Laser welding method

A technology of laser welding and laser welding machine, applied in laser welding equipment, welding equipment, welding equipment and other directions, can solve the problem of not easy to ablate solder joints, and achieve the effect of avoiding welding errors, shortening welding time, and fast welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose, technical solutions and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and implementation examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

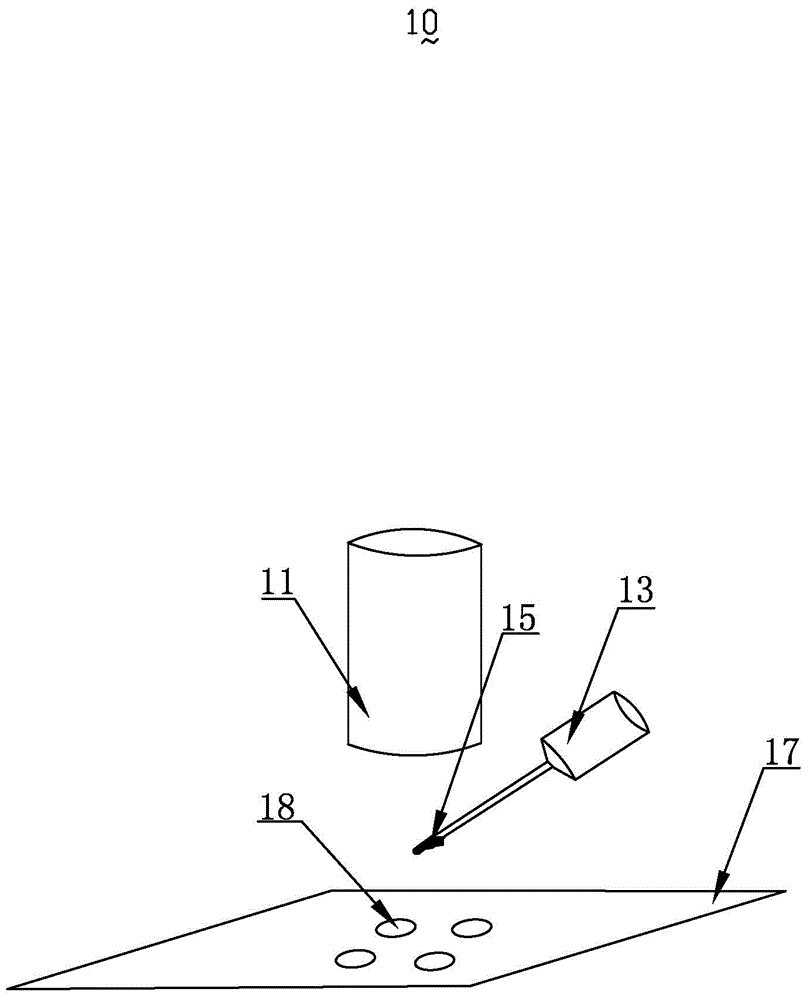

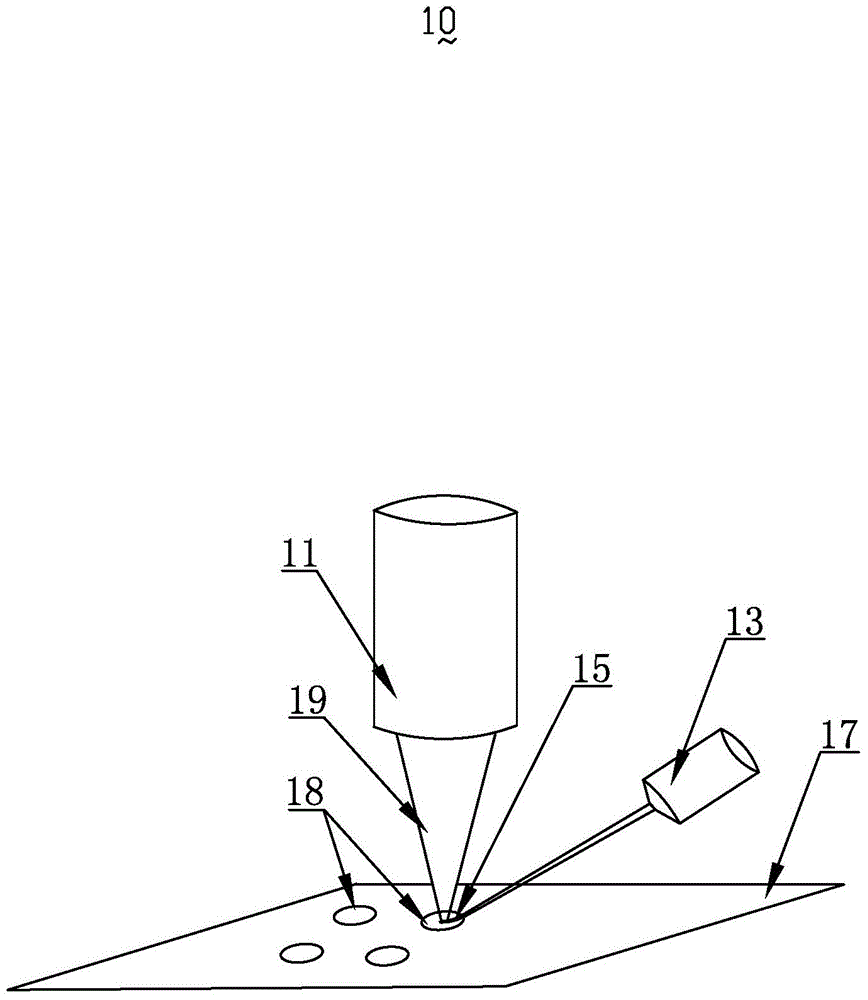

[0033] see figure 2 In the laser welding method of the present invention, a circuit board 17 and a laser welding machine 10 need to be provided. There are one or more pads 18 to be soldered on the circuit board 17 , where the melted solder forms solder joints to complete the soldering of the pads 18 . The laser welding machine 10 (partial structure is not shown) that is positioned at the top of the circuit board 17 is used to realize the fast welding of the pad 18. The laser welding machine 10 includes a focusing head 11 and a tin feeding head 13. The focusing head 11 is laser we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com