Graphene modified laser absorption layer coating and coating method thereof

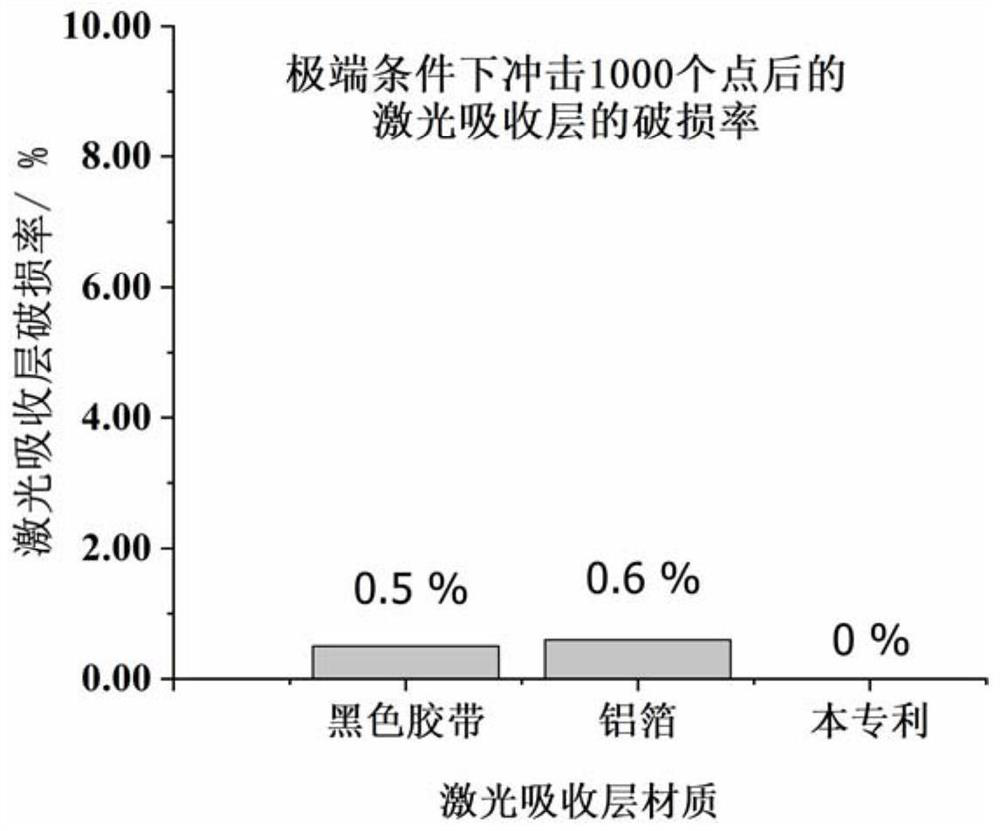

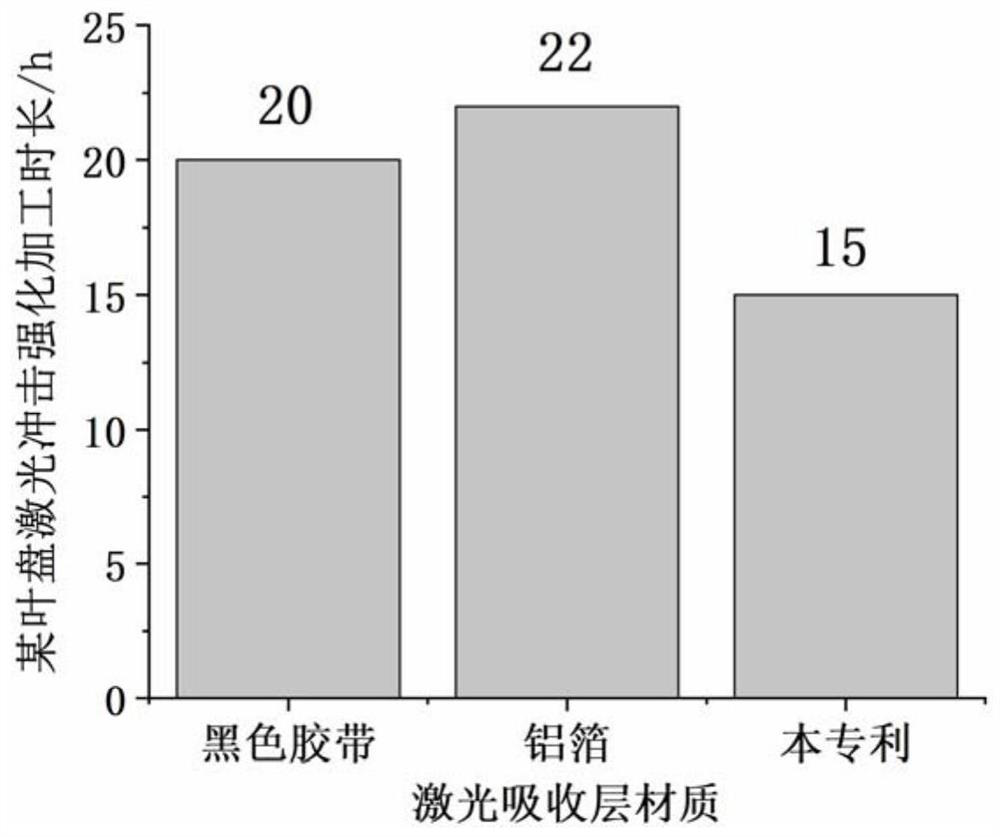

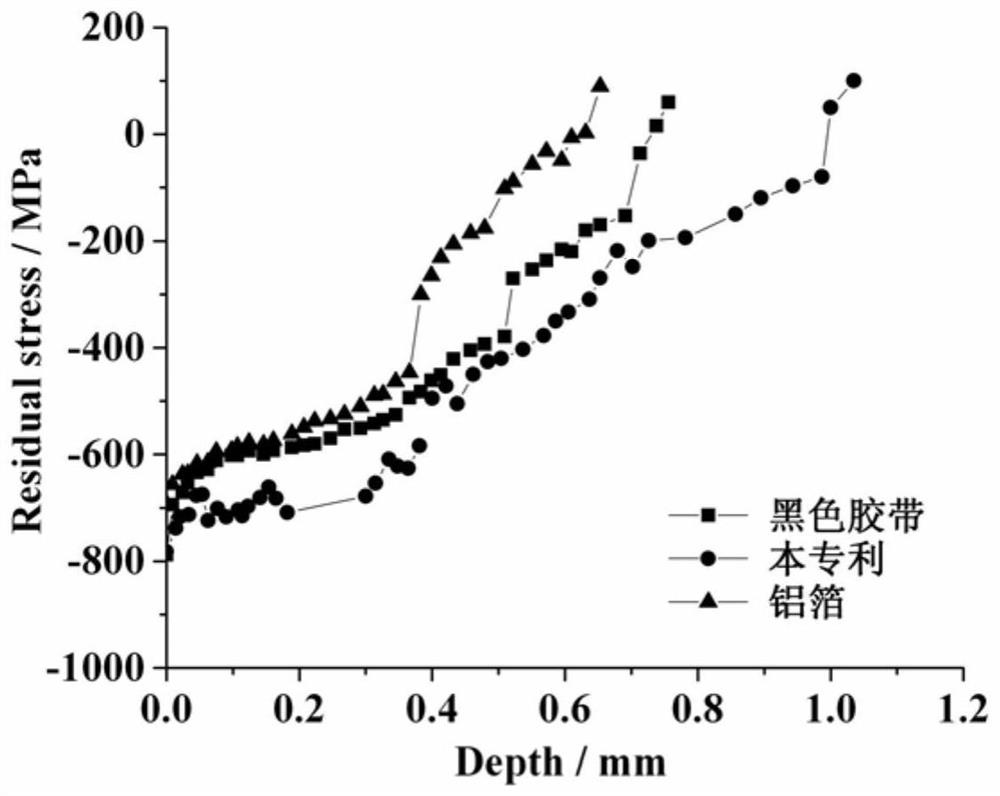

A graphene modification and laser absorption technology, which is applied in the field of surface treatment of parts, can solve problems such as low efficiency, poor quality uniformity, and poor coating quality of laser absorption layers, so as to reduce damage rate and improve laser burn resistance Erosion ability, the effect of improving the utilization rate of laser energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The invention discloses a graphene-modified laser absorbing layer coating, which is mainly composed of polyurethane resin, black auxiliary material, functional auxiliary agent and deionized water. Wherein, polyurethane resin (50%), black auxiliary material (20%), functional auxiliary agent (10%) and deionized water (20%) are all percentages by mass; polyurethane resin is an aqueous emulsion with a solid content of 10% (mass percentage); black auxiliary material is the carbon black that comprises graphene powder, and the content of graphene is 1.0% (mass percentage); Functional auxiliary agent is sodium stearate.

[0038] The coating method of the laser absorbing layer coating of this graphene modification, the step of coating is as follows:

[0039] (1) Part surface cleaning: use alcohol ultrasonic cleaning to clean the surface of the part to be strengthened by laser shock;

[0040] (2) Coating preparation: Add graphene powder into deionized water to form graphene slur...

Embodiment 2

[0044] The contents of polyurethane resin, black auxiliary material, functional auxiliary agent and deionized water of the coating are X, Y, Z and R respectively, wherein X=70%, Y=15%, Z=10%, R=5% , both are mass percentages. In addition, the polyurethane resin is an aqueous emulsion with a solid content of 60% (mass percentage); the black auxiliary material is black iron oxide containing water-based graphene slurry, and the content of graphene is 5.0% (mass percentage);

[0045] The coating method of the laser absorbing layer coating of this graphene modification, the step of coating is as follows:

[0046] (1) Part surface cleaning: Use alcohol dipped in gauze to wipe the surface of the part to be laser shock strengthened;

[0047] (2) Coating preparation: add the water-based graphene slurry into deionized water to form a graphene slurry, then ultrasonically disperse iron oxide black in the graphene slurry, and then add the mixed slurry into the water-based polyurethane res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com