Patents

Literature

32results about How to "Good quality and reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

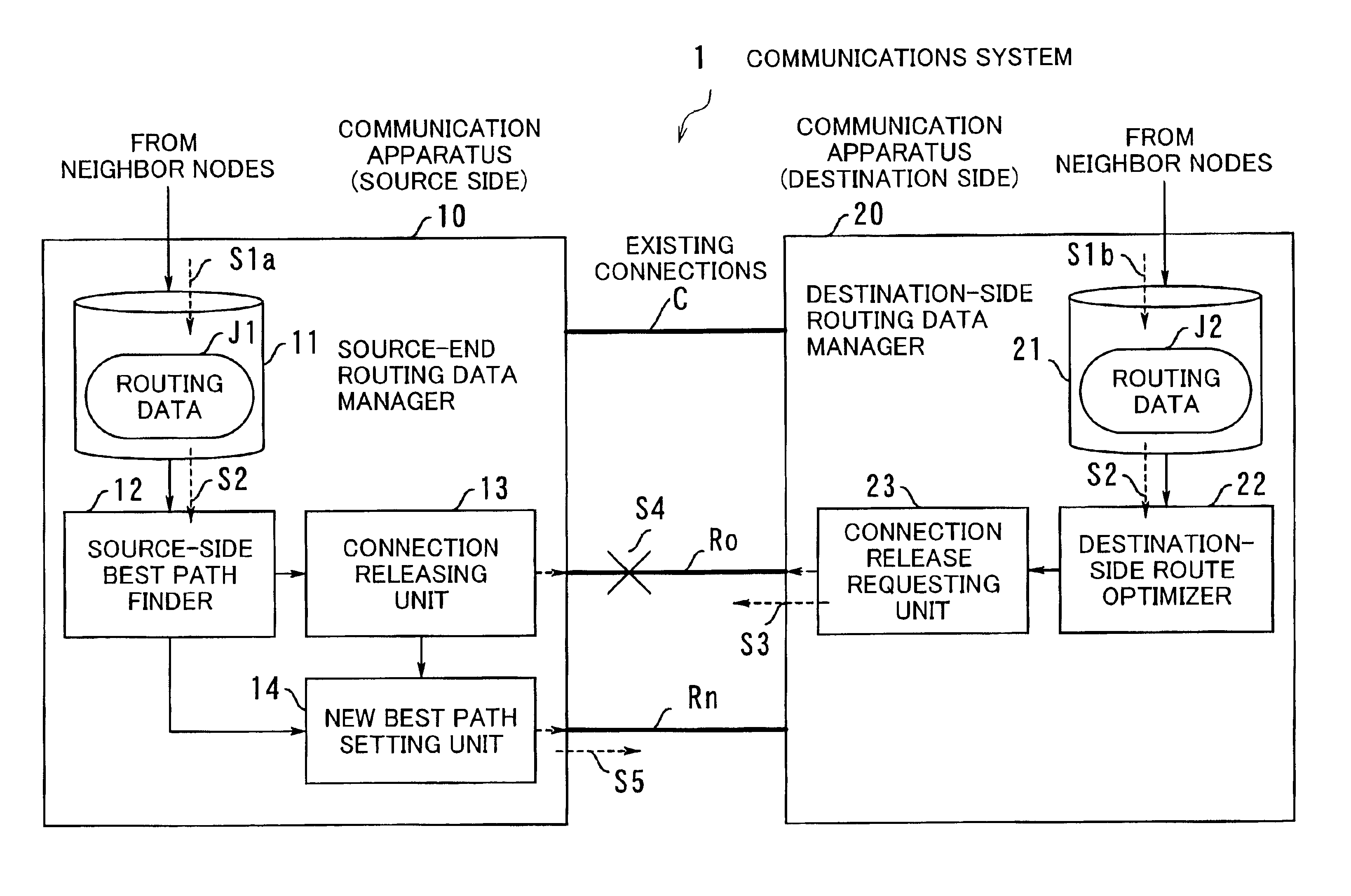

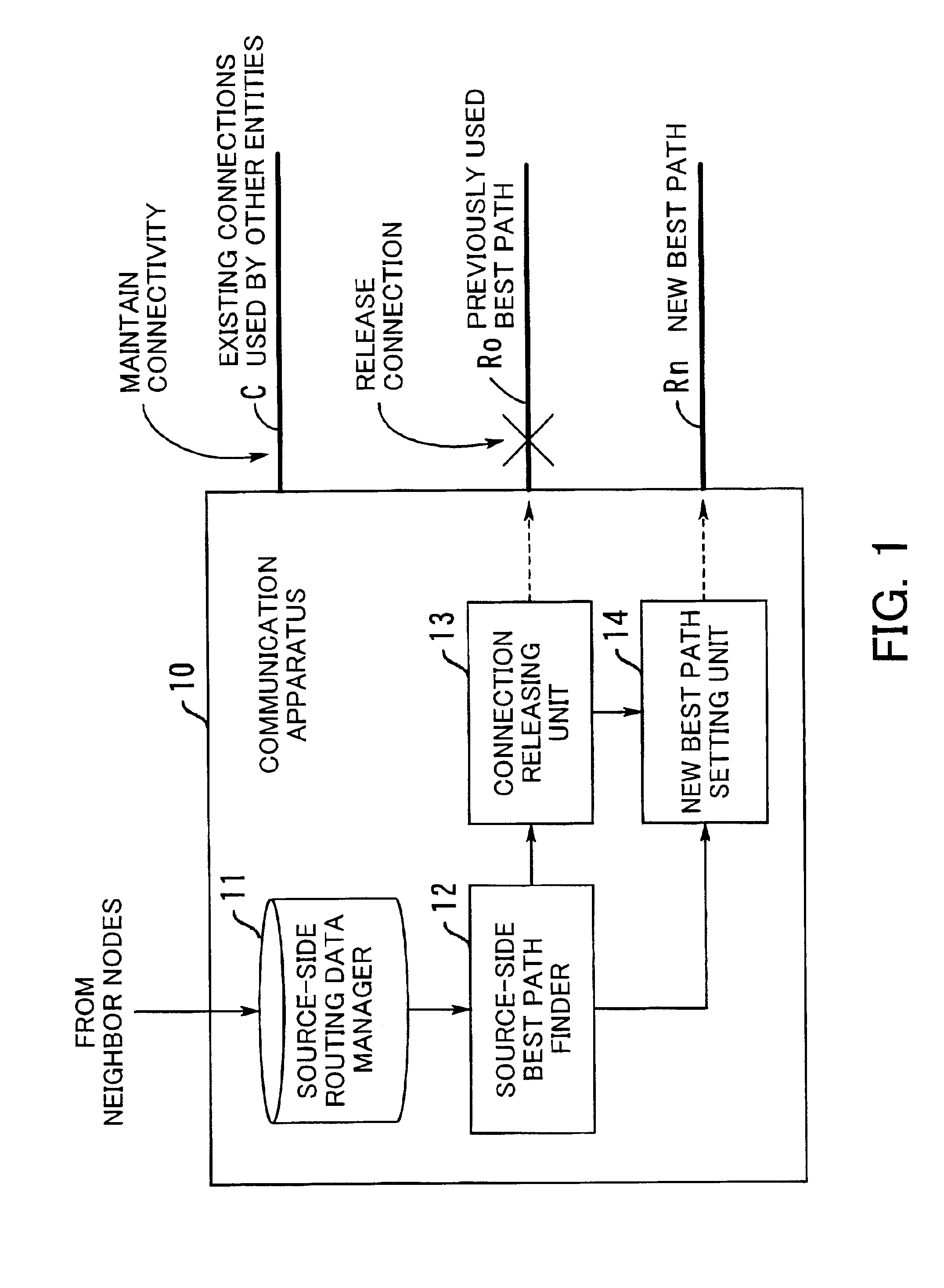

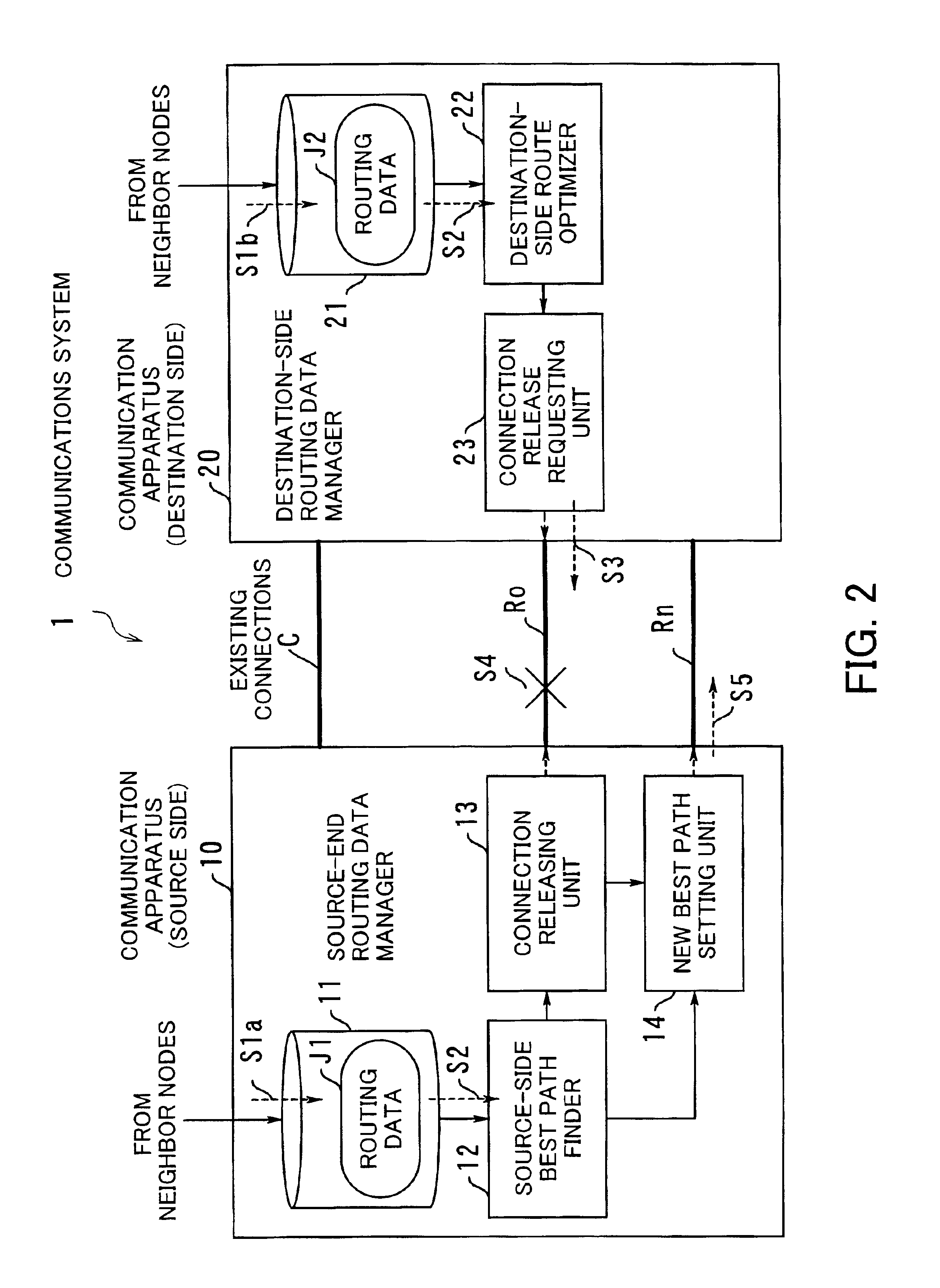

Communication apparatus with selective route optimization capabilities

InactiveUS6922394B2Good quality and reliabilityOptimize connectionError preventionTransmission systemsTelecommunications serviceAdverse effect

A communication apparatus which effectively optimizes the route for each call connection without causing any adverse effect on other existing sessions and thus contributes to better quality and reliability of telecommunications services. A source-side routing data manager collects information necessary for path calculation, evaluates every possible path with the collected information, and manages routing data that is obtained through the path evaluation. A source-side best path finder selects a best path from among those listed in the routing data. A connection releasing unit releases a particular connection when the source-side best path finder has found a new best path that is more suitable for that particular connection than the current path, while maintaining the connectivity of other existing calls. A new best path setting unit performs a call connection procedure by using the newly selected best path, after the connection releasing unit has released the current connection.

Owner:FUJITSU LTD

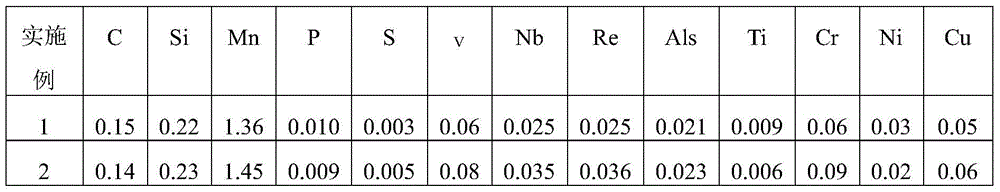

Low-temperature resistant low-alloy structural steel and preparation method thereof

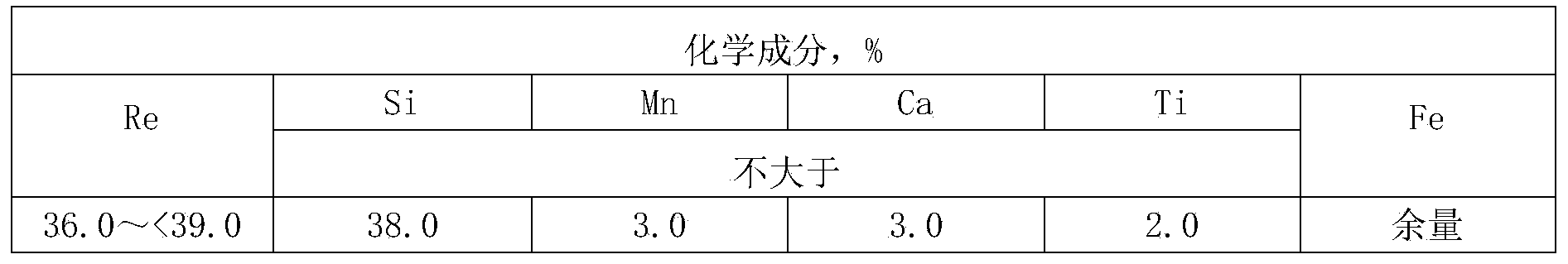

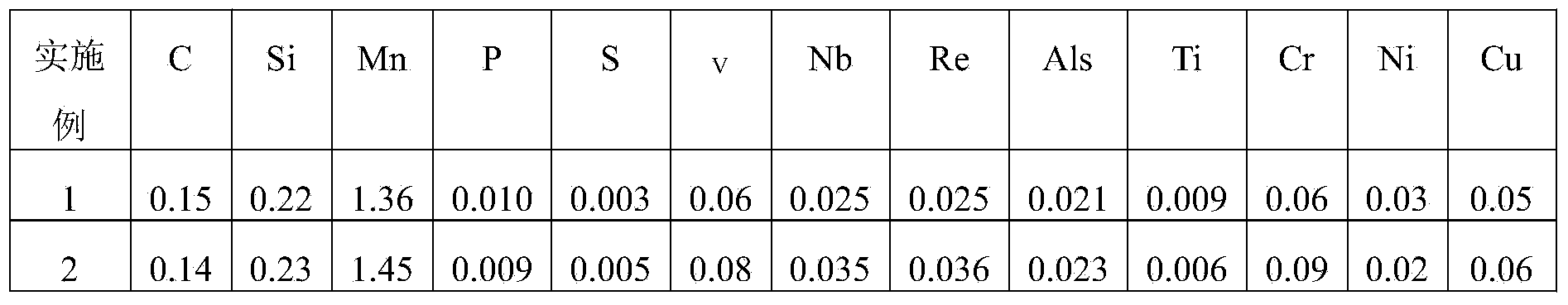

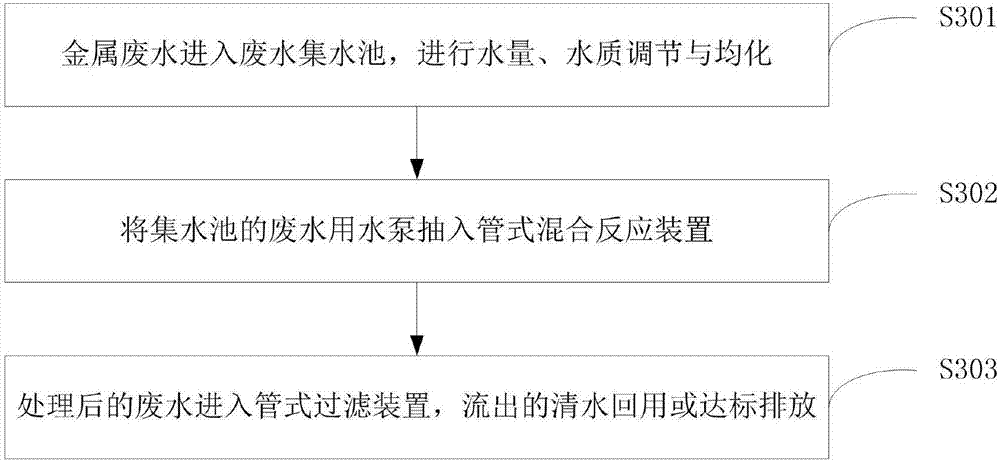

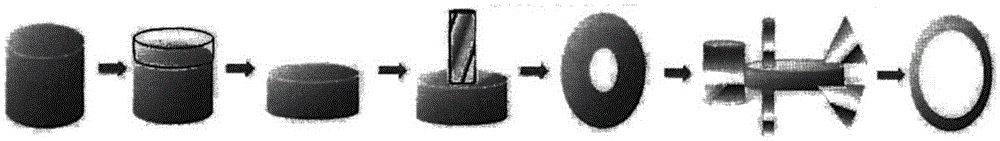

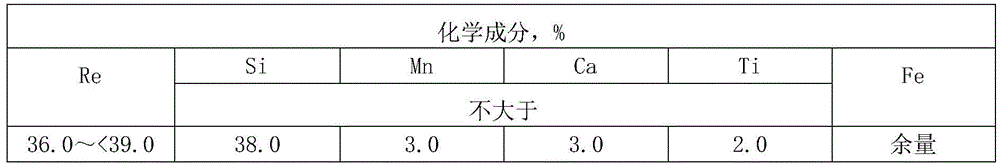

The invention discloses low-temperature resistant low-alloy structural steel. The low-temperature resistant low-alloy structural steel comprises the following ingredients in percentage by mass: 0.13-0.20% of C, 0.15-0.55% of Si, 1.00-1.75% of Mn, not higher than 0.015 of P, not higher than 0.005 of S, 0.02-0.12% of V, 0.015-0.050% of Nb, 0.010-0.035% of Als, 0.020-0.050% of Re, not higher than 0.010% of Ti, not higher than 0.35% of Cr, not higher than 0.55% of Ni, not higher than 0.15% of Cu, not higher than 0.020% of As, not higher than 0.020% of Sn, not higher than 0.0025% of Pb, not higher than 0.025% of Sb, not higher than 0.005% of Bi, not higher than 15ppm of [O], not higher than 2.0ppm of [H] and the balance of Fe and unavoidable impurities. A wind power generator tower tube flange, which is manufactured through forging a steel billet prepared from the steel, has the advantages that the mechanical properties are stable, the low-temperature impact property is excellent, and the internal quality is excellent.

Owner:LAIWU IRON & STEEL GRP

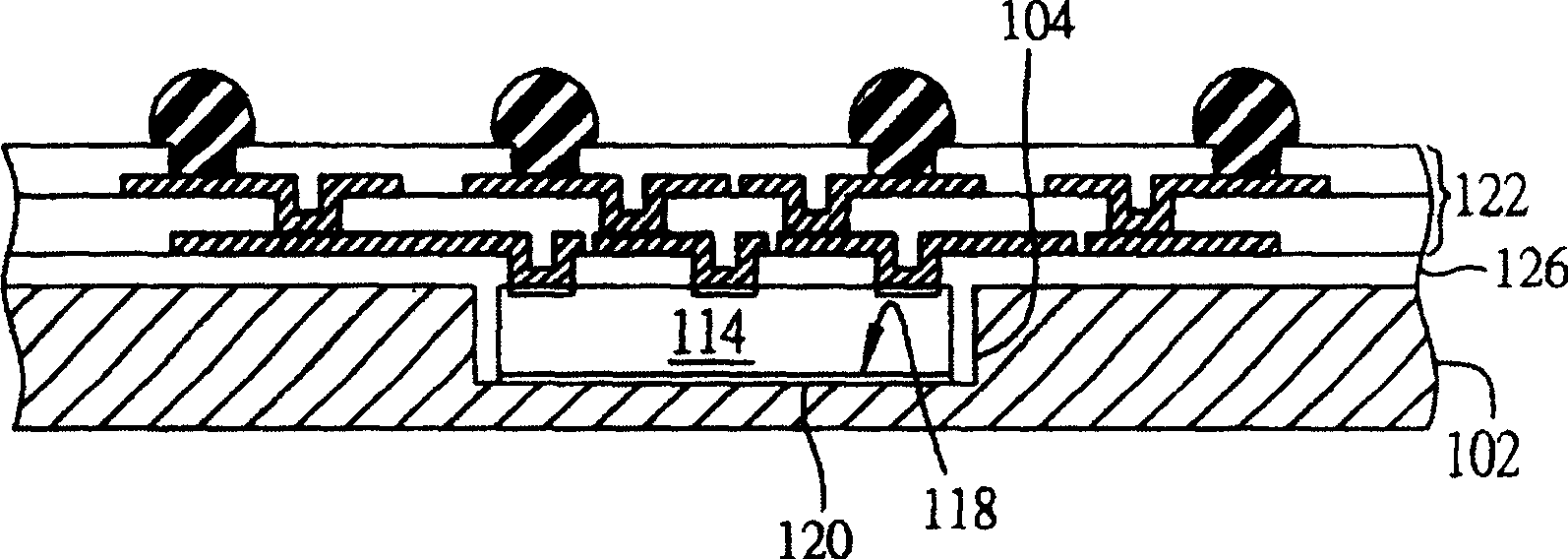

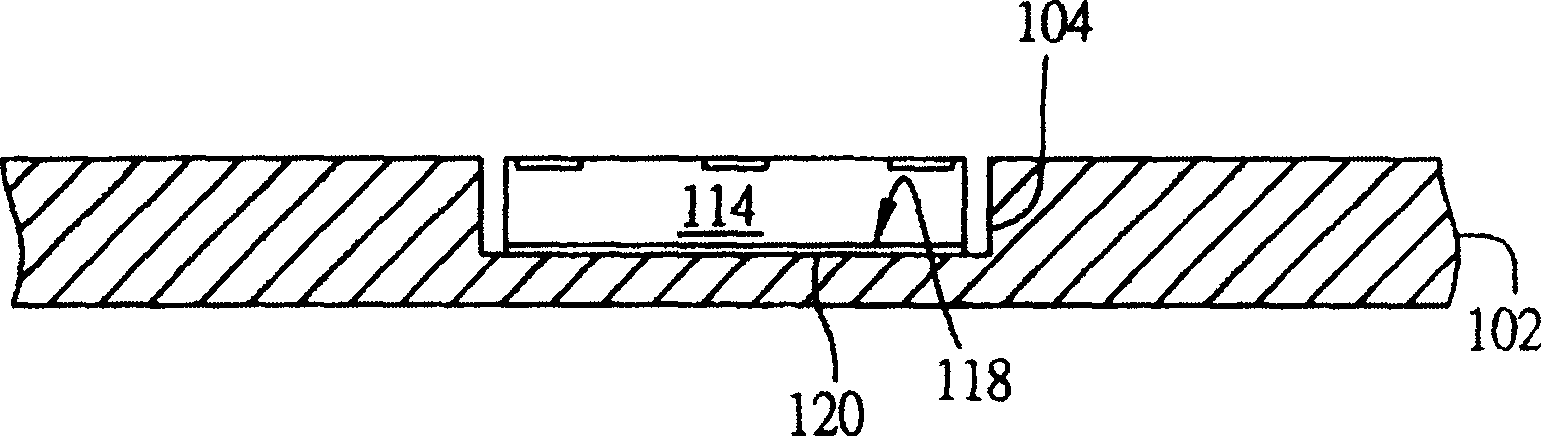

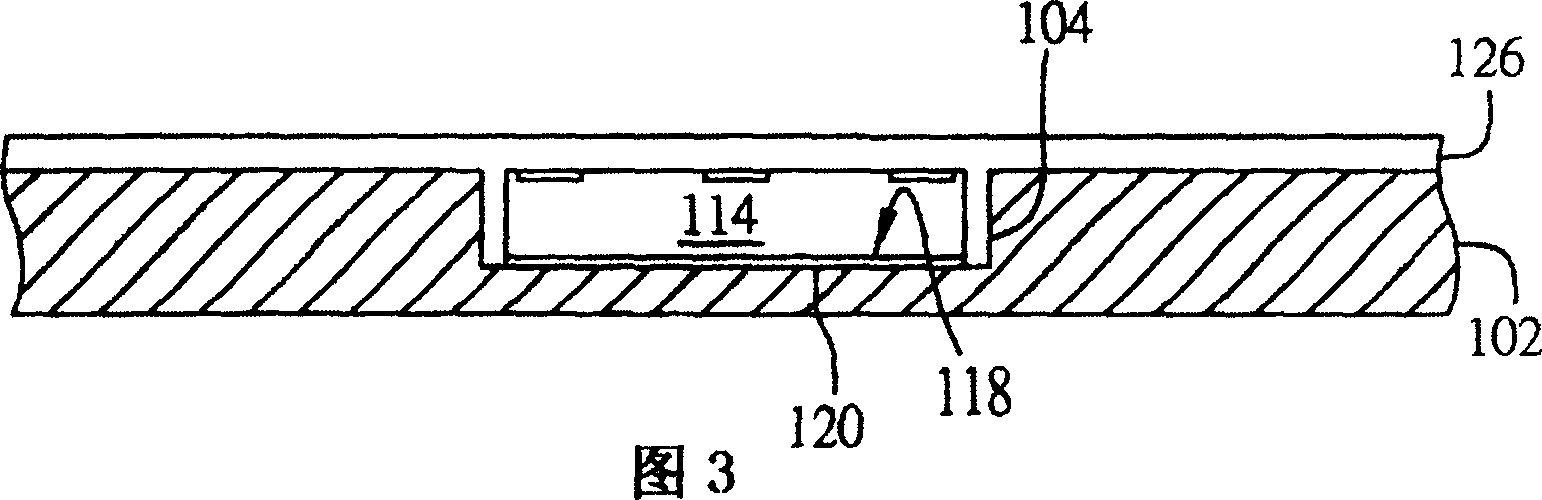

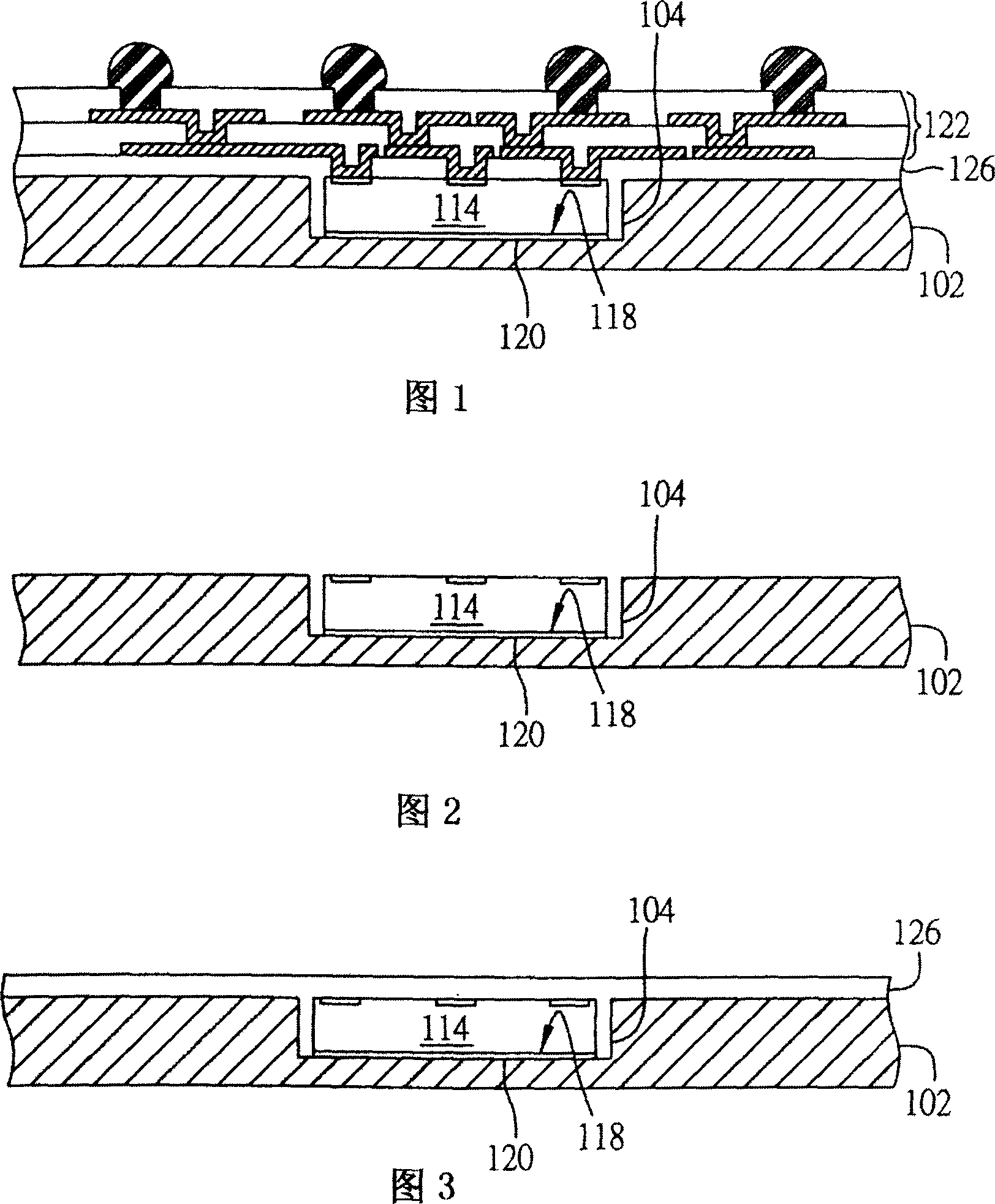

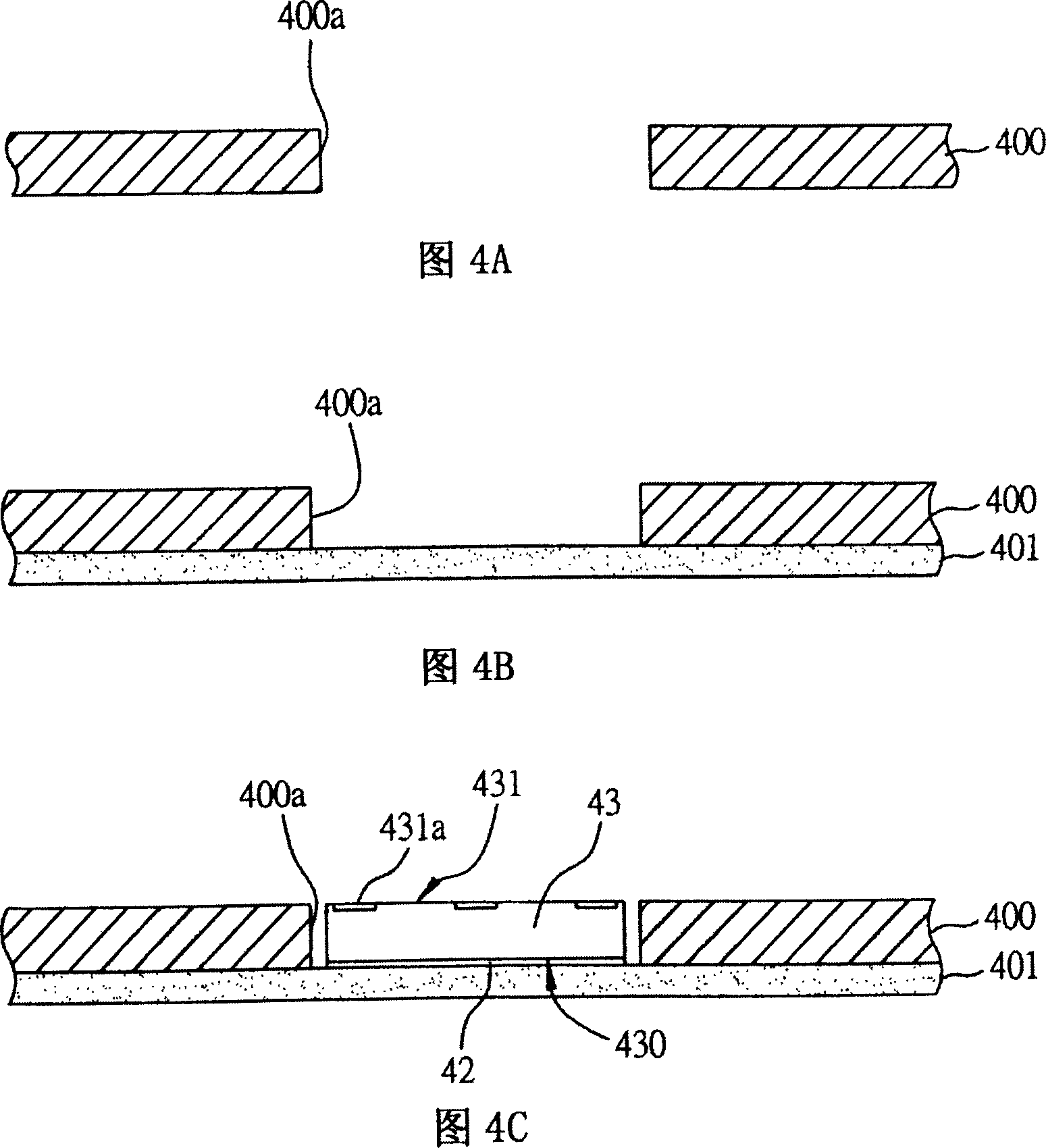

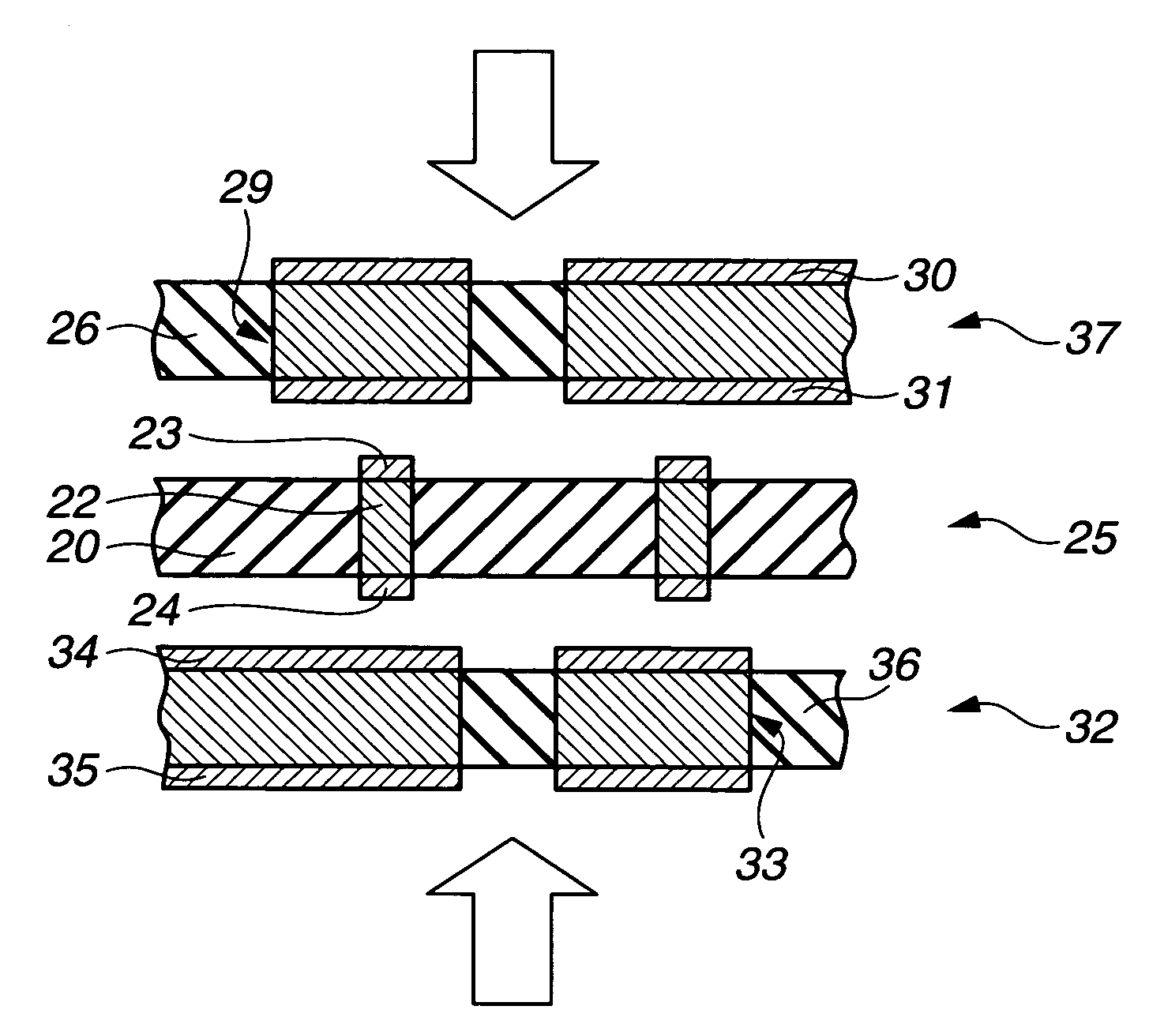

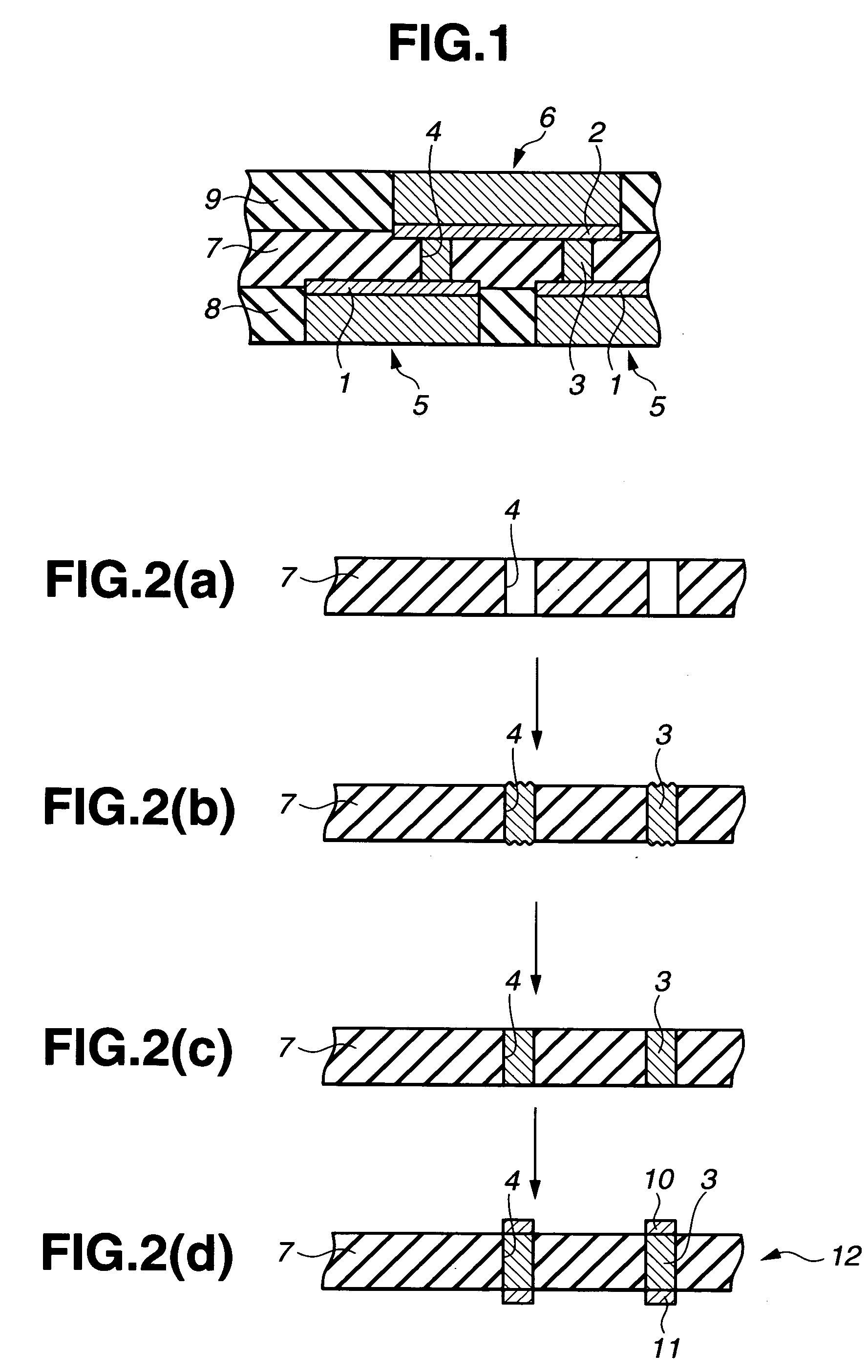

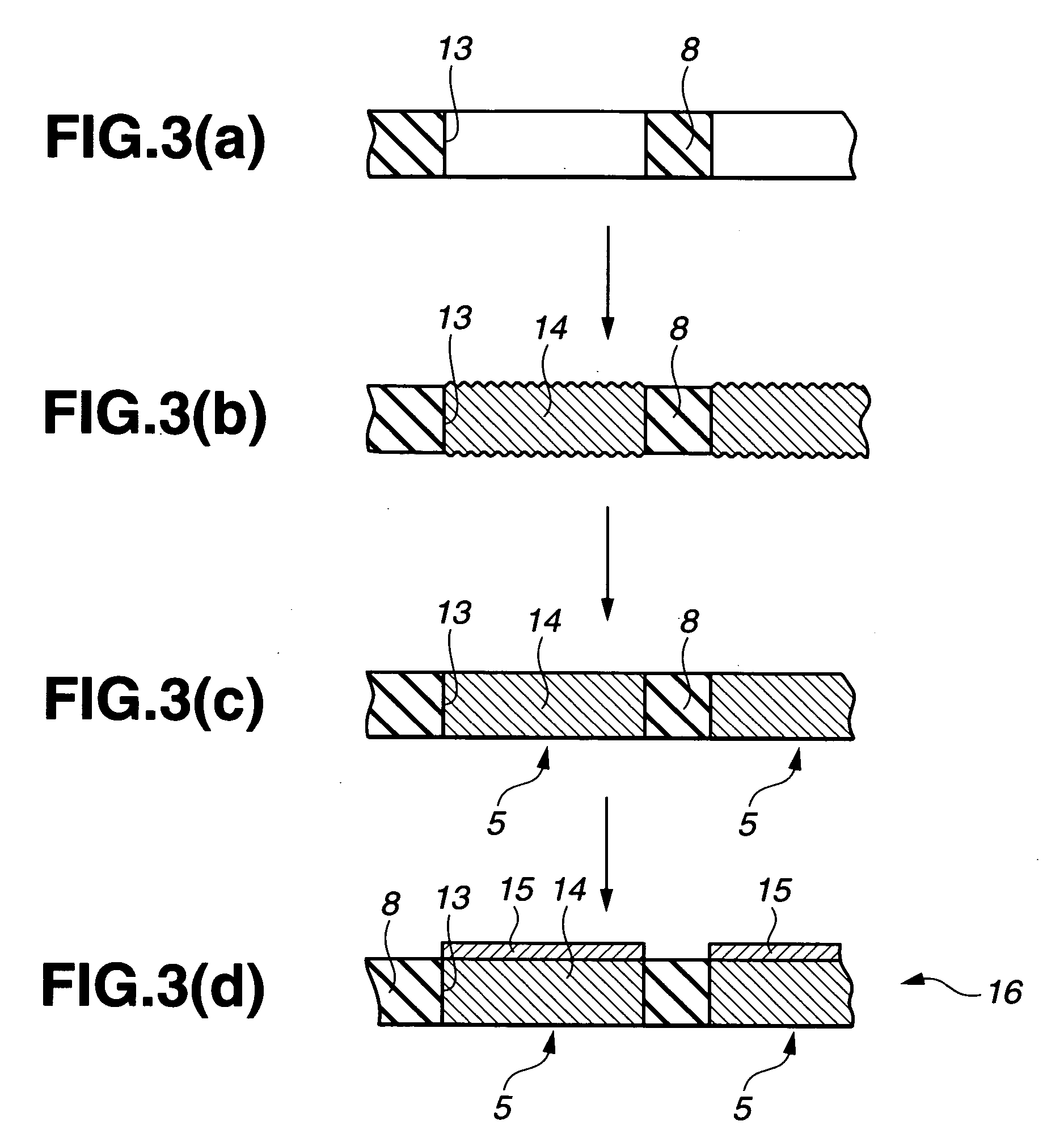

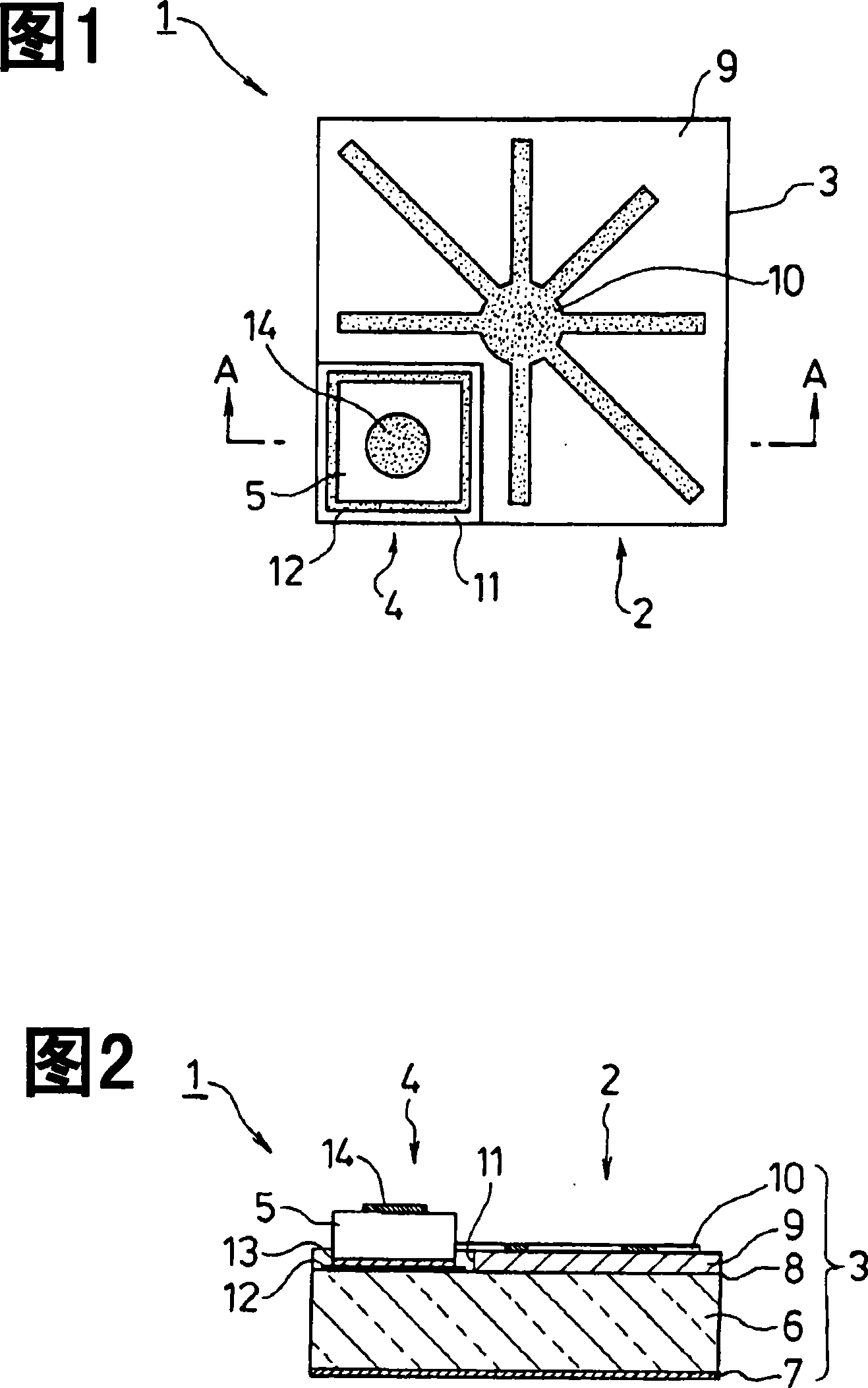

Semiconductor chip buried base plate 3D construction and its manufacturing method

ActiveCN100463128CWon't pushEasy to pushSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorInsulation layer

This invention relates to semiconductor chip imbed baseboard three dimensional seal structure and its process method, which comprises the following steps: connecting load parts with at least one hole to first insulation layer and at least one conductor chip onto first insulation contained in the load holes; then forming second insulation layer onto load part and chips for adhesion and filling insulation resin into gap between load board and chip to form electricity connection to chip circuit layer; forming chip dissipation blind hole on first insulation layer to aid semiconductor chip to dissipate heat outside.

Owner:PHOENIX PRECISION TECH CORP

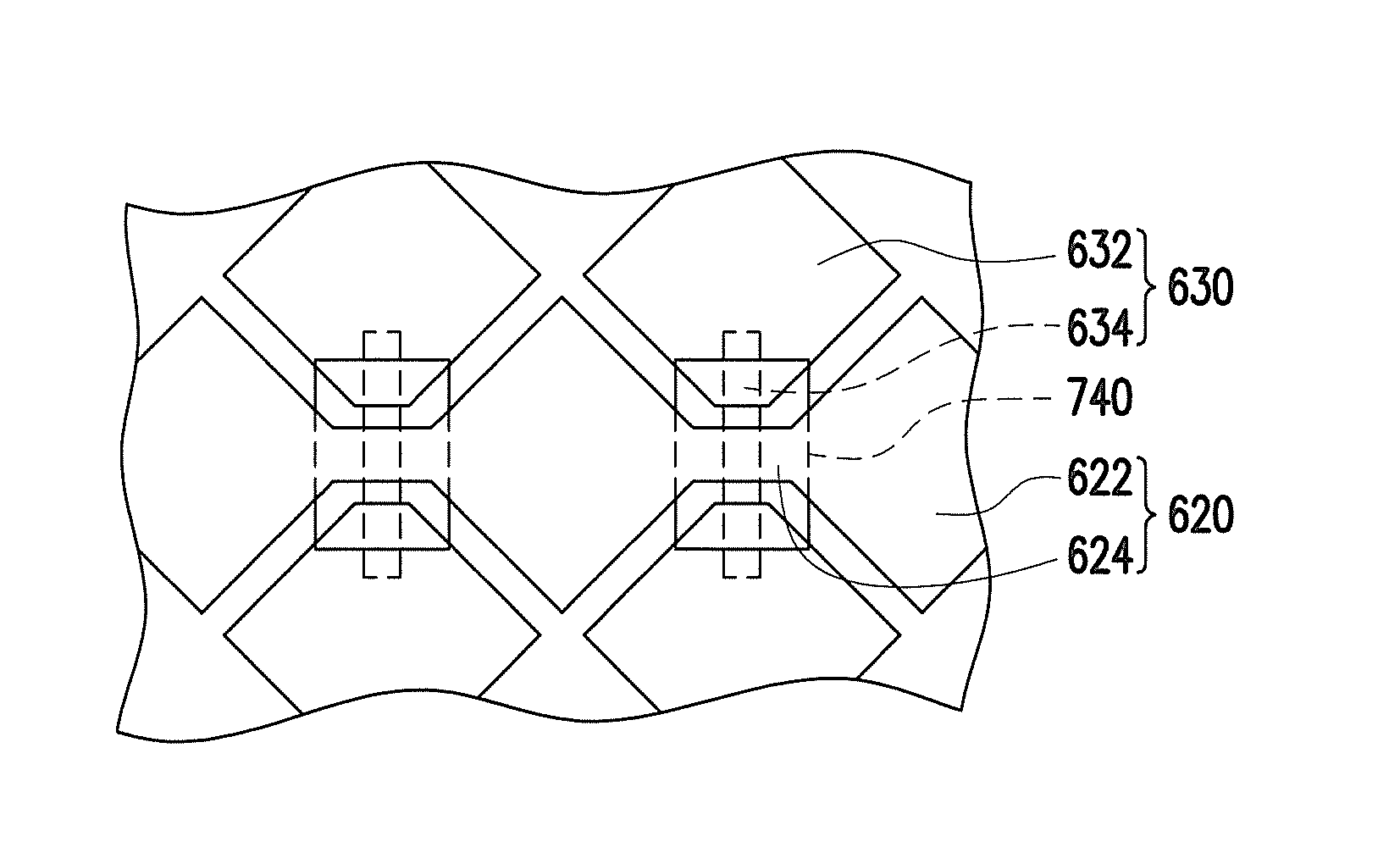

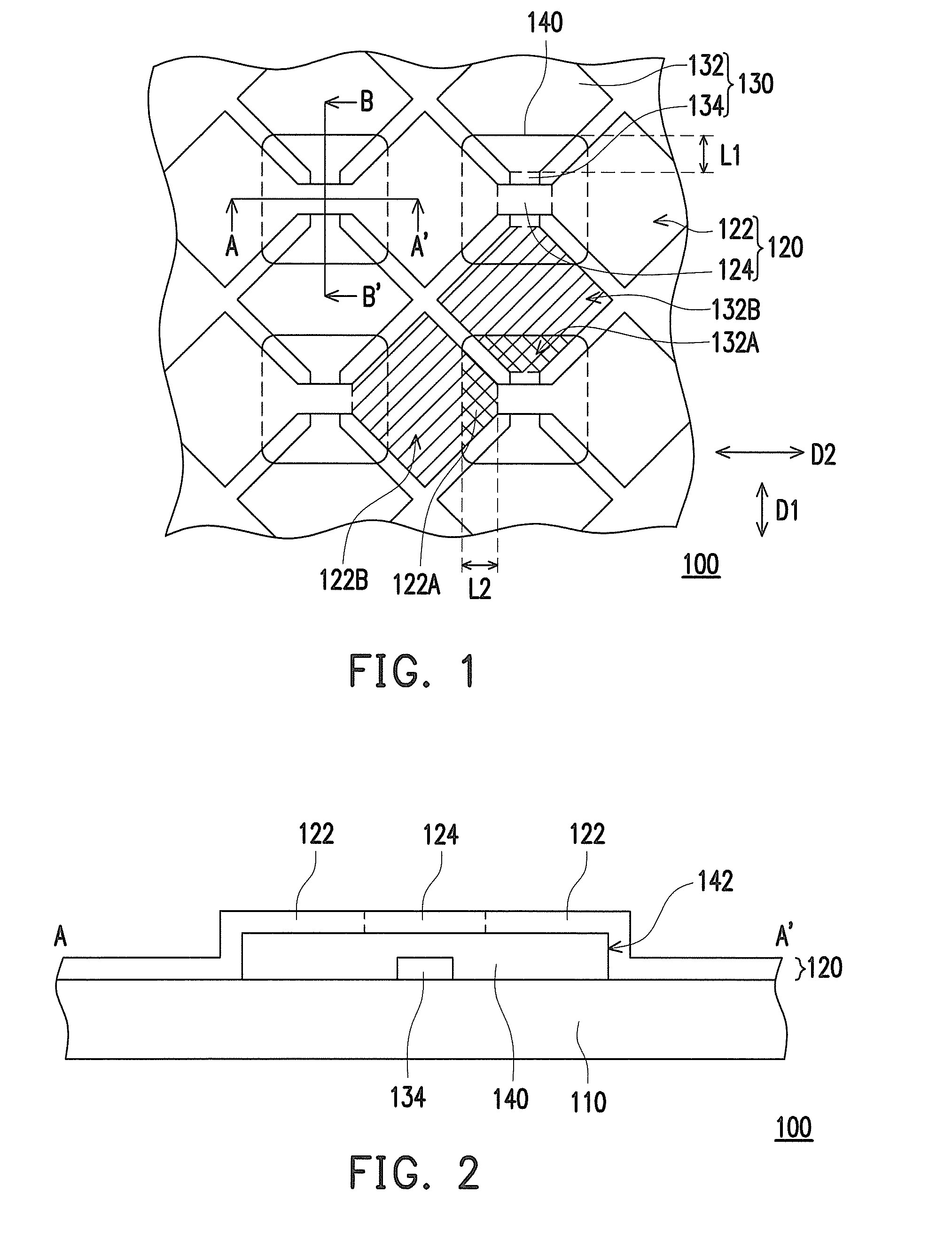

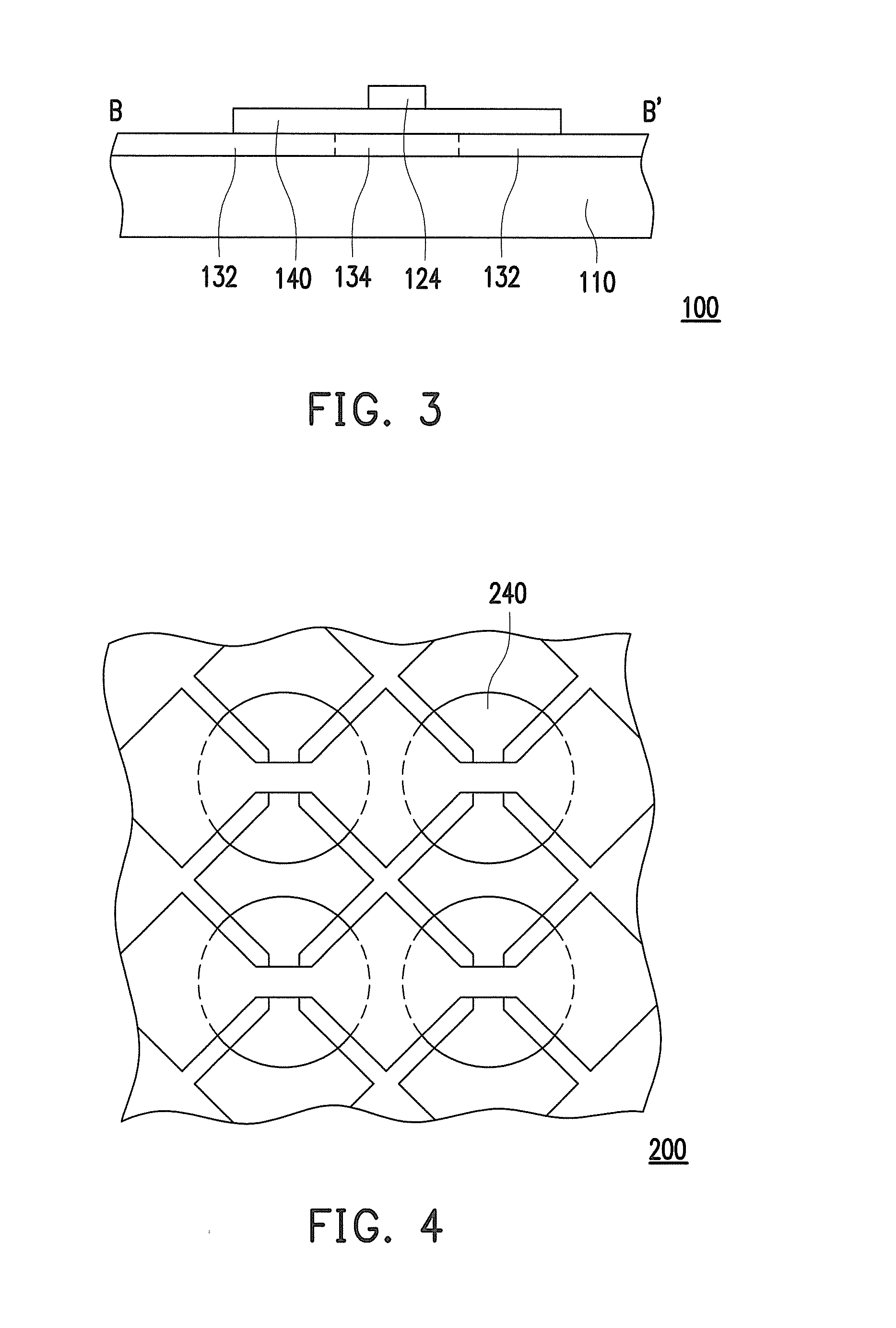

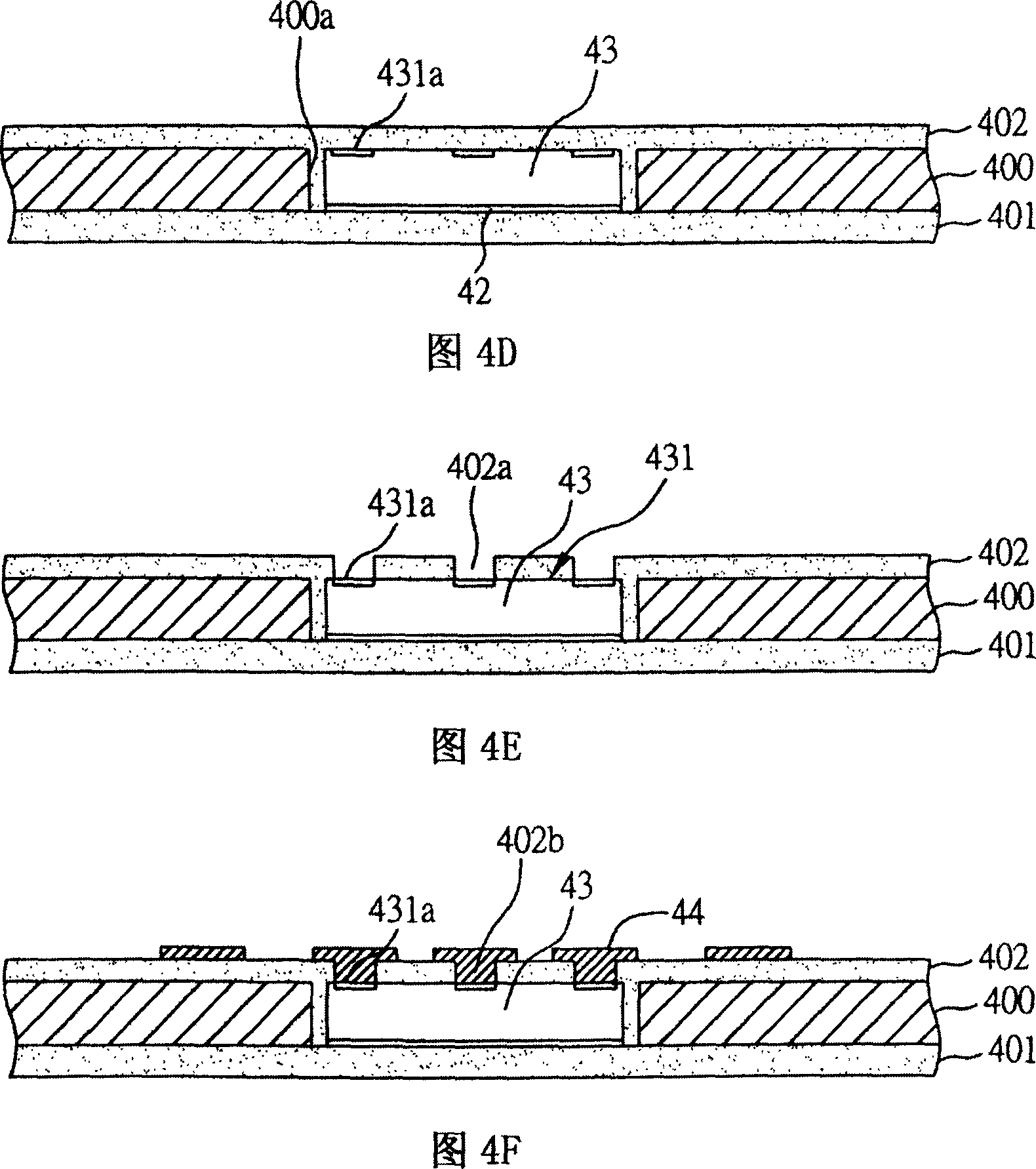

Touch panel

InactiveUS20150034472A1Quality improvementImprove reliabilityElectronic switchingElectric switchesEngineeringTouch panel

A touch panel includes a substrate, first conductive series, second conductive series, and insulation patterns. Each of the first conductive series includes first conductive patterns arranged in a first direction and first narrow portions, and each first narrow portion is connected to two adjacent first conductive patterns. The second conductive series are insulated from the first conductive series. Each of the second conductive series extends in a second direction and includes a plurality of intersections intersected with the first narrow portions. The insulation patterns are located between the first narrow portions and the intersections, so that one of the first narrow portions and a respective one of the intersections intersected with the one of the first narrow portions are separate. An edge of each of the insulation patterns and one of the first conductive patterns of each of the first conductive series partially overlap.

Owner:WINTEK CORP

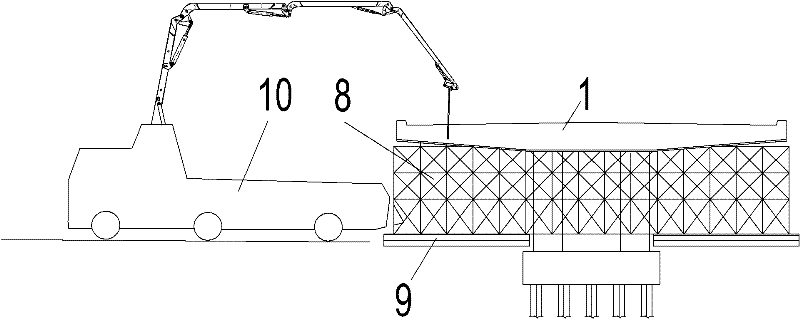

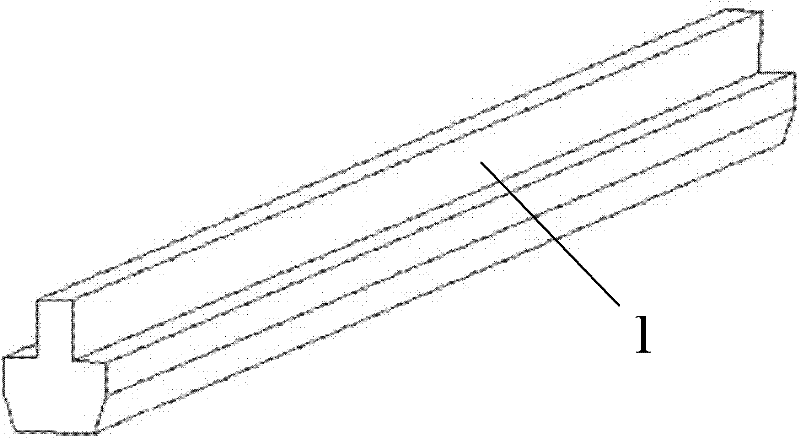

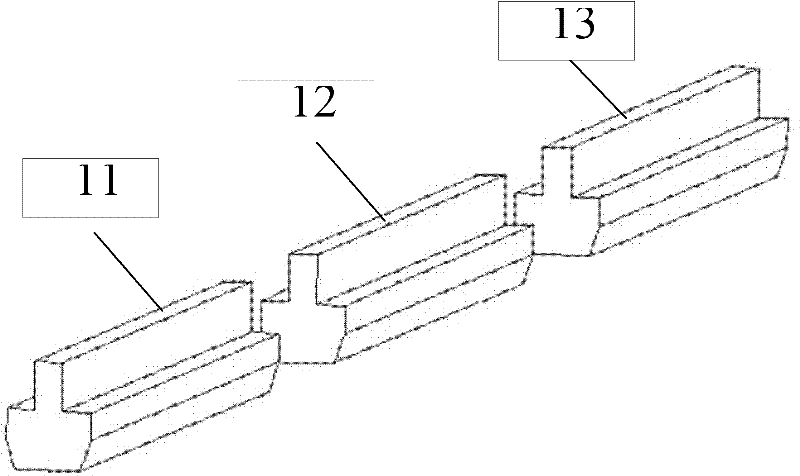

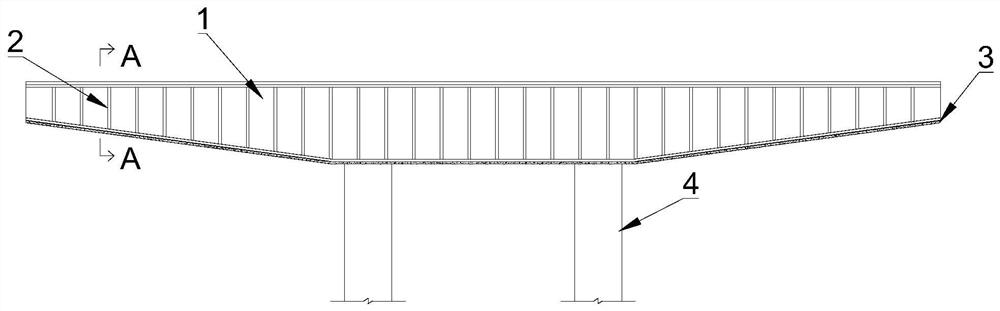

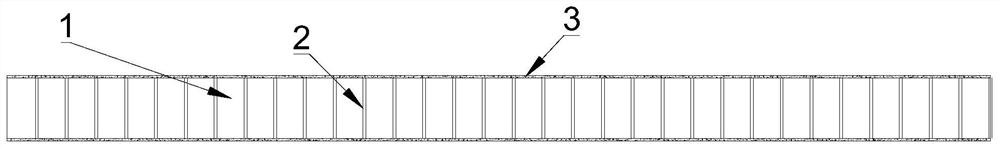

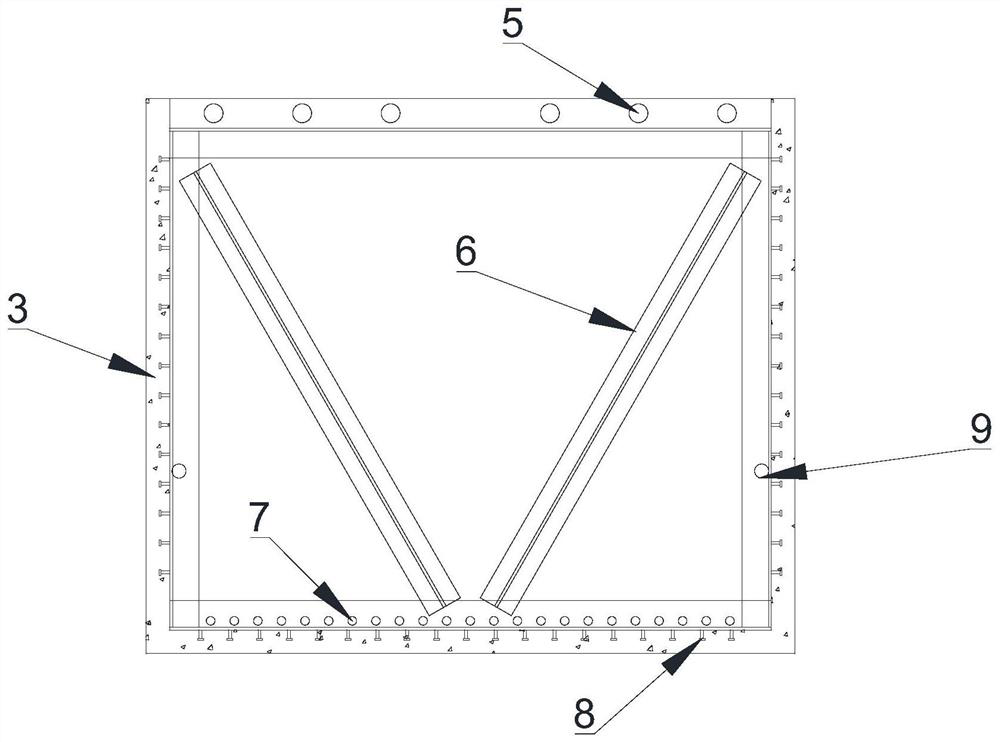

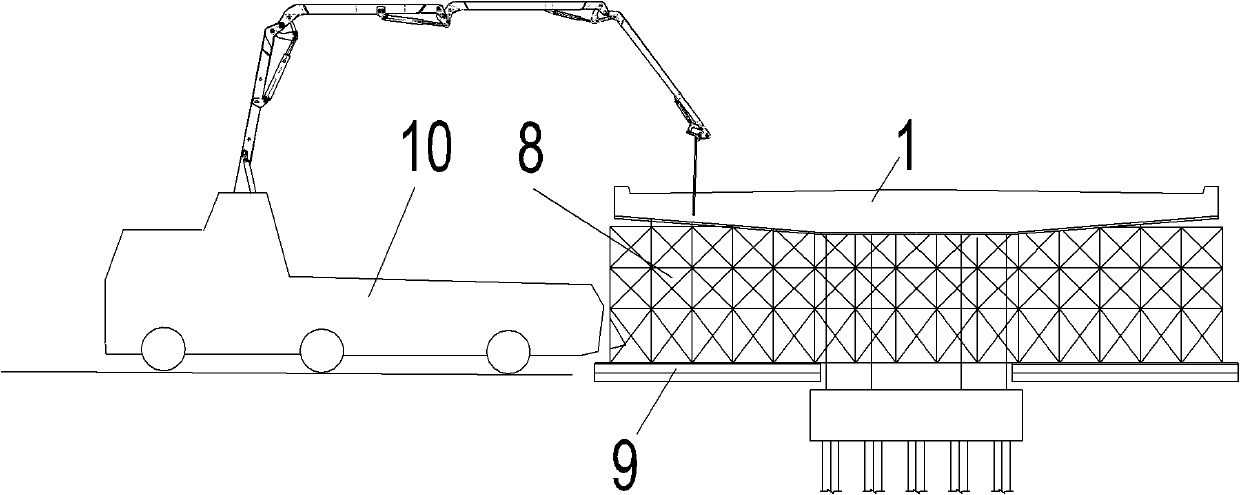

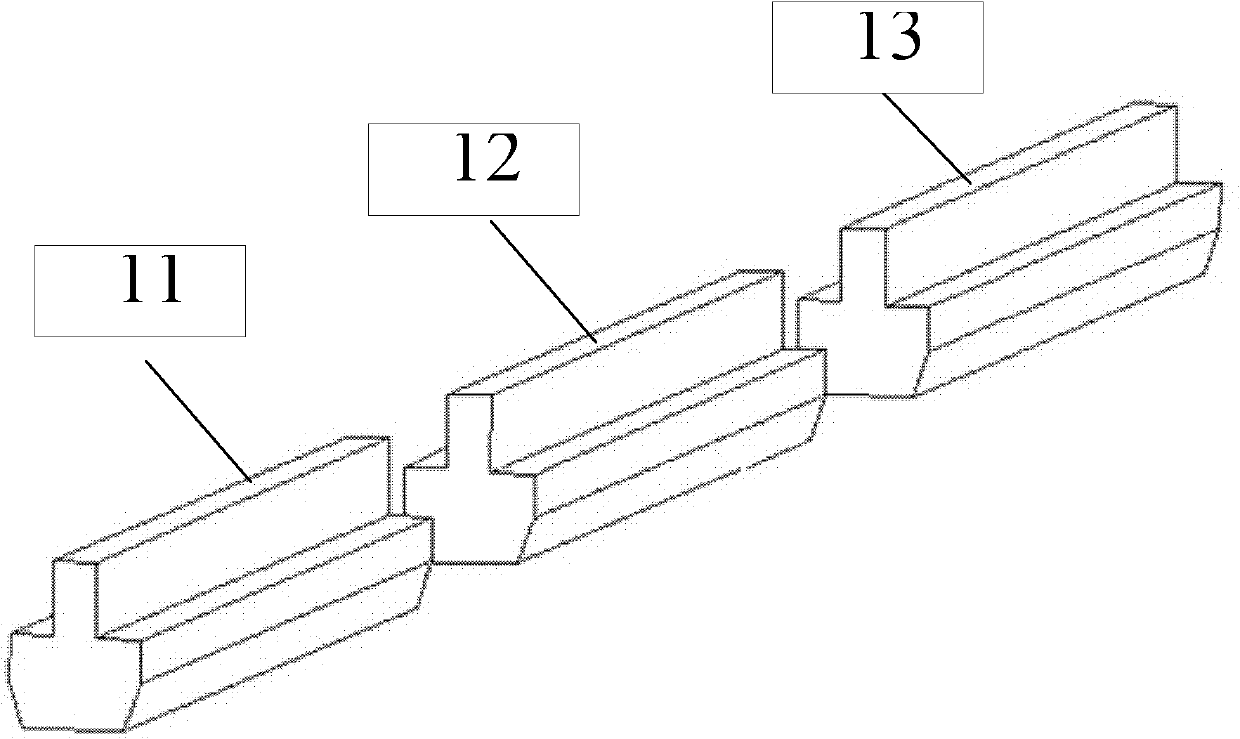

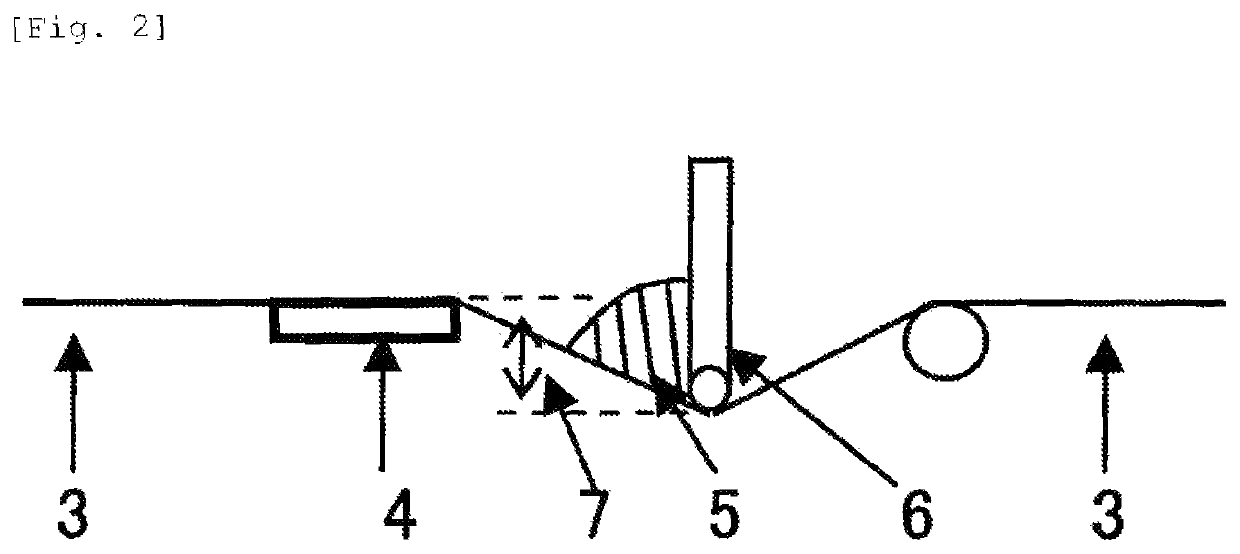

Separately precast and assembled bent cap and construction technology

ActiveCN102409607AReduce weightEasy to transportBridge structural detailsBridge erection/assemblyPre stressEngineering

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

Semiconductor chip buried base plate 3D construction and its manufacturing method

ActiveCN1971863AGood quality and reliabilityImprove product reliabilitySemiconductor/solid-state device detailsSolid-state devicesElectrical conductorInsulation layer

This invention relates to semiconductor chip imbed baseboard three dimensional seal structure and its process method, which comprises the following steps: connecting load parts with at least one hole to first insulation layer and at least one conductor chip onto first insulation contained in the load holes; then forming second insulation layer onto load part and chips for adhesion and filling insulation resin into gap between load board and chip to form electricity connection to chip circuit layer; forming chip dissipation blind hole on first insulation layer to aid semiconductor chip to dissipate heat outside.

Owner:PHOENIX PRECISION TECH CORP

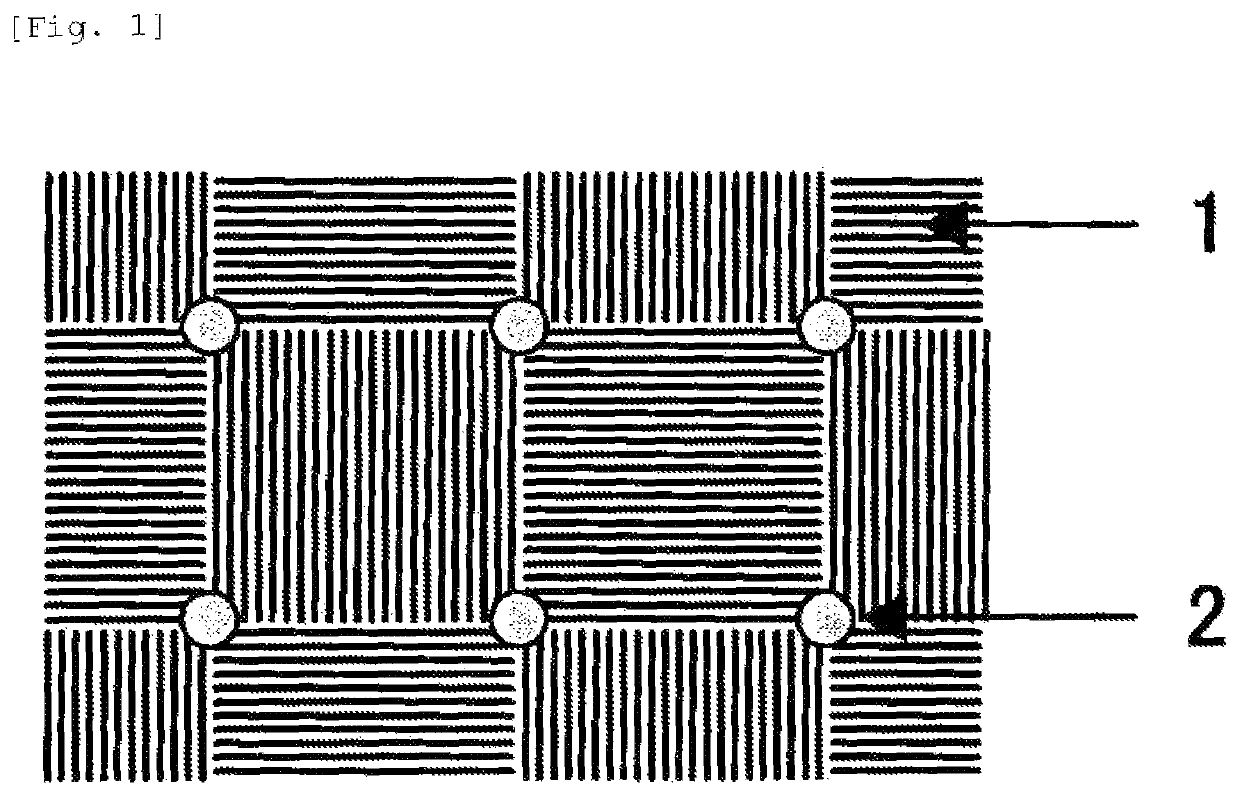

Coated fabric for airbag

ActiveUS20170136982A1Quality improvementImprove reliabilityPedestrian/occupant safety arrangementFibre treatmentYarnCoated surface

A coated fabric for an airbag having improved tensile strength of coated fabric without increasing the strength of a raw yarn is provided. The coated fabric for the airbag comprises a coated silicone resin on one surface of a textile made of synthetic fiber filaments, wherein the silicone resin is present at a joint between warp and weft of a non-coated surface of the textile.

Owner:TOYO TOYOBO CO LTD

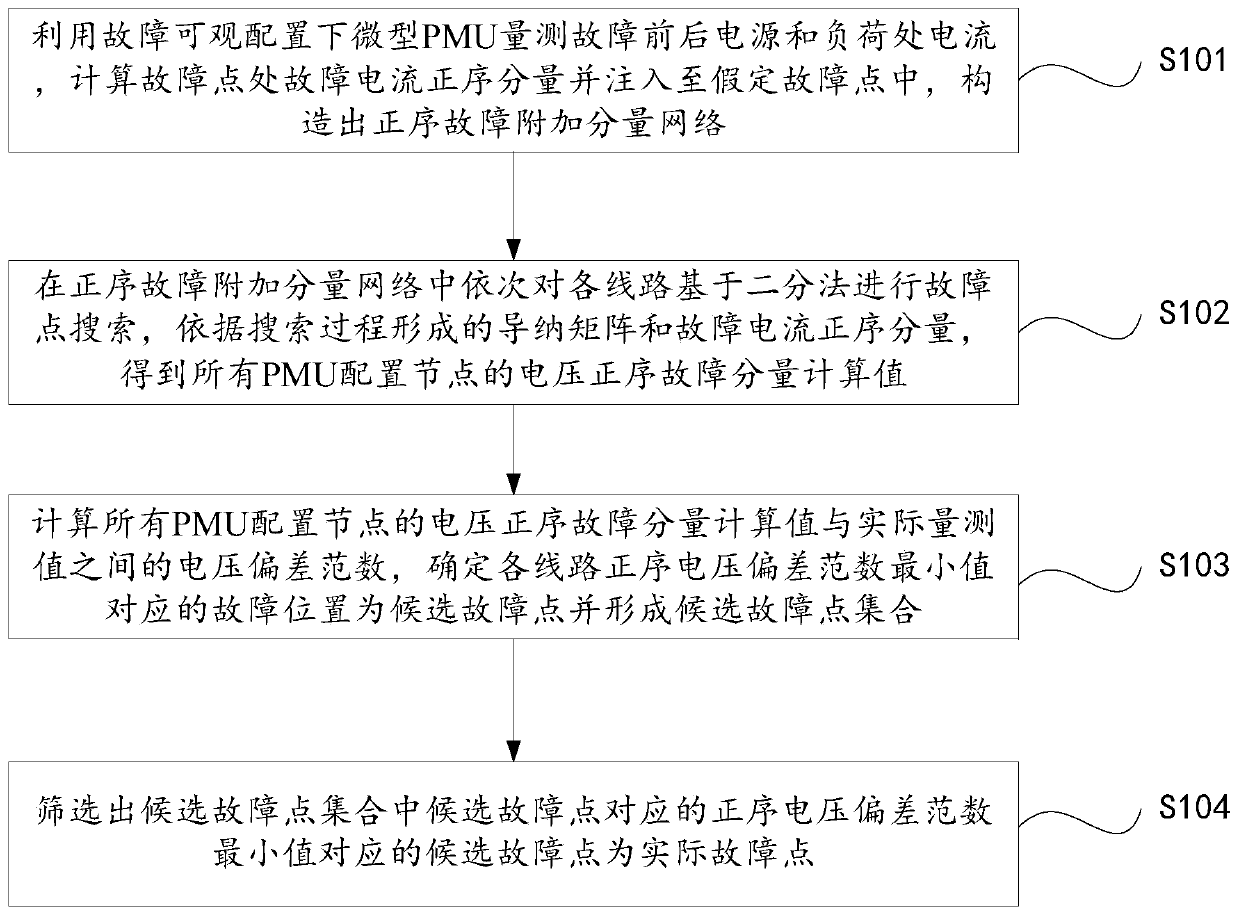

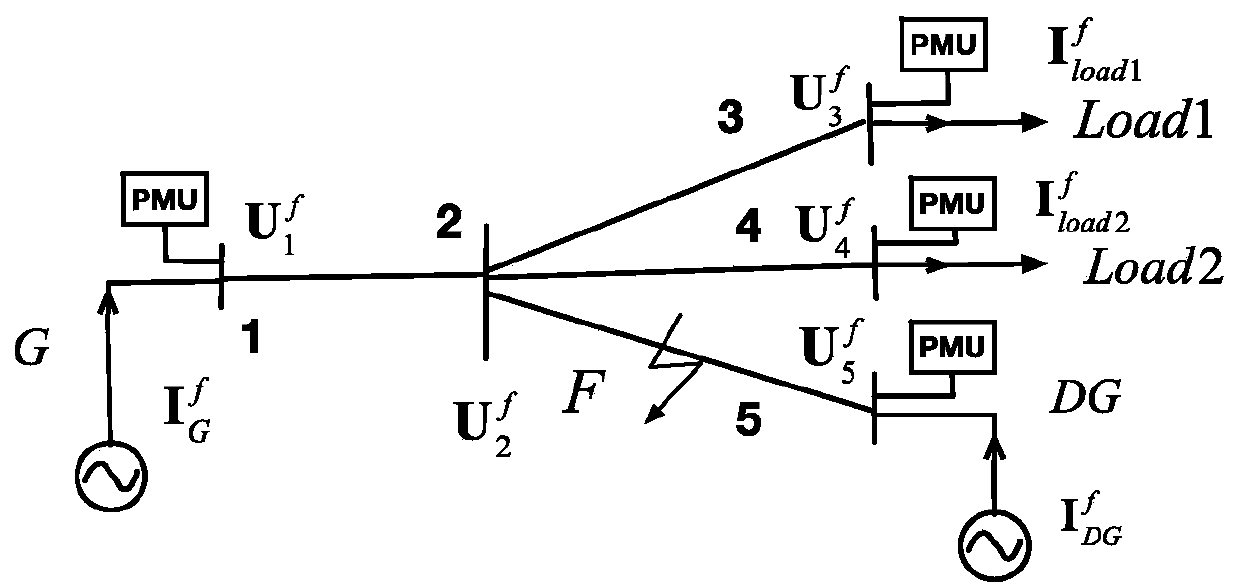

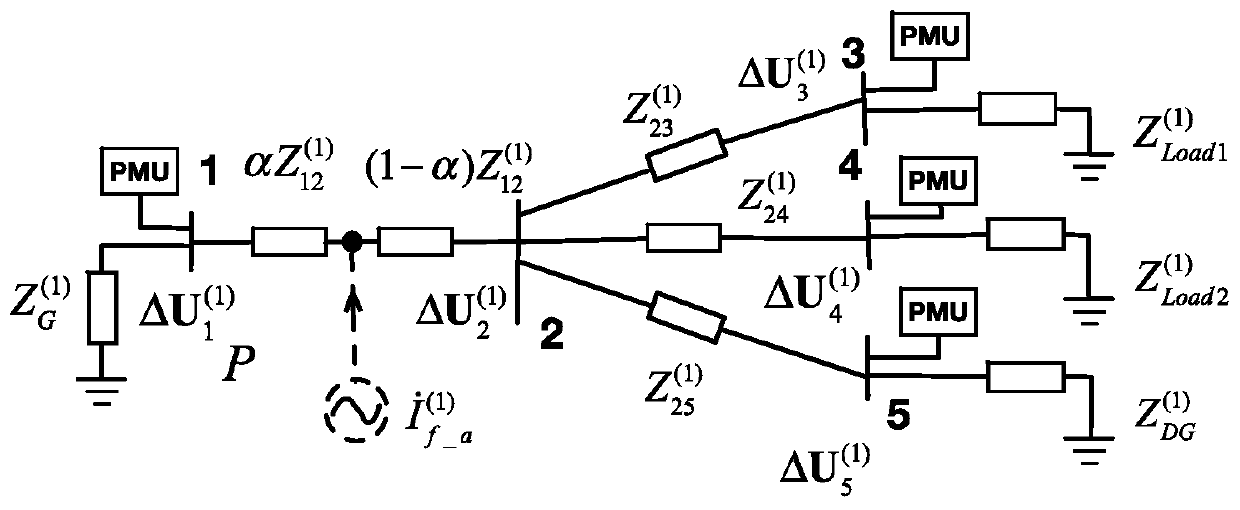

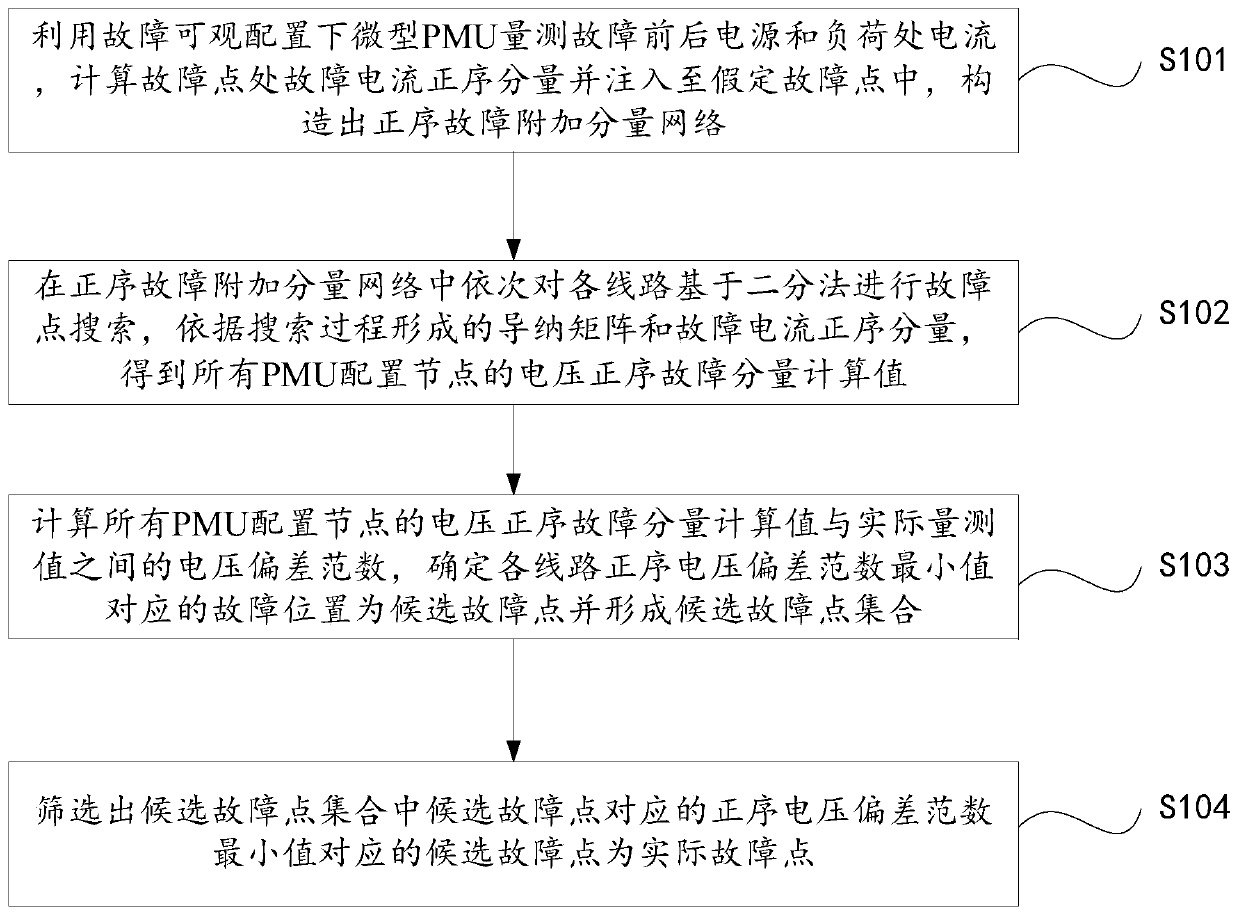

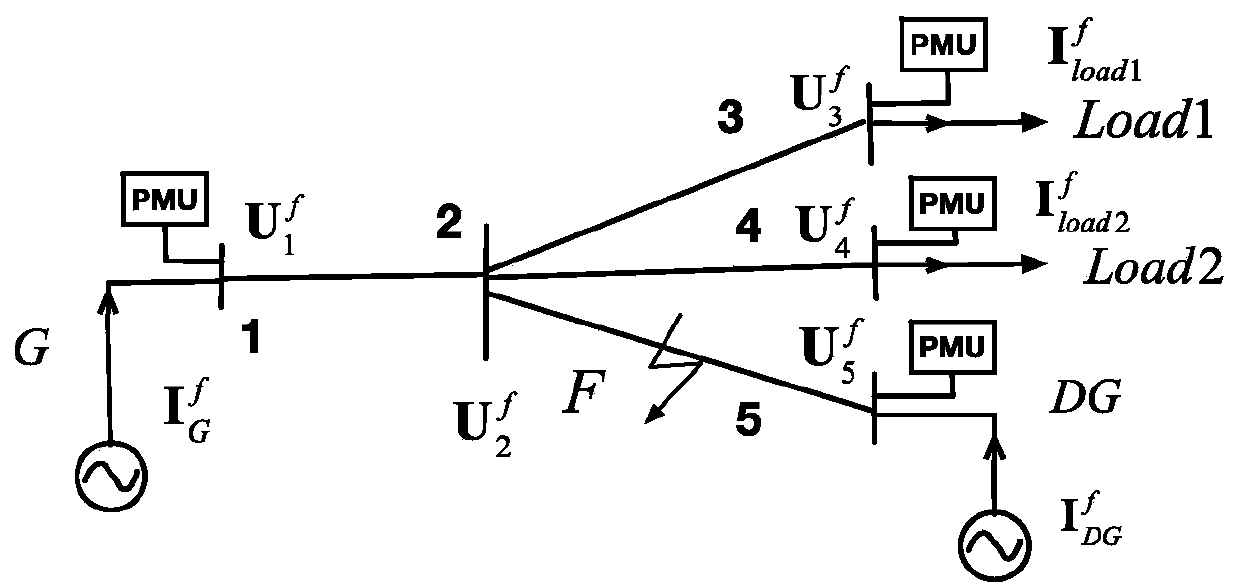

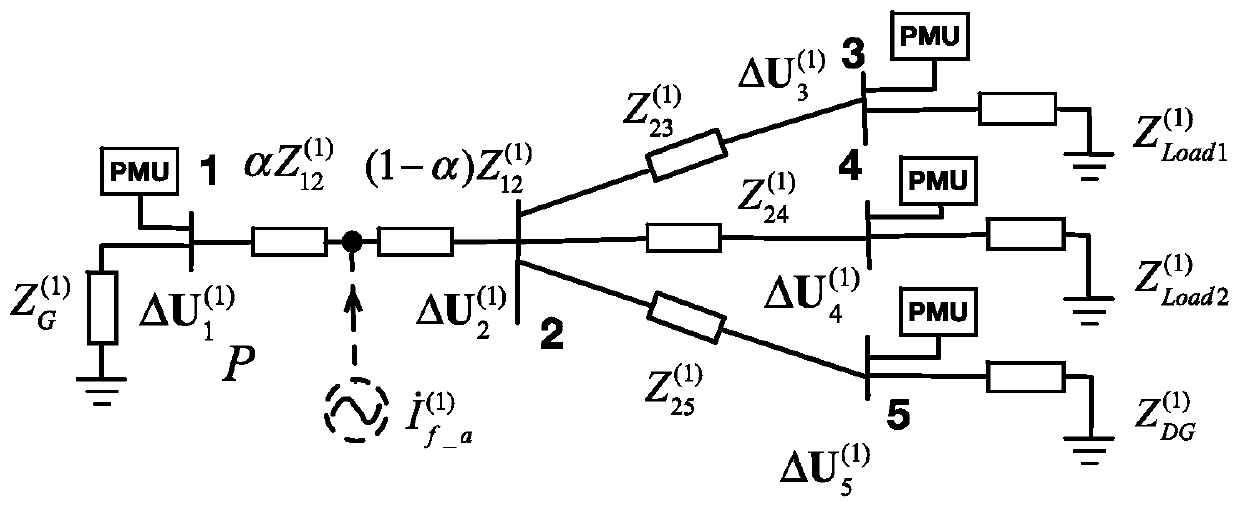

Power distribution network fault positioning method and system based on micro PMU and dichotomy search

ActiveCN110133451AReduce outage timeGood quality and reliabilityFault location by conductor typesSystems intergating technologiesDistribution gridDistribution networks

The invention provides a power distribution network fault positioning method and system based on a micro PMU and dichotomy search. The power distribution network fault positioning method comprises thesteps of calculating a positive sequence component of a fault current at a fault point by utilizing a power supply before and after fault measurement by the micro PMU in a fault observable configuration and a current at a load, and injecting the positive sequence component into the assumed fault point to construct a positive sequence fault additional component network; performing fault point searching on lines on the basis of dichotomy in the positive sequence fault additional component network in sequence, and according to an admittance matrix formed in the search process and the positive sequence component of the fault current, obtaining voltage positive sequence fault component calculation values of all PMU configuration nodes; calculating voltage deviation norms between the voltage positive sequence fault component calculation values of all the PMU configuration nodes and actual measurement values, and determining fault positions corresponding to the minimum values of the positivesequence voltage deviation norms of the lines as candidate fault points; and screening out the candidate fault points corresponding to the minimum values of the positive sequence voltage deviation norms corresponding to the candidate fault points to serve as actual fault points.

Owner:SHANDONG UNIV

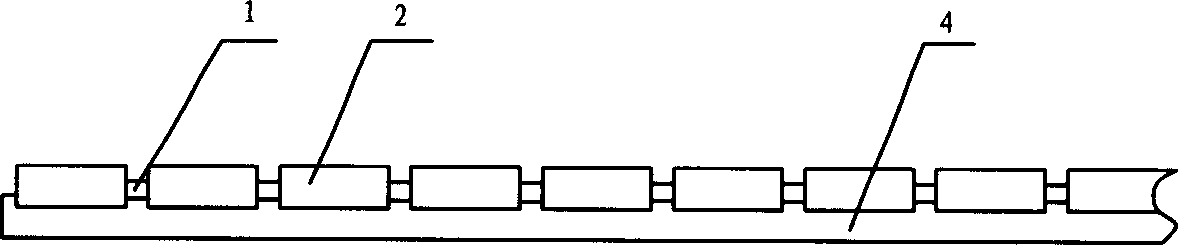

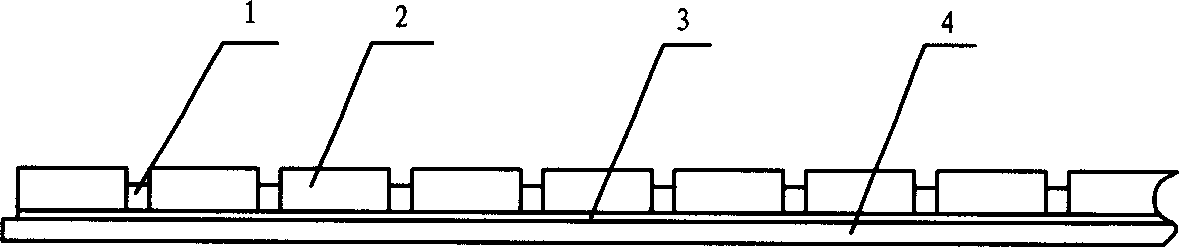

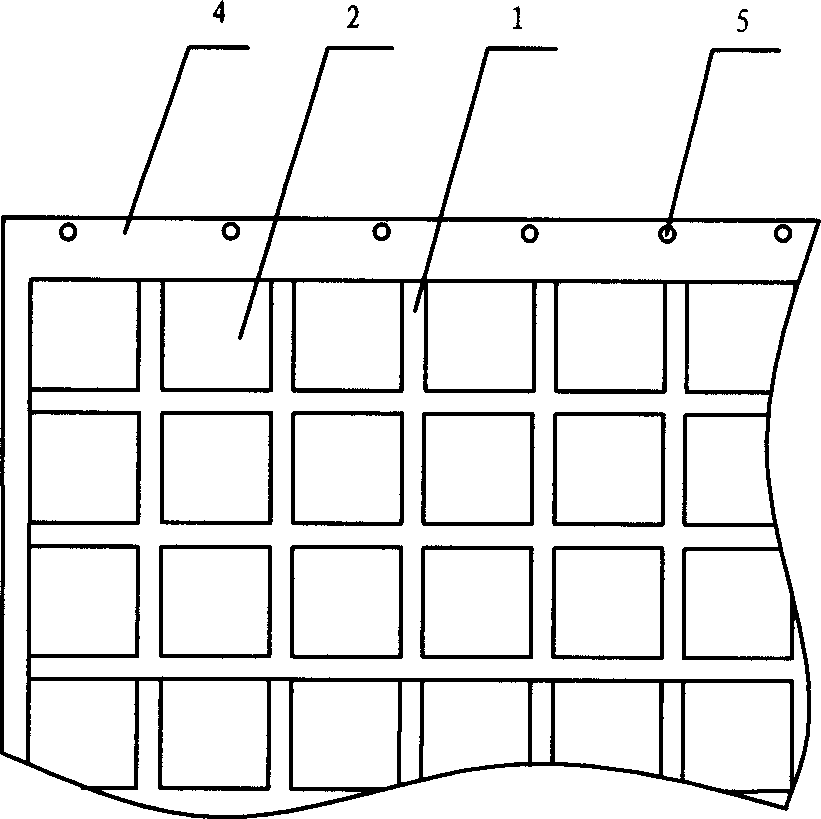

Integrated mosaic decoration plate and its processing and mounting method

InactiveCN1807810AFast constructionRealize factory productionCovering/liningsLaminationAgricultural engineeringBuilding construction

The invention relates to an integrated mosaic ornament plate and relative method. It comprises a waterproof or humid-resistant basic plate on which the mosaic blocks are fixed. Wherein, said basic plate is made from thermosol material, which can directly adhere the mosaic blocks at one temperature and fix them after be cooled. The invention can apply the industry batch production to reduce the on-site workload, while it can improve the construction speed with high quality.

Owner:任建国

Multilayer circuit board and method of producing the same

InactiveUS20060042832A1Quality improvementImprove reliabilityPrinted circuit aspectsPrinted circuit manufactureElectrical conductorInsulation layer

A multilayer circuit board comprises a conductor wiring layer, and an insulation layer, wherein the conductor wiring layer and the insulation layer are laminated alternately, wherein the conductor wiring layer is electrically connected by a via through the insulation layer, wherein the via is filled with a conductor material, and wherein the conductor material is junctured to the conductor wiring layer with an alloy.

Owner:SANEI KAGAKU KK

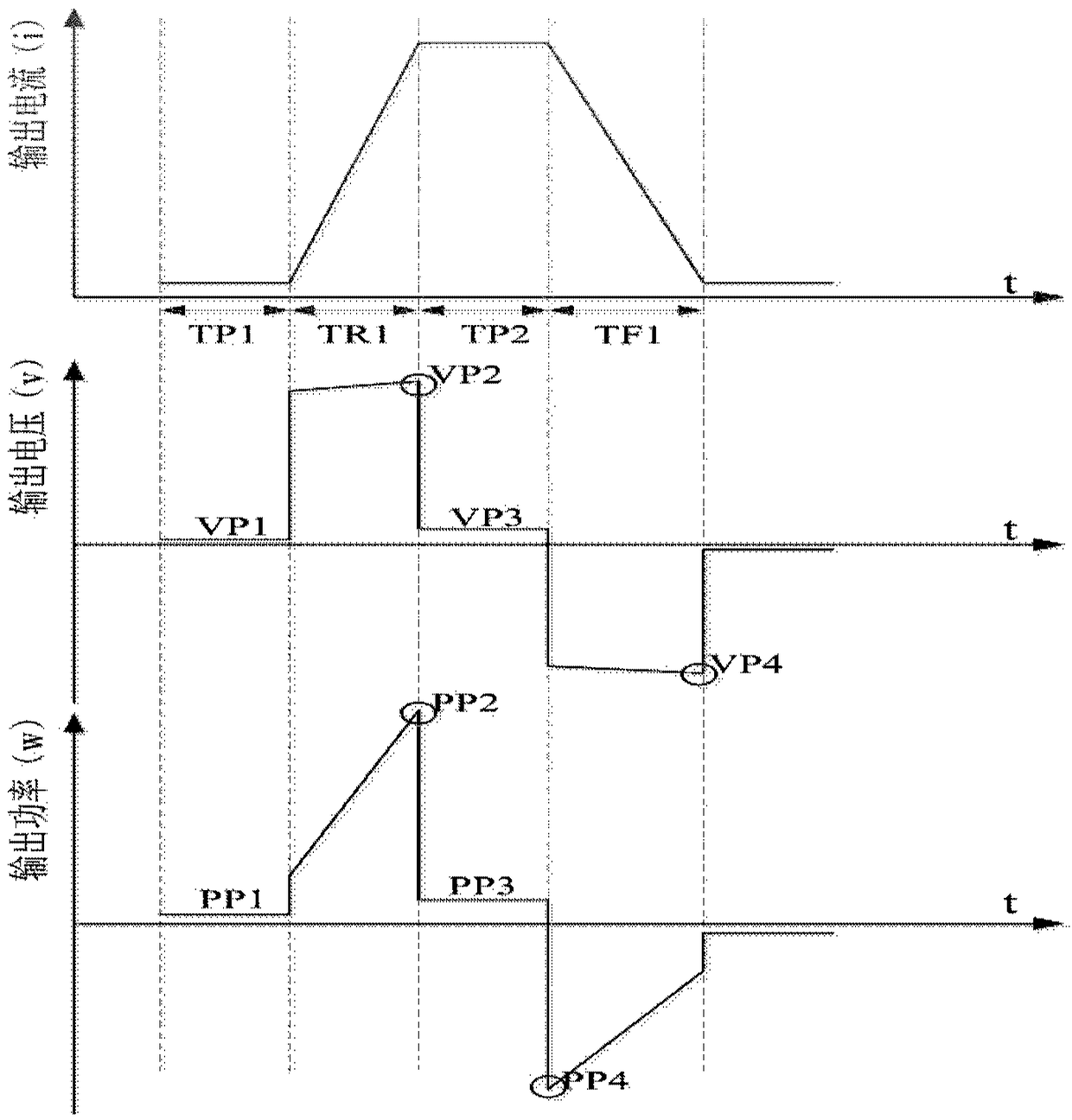

Full energy storage pulse power supply and current pulse generation method

PendingCN108134534ARealize two-way controlReduce shockPulse generation by energy-accumulating elementAcceleratorsCapacitanceParticle accelerator

The present invention relates to a current pulse generation method. The method comprises the steps of: employing an energy storage capacitor to store energy, wherein energy required by an ascent stageof current waveform pulses is supplied by the energy storage capacitor; and returning energy stored in a magnet load inductor at a descent stage of the current waveform into the energy storage capacitor to be prepared for the next pulse so as to achieve repeat utilization of the energy. The full energy storage mode is employed to specifically solve the main problem of the high excitation power supply of the pulse power supply of a particle accelerator.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

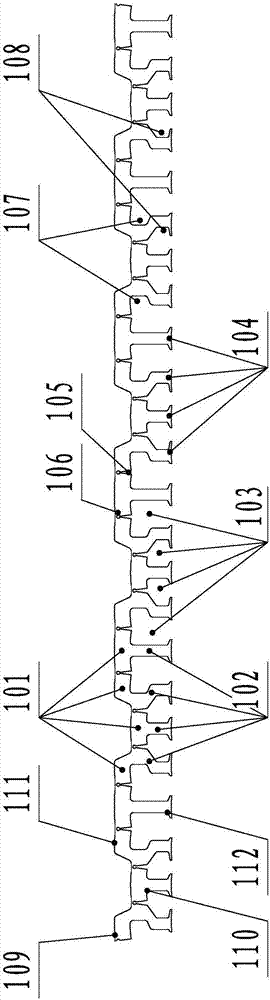

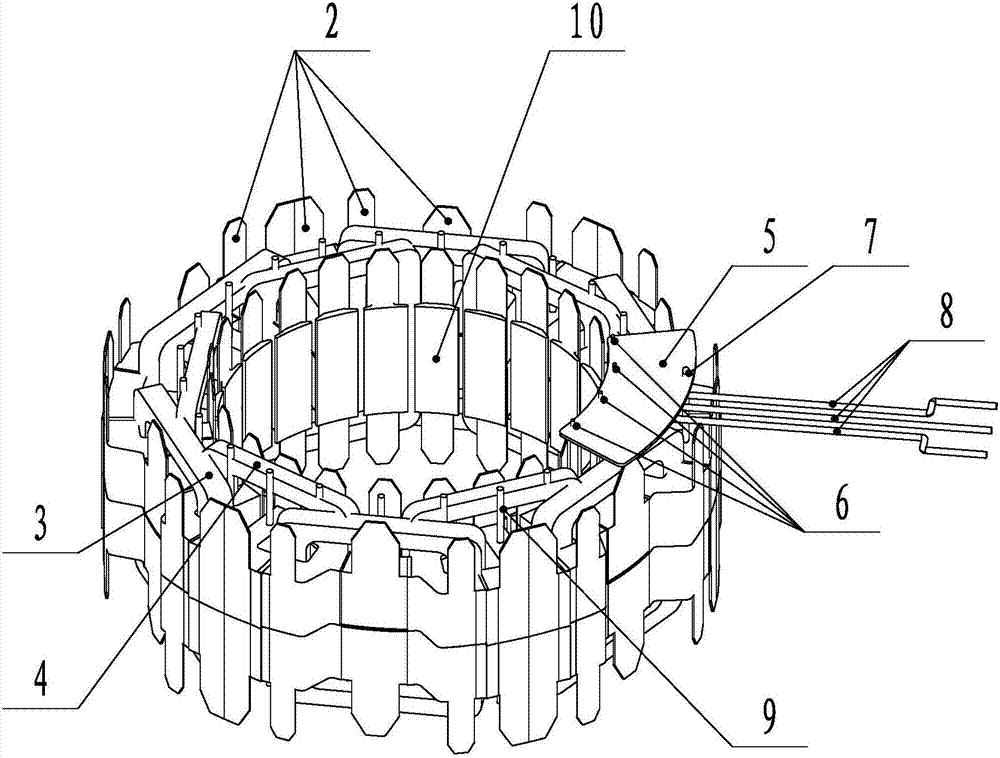

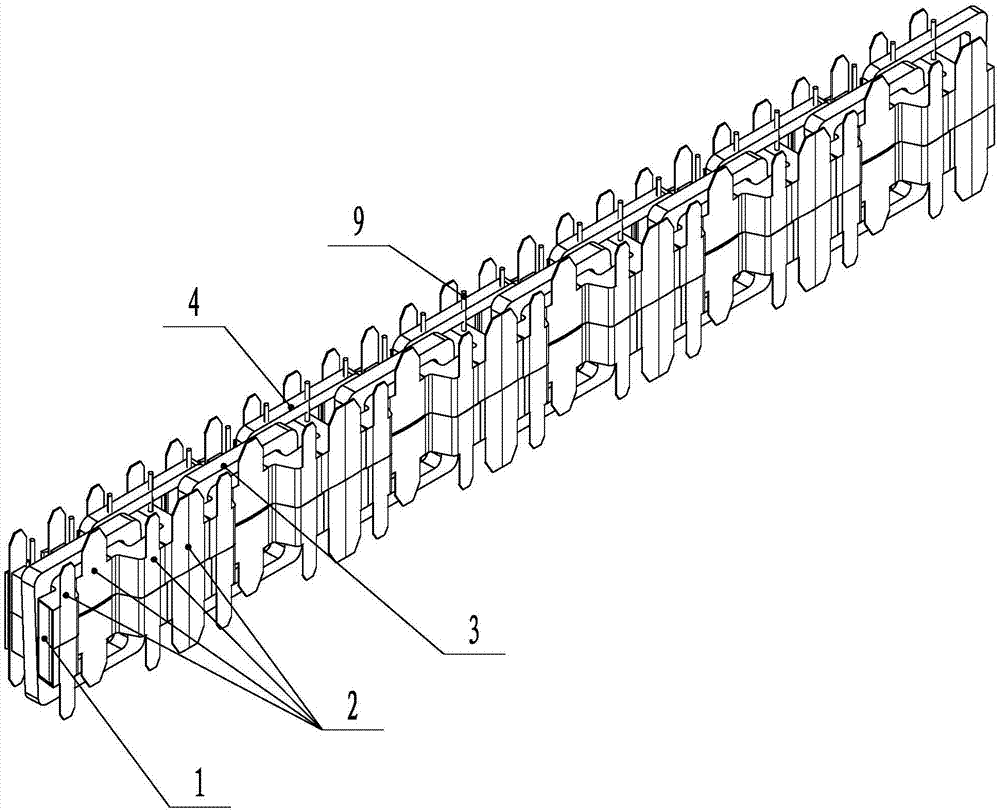

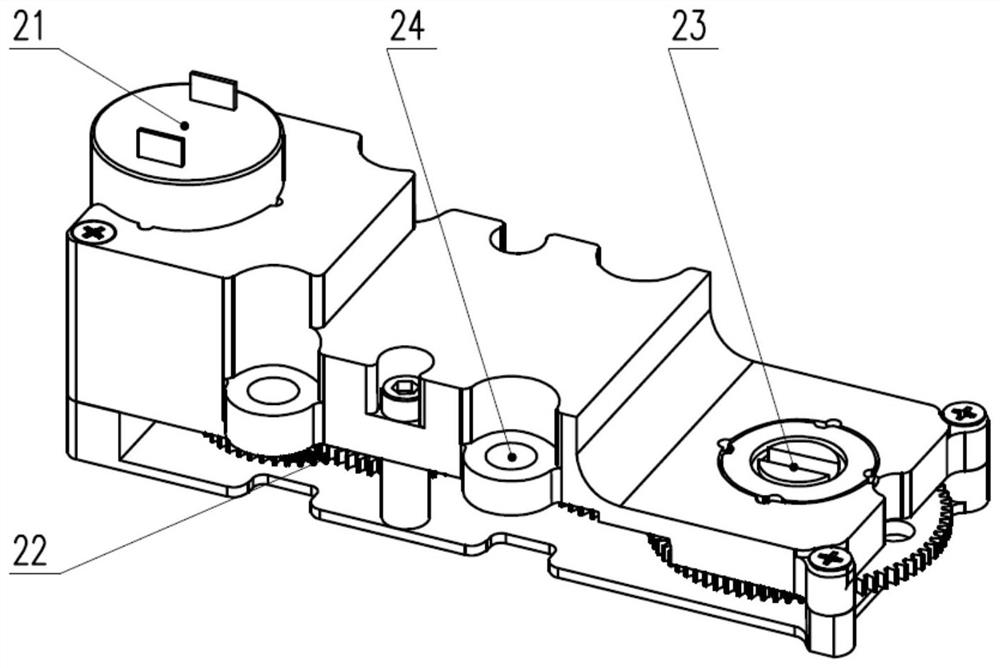

Novel single-phase asynchronous AC motor stator structure

ActiveCN106992612AHigh material utilizationReduce dosageAssociation with control/drive circuitsWindings insulation shape/form/constructionPunchingElectric machine

The invention relates to a novel single-phase asynchronous AC motor stator structure and relates to the field of single-phase asynchronous AC motor. The stator structure in the prior art has disadvantages in manufacturing process such as too many steps, complex operation and low utilization rate of silicon steel sheet. The invention comprises a stator core, an insulating bushing arranged on outside of the stator core and a winding winded on outside of the insulating bushing, the stator core is formed by stacking and rolling a linear iron core punching sheet, the stator core comprises punching sheet groups, each punching sheet group comprises a first punching sheet body, a second punching sheet body, a third punching sheet body and a fourth punching sheet body, each punching sheet body comprises an independent insulating bushing, the winding comprises an outer winding and an inner winding arranged on the radial inner side of the outer winding, the outer winding winds the adjacent first punching sheet body, second punching sheet body and third punching sheet body as one, and the inner winding winds the adjacent third punching sheet body, fourth punching sheet body and first punching sheet body as one. According to the technical scheme of the invention, the material utilization rate of the stator core punching sheet is improved, the dosage of winding enameled wire is reduced, the manufacturing process is simplified, the production efficiency is improved, the reliability of motor quality is good, and the cost is low.

Owner:WOLONG ELECTRIC GRP CO LTD

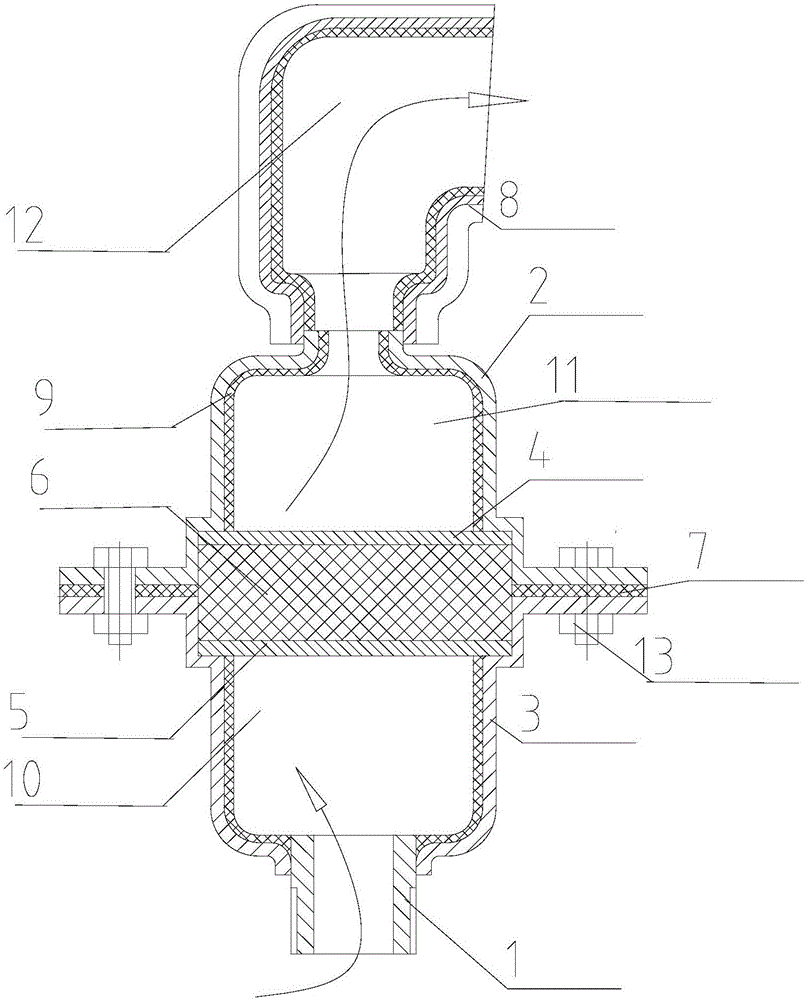

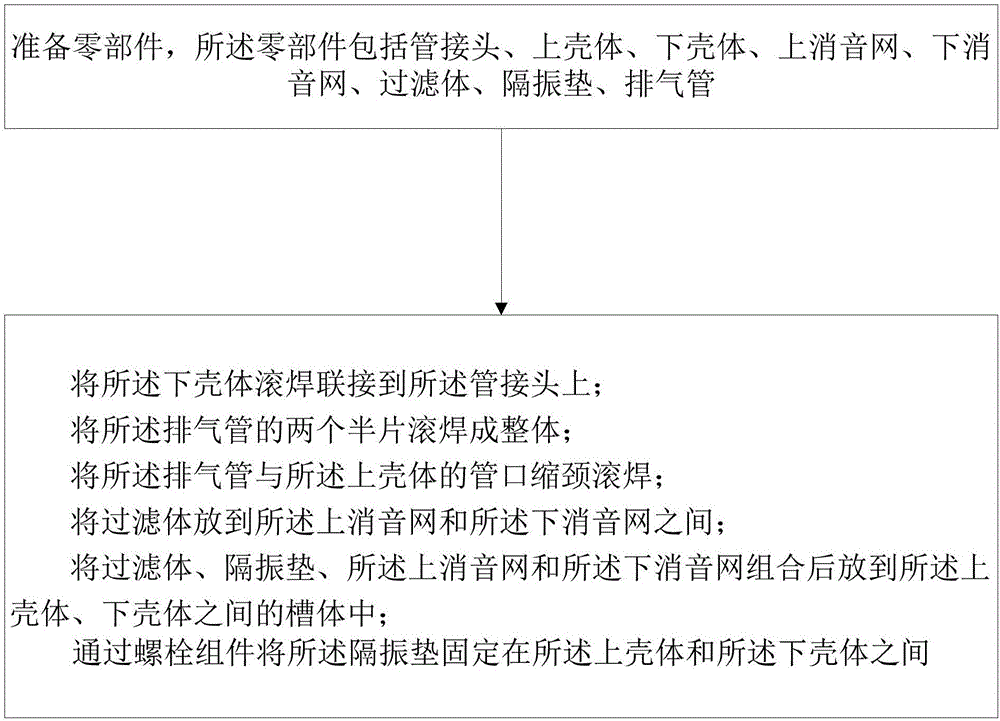

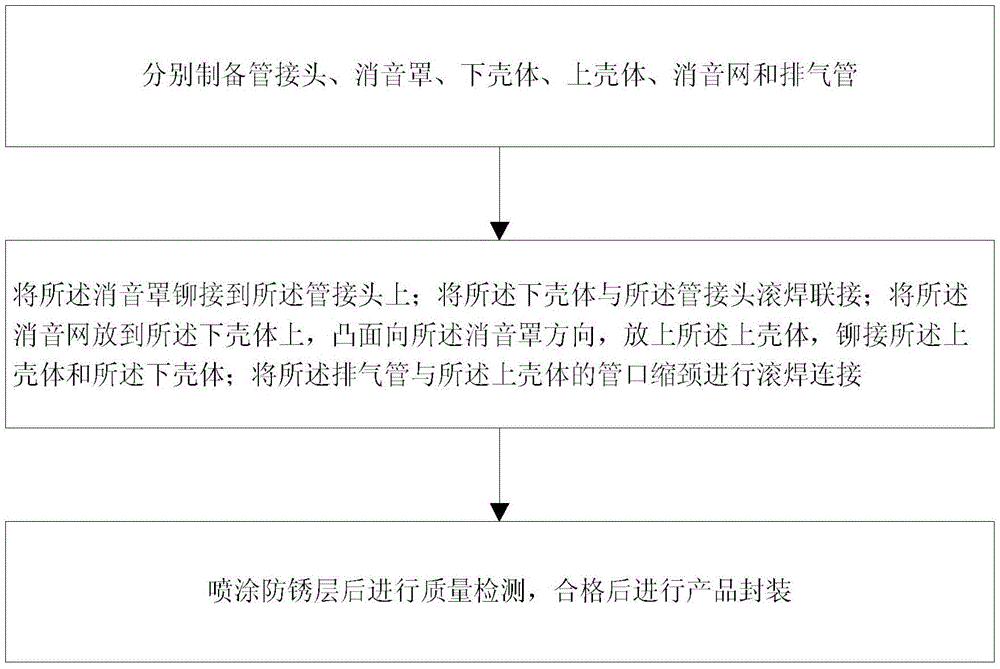

Silencer for single cylinder diesel capable of reducing noise and emission and manufacturing method of silencer

InactiveCN106285837AGood quality and reliabilityImprove appearance qualitySilencing apparatusMachines/enginesAirflowSmall hole

The invention discloses a silencer for a single cylinder diesel capable of reducing noise and emission and a manufacturing method of the silencer. The silencer comprises a pipe connector, an upper shell, a lower shell, an upper silencing net, a lower silencing net, a filtering body, vibration isolation pads, an exhaust pipe and a sound absorbing material layer. One end of the pipe connector is connected to an exhaust elbow pipe of a cylinder cover of an engine through threads, and the other end of the pipe connector is fixedly connected with the lower shell. A groove is formed between the lower shell and the upper shell. The exhaust pipe is in necking connection with a pipe orifice of the upper shell. The upper silencing net is arranged at the upper end of the filtering body. The lower silencing net is arranged at the lower end of the filtering body. The two ends of the filtering body are provided with the vibration isolation pads extending outwards correspondingly. The filtering body, the upper silencing net and the lower silencing net are arranged in the groove between the upper shell and the lower shell. The inner wall of the upper shell, the inner wall of the lower shell and the inner wall of the exhaust pipe are filled with the sound absorbing material layer. The method that a ventilation net section three-stage step-by-step magnified silencing mode is adopted, and airflow is subjected to big and small hole alternate silencing and sound absorbing material combined silencing is adopted, and thus noise can be effectively reduced.

Owner:SUZHOU INDAL PARK INSTITUE OF VOCATIONAL TECH

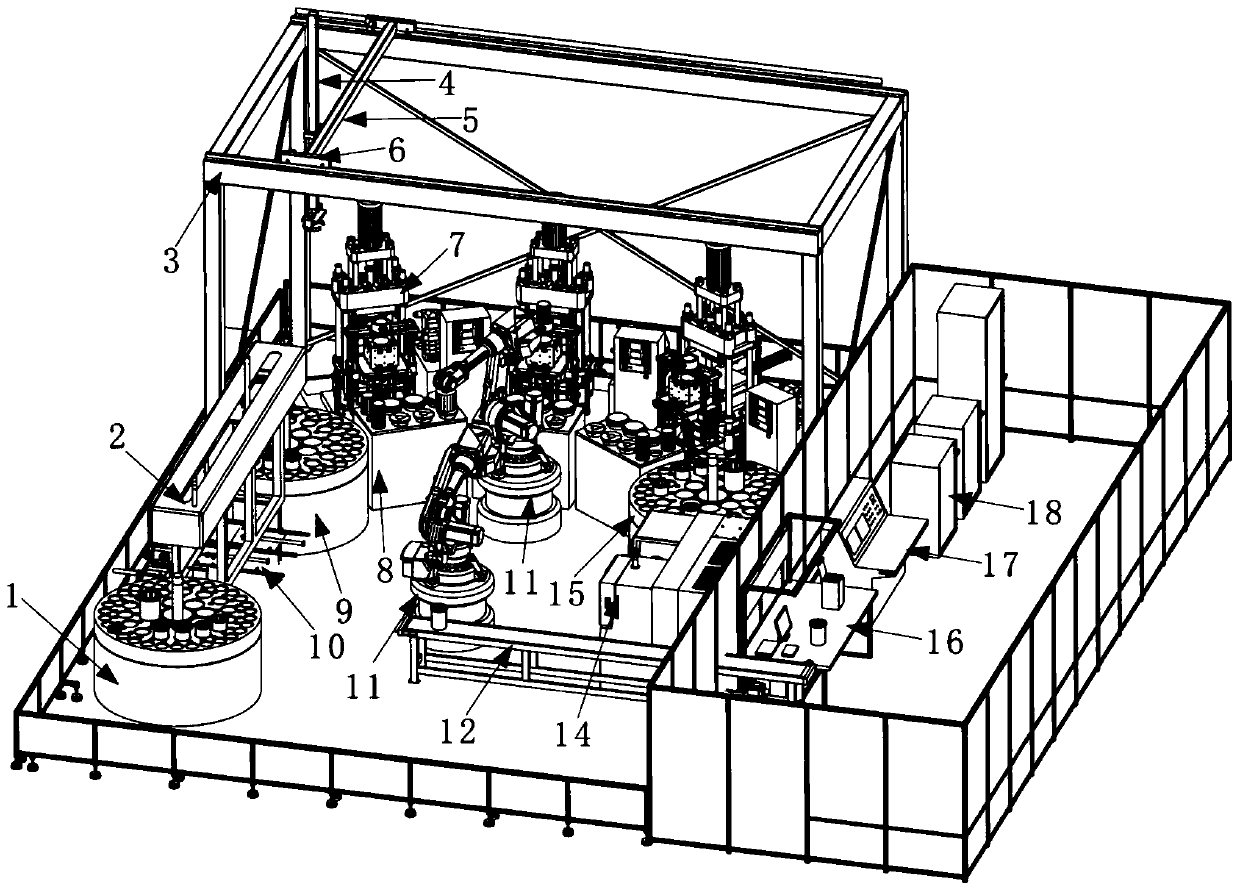

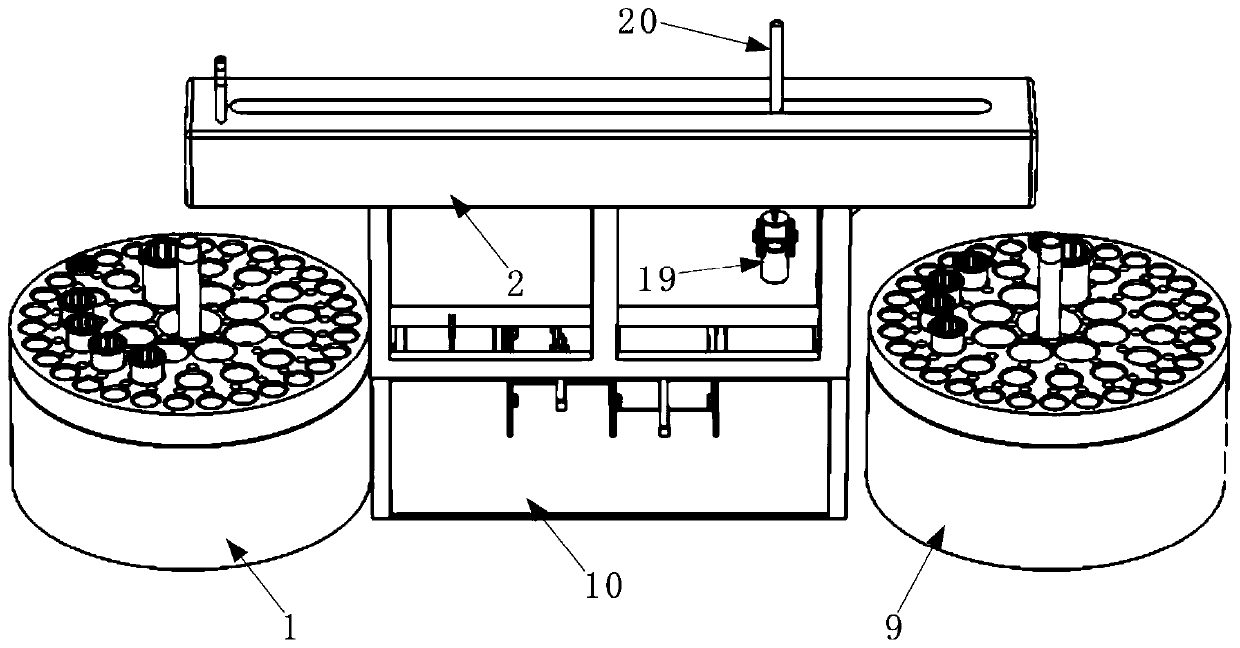

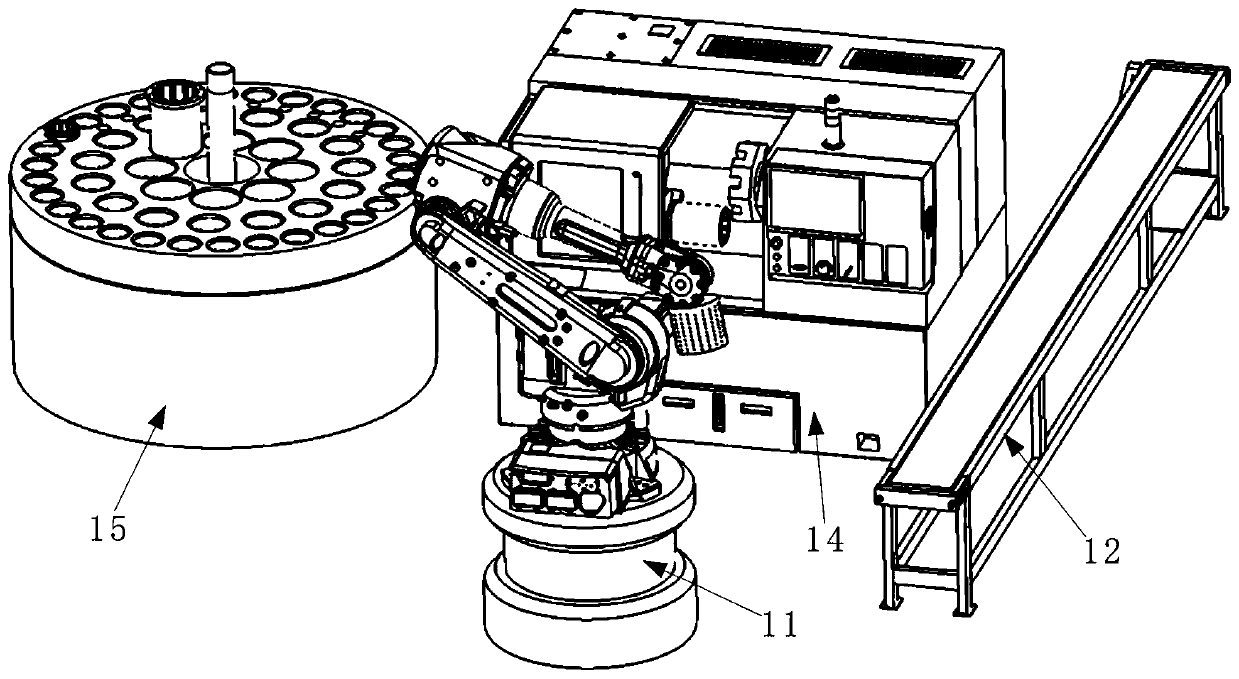

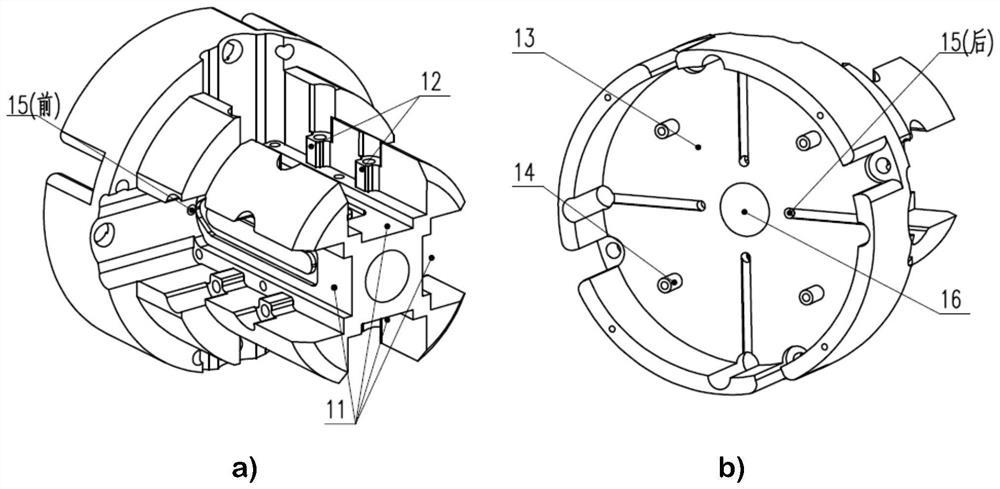

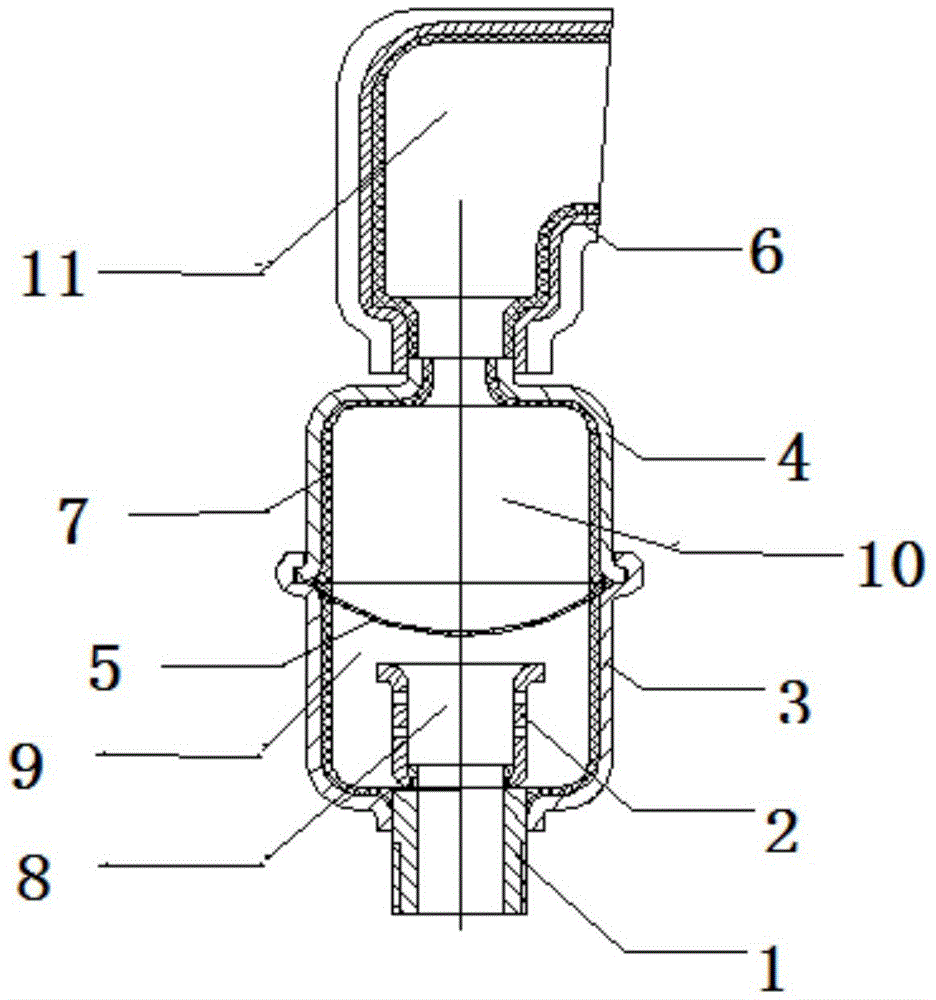

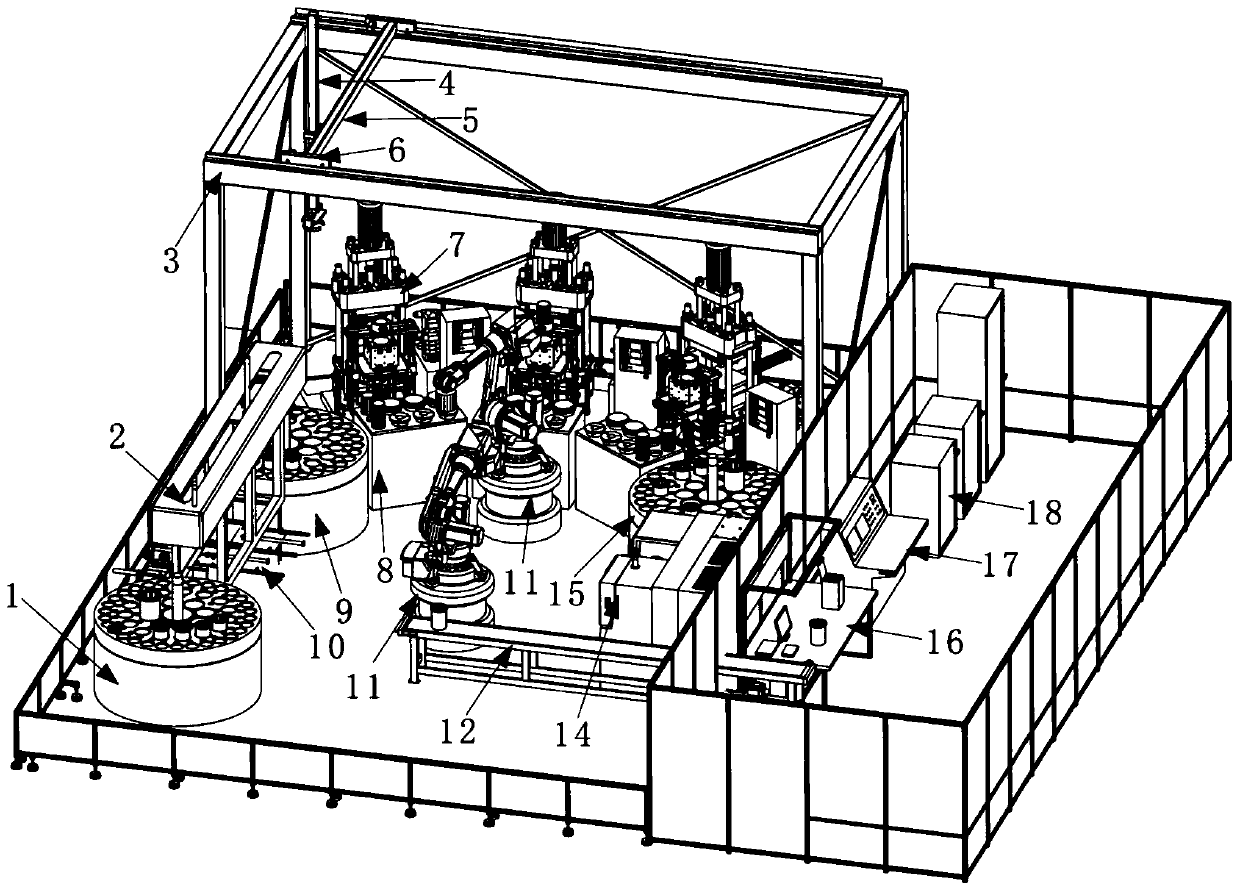

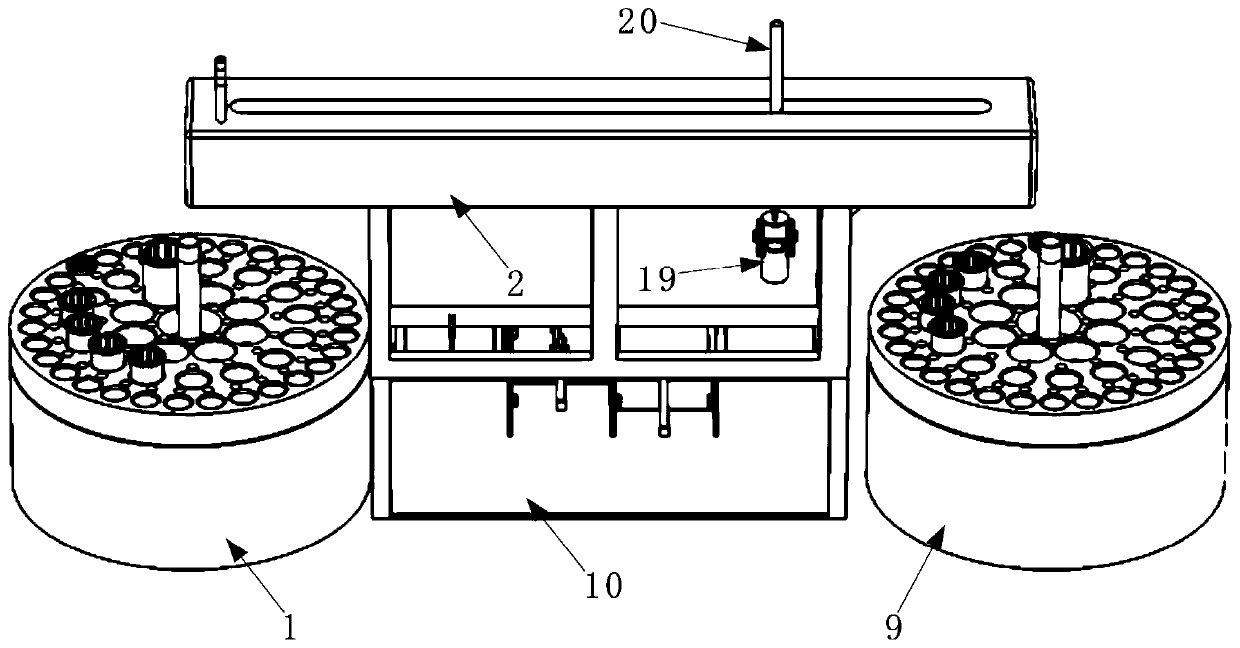

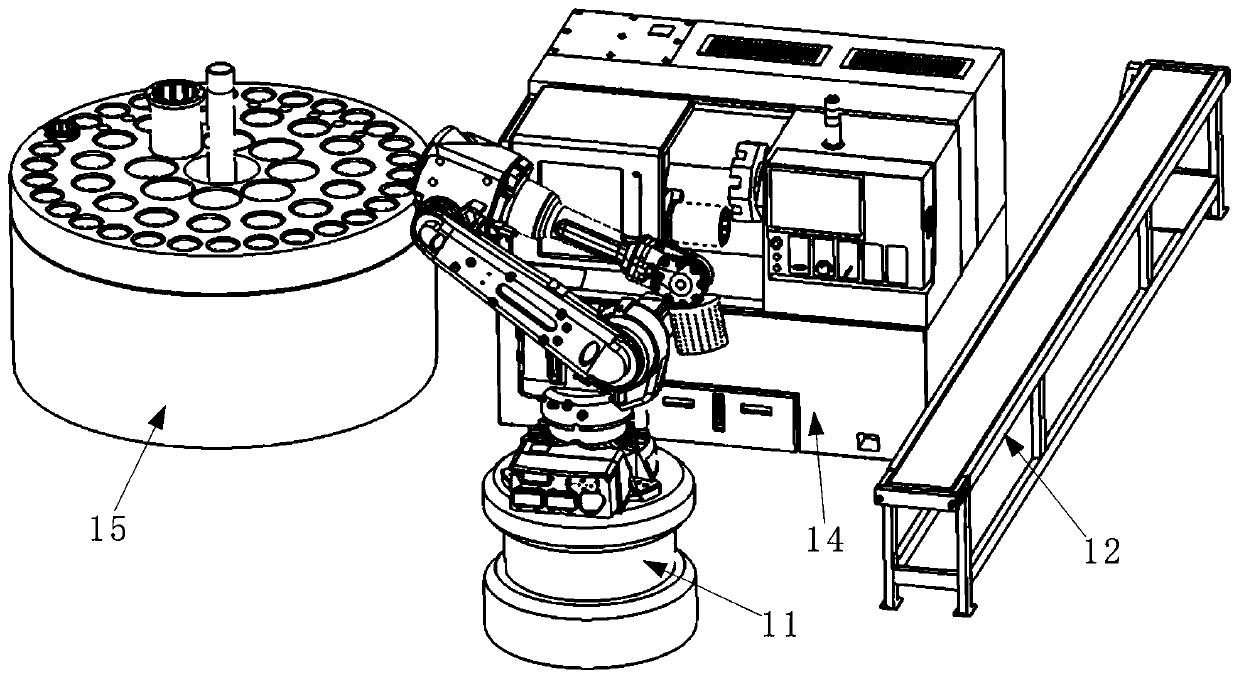

Efficient and high-quality intelligent manufacturing device and system for high-performance core base parts

ActiveCN110640971AHigh quality and efficient productionHigh degree of automationCleaning using liquidsMetal working apparatusIndustrial roboticsProcess engineering

The invention discloses an efficient and high-quality intelligent manufacturing device and system for high-performance core base parts. The manufacturing device comprises an automatic cleaning system,a molding vulcanization forming system, a precision machining system and an inspection and storage system, wherein the automatic cleaning system comprises a first rotary plate, a cleaning device anda second rotary plate which are installed in sequence; the molding vulcanization forming system comprises injection molding machining devices which are arranged in sequence; the inspection system comprises an inspection room, and the inspection room is provided with an inspection table, an input table and a storage device. According to the efficient and high-quality intelligent manufacturing device and system for the high-performance core base parts, through a complete intelligent production system, based on an industrial robot, various related production systems are connected in series, and intelligent production of the products is achieved. The efficient and high-quality intelligent manufacturing device has the advantages of being high in automation degree, high in production efficiency,high in product surface integrity, high in product reliability and consistency and the like. Therefore, intelligent manufacturing and production for general customers are achieved, and large-scaled,high-quality and efficient production of series products of the high-performance composite parts of many specifications and many varieties is achieved.

Owner:SOUTHWEST JIAOTONG UNIV +1

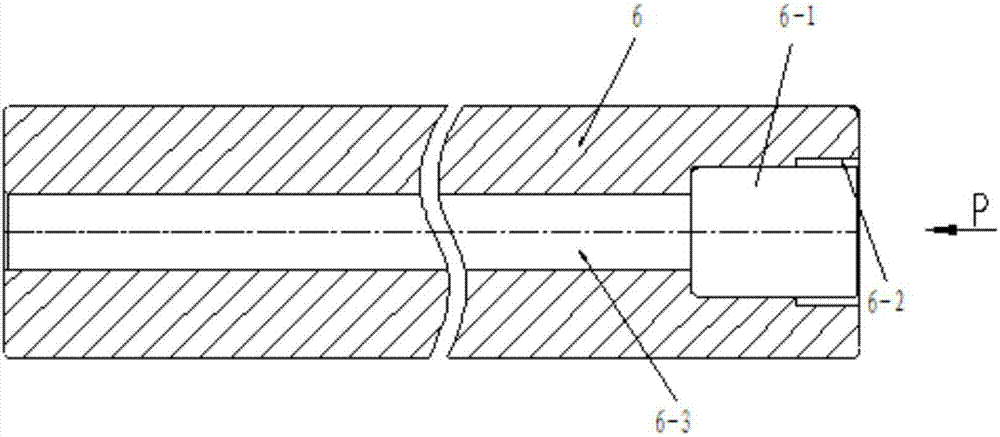

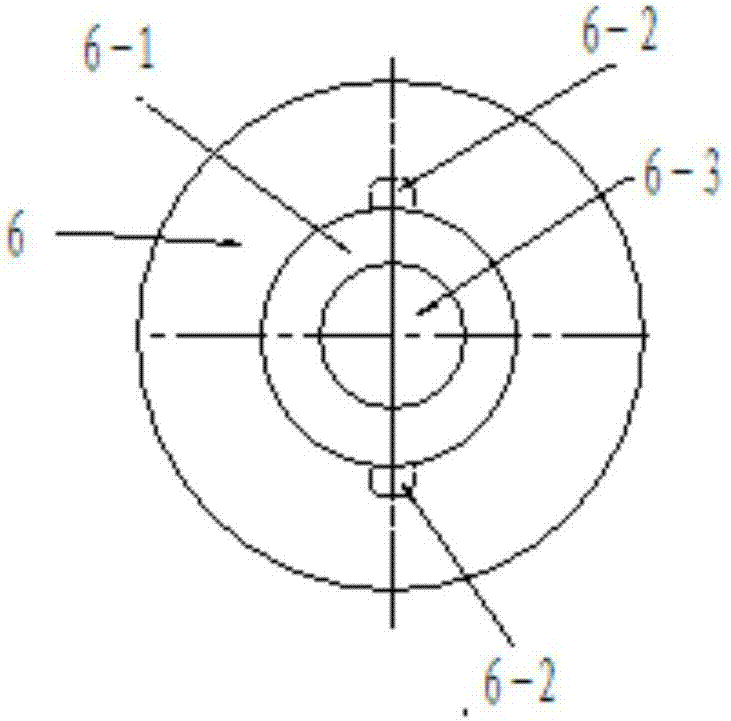

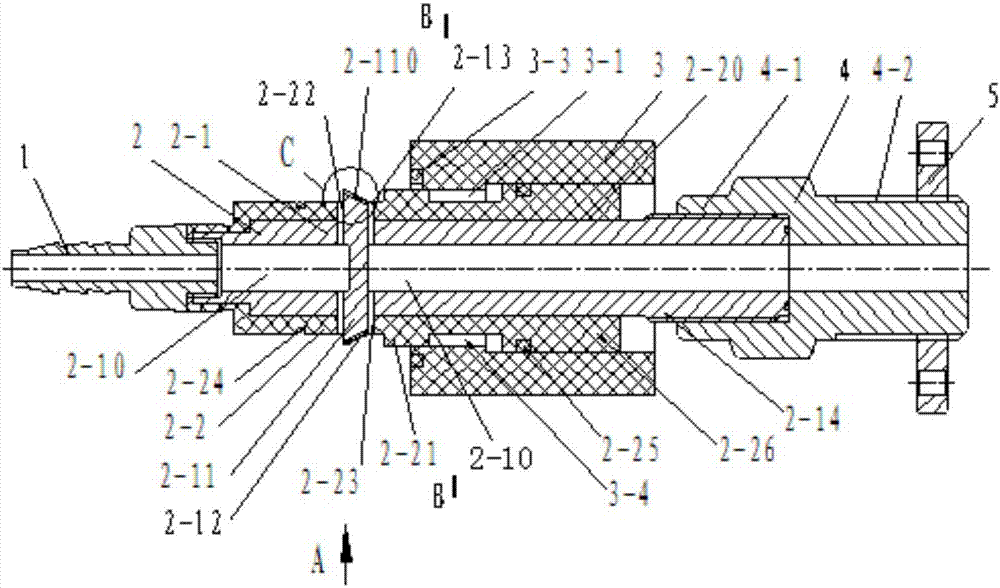

Large shaft end keyway electrolytic machining device

PendingCN107309511AImprove machining accuracy and efficiencyGood quality and reliabilityMachining electrodesElectrical-based machining electrodesEngineeringHose coupling

The invention discloses a large shaft end keyway electrolytic machining device with high processing precision. A sealing case is mounted onto two guide keys and an assembling unit of an insulating guide body respectively through two keyways of a left shaft hole and a right shaft hole in a clearance sleeved manner; the insulating guide body is mounted onto a copper unit in a sleeving mode through casting, the left end of the insulating guide body is aligned to the left end of the copper unit, the right end of the insulating guide body is arranged inside the right end of the right shaft hole of the sealing case, and two radial holes and two external radial electrolyte inlet and outlet holes on the sides of the radial holes are aligned to and communicated with two bosses on the copper unit and two internal radial electrolyte inlet and outlet holes on the sides of the bosses respectively; the two bosses of the copper unit extend out of the two radial holes of the insulating guide body respectively, the left end of the copper unit is connected with the right end of a hose connector, the right end of the copper unit extends out of the right end of the sealing case, and the left end of the hose connector is connected with an electrolyte output hose; the left end of a connector is detachably connected with the right end of the copper unit of an electrolytic cathode, and a flange disc is detachably mounted on the right of the connector.

Owner:CHONGQING WANGJIANG IND

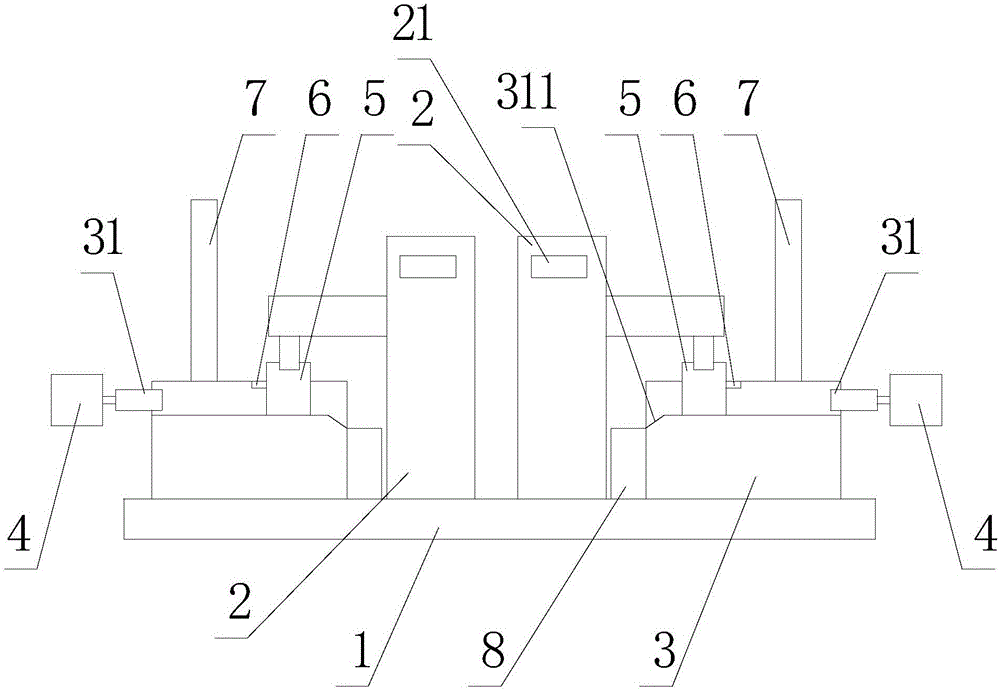

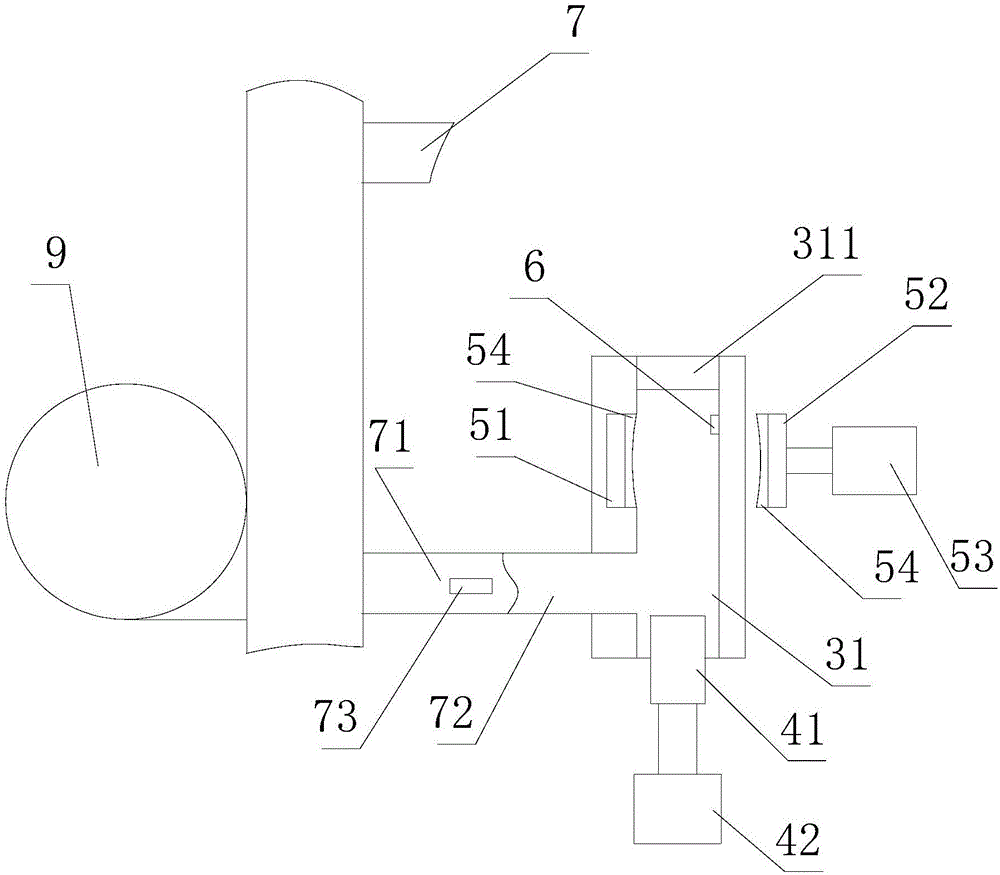

Lithium battery cap pressure welding device

ActiveCN103692084BNo movementGood quality and reliabilityWelding/cutting auxillary devicesAuxillary welding devicesBiochemical engineeringLithium battery

The invention relates to a lithium battery cap pressure welding device, which comprises a bed and at least one pressure welder fixedly connected with the bed, a fixture is fixedly connected with the bed at the bottom of each pressure welder, each fixture is a base with a through channel on the top, the inlet section of each through channel is provided with a pusher which can push a cap to the bottom of the corresponding pressure welder, and lockers which can lock the pushed caps in the through channels are arranged on the bed. The lithium battery cap pressure welding device has the advantages that because the pushers are utilized to push the caps to the bottoms of the pressure welders and the lockers are utilized to lock the caps, the caps cannot move during pressure welding, the efficiency of production is increased, the danger caused by manual feeding and discharging is reduced, the lithium battery cap pressure welding device is highly practical, and the quality reliability of the pressure-welded caps is high.

Owner:浙江长兴竹园锂电池材料有限公司

Prestressed UHPC shell-concrete inner core combined cover beam structure and construction method thereof

InactiveCN113605246AReduce usageSmall sizeBridge structural detailsBridge erection/assemblyPre stressArchitectural engineering

The invention discloses a prestressed UHPC shell-concrete inner core combined cover beam structure which comprises a cover beam shell, the cover beam shell comprises webs and a bottom plate, multiple webs are connected to the bottom plate, an inner cavity with an upward opening is defined by the webs and the bottom plate, the cover beam shell is a prefabricated UHPC shell, a plurality of reinforcing frames are vertically arranged in the inner cavity, multiple reinforcing frames are arranged in the length direction of the bent cap shell at intervals, and the inner cavity is filled with common concrete inner cores in a pouring mode. The structure has the advantages of being low in self weight, good in durability and high in bearing capacity.

Owner:HUNAN UNIV

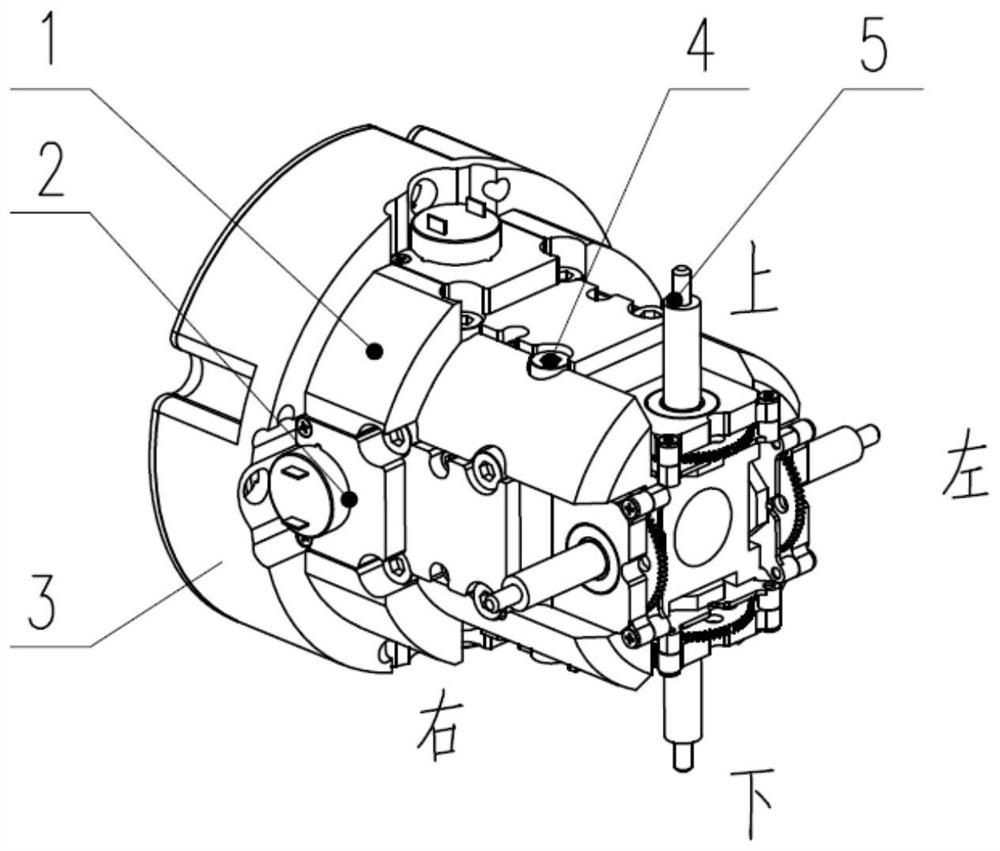

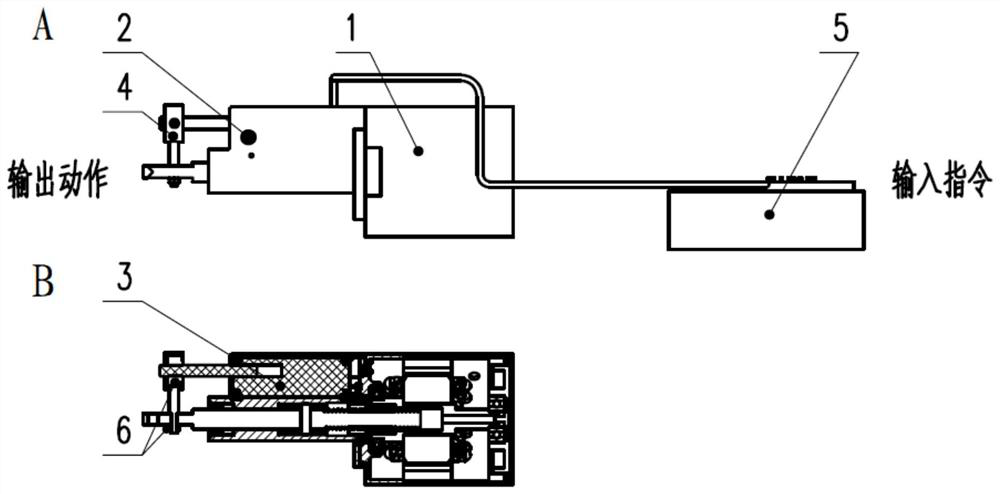

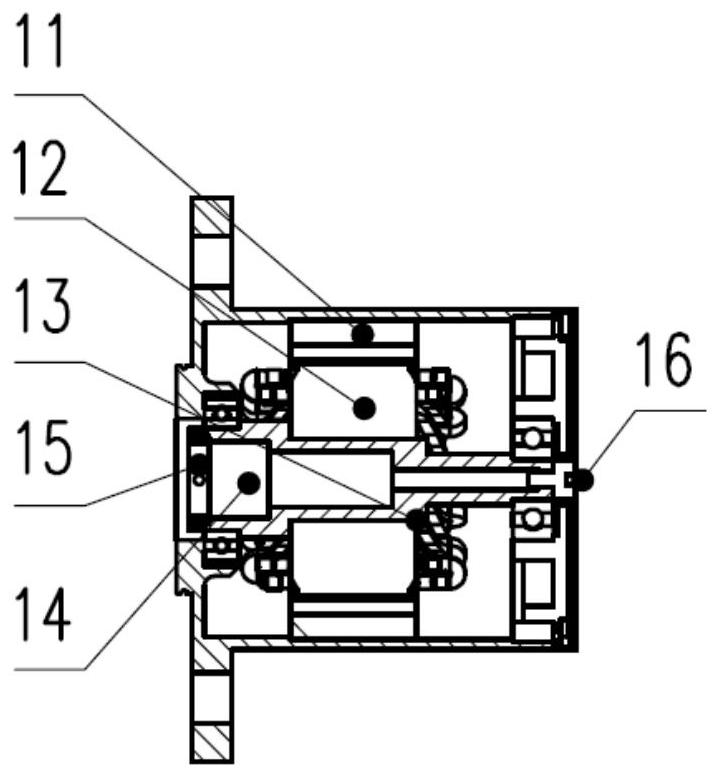

Universality integration four-direction servo steering control device

PendingCN112066821AImprove space utilizationEasy maintenanceMarine torpedoesSelf-propelled projectilesControl functionServo

The invention relates to a universality integration four-direction servo steering control device and belongs to the technical field of electric steering engine structures. The device comprises a complete servo steering control device body, four modularized small steering control devices, a complete device drive control system and a plurality of connecting fasteners. The complete servo steering control device body comprises four universality steering control device stations. The four modularized small steering control devices are installed on the four device stations correspondingly, so that the upper, lower, left and right steering control directions are controlled. Under an instruction of the complete device drive control system, the overall precise direction control function of the steering control device is achieved. The device is compact in size, light in mass and high in universality, and achieves high steering control precision. The whole device can be widely applied to various weapons such as guided missiles and torpedo bodies universally, and the device is flexible to disassemble and assemble, reliable and stable.

Owner:BEIJING AEROSPACE GUANGHUA ELECTRONIC TECH CO LTD

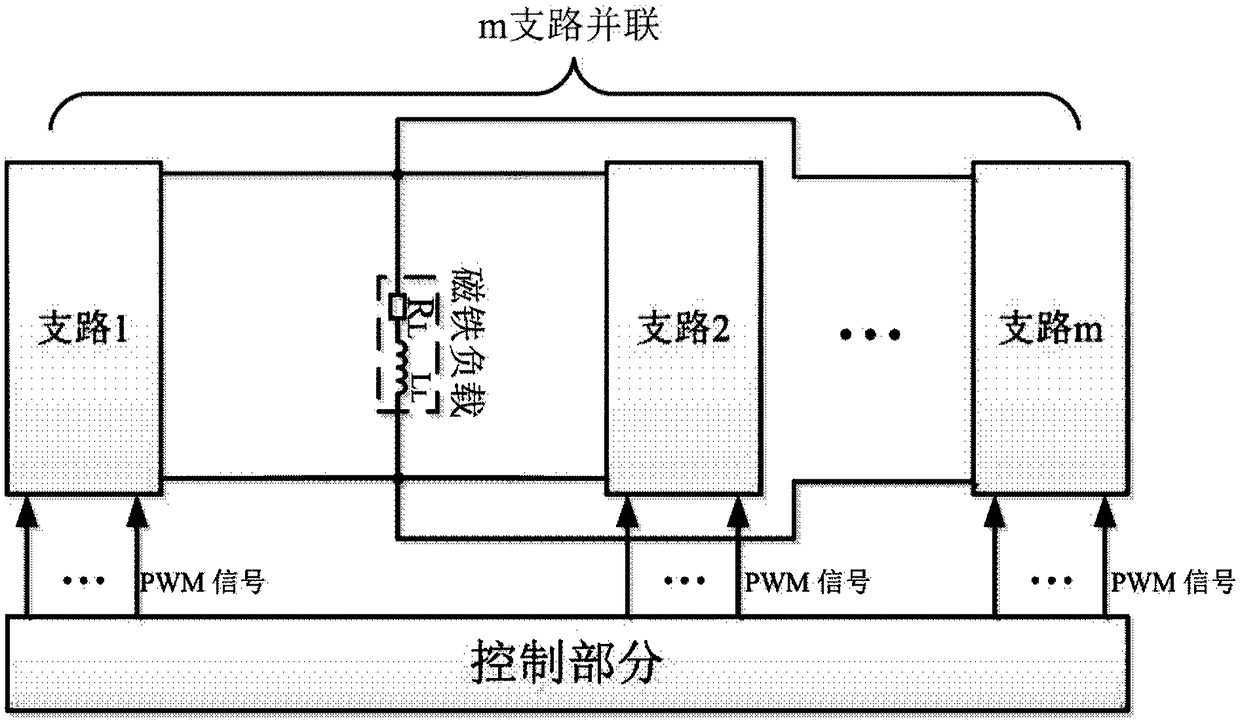

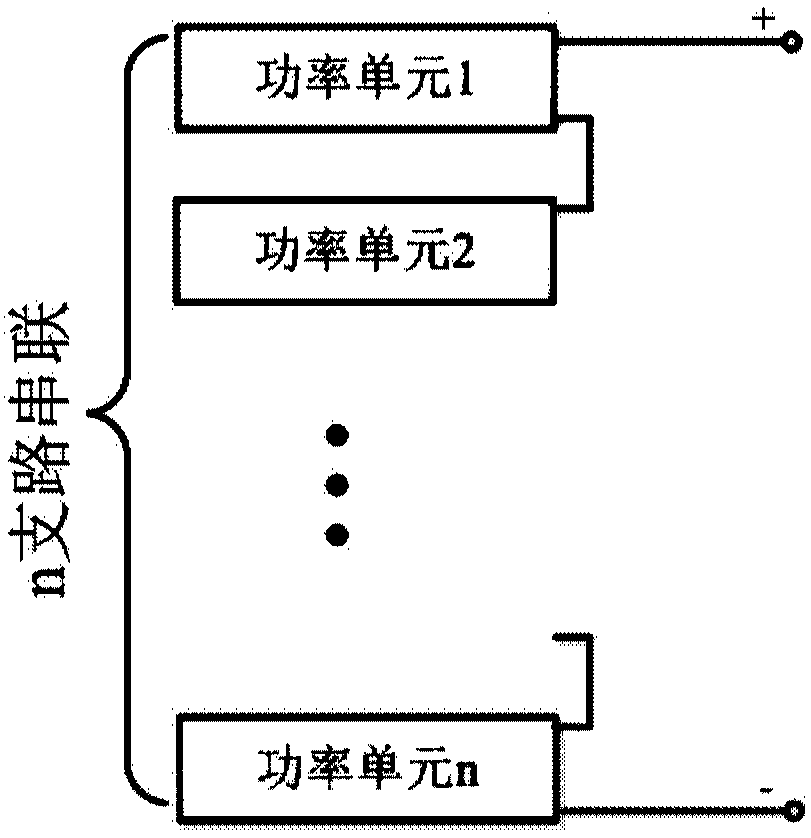

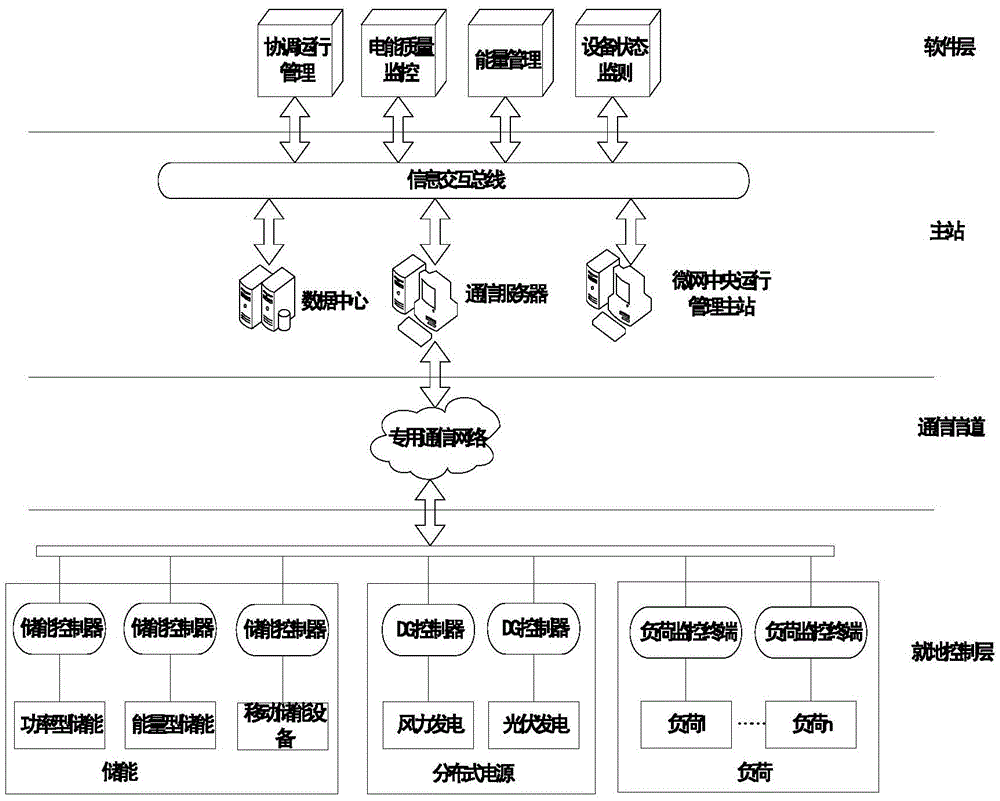

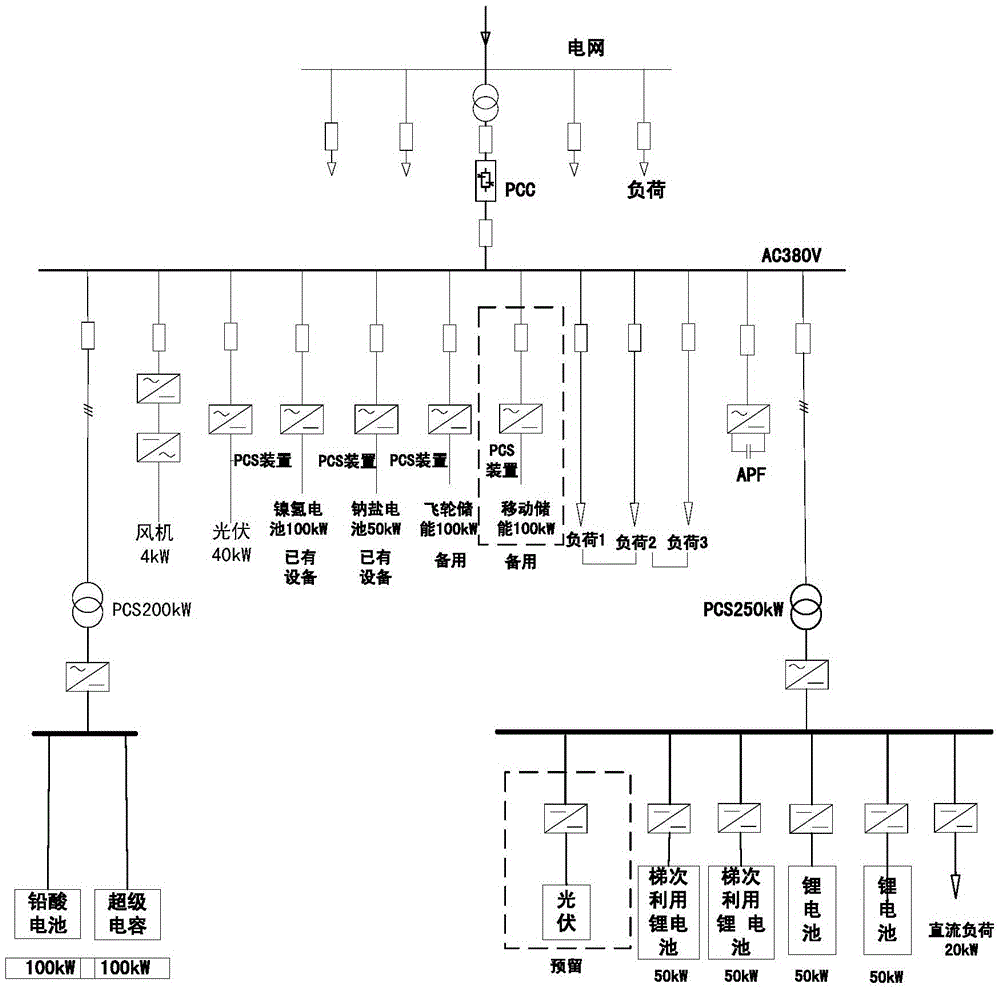

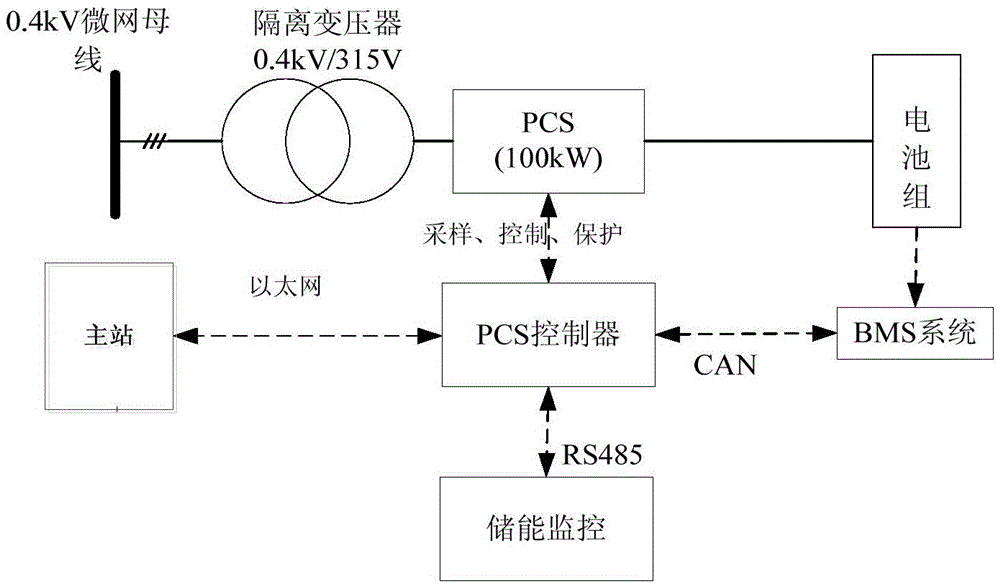

A smart microgrid system

ActiveCN103595138BImprove utilization efficiencyReduce the burden onSingle network parallel feeding arrangementsAc network load balancingPower qualityControl layer

The invention relates to a smart micro-grid system. The smart micro-grid system comprises a local control layer, a network communication layer, a master station layer and a software layer, wherein the local control layer is in communication with the master station layer through the network communication layer, and the master station layer is in communication with the software layer through an information interaction bus. The smart micro-grid system integrates photovoltaic power generation, wind power generation, multiple types of energy storage systems multiple in capacity and modern power electronic, communication and control technologies. While high-reliability power supply is achieved, optimized allocation of renewable energy resources and high-reliability power supply to loads in a micro-grid are achieved; the interaction relation between the micro-grid and an external power grid is reflected correctly, and the effect of distributed energy on improvement of power supply reliability is fully shown; operation data of photovoltaic, wind power and energy storage systems and the micro-grid systems can be collected and stored, and the operation data are accumulated for researches on key technologies about micro-grids. The smart micro-grid system solves the problems that an existing micro-grid system is low in energy utilization ratio and poor in environmental benefit, electric energy quality and power supply reliability.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

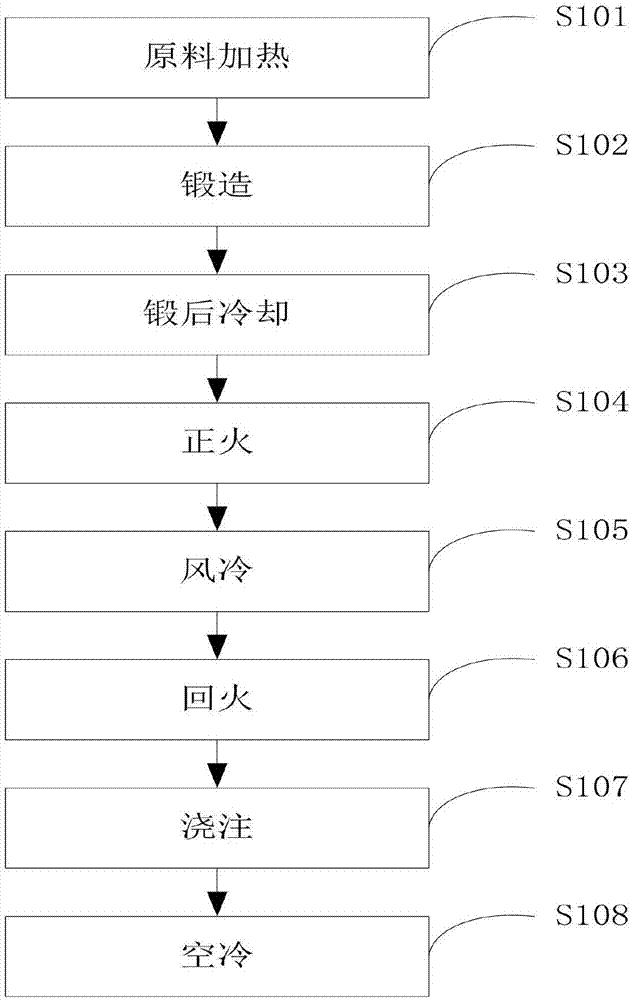

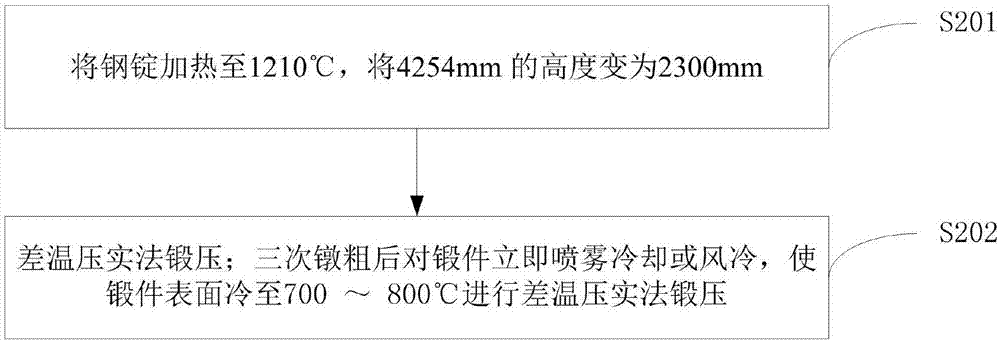

Manufacturing process for low-alloy structural steel for coal mine machinery

The invention belongs to the field of steel, and discloses a manufacturing process for low-alloy structural steel for coal mine machinery. The manufacturing process comprises the following steps of: heating and forging low-alloy steel raw materials, cooling the low-alloy steel raw materials after forging, normalizing the low-alloy steel raw materials, performing air-cooling on the low-alloy steel raw materials, tempering the low-alloy steel raw materials, casting the low-alloy steel raw materials and performing air-cooling on the low-alloy steel raw materials. The alloy steel structure manufactured by the manufacturing process for the low-alloy structural steel for coal mine machinery is excellent in performance, is high in strength, is resistant to pressure, and can meet long-term use requirements; low-carbon structural steel and low-alloy structural steel are treated by a normalizing and tempering process, so that toughness of the low-carbon structural steel and the low-alloy structural steel is improved, an elastic-plastic deformation delay region is relatively great, the grain size of the low-carbon structural steel and the low-alloy structural steel is refined, and good low-temperature performance and quality reliability of steel are guaranteed by continuous casting.

Owner:曹小荣

Low-temperature resistant low-alloy structural steel and manufacturing method thereof

Owner:LAIWU IRON & STEEL GRP

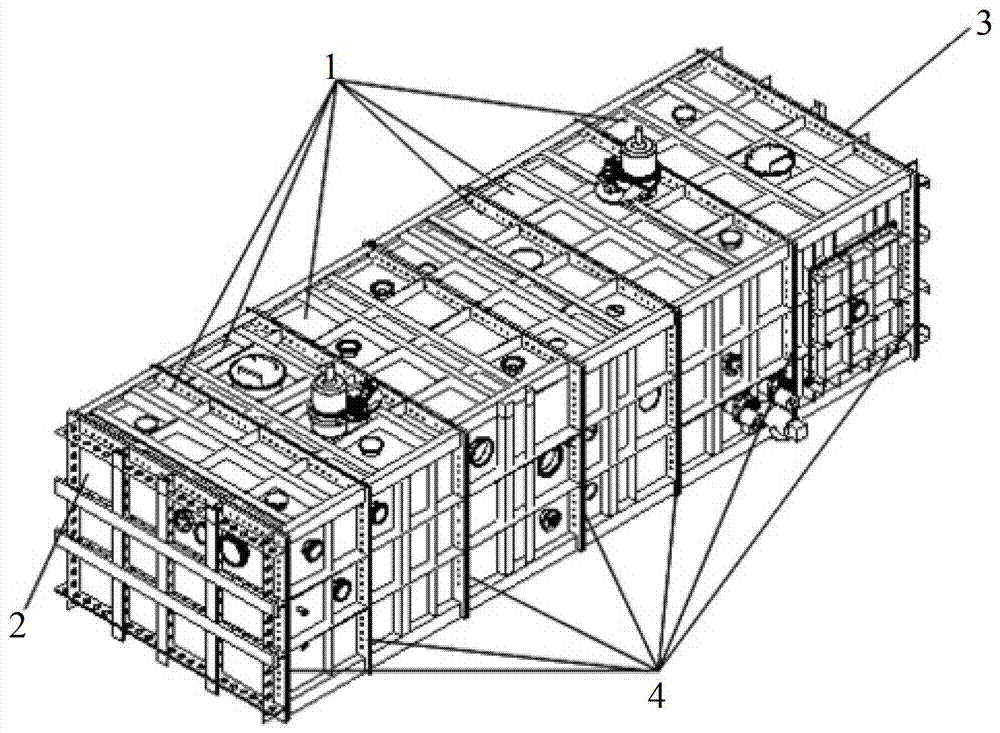

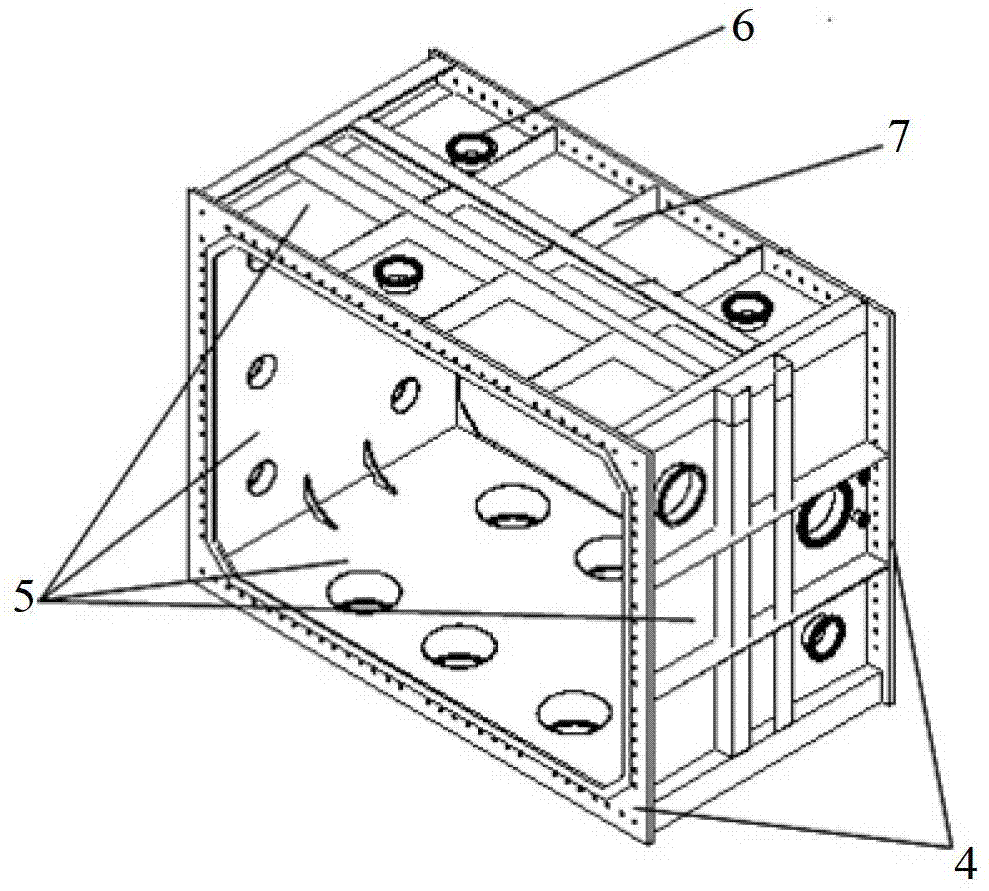

Welding method for large nuclear detection container structure

ActiveCN103878468BBreak through the technical problems of welding technologyMeet the use requirementsArc welding apparatusDomestic vesselsNuclear testingFlange

The invention provides a welding method of a large nuclear detecting container structure. The method includes adopting a double-sided welding groove on a square flange, bottoming through TIG welding, and capping layer by layer, tailor welding forming and leveling through MIG welding; welding and positioning four wall plates, assembling the same into a box component, and positioning through TIG welding; positioning and assembling the box component with the square flange, and positioning through TIG welding; positioning and assembling reinforcing ribs and a circular flange with the box component, and positioning through TIG welding; welding the weld joints among the components such as the square flange, the circular flange, the wall plates and the reinforcing ribs. The welding method is high in weld joint quality and good in quality reliability, vacuum degree requirements can be satisfied, and use requirements of large seal vacuum nuclear detecting containers can be satisfied.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

Distribution network fault location method and system based on micro-pmu and binary search

ActiveCN110133451BReduce outage timeGood quality and reliabilityFault location by conductor typesSystems intergating technologiesDistribution gridDistribution networks

The invention provides a power distribution network fault positioning method and system based on a micro PMU and dichotomy search. The power distribution network fault positioning method comprises thesteps of calculating a positive sequence component of a fault current at a fault point by utilizing a power supply before and after fault measurement by the micro PMU in a fault observable configuration and a current at a load, and injecting the positive sequence component into the assumed fault point to construct a positive sequence fault additional component network; performing fault point searching on lines on the basis of dichotomy in the positive sequence fault additional component network in sequence, and according to an admittance matrix formed in the search process and the positive sequence component of the fault current, obtaining voltage positive sequence fault component calculation values of all PMU configuration nodes; calculating voltage deviation norms between the voltage positive sequence fault component calculation values of all the PMU configuration nodes and actual measurement values, and determining fault positions corresponding to the minimum values of the positivesequence voltage deviation norms of the lines as candidate fault points; and screening out the candidate fault points corresponding to the minimum values of the positive sequence voltage deviation norms corresponding to the candidate fault points to serve as actual fault points.

Owner:SHANDONG UNIV

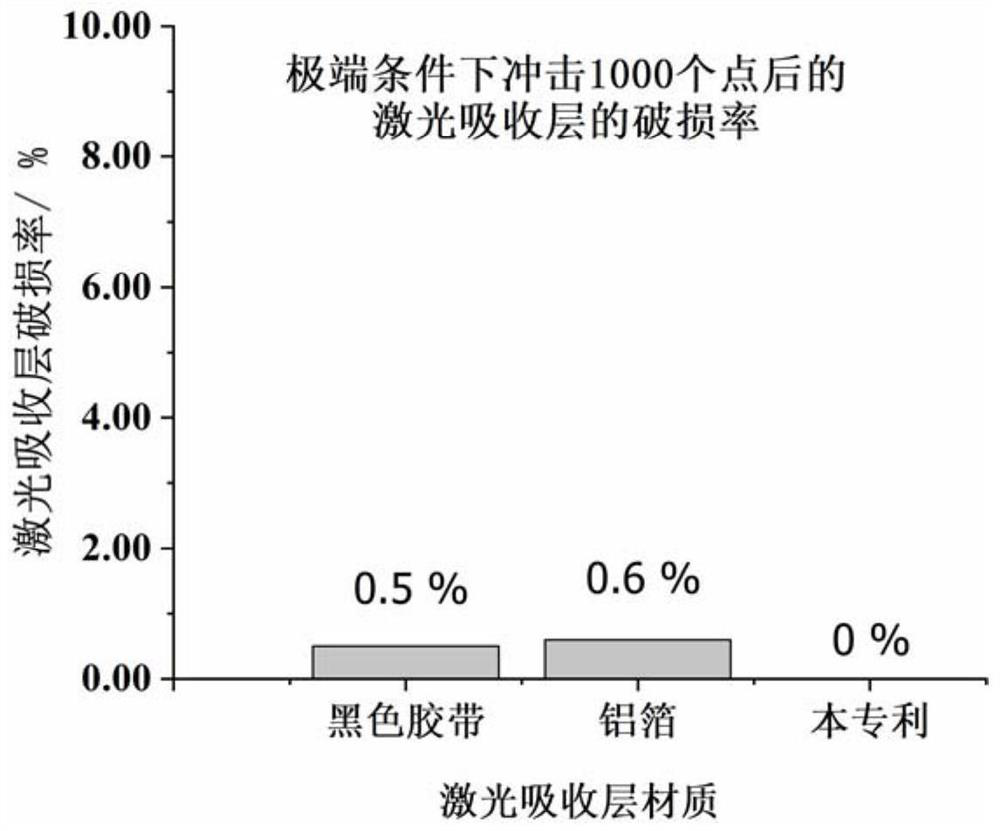

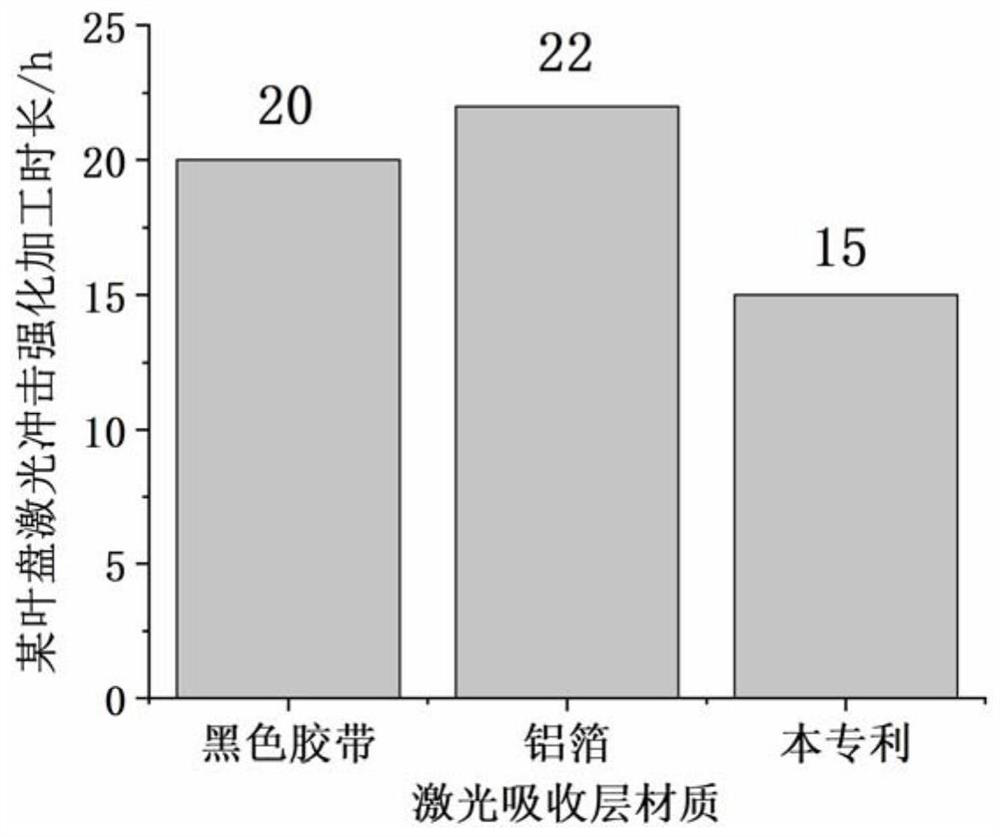

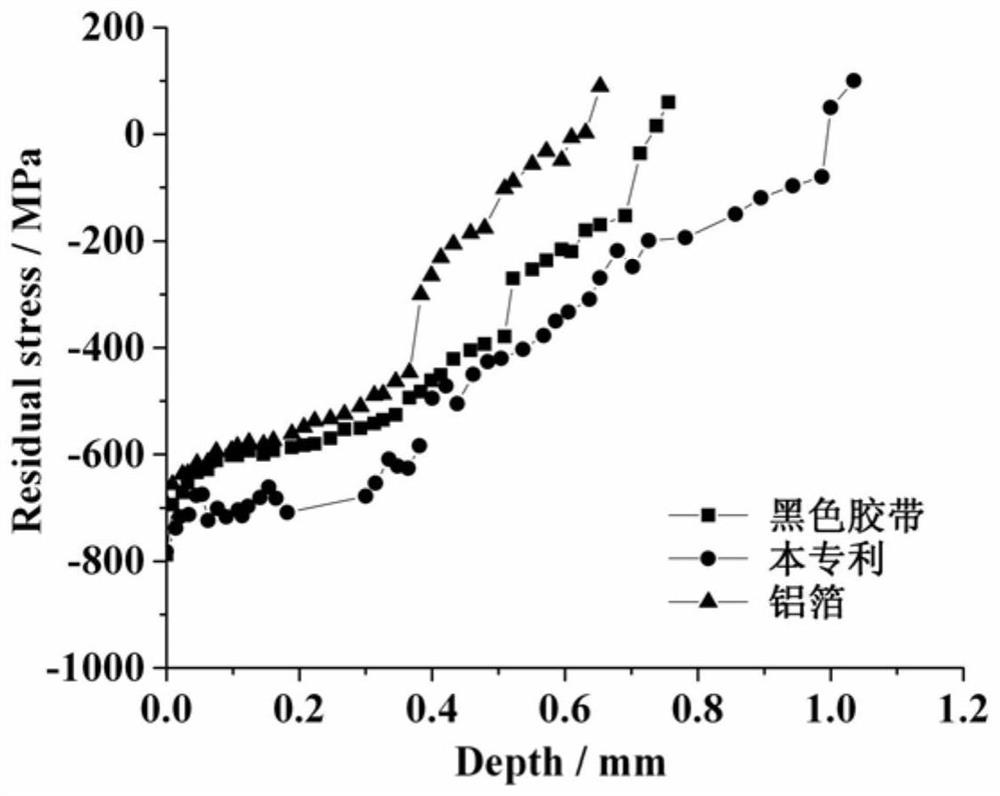

A graphene-modified laser absorbing layer coating and coating method thereof

ActiveCN113088172BImprove laser absorption rateImprove the utilization rate of laser energyLiquid surface applicatorsPolyurea/polyurethane coatingsHigh volume manufacturingPhysical chemistry

The invention belongs to the technical field of parts surface treatment, and relates to a graphene-modified laser absorbing layer coating and a coating method thereof; the coating is mainly composed of polyurethane resin, black auxiliary materials, functional additives and deionized water; the invention uses graphite After olefin modification, a higher amplitude and deeper surface residual compressive stress distribution is produced on the surface of the part. The laser absorbing layer coating is coated on the surface of the part by high-pressure gas-driven spraying. After drying, a coating with uniform thickness is obtained on the surface of the complex part, and the bonding force between the coating and the part is good. It can be removed by hand peeling. The method has the advantages of high coating efficiency, good quality reliability, and high removal efficiency, and is beneficial to the processing of complex parts and its mass production.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

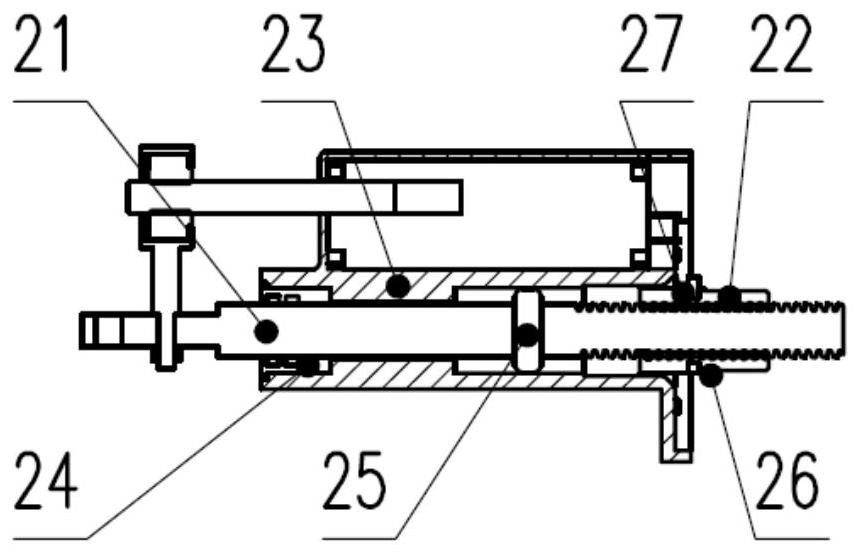

Integrated universal linear actuator and manufacturing process thereof

ActiveCN113685520AOptimize volumeWeight optimizationGearingGear lubrication/coolingManufacturing technologyControl system

The invention provides an integrated universal linear actuator and a manufacturing process thereof. The linear actuator comprises a hollow motor, a transmission-action module, a displacement sensor, a mechanical-electric linkage locking device and a driving control system. The hollow motor is connected with the transmission-action module through a lead screw and nut pair so that the rotating motion of the hollow motor can be directly converted into the linear reciprocating motion of the transmission-action module. The displacement sensor is connected with the transmission-action module through the mechanical-electric linkage locking device and used for outputting a position feedback signal of the transmission-action module to the driving control system. The driving control system is electrically connected with the hollow motor and used for sending a driving instruction signal to the hollow motor, controlling the hollow motor to operate and receiving the position feedback signal output by the displacement sensor so as to judge the current displacement of the transmission-action module, regulate and control the linkage motion of the hollow motor and the transmission-action module and enable the linear actuator to output continuous linear reciprocating motion.

Owner:BEIJING AEROSPACE GUANGHUA ELECTRONIC TECH CO LTD

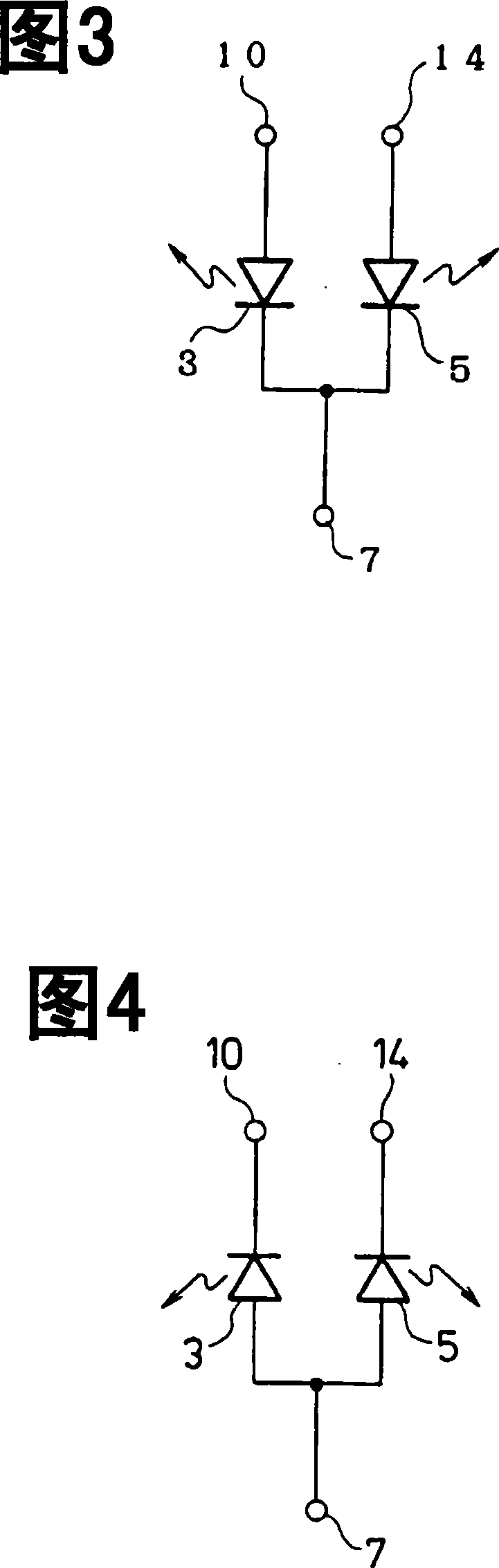

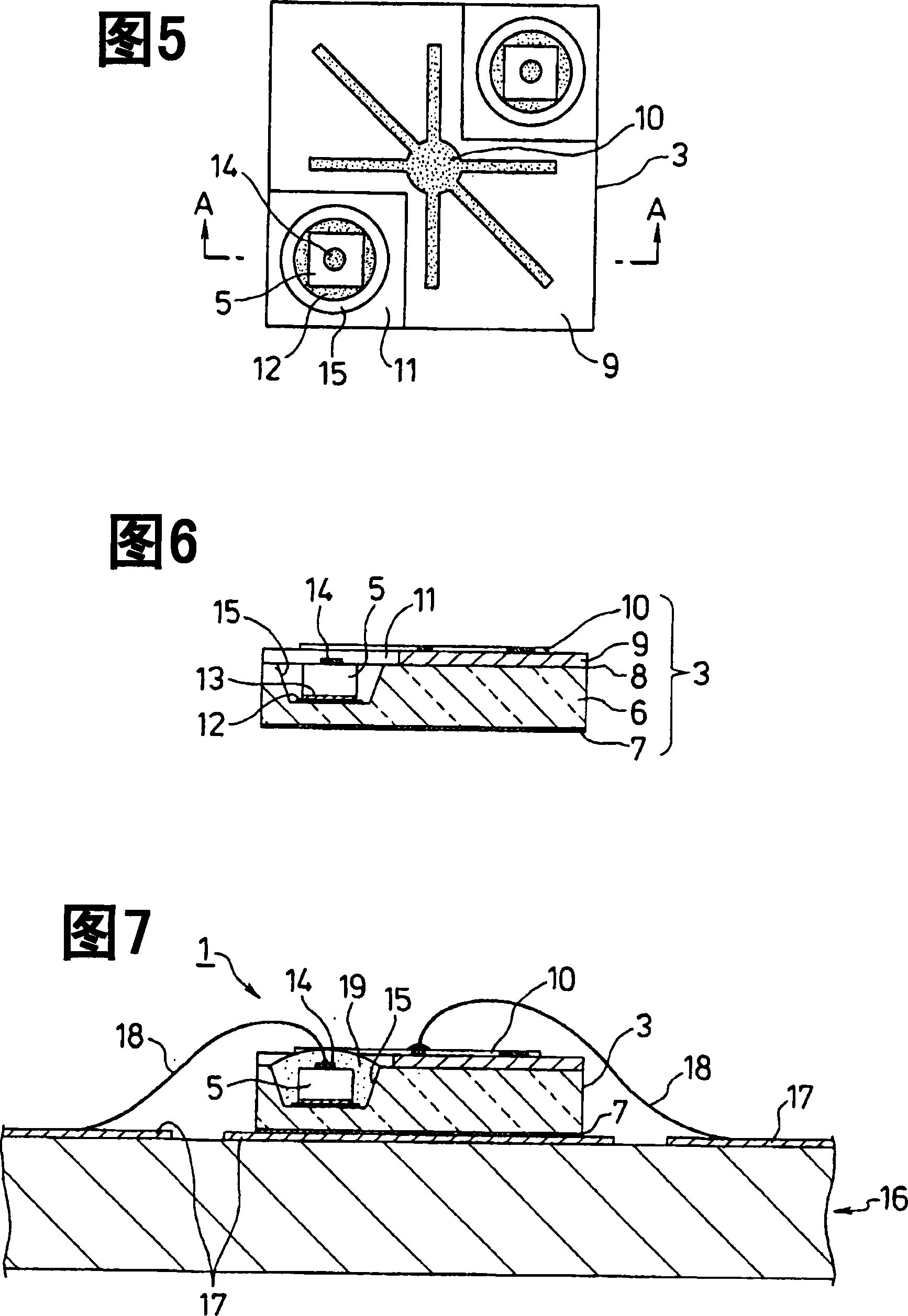

Composite semiconductor device and method of manufacturing the same

InactiveCN101090108AStrong heat radiationImprove color mixingSolid-state devicesSemiconductor/solid-state device manufacturingSubject matterSemiconductor

The disclosed subject matter provides a composite semiconductor device which can include a common substrate, a first semiconductor light emitting structure, and a second semiconductor light emitting structure. The first semiconductor light emitting structure can include an epitaxial grown layer containing a light emitting layer formed on part of the common substrate either directly or via a bonding layer. The second semiconductor light emitting structure can be provided in a notch at at least one location to which the epitaxial grown layer is not bonded, or in a recess formed in the notch at one location. The disclosed subject matter also provides a method of manufacturing a composite semiconductor device having the above-described and other structures.

Owner:STANLEY ELECTRIC CO LTD

A kind of muffler of multi-stage compound noise reduction and preparation method thereof

ActiveCN103953418BReduce distractionsReduce harmExhaust apparatusSilencing apparatusProduction rateEngineering

The invention discloses a multistage composite silencing silencer. The multistage composite silencing silencer comprises a pipe joint, a silencing cover, a lower shell, an upper shell, a silencing net, an exhaust pipe and sound absorbing materials. By arranging four stages of silencing chambers with ventilation net section area which is gradually increased, the silencing cover and the silencing net with alternating large and small holes for silencing and the sound absorbing materials for composite silencing, noises can be reduced by 20-25 decibels, the noises beside ears become gentle from harsh, high, medium and low hearable components in audio spectra are obviously decreased and interference and harm to people are reduced. The invention additionally provides a preparation method of the multistage composite silencing silencer. Riveting and roll welding processes are used for replacing an oxyacetylene welding process, the quality reliability is high, the appearance quality is obviously improved and the corresponding productivity is improved by 1-2 times.

Owner:扬州新扬通风设备有限公司

Separately precast and assembled bent cap and construction technology

ActiveCN102409607BReduce weightEasy to transportBridge structural detailsBridge erection/assemblyPre stressBuilding construction

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

A high-efficiency and high-quality intelligent manufacturing equipment and system for high-performance core basic components

ActiveCN110640971BHigh quality and efficient productionHigh degree of automationCleaning using liquidsTurning machinesProcess engineeringSmart manufacturing

The invention discloses a high-efficiency and high-quality intelligent manufacturing equipment and system for high-performance core basic components, which include an automatic cleaning system, a molding and vulcanization forming system, a precision processing system, and an inspection and storage system. The automatic cleaning system includes a first turntable installed in sequence, The cleaning device and the second turntable; the molding vulcanization forming system includes injection molding processing devices placed in sequence, and the inspection system includes an inspection room, which is provided with an inspection table, an input table and a storage device. The high-performance core basic components of this solution, high-efficiency and high-quality intelligent manufacturing equipment and systems, through a complete intelligent production system, relying on industrial robots, connect various related production systems in series to realize intelligent production of products, with a high degree of automation , high production efficiency, good product surface integrity, quality reliability and consistency, etc.; so as to realize the intelligent manufacturing and production for the majority of customers, and realize the large-scale production of multi-specification and multi-variety high-performance composite parts and components High quality and efficient production.

Owner:SOUTHWEST JIAOTONG UNIV +1

Coated fabric for airbag

ActiveUS10889259B2Good quality and reliabilityPacked tightlyFibre treatmentPedestrian/occupant safety arrangementEngineeringUltimate tensile strength

A coated fabric for an airbag having improved tensile strength of coated fabric without increasing the strength of a raw yarn is provided. The coated fabric for the airbag comprises a coated silicone resin on one surface of a textile made of synthetic fiber filaments, wherein the silicone resin is present at a joint between warp and weft of a non-coated surface of the textile.

Owner:TOYOBO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com