Linear array laser coherent mirror

A linear array laser and optical waveguide technology, applied in the direction of lasers, laser components, phonon exciters, etc., can solve the problems of poor coherence, poor stability, and high cost of linear array lasers, and achieve high beam quality, high coherence efficiency, and The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

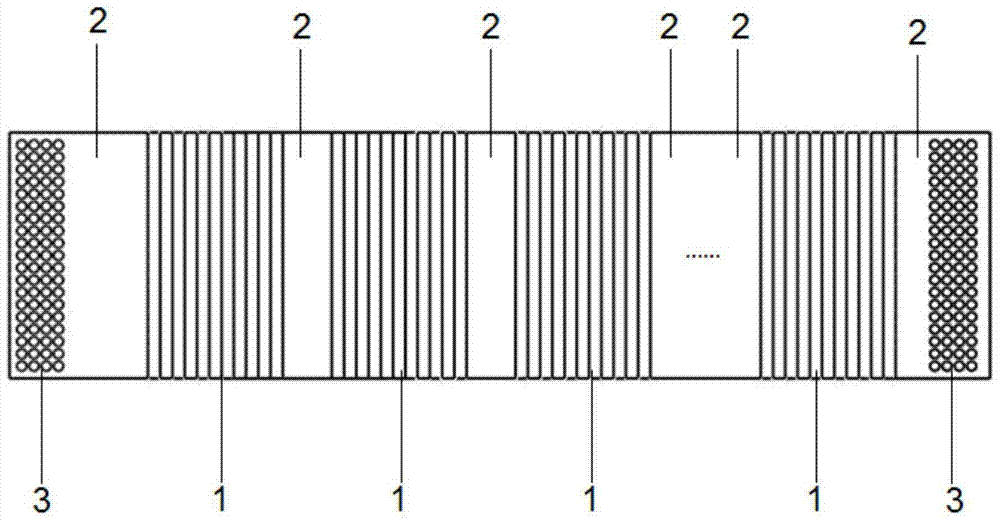

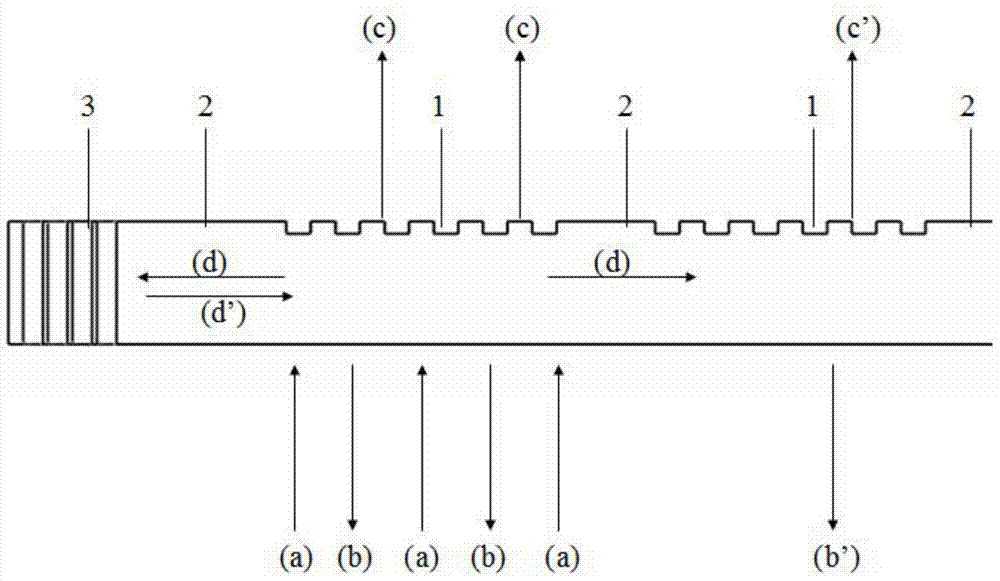

[0039] See attached figure 1 , the linear array laser coherent mirror of the present invention includes n diffraction gratings 1 and n+1 optical waveguides 2 that are alternately connected, and on both sides of the structure formed by the diffraction grating 1 and the optical waveguide 2, a waveguide reflection structure 3 is prepared; the diffraction grating 1 Diffraction can be performed on the laser light in the selected band, the optical waveguide 2 is above the cut-off frequency, and the optical mode transmission of the laser light in this band can be realized, and the waveguide reflection structure 3 can reflect the optical mode in the optical waveguide 2 .

[0040] The value range of n is: n≥1.

[0041] The diffraction grating 1 is grown or etched on the optical waveguide 2 .

[0042] The waveguide reflective structure 3 is an optical structure that can be used to reflect the optical modes transmitted in the optical waveguide 2 .

[0043] The waveguide reflection stru...

Embodiment 2

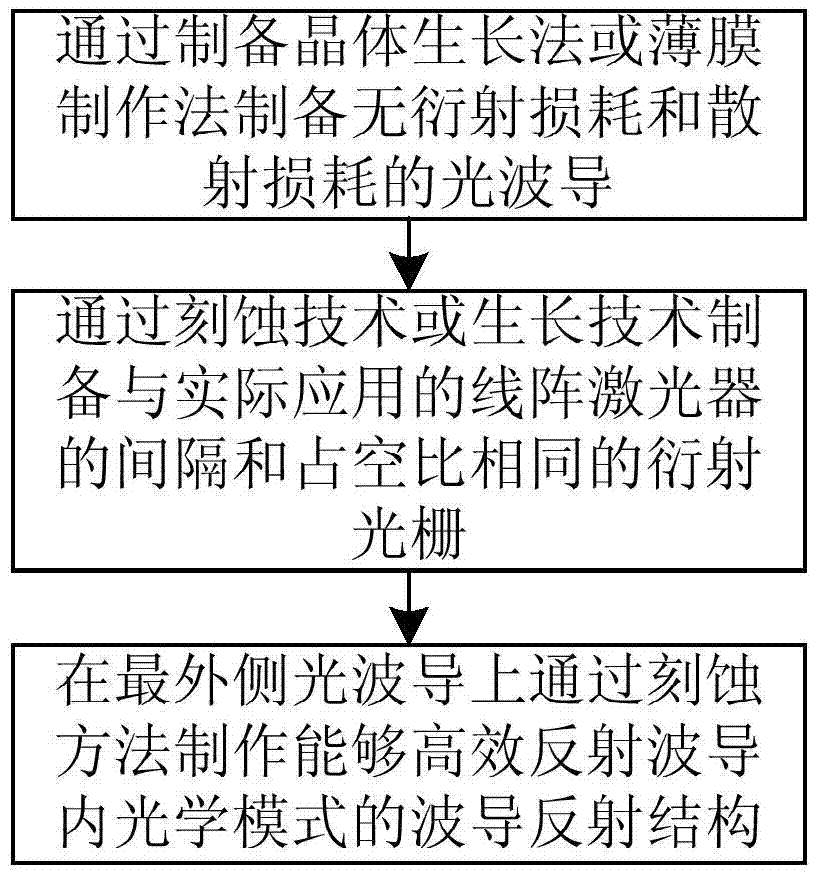

[0057] The difference between the present embodiment and the first embodiment is that, according to the actual process conditions, the order of the second step and the third step are interchanged. The preparation method obtained after the interchange comprises the following steps:

[0058] Step 1: For the wavelength band of the linear array laser used, select a transparent material in this band, and prepare the optical waveguide 2 without diffraction loss and scattering loss through the crystal growth method or thin film manufacturing method. The size and structure of the optical waveguide 2 should make its own The cutoff frequency is smaller than the selected band;

[0059] Step 2: Designate the position where the diffraction grating (1) needs to be fabricated and the position of the optical waveguide (2) connected to it, and fabricate a waveguide reflector that can reflect the optical mode in the waveguide by etching on the outermost optical waveguide 2 Structure 3;

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com