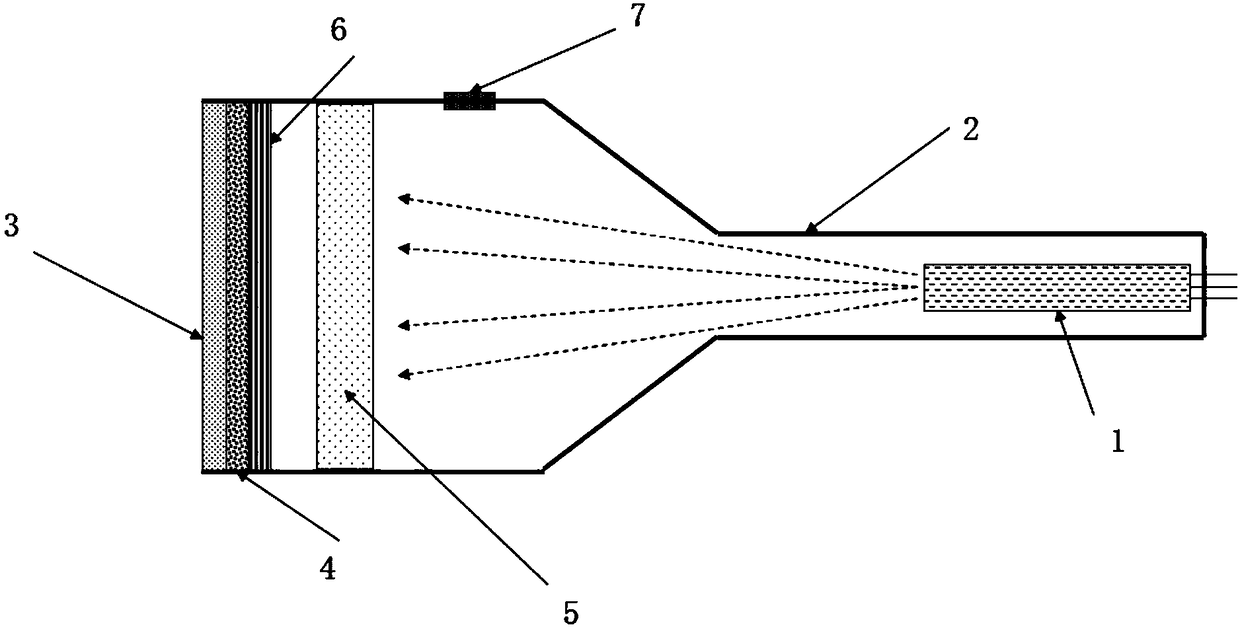

Side pump source of vertical-cavity surface-emitting laser and manufacturing method of side pump source

InactiveCN102856790AIncrease the number of light emitting unitsIncrease light output powerLaser detailsSemiconductor lasersHeat sinkVertical-cavity surface-emitting laser

The invention relates to a side pump source of a vertical-cavity surface-emitting laser and a manufacturing method of the side pump source and relates to the technical field of semiconductor optoelectronics. The side pump source of the vertical-cavity surface-emitting laser comprises a large-channel heat sink in which refrigeration liquid is contained, wherein a horizontal installation plane and an insulating heat sink of serially connected structure, metal films at the surface of the heat sink, gold wire leads and a vertical-cavity surface-emitting laser array are arranged at the upper end of the heat sink. With the adoption of the side pump source of the vertical-cavity surface-emitting laser, a light emitting area is increased when a current is not increased, power is increased, an integration degree is high, and a light beam is good in quality.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

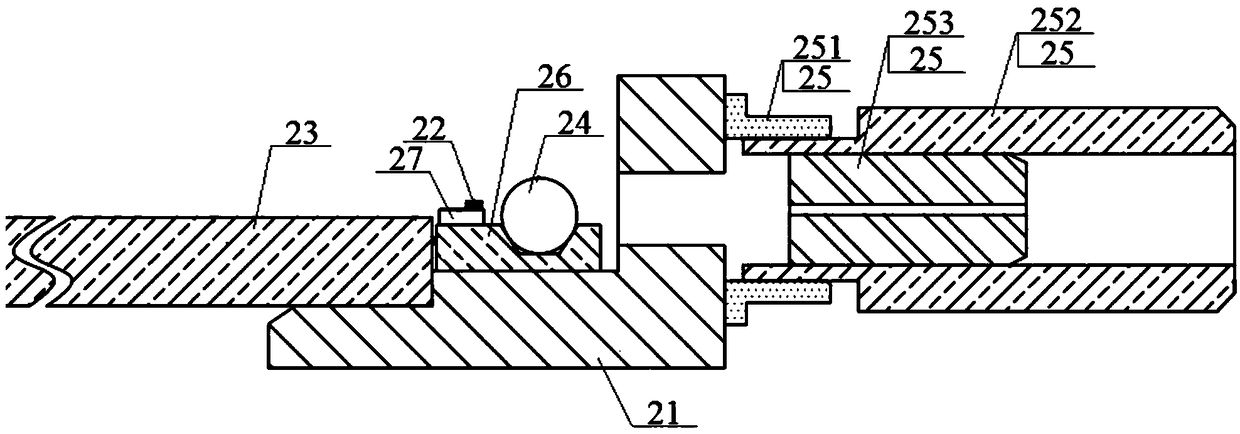

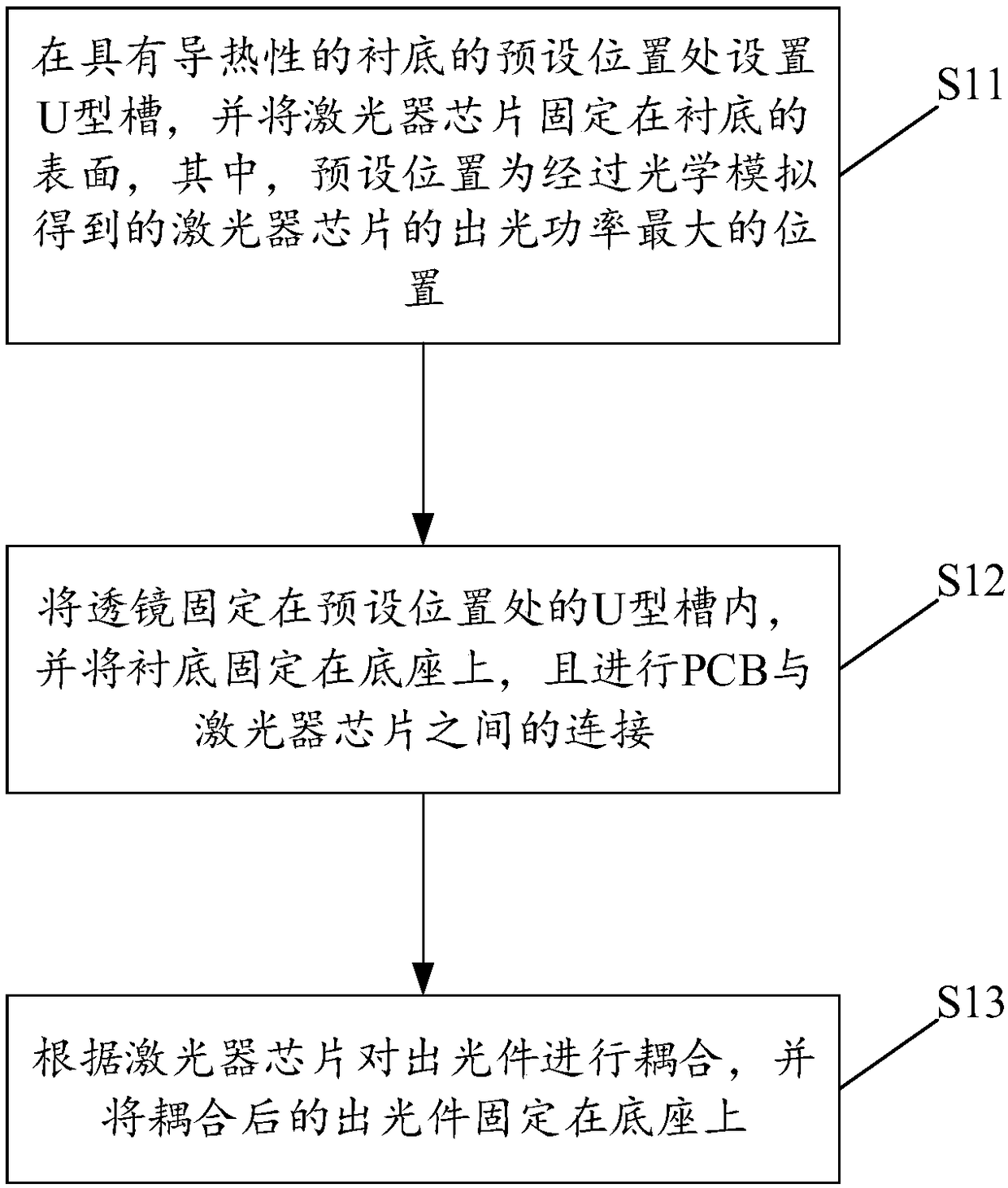

Optical module, optical module emitting optical device and preparation method thereof

PendingCN109358398AIncrease light output powerThermally conductiveCoupling light guidesOptical ModuleCoupling

The invention discloses an optical module, an optical module emitting optical device and a preparation method thereof. The optical module emitting optical device comprises a base, a laser chip, a PCBconnected to the laser chip, a lens, and a light-emitting member connected to the laser chip and fixed on the base. The invention further comprises a substrate fixed on the base and provided with a U-shaped groove at a preset position. The substrate has thermal conductivity. The laser chip is fixed on the surface of the substrate. The lens is fixed in a U-shaped groove at a preset position. The preset position is a position where the optical power of the laser chip obtained by optical simulation is the largest. The above technical solution disclosed in the present application can directly fixthe lens in the U-shaped groove of the substrate without coupling and fixing the lens by the automatic lens coupling machine and the laser welding machine. Therefore, the coupling complexity of the optical module emitting optical device can be reduced, the preparation efficiency of the optical module emitting optical device can be improved, and the manufacturing cost of the optical module emittingoptical device can be reduced.

Owner:DONGGUAN MENTECH OPTICAL & MAGNETIC CO LTD

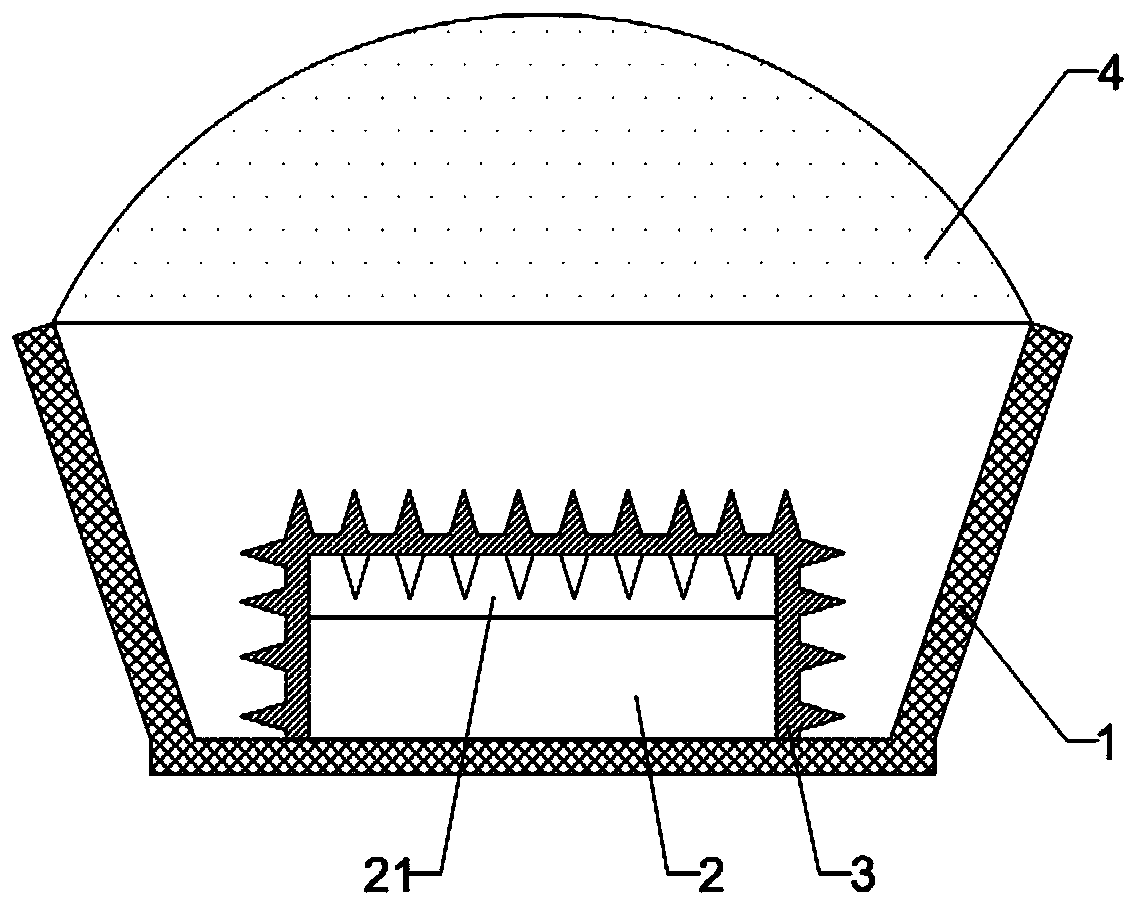

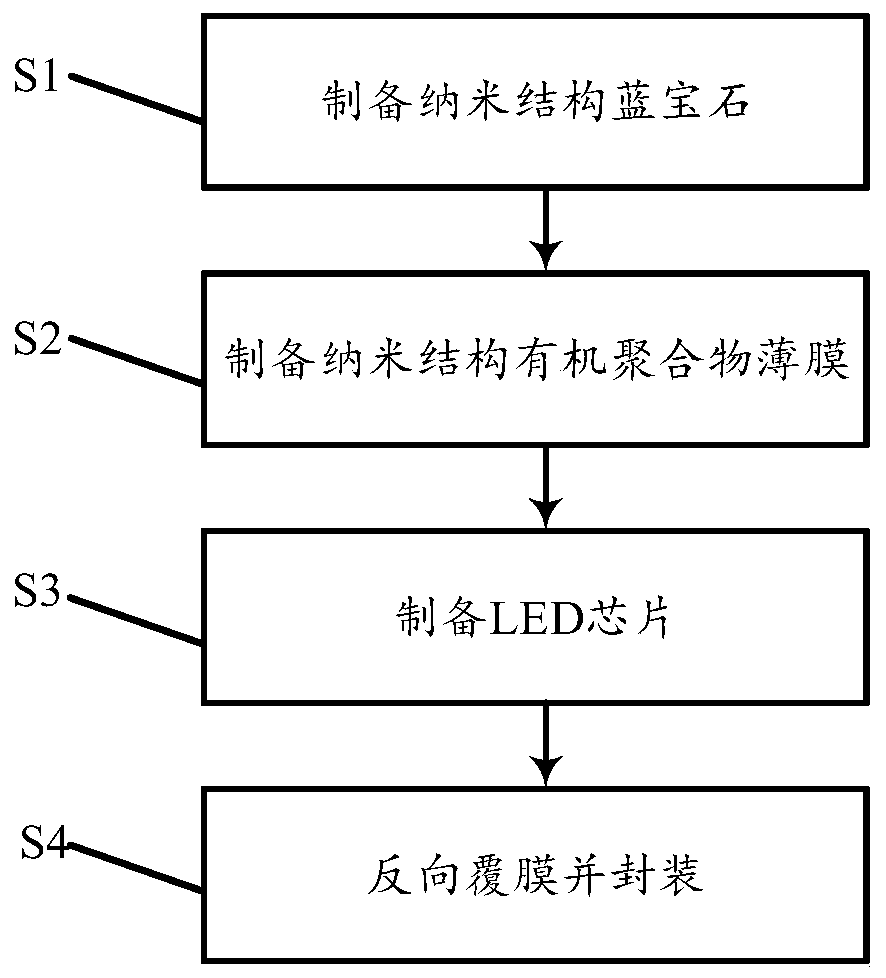

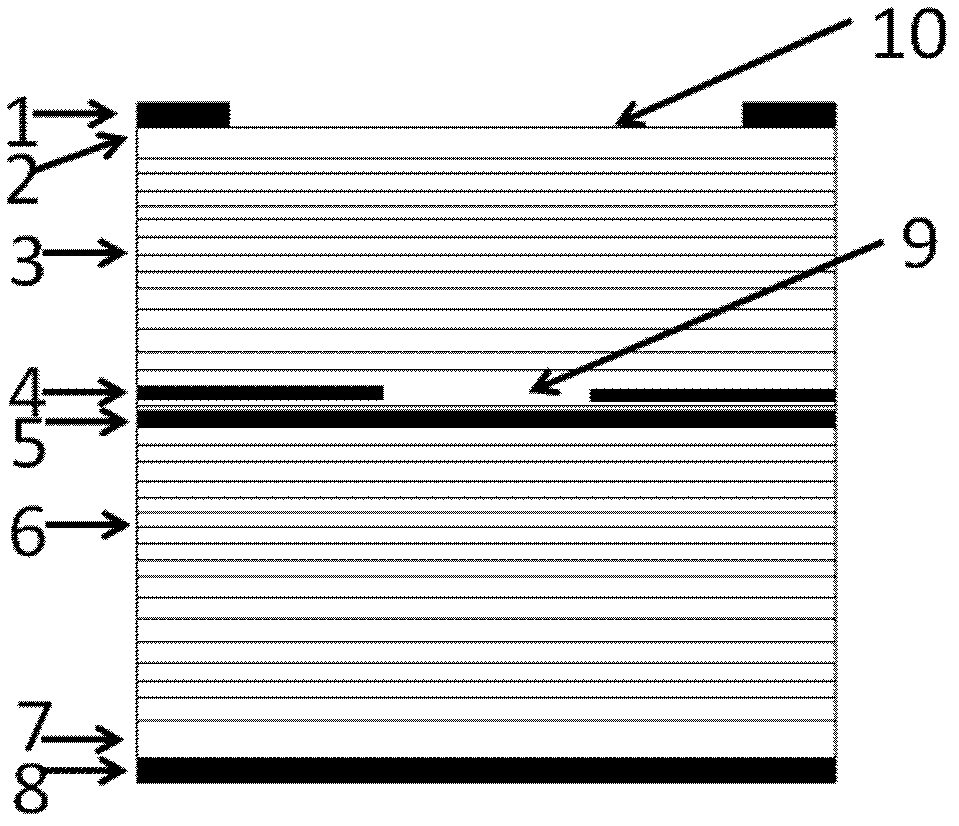

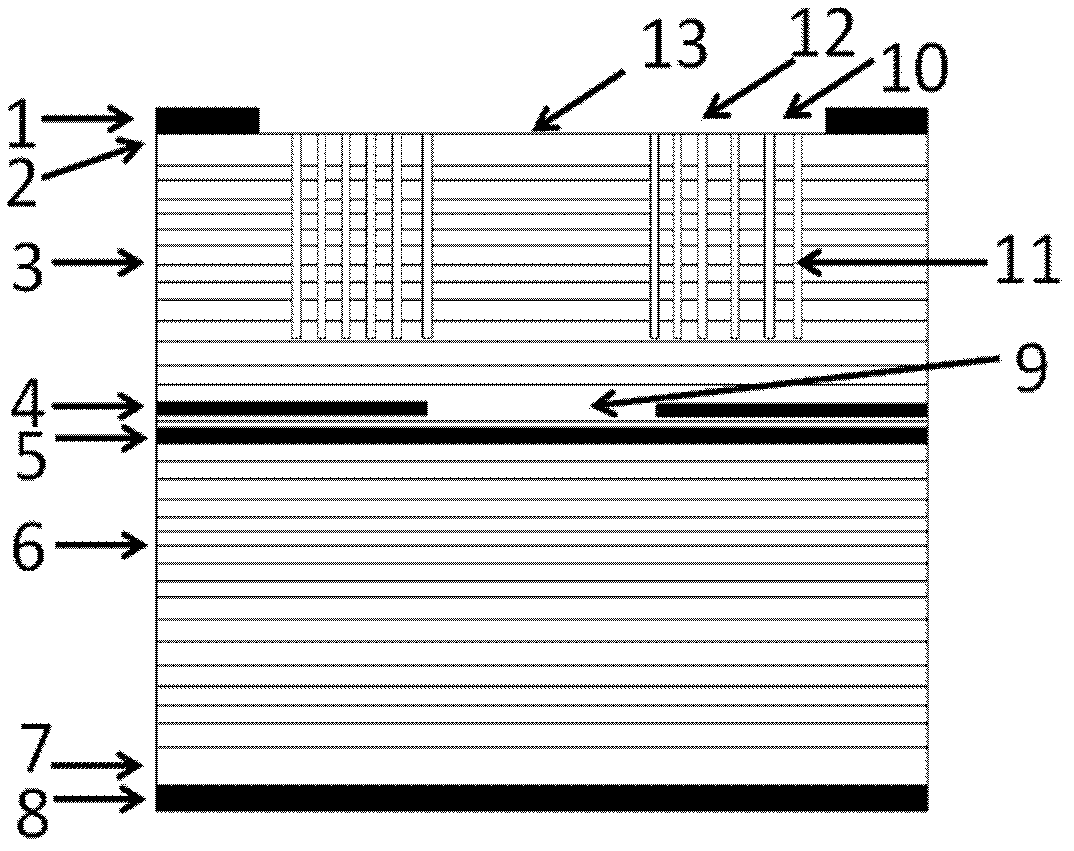

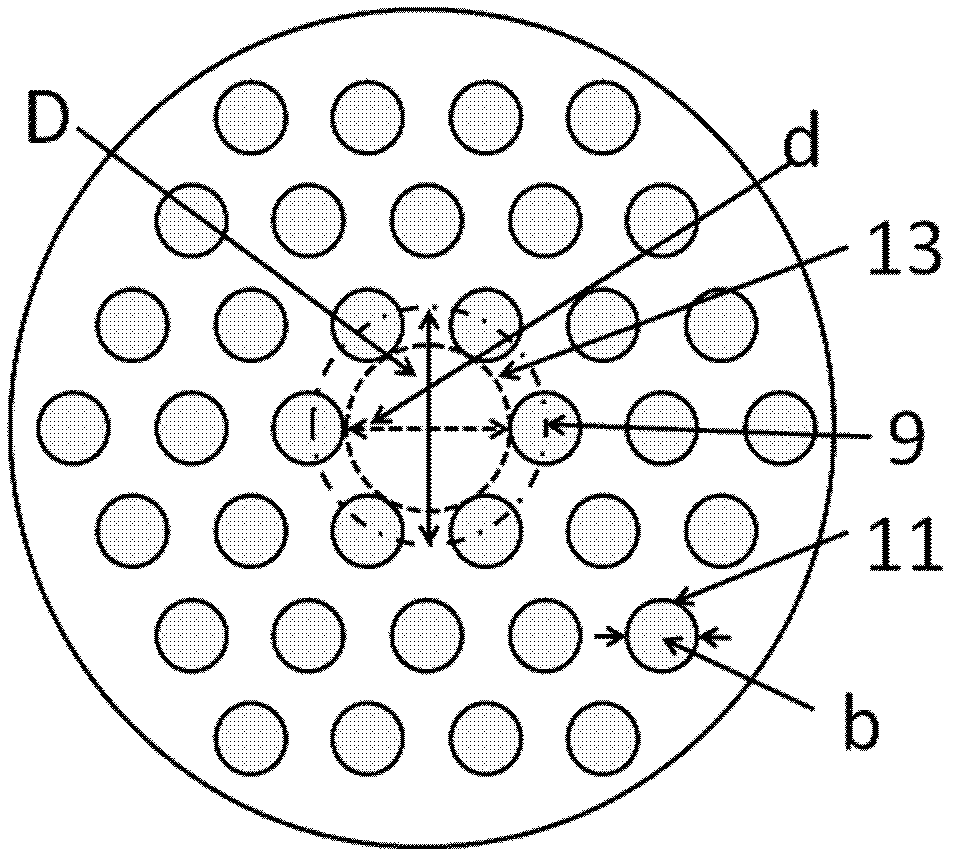

Dual-layer nanometer array-structure inverted ultraviolet LED and fabrication method thereof

ActiveCN110600598AIncrease light output powerExtraction efficiency limitSemiconductor devicesAir interfaceUltraviolet lights

The invention discloses a dual-layer nanometer array-structure inverted ultraviolet LED and a fabrication method thereof. The ultraviolet LED comprises a support, an LED chip, an organic polymer layerand a lens, wherein the lens is arranged at the top of the support, the LED chip and the organic polymer layer both are arranged in an enclosed space encircled by the support and the lens, the LED chip is arranged at the bottom of the support and comprises a sapphire layer with a first nanometer array structure, the sapphire layer is arranged at one side far away from the bottom of the support, the LED chip is coated with the organic polymer layer, and a second nanometer array structure is arranged at one side, far away from the sapphire layer, of the organic polymer layer. In the dual-layernanometer array structure comprising the high-transmittance organic polymer material and sapphire, vacuum is maintained between the organic polymer material and the sapphire, the limitation of ultraviolet light total reflection of a sapphire / air interface on light extraction efficiency is substantially reduced, so that the light giving-out power of an LED is remarkably improved.

Owner:SUZHOU UVCANTEK CO LTD

Method for optimizing photonic crystal surface emitting laser

InactiveCN102611001ASimple preparation processFast transmissionLaser detailsSemiconductor lasersWavelength rangeLower threshold

The invention relates to a method for optimizing photonic crystal surface emitting laser, belonging to the technical field of the semiconductor optoelectronics. In the method, an oxidized aperture and a photonic crystal defect aperture are horizontally matched and coupled on the basis of transverse coupling of an oxidation restricted type surface emitting laser and a two-dimensional photonic crystal. By the optimization of the relationship of the oxidized aperture and the photonic crystal defect aperture, the device whose oxidized aperture is greater than the photonic crystal defect aperture by one photonic crystal air hole diameter is prepared to allow the device to work in low threshold current, small series resistance and high single-mode output power state. According to the invention, the method can be applied to oxidation limit photonic crystal surface emitting lasers of different materials and cannot be influenced by the wavelength range.

Owner:BEIJING UNIV OF TECH

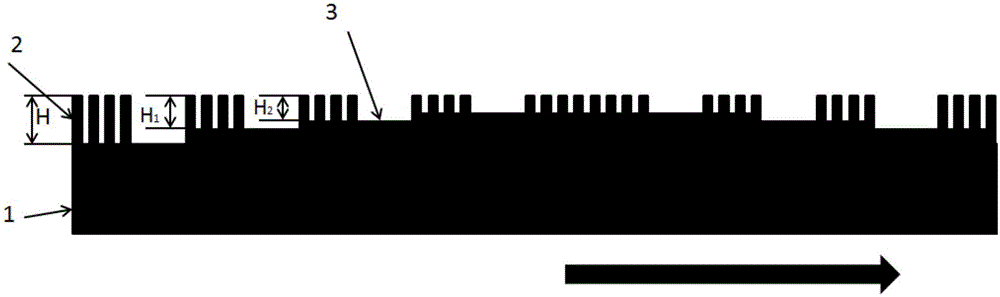

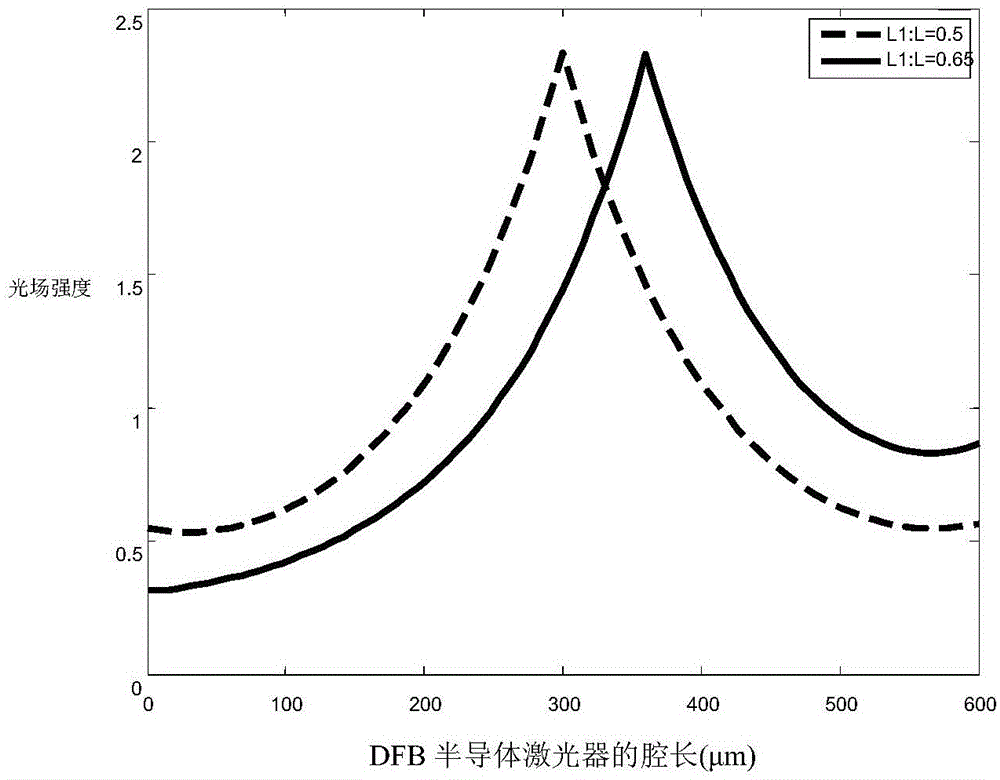

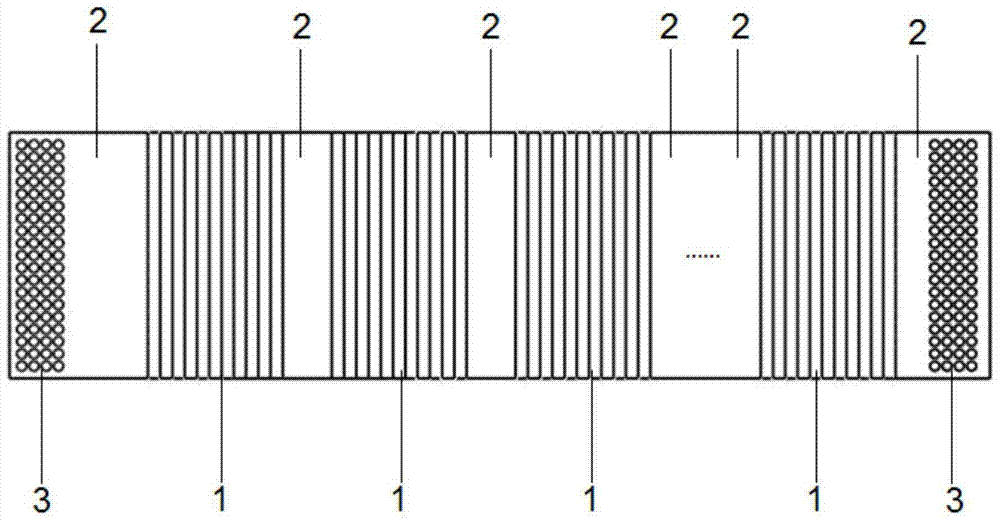

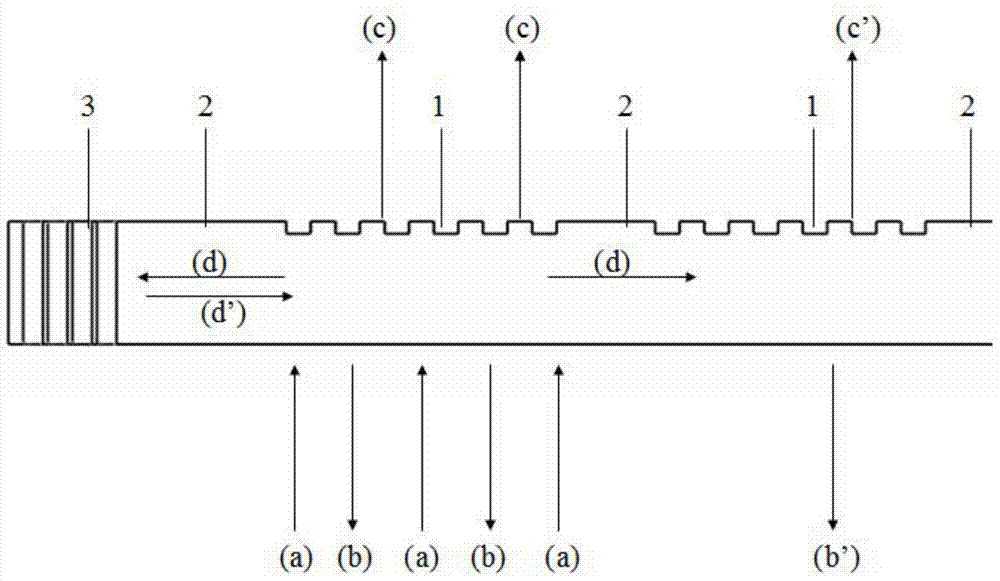

Asymmetric phase shift and apodization sampling raster and DFB laser

InactiveCN105161977AIncreased output powerImproved single-mode stabilityLaser optical resonator constructionNon symmetricPhase shifted

The invention discloses an asymmetric phase shift and apodization sampling raster and a DFB laser. According to the technical scheme, the sampling raster is designed and manufactured based on a reconstruction-equivalent chirp technology. For asymmetric phase shift of the sampling raster, an equivalent phase shift is introduced into a sampling raster structure and is arranged at a position, approaching one end of light emitting of the laser, in a 55% to 75% of the region of the length of a cavity of a DFB semiconductor laser; for apodization, symmetric rasters with gradually changed notch depths are manufactured at the two sides of the equivalent phase shift region to change the coupling coefficient of the raster. With phase shift deviation, the optical output power of the DFB semiconductor laser can be effectively increased; and on the basis of the apodization effect realized by tooth depth changing of the raster, the modulating intensity of the refractive index near the phase shift region can be effectively reduced and the spatial hole burning effect can be effectively weakened. Generally speaking, with the provided structure, the optical output power of the DFB semiconductor laser can be effectively improved and the single longitudinal mode characteristic on the high-power operating condition can be guaranteed.

Owner:NANJING UNIVERSTIY SUZHOU HIGH TECH INST

Vertical distribution feedback surface emitting laser and preparation method thereof

PendingCN113823995AIncrease the effective cavity lengthImproved wavelength stabilityLaser detailsSemiconductor lasersGratingLine width

The embodiment of the invention discloses a vertical distribution feedback surface emitting laser and a preparation method thereof. The laser comprises a first cavity surface, a periodic distribution feedback structure and a second cavity surface; the periodic distributed feedback structure comprises a plurality of distributed feedback structures along a first direction, each distributed feedback structure comprises an oxide layer, an active region and a tunnel junction, the plurality of oxide layers are arranged to replace a second-order grating to adjust uniform distribution of light, the oxide layers are arranged to be high-impedance structures, the current flowing direction is controlled, the light emitting power is improved, and further, the period of the periodical distribution feedback structure is set to be integral multiples of the half-wavelength of the effective emergent wavelength of the vertical distribution feedback surface emitting laser, the emergent wavelength range of the laser is limited, the spectral line width is reduced, and the wavelength stability of the laser is improved. The technical problems that in the prior art, a laser is poor in wavelength stability, low in power density, complex in structure and difficult to achieve mass production and narrow linewidth application requirements are solved.

Owner:VERTILITE CO LTD

Photonic integrated device and fabrication method thereof

ActiveCN108242452AAvoid the problem that the quality of the bonding interface is difficult to guaranteeLow manufacturing process requirementsOptical wave guidanceLaser detailsOptical pumpingPhotonics

The invention provides a photonic integrated device. The photonic integrated device comprises a substrate; a two-dimensional material unit and semiconductor light emitting units located at two sides of the two-dimensional material unit are arranged on the substrate; a light emitting two-dimensional material whose light emitting band is longer than that of the semiconductor light emitting unit is arranged in the two-dimensional material unit; and the semiconductor light emitting unit provides a pumping light source for the two-dimensional material unit to pump the light emitting two-dimensionalmaterial to emit light. According to the photonic integrated device, through changing the layer number or the kinds of the light emitting two-dimensional material, different light emitting bands canbe acquired; and besides, as an optical pumping light emitting mode is adopted, forming of a p-n junction is not needed, and in comparison with an electrical pumping light emitting mode of fabricatinga p-n junction based on the light emitting two-dimensional material in the prior art, the process difficulty is simplified. The invention also provides a fabrication method for the above photonic integrated device. The fabrication method can realize process standardization easily and is compatible with the existing semiconductor device fabrication process, the fabrication cost is reduced, and batch production is facilitated.

Owner:QINGDAO YICHENLEISHUO TECH CO LTD QINGDAO CITY

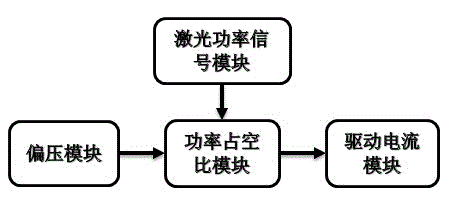

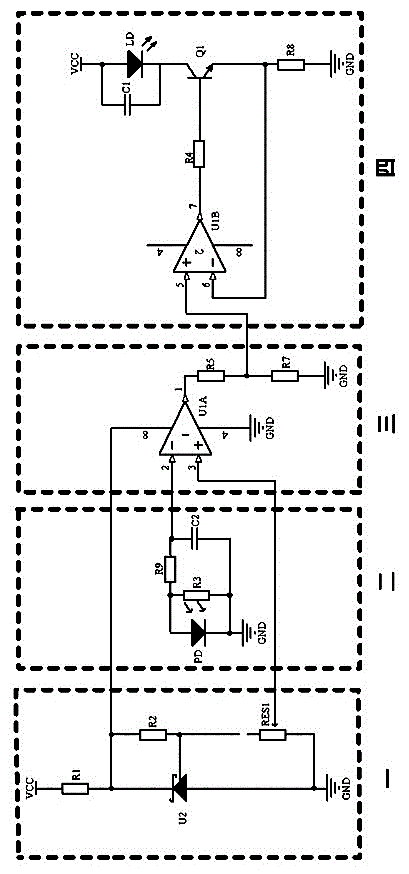

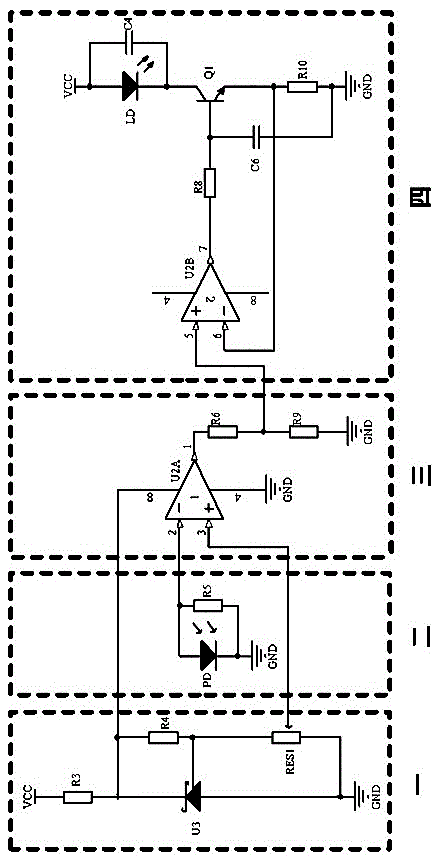

Laser device wide-temperature circuit

InactiveCN103066492AHighly integratedImprove portabilityLaser detailsLaser output parameters controlDriving currentDriver circuit

The invention relates to the field of laser application, in particular to the field of the laser application with more strict temperature change requirement. The invention provides a laser device wide-temperature circuit which achieves that the size is small, and the upper limit of current is set with high accuracy, dynamic regulation is achieved with drive current, laser power is controlled with high accuracy, and response to the temperature change is minimal. The laser device wide-temperature circuit comprises a bias module, a laser power signal module, a power duty radio module, and a drive current module, wherein the bias module and the laser power signal module are both connected with the power duty radio module, and the power duty radio module is connected with the drive current module. According to the laser device wide-temperature circuit, a laser drive circuit with small size, wide temperature and low temperature drift is achieved. The laser device wide-temperature circuit is high in integration level, strong in transportability, easy to process and assemble, and economical in cost. The laser device wide-temperature circuit can be used in the fields of military, measurement and other fields with more strict requirements on size and which need a wider range of temperature.

Owner:QINGDAO LASENCE

Deep ultraviolet source of electron beam activated fluorescent powder

The invention relates to the field of ultraviolet sources, and in particular relates to a deep ultraviolet source of electron beam activated fluorescent powder. The electron beam activated fluorescentpowder comprises a fluorescent screen, an electronic gun and a glass shell, wherein the fluorescent screen comprises quartz sand and an ultraviolet fluorescent layer coated to the quartz glass; the electronic gun is arranged in the glass shell, electron beams generated by the electronic gun faces the ultraviolet fluorescent powder layer, and the ultraviolet fluorescent powder layer sends out ultraviolet light through the quartz sand under electron beam activation; and the fluorescent screen is hermetically connected to the glass shell through transitional glass. The deep ultraviolet source provided by the invention is free from pollution, low in cost and easy for scaled production.

Owner:上海极优威光电科技有限公司

A kind of fabrication method of electric injection gan-based resonator

ActiveCN103325894BHigh Q valueGood electrical and optical propertiesLaser optical resonator constructionSemiconductor devicesCurrent limitingResonant cavity

The invention discloses a manufacturing method of an electrically injected GaN-based resonant cavity, which relates to a GaN-based resonant cavity luminescent device. The method comprises the steps of growing a p type current expanding layer ITO on a GaN-based epitaxial wafer with a sapphire substrate, sequentially carrying out etching, polishing and ICP (Inductively Coupled Plasma) etching on the surface of the p type current expanding layer ITO to form a n type table facet, manufacturing a current limiting layer, a n type metal contact layer, a p type metal contact layer and a top dielectric film DBR (Distributed Bragg Reflector), bonding the components with a temporary substrate, removing the sapphire substrate by a laser lift-off technology, grinding and polishing the GaN surface subjected to laser lift-off, growing a bottom dielectric film DBR on the polished GaN surface, bonding the obtained component with a permanent substrate, and removing the temporary substrate, thus completing the manufacturing of the electrically injected GaN-based resonant cavity. The high-performance GaN-based resonant cavity is realized by adopting the two high-quality dielectric film DBRs and the low-loss p type current expanding layer ITO.

Owner:XIAMEN UNIV

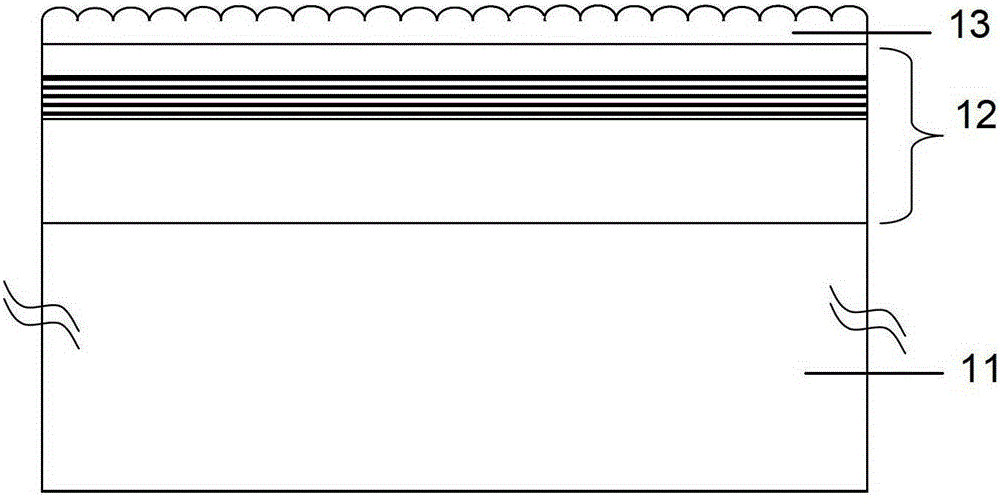

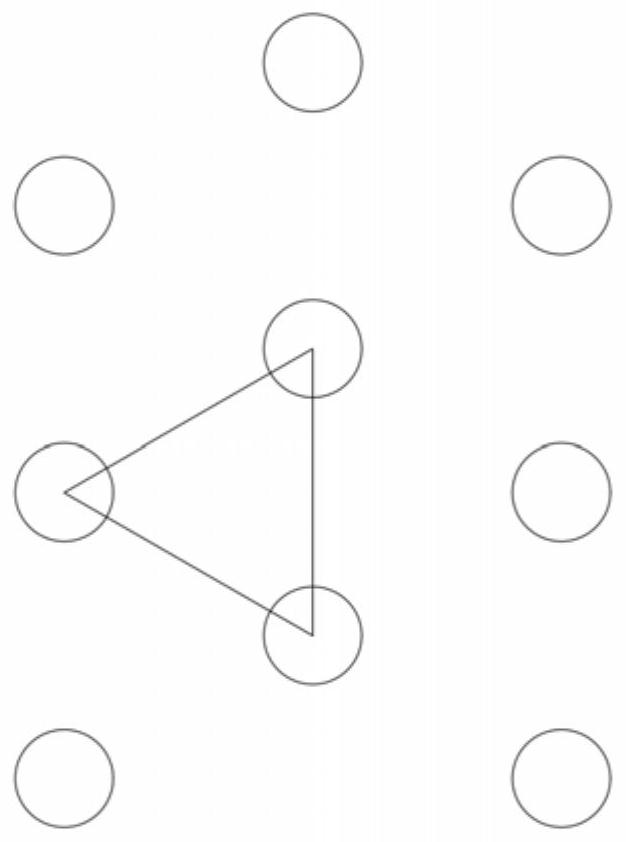

Single-laser vertical cavity surface emitting laser (VCSEL) chip and fabrication method thereof

InactiveCN108879323AIncrease light output powerEasy to prepareLaser detailsSemiconductor lasersEpoxyVertical-cavity surface-emitting laser

The invention relates to the field of a vertical cavity surface emitting laser (VCSEL) chip, and provides a single-laser VCSEL chip and a fabrication method thereof. The chip comprises a GaAs substrate, an epitaxial layer, a SiNx layer, a grating layer, a triangular mirror surface, an epoxy resin layer and an electrode, wherein the epitaxial layer is grown on a surface of the GaAs substrate, a groove and a plurality of epitaxial units independent to one another are etched in the epitaxial layer, the plurality of epitaxial units are uniformly arranged along a central line of the groove, the SiNx layer is deposited on surfaces of the plurality of epitaxial units, the grating layer is limited on a surface of the SiNx layer, the triangular mirror surface is arranged in the groove, the surrounding of the triangular mirror surface is filled with the epoxy resin layer, and the electrode is connected to the surface of the SiNx layer. By the chip, light emitted from the plurality of epitaxial units can be gathered to a beam of laser, so that the light giving-out power of the single-laser VCSEL chip is high. The fabrication method is simple, the light of the obtained chip can be gathered toform the beam of laser, and the light giving-out power is high.

Owner:YANGZHOU CHANGELIGHT

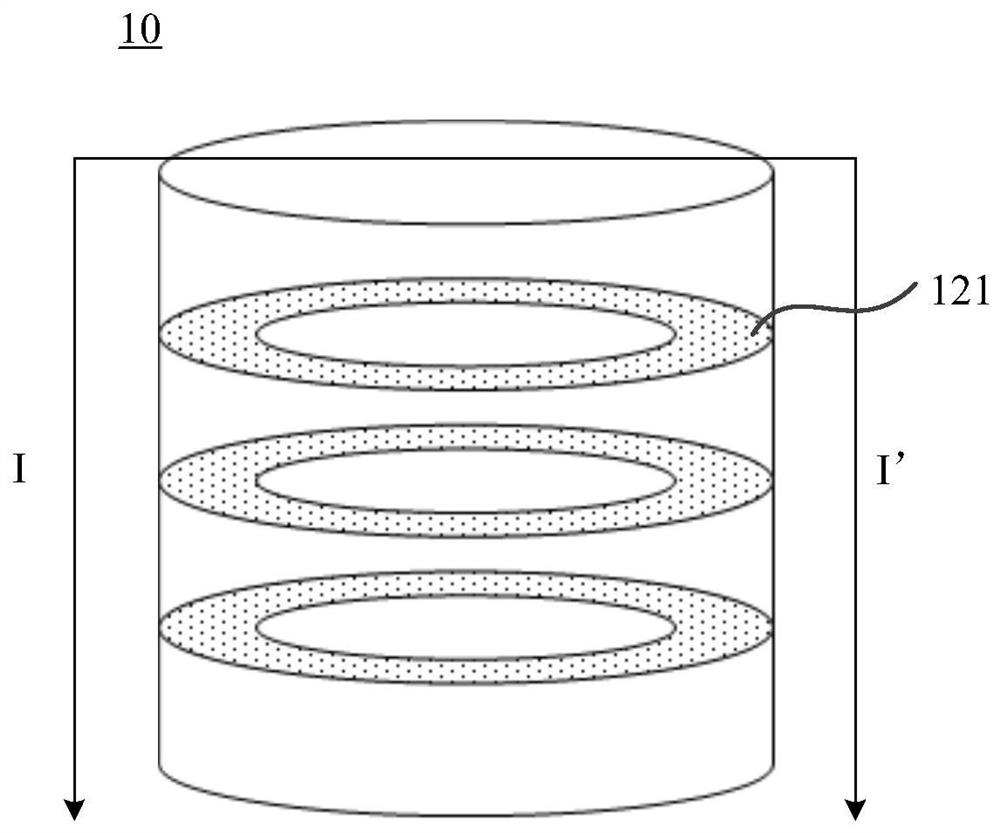

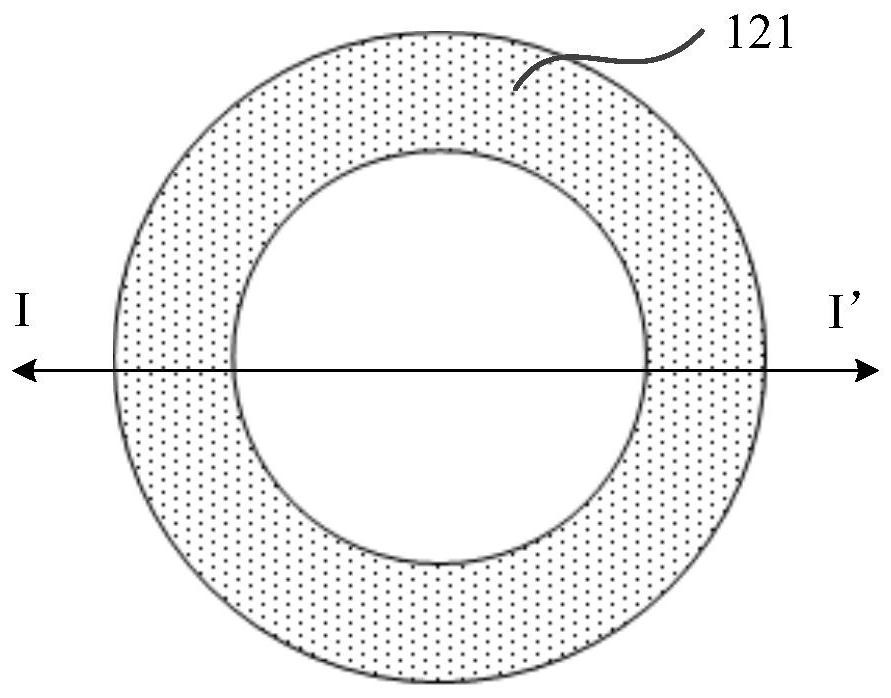

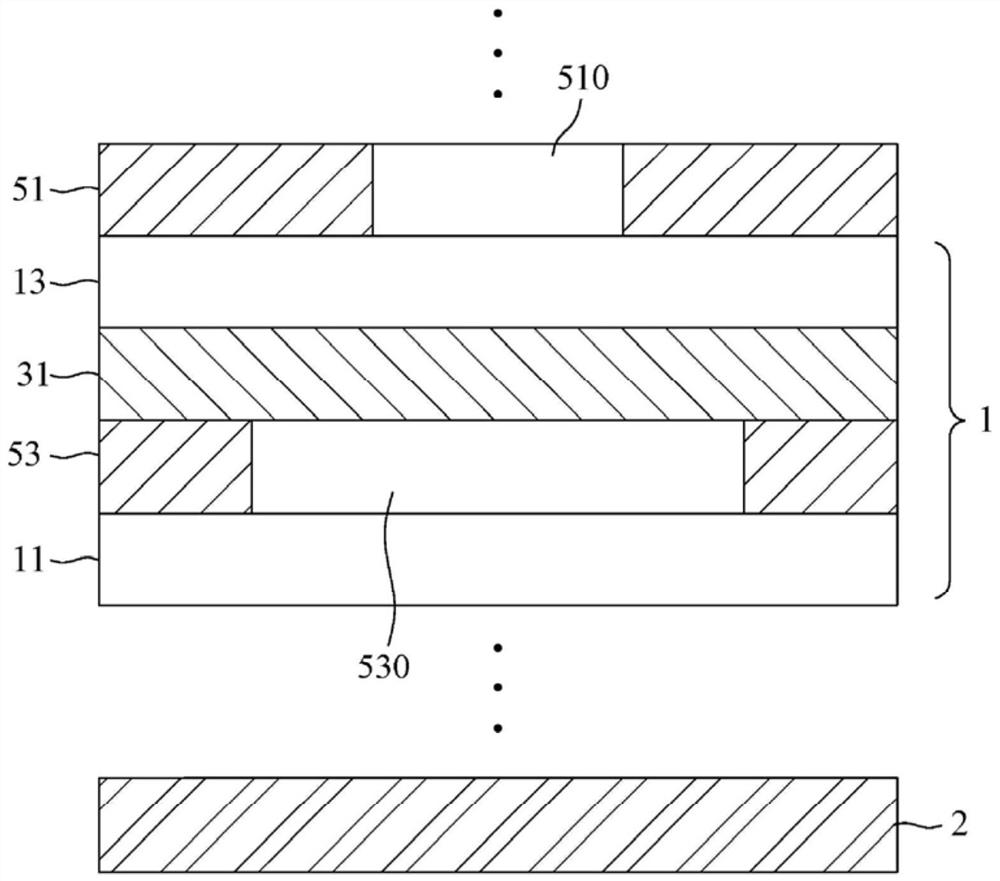

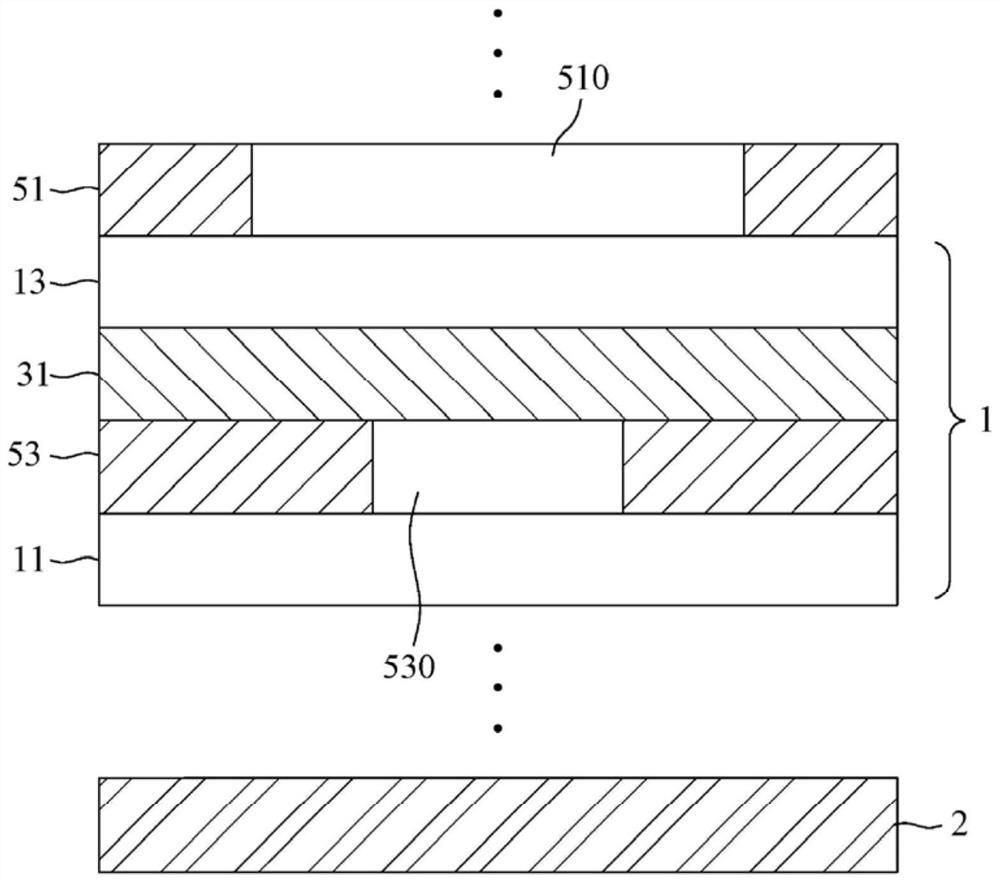

Vertical Resonant Cavity Surface Emitting Laser Diode (VCSEL) with Multiple Current Confinement Layers

ActiveCN112117639BIncreased carrier confinementEnhanced carrier confinementLaser detailsSemiconductor lasersResonant cavityOptical power

The present invention relates to a vertical resonant cavity surface emitting laser diode (VCSEL) with multiple current confinement layers, that is, a VCSEL with multiple current confinement layers. Generally, a tunnel junction layer needs to be arranged between the two active layers to allow the current from One active layer flows into the other active layer, but the tunneling junction layer will cause the current to diverge seriously in one active layer, making it difficult for the current in the other active layer to be confined to the desired area. A current confinement layer with carrier and light confinement functions is provided between, so that the carrier or light confinement effect of the active layer above and / or below the current confinement layer can be improved, which is helpful to improve the optoelectronic properties of the VCSEL Compared with the existing VCSEL, the VCSEL with multiple current confinement layers can significantly improve the optical power, slope efficiency and power conversion efficiency of the VCSEL.

Owner:VISUAL PHOTONICS EPITAXY

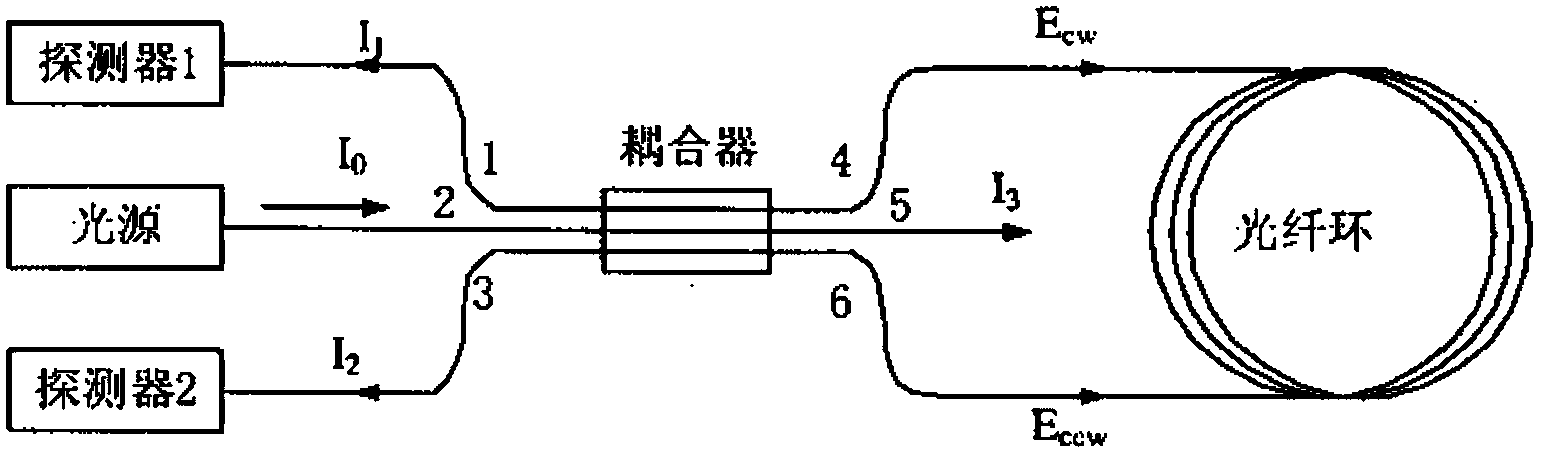

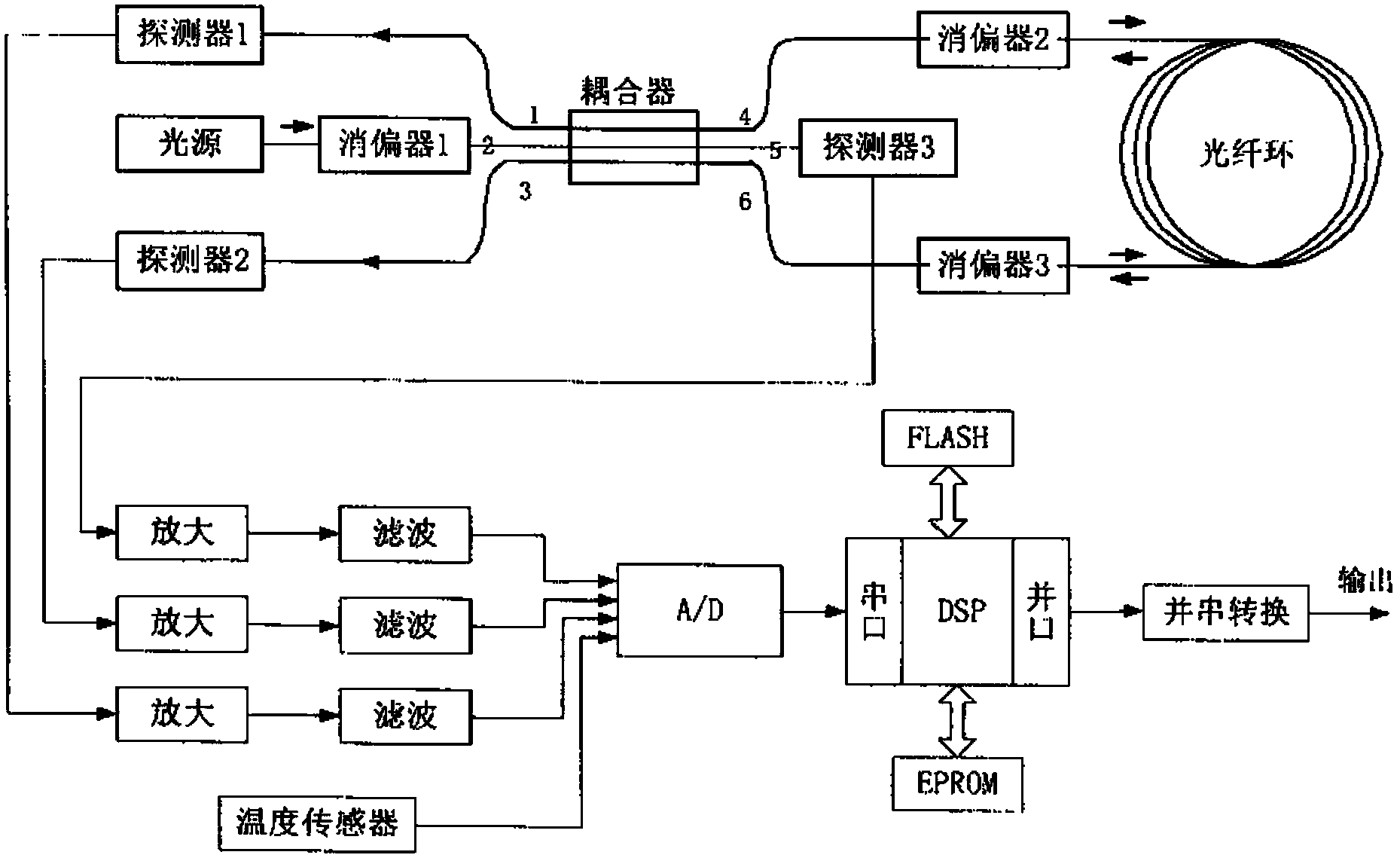

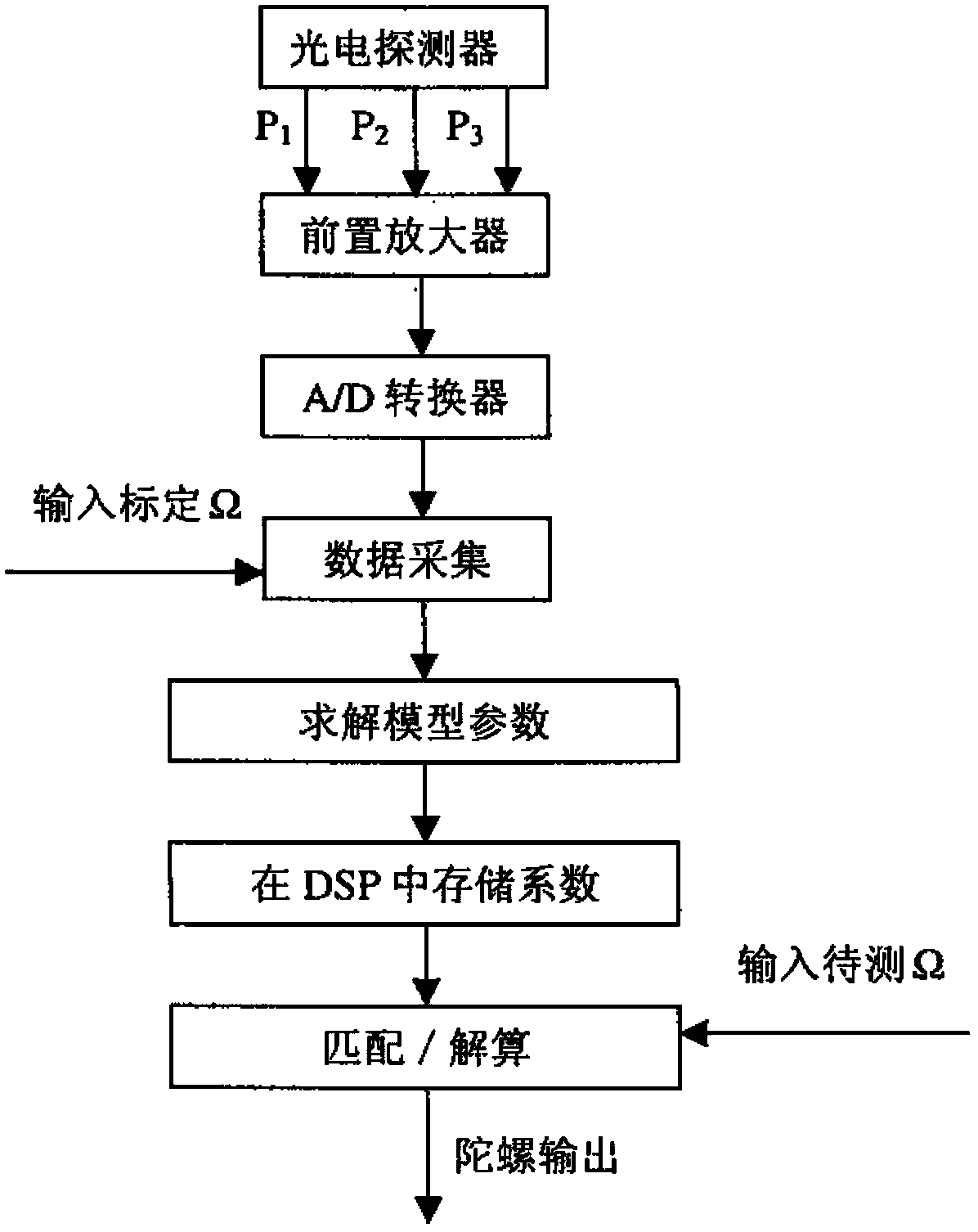

Open-loop fiber optic gyroscope signal detection method using 3×3 coupler

ActiveCN105659811BEliminate the effect of precisionReduce asymmetrySagnac effect gyrometersFiberPhysics

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

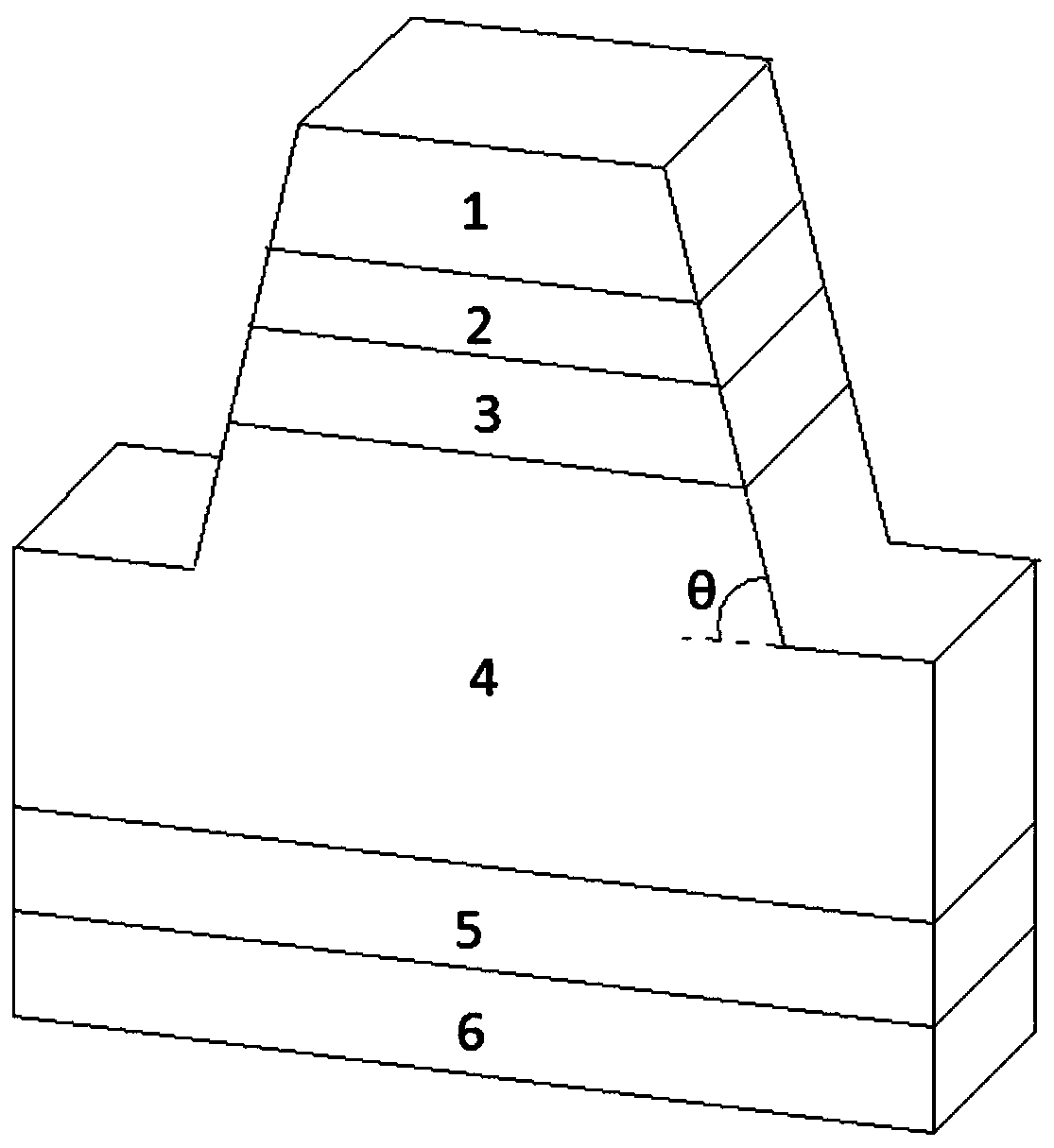

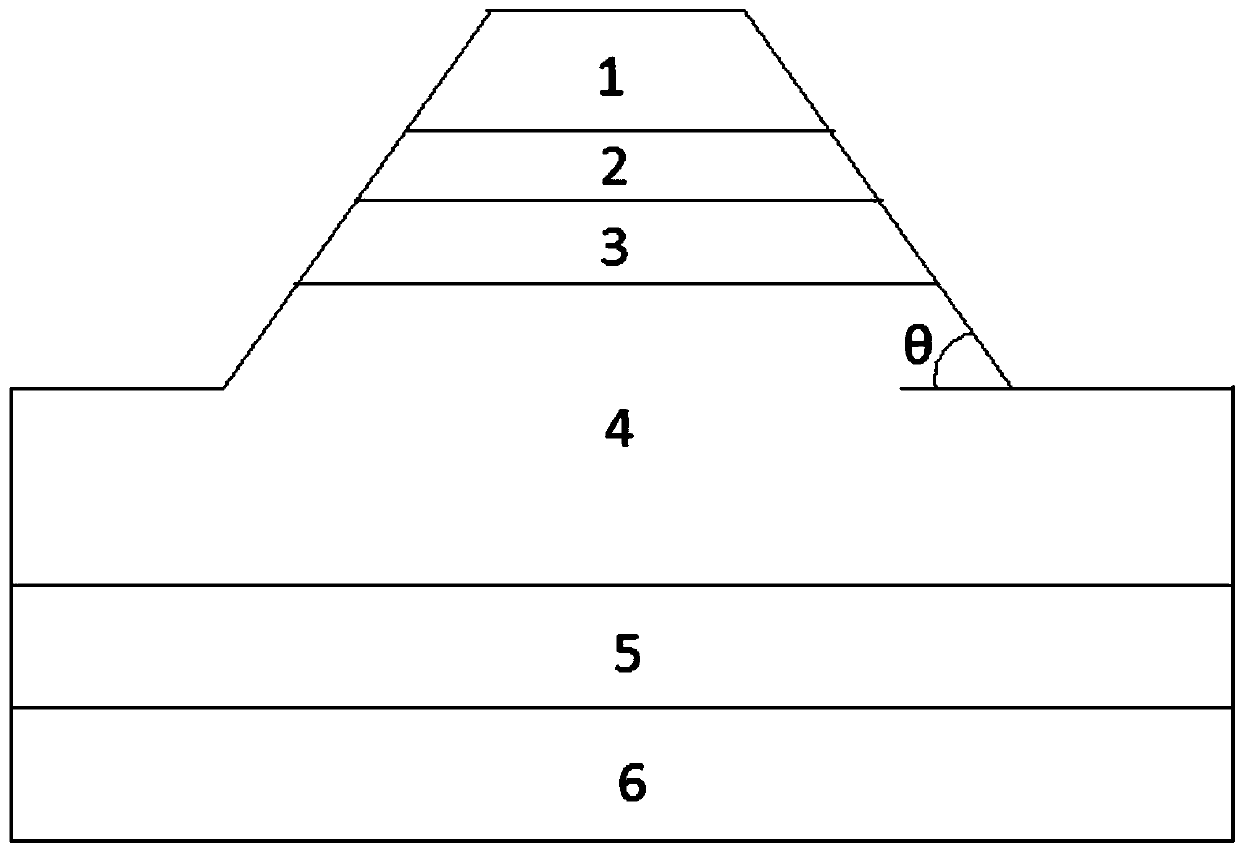

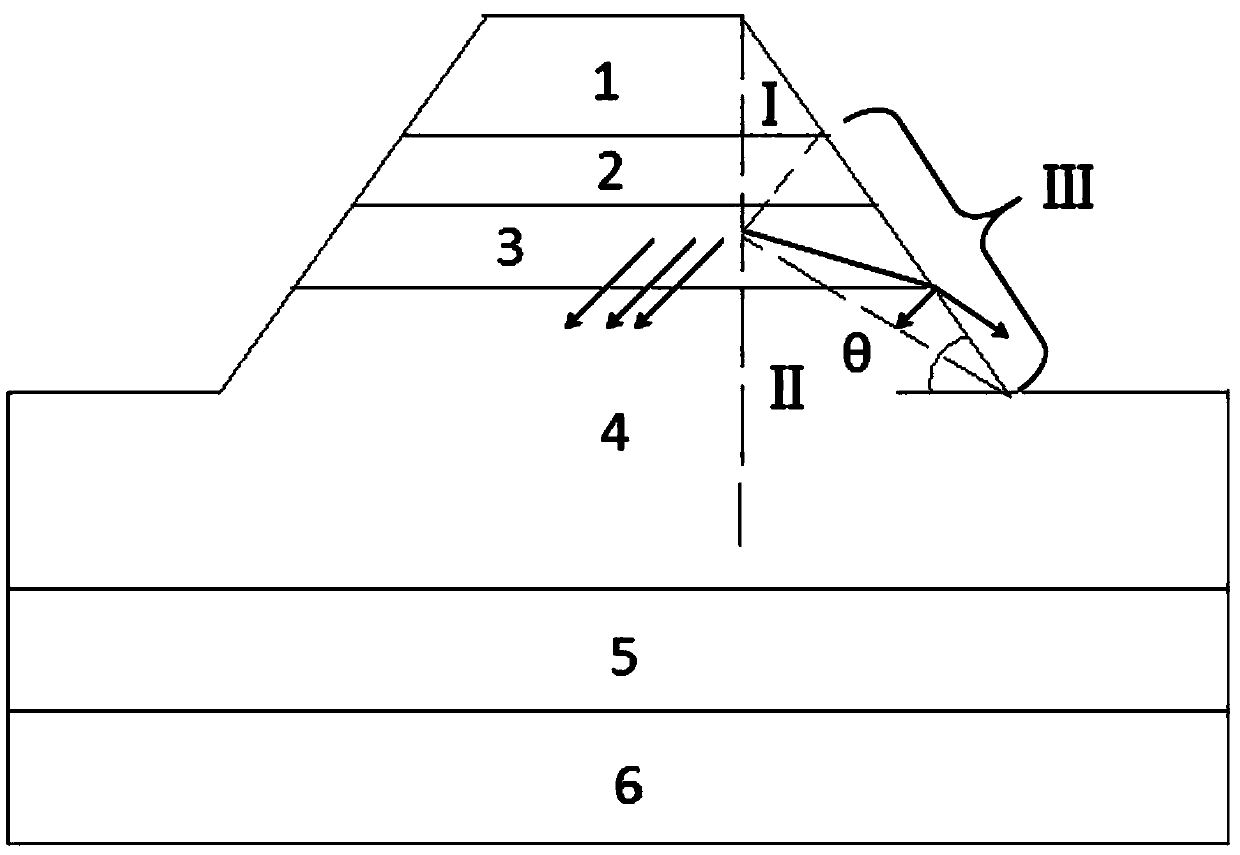

An epitaxial structure of a deep ultraviolet LED chip and a preparation method thereof

InactiveCN109103313AImprove extraction efficiencyIncrease light output powerSemiconductor devicesUltraviolet lightsActive layer

The invention provides an epitaxial structure of a deep ultraviolet LED chip, which includes a P-type GaN layer, a P-type AlGaN layer, a multiple quantum well active layer, an N-type AlGaN layer, an AlN layer and a sapphire substrate which are arranged in order of superposition. The structure is characterized in that the multiple quantum well active layer and the N-type AlGaN layer together form an adjusting layer, the adjusting layer has at least one inclined side surface, the included angle between the inclined side surface and the horizontal section near the center side of the adjusting layer is a top etching included angle, and the top etching included angle is 28-40 degree controllable. The invention also provides a preparation method of the epitaxial structure of the deep ultravioletLED chip, wherein the etching angle and the etching depth of the top are adjusted by controlling different dry etching parameters; the method can effectively extract the deep ultraviolet light of TEand TM mode, and improve the light-emitting efficiency of the deep ultraviolet LED.

Owner:EZHOU INST OF IND TECH HUAZHONG UNIV OF SCI & TECH +1

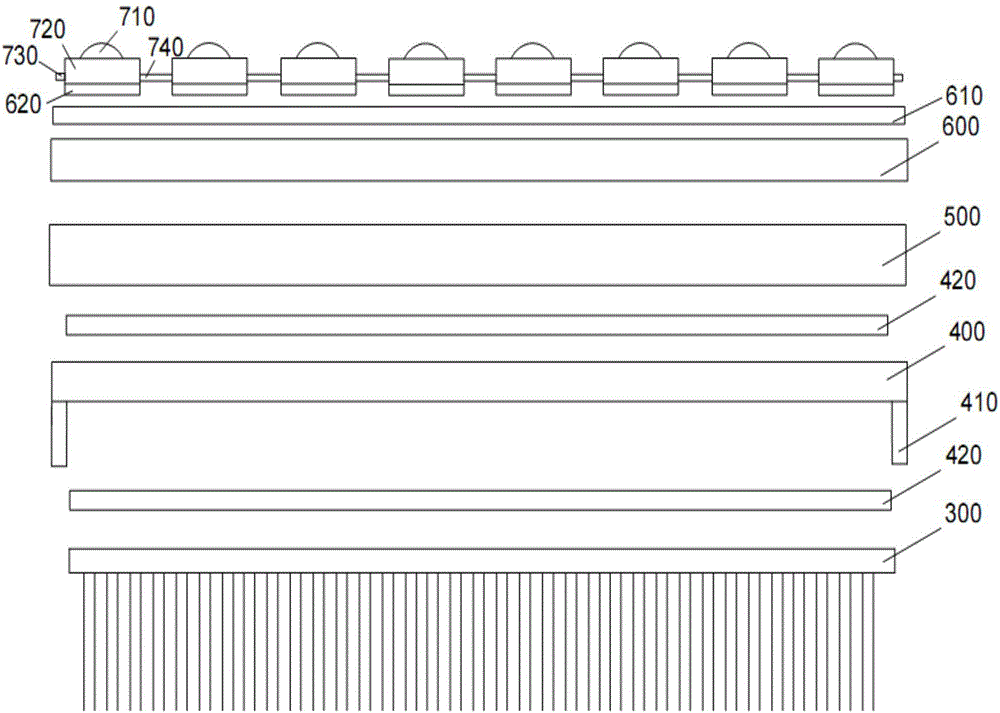

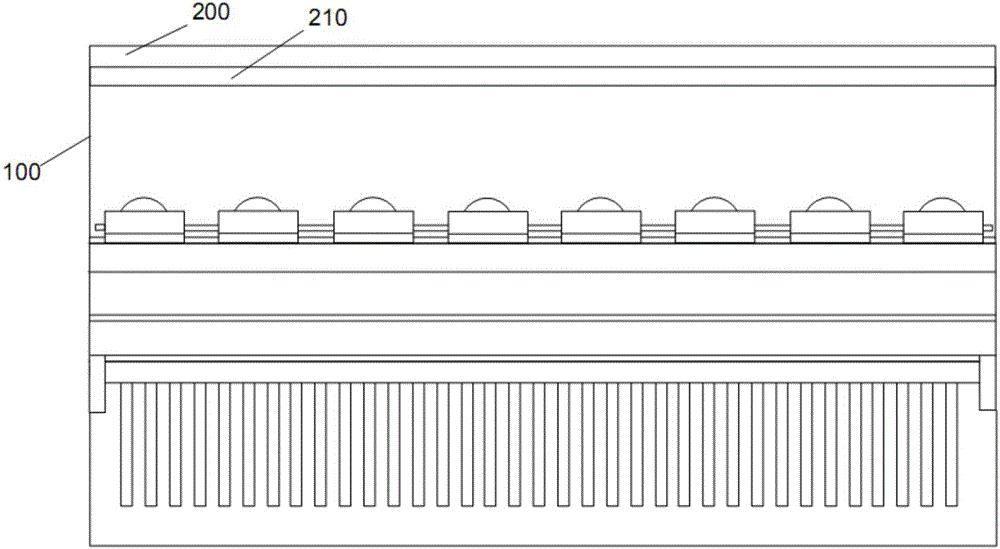

High-power LED backlight module

InactiveCN105042500ARealize multi-colorIncrease light output powerPoint-like light sourceLighting heating/cooling arrangementsEngineeringLED lamp

The invention discloses a high-power LED backlight module. The high-power LED backlight module comprises a plurality of LED lamps arranged on the surface of a partition board at intervals and connected in series, a heat transfer plate, a semiconductor refrigerator, a radiator and a framework. The upper surface of the heat transfer plate is attached to the lower surface of the partition board. The hot end of the semiconductor refrigerator is attached to the lower surface of the heat transfer plate. The upper surface of the radiator is attached to the cold end of the semiconductor refrigerator. An accommodating cavity is formed in the framework, through holes are formed in the bottom of the framework, and a display screen is arranged on the front portion of the framework. The radiator, the semiconductor refrigerator, the heat transfer plate and the partition board are sequentially arranged in the accommodating cavity. The lower surface of the radiator is arranged on the bottom of the accommodating cavity. The LED lamps face the display screen. By the adoption of the high-power LED backlight module, heat dissipation of a high-power LED light emission array is achieved, and accordingly the light emission efficiency of the backlight module is improved and thinning of the backlight module is achieved.

Owner:SUZHOU JINGLEI PHOTOELECTRIC LIGHTING TECH

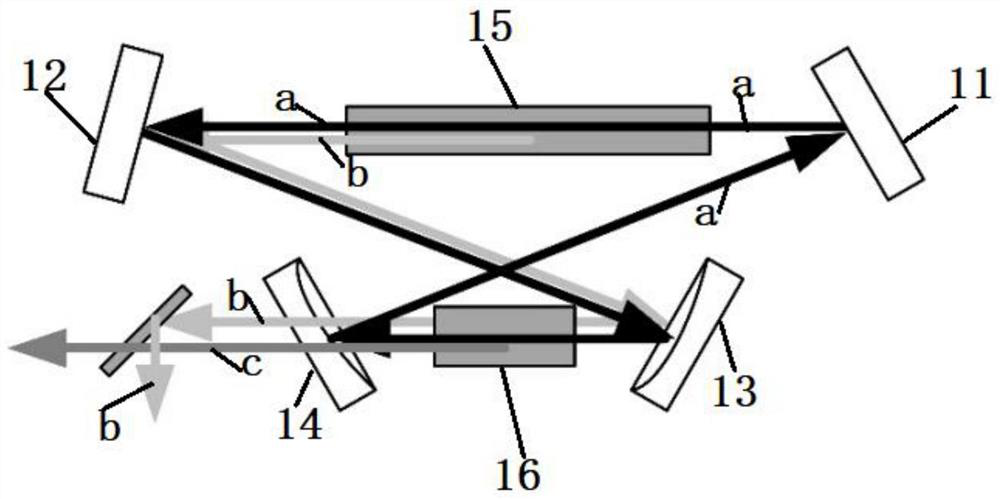

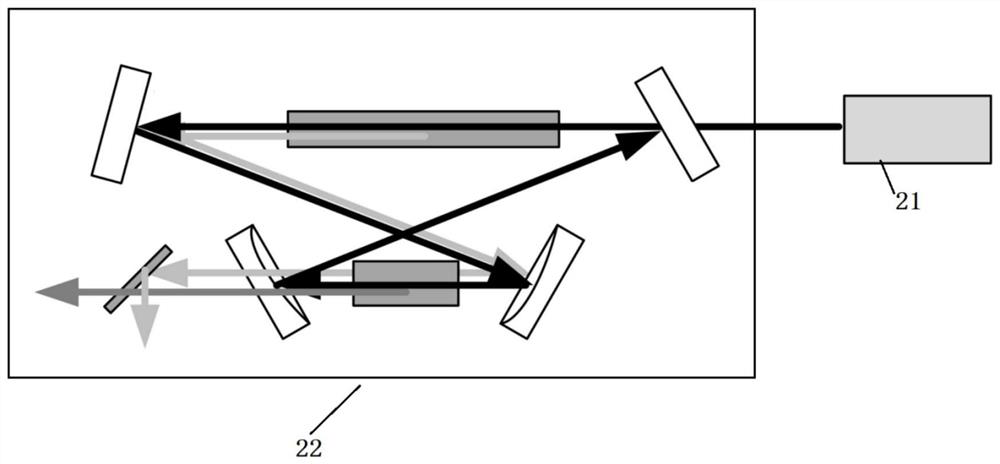

Laser-based frequency tripling device and laser system

PendingCN113872036AReduce the difficulty of adjustmentImprove stabilityLaser detailsErbium lasersNonlinear crystals

The invention belongs to the field of lasers, and particularly relates to a laser-based frequency tripling device and a laser system. The laser-based frequency tripling device comprises a first frequency doubling unit arranged at a first preset position; a second frequency doubling unit arranged at a second preset position, wherein the first frequency doubling unit and the second frequency doubling unit are symmetrically arranged; a nonlinear crystal arranged between the first frequency doubling unit and the second frequency doubling unit; a third frequency doubling unit arranged at a third preset position; a fourth frequency doubling unit arranged at a fourth preset position, wherein the third frequency doubling unit and the fourth frequency doubling unit are symmetrically arranged; and a nonlinear sum frequency crystal arranged between the third frequency doubling unit and the fourth frequency doubling unit.

Owner:SHANGHAI PRECILASERS TECH CO LTD

Liquid flow non-immersive measuring device and sensing probe

ActiveCN103344289BEnables non-immersive measurementsRealize measurementCladded optical fibreVolume/mass flow measurementMeasurement deviceGrating

The invention discloses a liquid flow non-immersive measuring device and a sensing probe. The liquid flow non-immersive measuring device comprises the sensing probe and is characterized in that the sensing probe is connected with a circulator through an optical path, light emitted by a pump light source of 980nm is received by the circulator through a separator, optical signals output by the circulator is sent to a coupler through the separator, two optical signals are output by the coupler, one signal is sent to a first Faraday rotary mirror through a phase modulator, and the other signal is directly sent to a second Faraday rotary mirror; the optical signals output by the coupler are sent to a photoelectric detector, electric signals output by the photoelectric detector enter a phase carrier wave demodulating device, weak dynamic variation of the wave length of a DFB optical fiber laser is demodulated, and flow is calculated according to the variation of the wave length; the sensing probe relates to a section of asymmetric phase shifting optical fiber grating fixed on the outer wall of an oil pipe in the circumferential direction.

Owner:LASER RES INST OF SHANDONG ACAD OF SCI

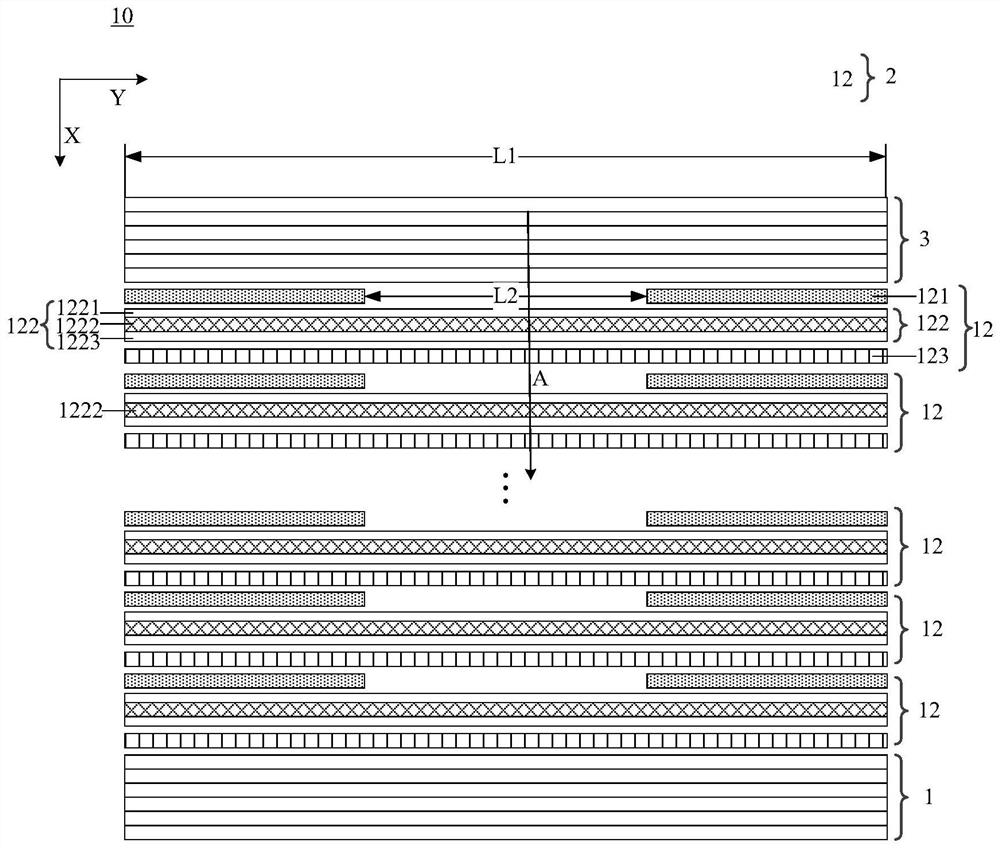

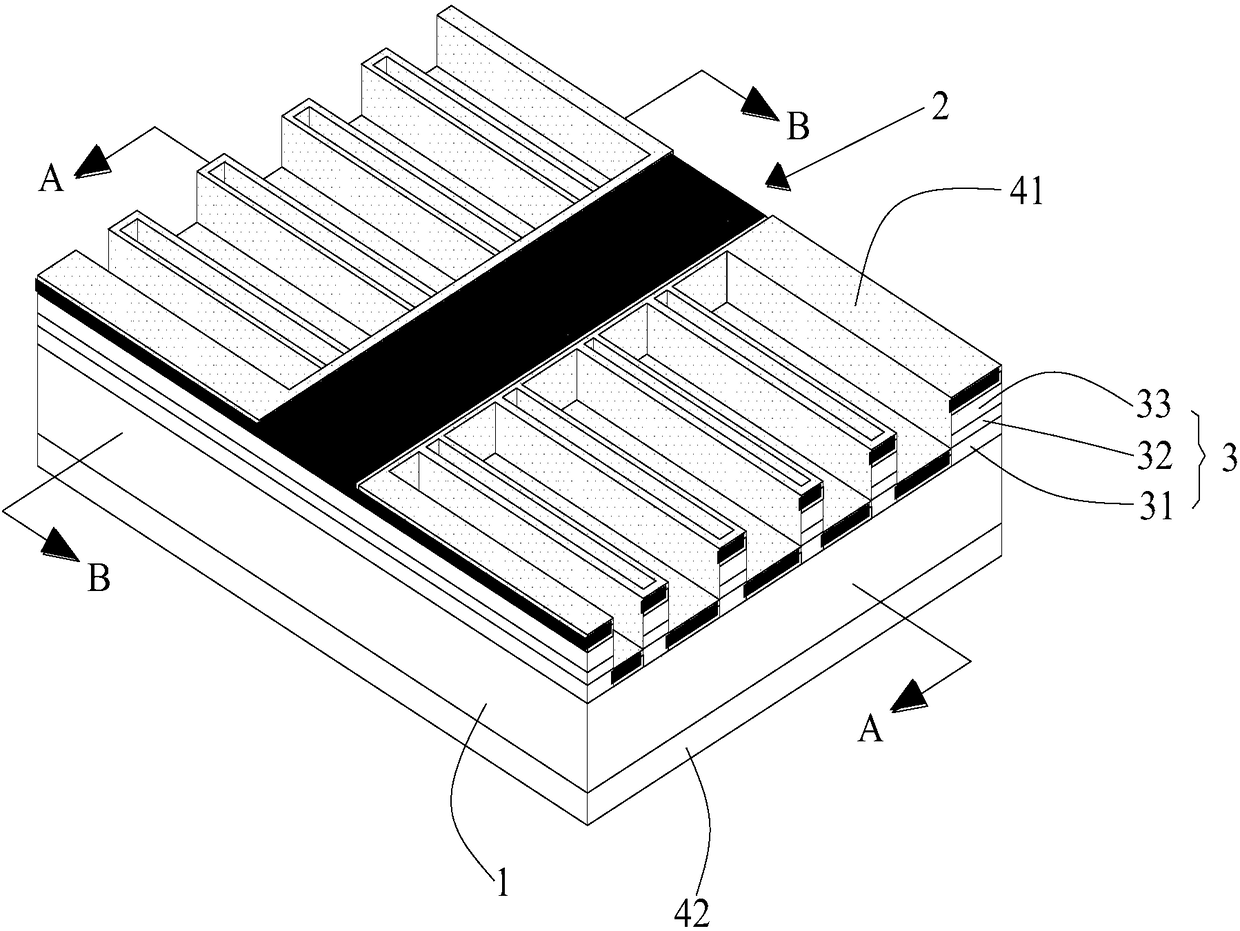

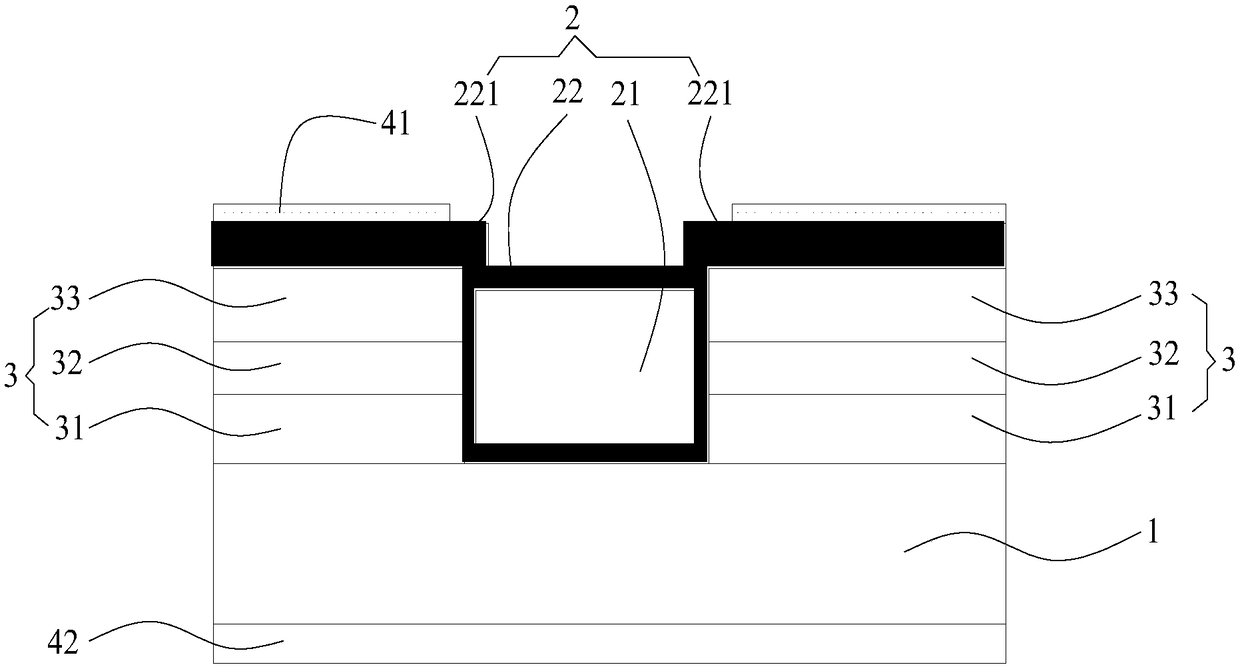

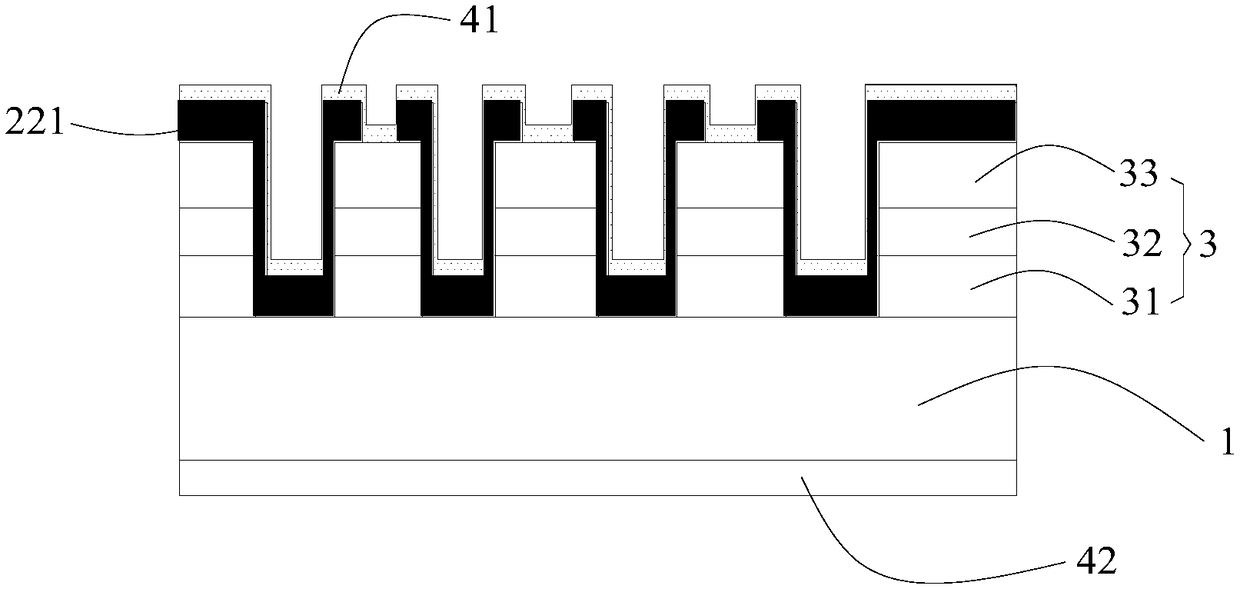

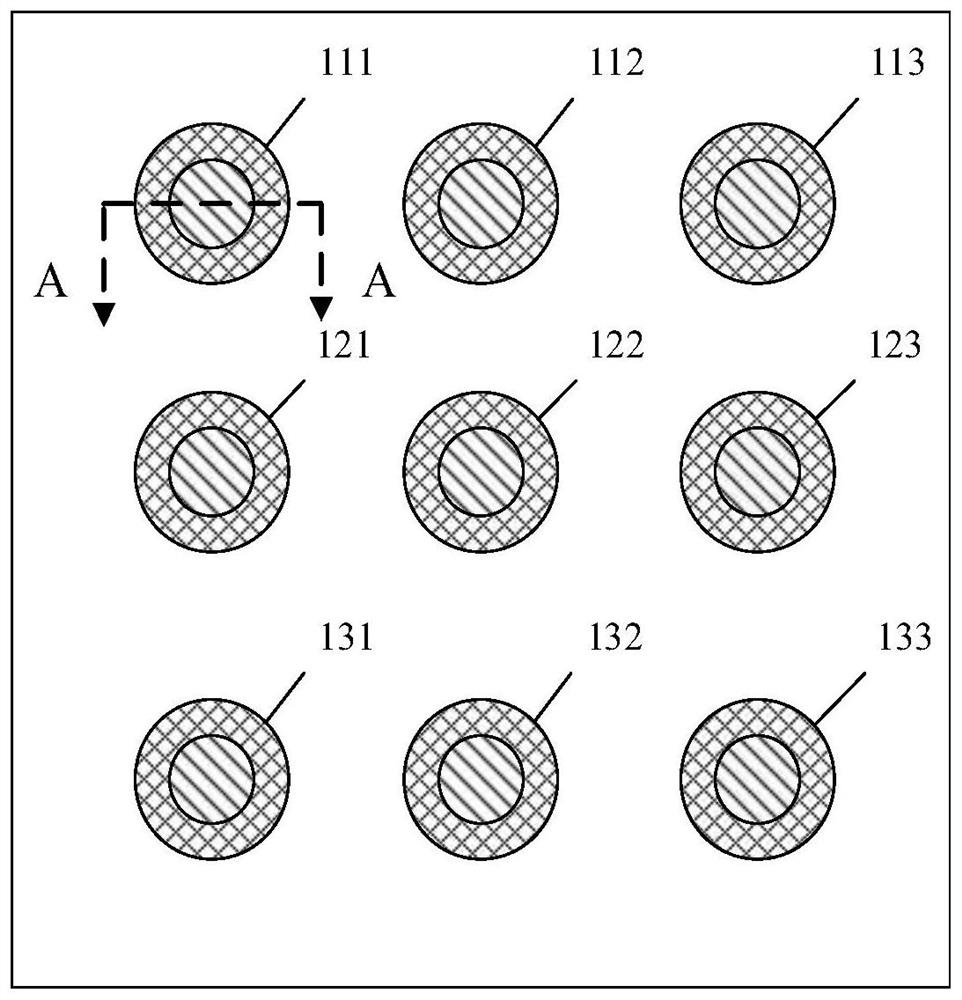

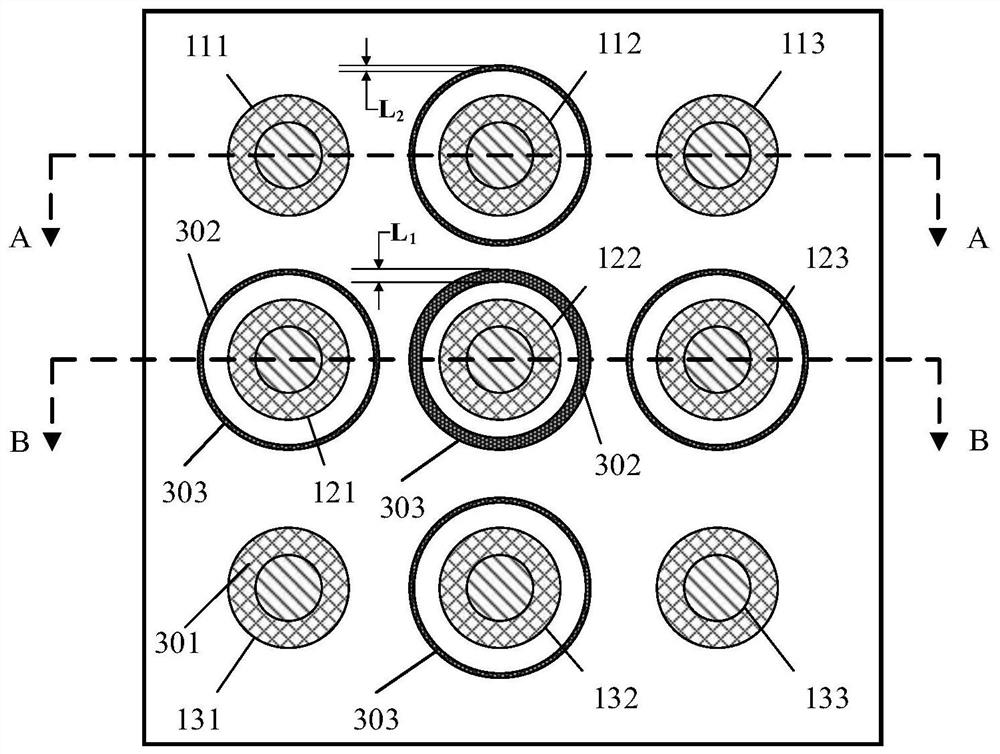

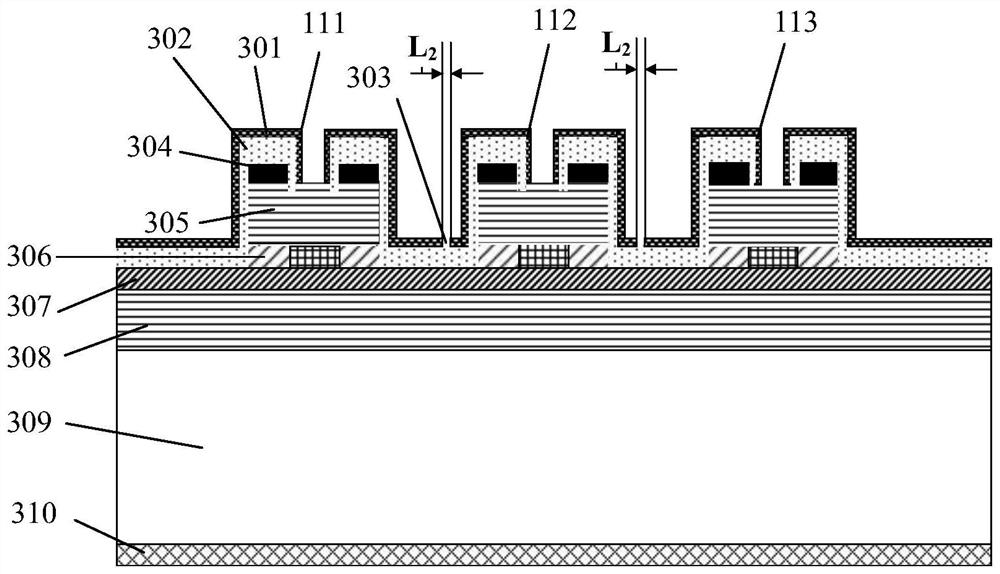

Vertical-cavity surface-emitting laser array with uniform light output power and manufacturing method thereof

ActiveCN112448267BIncrease light output powerImprove uniformitySemiconductor laser arrangementsLaser arrangementsVertical-cavity surface-emitting laserOptical cavity

Owner:BEIJING UNIV OF TECH

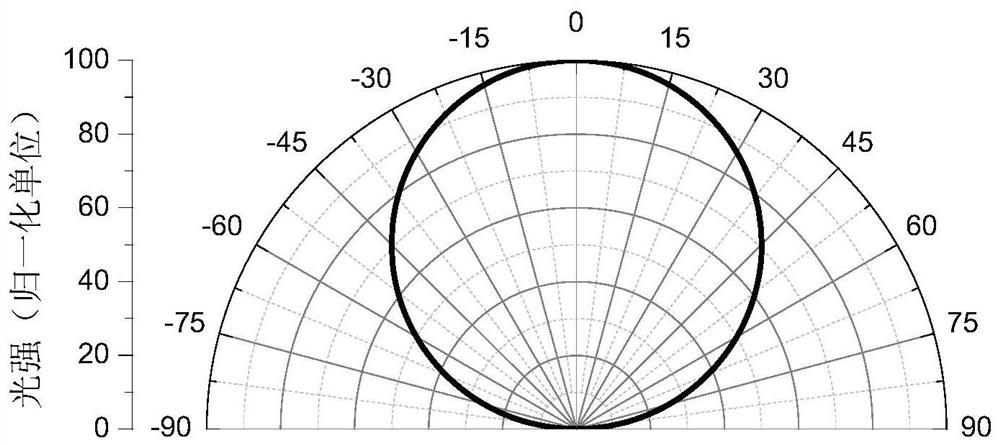

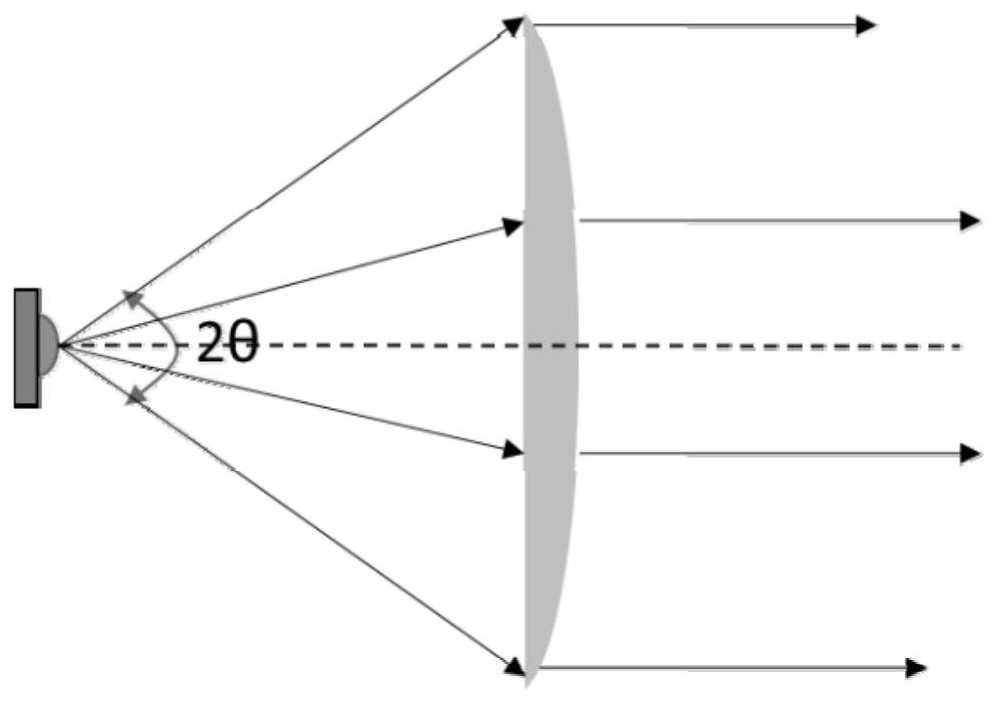

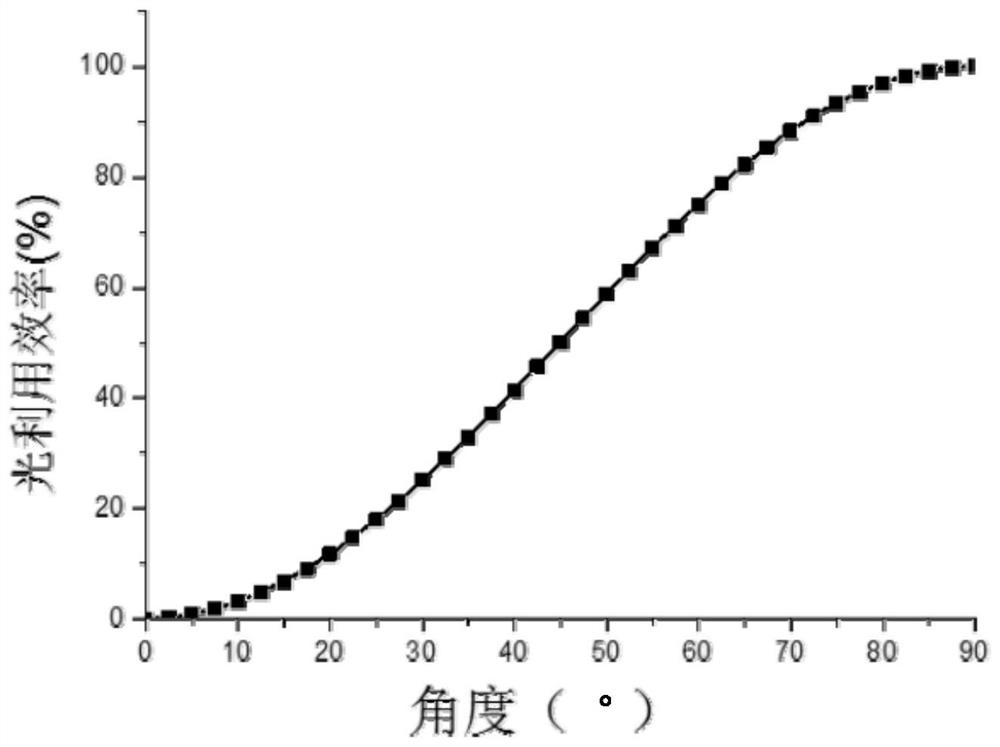

Light source with small beam angle

PendingCN111609330AImprove removal efficiencySimple structureSemiconductor devices for light sourcesRefractorsBeam angleOptical axis

The invention discloses a light source with a small beam angle. The light source comprises a semiconductor light-emitting element and a lens, the semiconductor light-emitting element is embedded in the lens and is seamlessly combined with the lens. The lens is provided with a top surface and a side surface connected with the top surface; the semiconductor light-emitting element is provided with more than one light-emitting surface, at least one light-emitting surface is arranged towards the top surface of the lens, and at least part of light emitted to the side surface of the lens by the semiconductor light-emitting element can be reflected by the side surface of the lens and then transmitted out along the optical axis. The light source with the small beam angle is simple in structure, andthe light utilization efficiency in reflective lighting application is greatly improved; compared with a light source without a lens, the light emitting power is improved by more than 10%; compared with a secondary lens, the primary lens is small in size and light in weight, seamless connection with a chip is achieved in the light source packaging process, installation is convenient, and the light emitting rate is improved; meanwhile, the manufacturing process is simple, convenient, low in cost, small in size and suitable for large-scale manufacturing and application.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

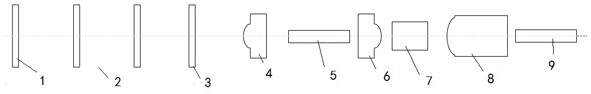

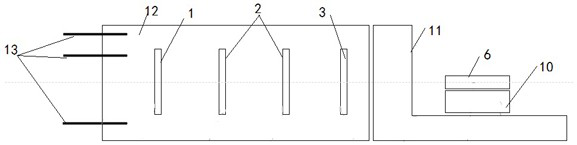

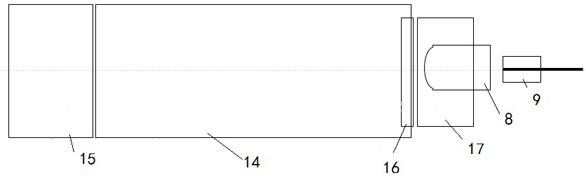

Wavelength tunable laser with low cost and low power consumption

PendingCN114583552AReduce lossEasy to processLaser optical resonator constructionAspheric lensDivergence angle

The invention relates to a wavelength tunable laser with low cost and low power consumption. The wavelength tunable laser comprises a reflector, an optical etalon, a phase controller, an aspheric lens A, a laser chip, an aspheric lens B, an optical isolator, a converging lens and an optical fiber which are sequentially arranged from left to right, the laser chip is an SLD chip, the left end face and the right end face of the laser chip are plated with an anti-reflection optical film and a partial reflection optical film respectively, and the partial reflection optical film away from the end face of the reflector and the reflector form a resonant cavity of the laser. The aspherical lens A and the aspherical lens B are used for shaping light beams with larger divergence angles into parallel light with smaller divergence angles; the optical etalon is used for wavelength selection and comprises two optical parallel plain films which are arranged at intervals, the optical parallel plain films are perpendicular to or form a certain angle with the optical axis of the laser, the two optical parallel plain films are different in thickness, and the left side face and the right side face of each optical parallel plain film are plated with high-reflection optical films. And a resistor containing an electrode is photoetched on the surface of the optical parallel plain film.

Owner:FUJIAN Z K LITECORE LTD

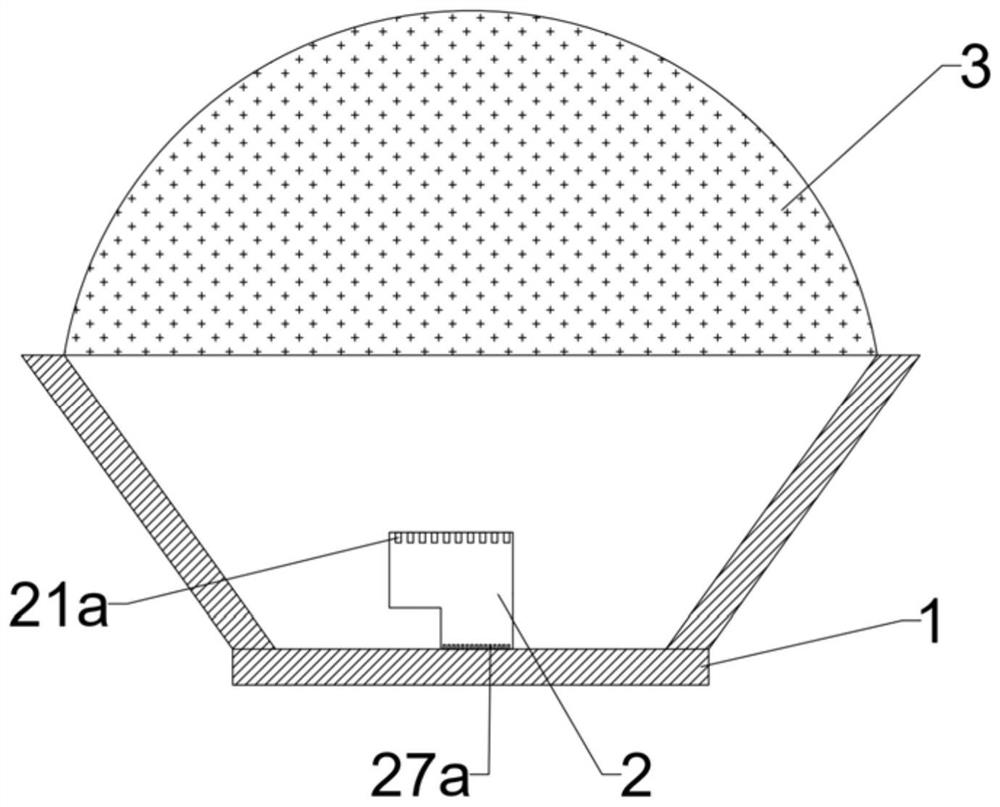

A flip-chip deep ultraviolet LED with a double-layer photonic crystal structure and its preparation method

ActiveCN111312877BIncrease light output powerBreaking the upper limit of light extraction efficiencyMaterial nanotechnologySemiconductor devicesPhotonic crystal structureUltraviolet

The invention discloses a flip-chip deep-ultraviolet LED with a double-layer photonic crystal structure and a preparation method thereof. The flip-chip deep-ultraviolet LED with a double-layer photonic crystal structure includes a bracket, a deep-ultraviolet LED chip and a lens, wherein: the lens is set On the top of the support, and the deep ultraviolet LED chip is located in the enclosed space surrounded by the support and the lens; the deep ultraviolet LED chip is arranged at the bottom of the support, and the deep ultraviolet LED chip is close to the support A first nano-array structure is provided on one side surface of the bottom, and a second nano-array structure is provided on a side surface of the deep ultraviolet LED chip away from the bottom of the bracket. The present invention sets the first nano-array structure on the P-type GaN contact layer of the deep-ultraviolet LED, and at the same time sets the second nano-array structure on the sapphire substrate, breaking the existing upper limit of light extraction efficiency and making the light output of the deep-ultraviolet LED The power has more than doubled.

Owner:SUZHOU UVCANTEK CO LTD

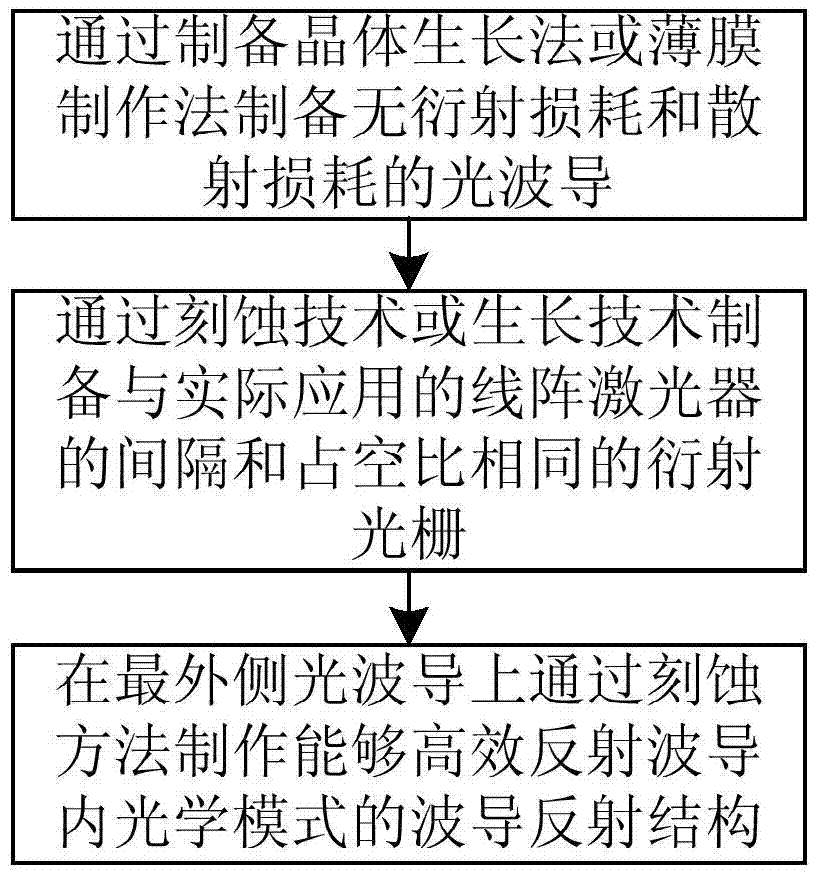

Linear array laser coherent mirror

The linear array laser coherent mirror and the preparation method thereof belong to the technical field of laser coherent coupling, aiming at solving the problems of poor coherence, poor stability, low power and high cost of the linear array laser existing in the prior art. The linear array laser coherent mirror of the present invention includes n diffraction gratings and n+1 optical waveguides which are connected alternately, and waveguide reflection structures are prepared on both sides of the structure formed by the diffraction gratings and optical waveguides. The preparation method of the linear array laser coherent mirror, firstly, the optical waveguide is prepared by the crystal growth method or the thin film manufacturing method; secondly, the optical waveguide prepared in step 1 is prepared by the growth method or the etching method and the actual application of the linear array laser. Diffraction gratings with the same interval and duty ratio; finally, a waveguide reflective structure that can efficiently reflect the optical mode in the waveguide is fabricated on the outermost optical waveguide by etching. The invention utilizes the diffraction grating to realize mutual injection and phase locking of photons, thereby realizing optical coherence, improving light brightness and narrowing line width.

Owner:吉光半导体科技有限公司

Optical fiber distributed type sound wave monitor system

ActiveCN103411660BImprove signal-to-noise ratioRealize Distributed Acoustic MonitoringSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansRayleigh scatteringLine width

Provided is an optical fiber distributed type sound wave monitor system. Narrow-linewidth frequency-modulated lasers output by a frequency modulation DFB fiber laser are used as the light source of the optical fiber distributed type sound wave monitor system, the lasers output by the frequency modulation DFB fiber laser enter an acoustic optical modulator and are modulated to be pulse lasers through the acoustic optical modulator, the pulse lasers pass through a first optical amplifier and a first optical filter and then enter a second circulator and sensor fibers, the pulse lasers per unit can emit rayleigh scattering light within the range of the passed sensor fibers per unit length, and signals output by the second circulator pass through a second optical amplifier to enter a second optical filter and output backscattering rayleigh signals. The backscattering rayleigh signals between different unit lengths on one sensor fiber are interfered with the method of an interferometer, the interfered signals pass through electrical signals output by a second photoelectric detector and enter the optical fiber distributed type sound wave monitor demodulation system though a phase carrier demodulation module, and the change analysis of the phases of the sensor signals at corresponding positions is achieved.

Owner:LASER RES INST OF SHANDONG ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com