Automotive lamp product and welding method thereof

A technology for car lights and products, applied in welding equipment, laser welding equipment, motor vehicles, etc., can solve problems such as inconvenient driving, poor absorption of laser beams, and inability to fully melt the melting layer, so as to enhance adhesion and prevent falling off , Enhance the effect of laser absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It should be noted that, in the case of no conflict, the following technical solutions and technical features can be combined with each other.

[0027] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

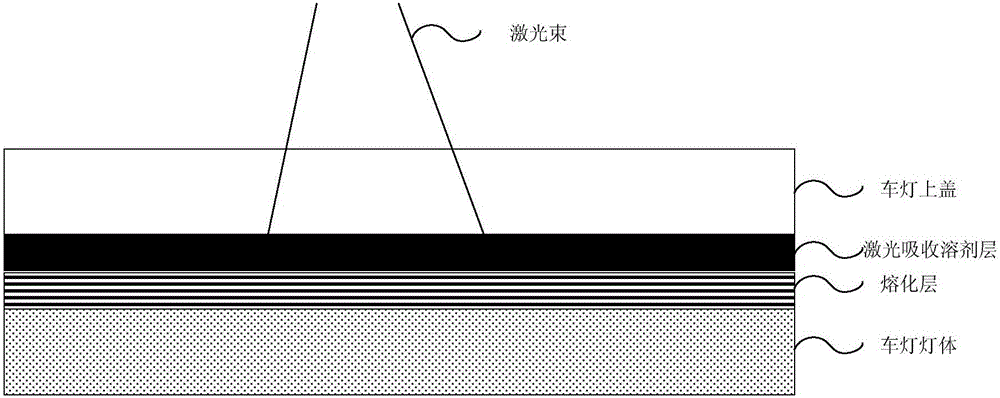

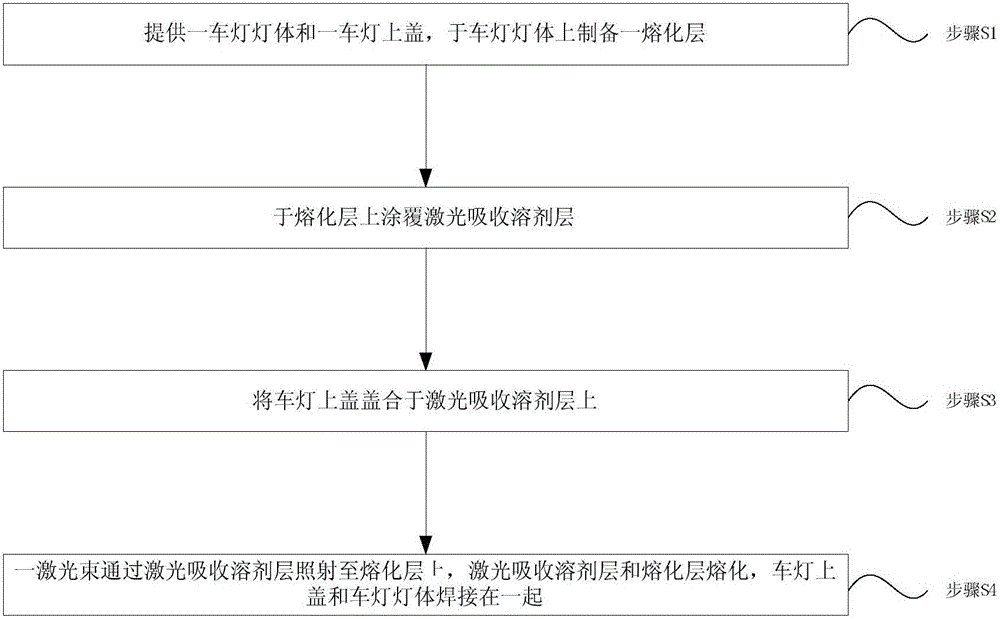

[0028] This embodiment provides a car lamp product, which is prepared by laser welding process, such as figure 1 shown, including:

[0029] The lamp upper cover and the lamp body, and the melting layer between the lamp upper cover and the lamp body;

[0030] Wherein, a laser absorbing solvent layer is coated on the melting layer, and the laser absorbing rate of the laser absorbing solvent layer is greater than that of the melting layer.

[0031] In the laser welding process, a laser device emits a laser beam, and the laser beam is irradiated onto the melting layer through the laser-absorbing solvent layer, so that the laser-absorbing solvent layer and the melting layer are melted to realize the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com