Integrated mosaic decoration plate and its processing and mounting method

A processing method and mosaic technology, applied in chemical instruments and methods, lamination devices, lamination, etc., can solve the problems of variable specifications, high flatness, labor-intensive and time-consuming surface cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

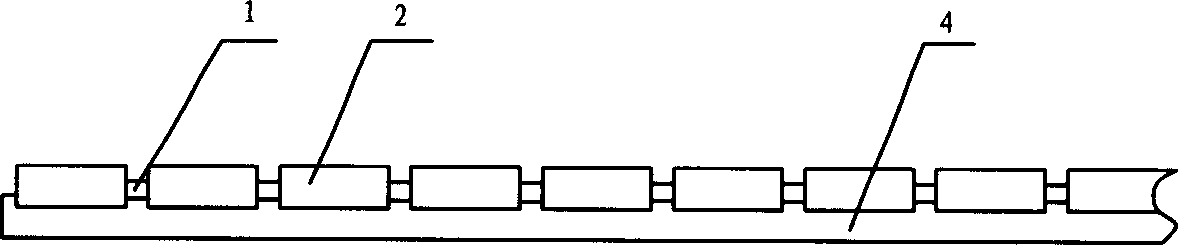

[0018] The product of this embodiment is composed of a base plate 4 made of a heat-melting material and a mosaic block 2 fixed thereon. Alternatively, it is composed of a base plate 4 made of a heat-soluble material, mosaic blocks 2 fixed thereon, and jointing material 1 between the mosaic blocks 2 .

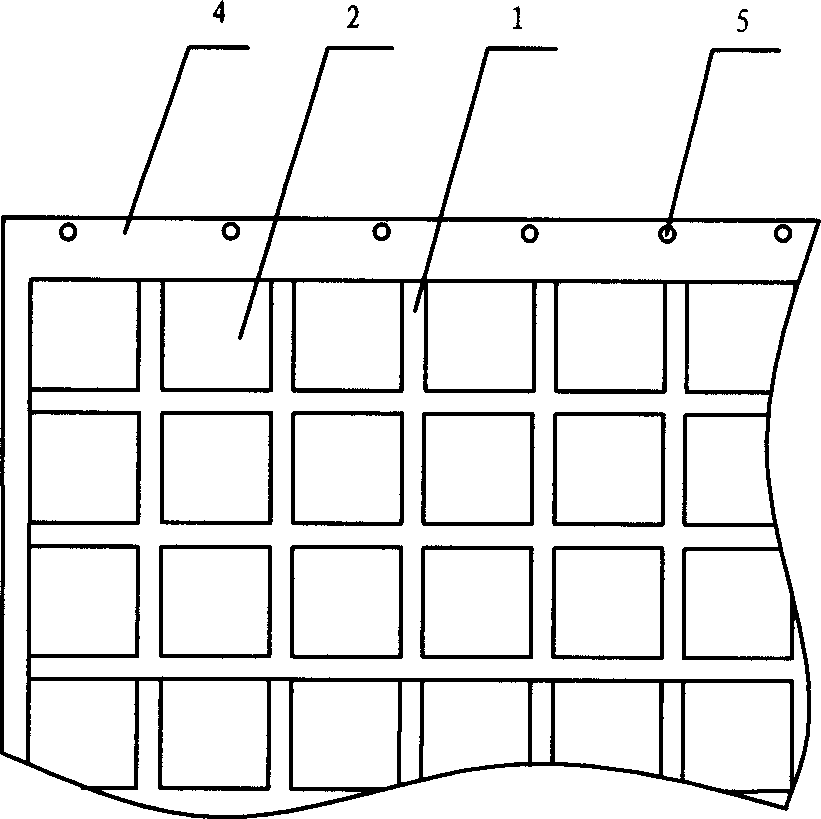

[0019] The base plate 4 is made of hot-melt material (such as plastic). During specific processing, molds of different shapes such as squares, circles, and prismatic shapes are designed according to needs, and the heated liquid raw material is placed in the mold to form a base layer in the mold, and then the mosaic block 2 is supplemented on it, and used The pressing plate exerts pressure to embed part or all of the mosaic block 2 into the base material, and then it is cooled to make a finished product. Thereafter, the grouting material 1 may be applied between the gaps of the mosaic blocks 2 as needed. In addition, bolt holes 5 can also be prefabricated at appropriate positio...

Embodiment 2

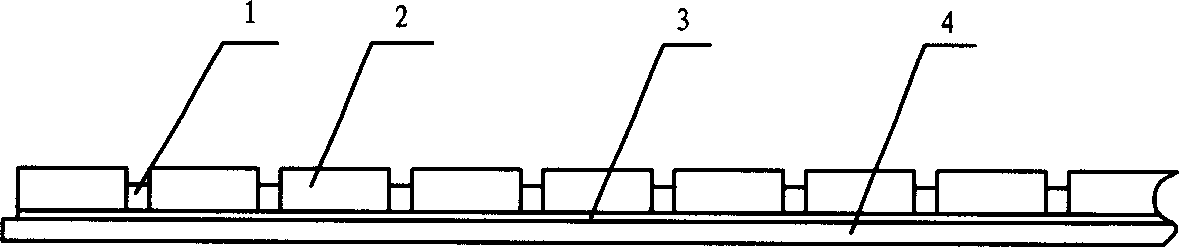

[0021] The product of this embodiment is composed of a base plate 4 made of a curable material and a mosaic block 2 fixed thereon. Alternatively, it is composed of a base plate 4 made of a curable material, mosaic blocks 2 fixed thereon, and jointing material 1 between the mosaic blocks 2 .

[0022] The base plate 4 adopts concrete or concrete with adhesive as raw material. During specific processing, molds of different shapes such as squares, circles, and prismatic shapes are designed according to needs, and concrete is placed in the mold to form a base layer in the mold, and then the mosaic block 2 is added to it, and pressure is applied with a pressure plate, Part or all of the mosaic block 2 is embedded in the base material, and then dried to make a finished product. After that, you can also apply a jointing material between the gaps of the mosaic blocks as needed. In addition, bolt holes 5 can also be prefabricated at appropriate positions of the base plate 1 according ...

Embodiment 3

[0024] In this embodiment, a fireproof board is used as the base board 4, and the two surfaces of the base board 4 are rough surfaces. There is an adhesive layer 3 on one surface thereof, and a mosaic block 2 is fixed on the adhesive layer 3 .

[0025] Alternatively, a fireproof board is used as the base board 4, and the two surfaces of the base board 4 are rough surfaces. There is an adhesive layer 3 on one surface thereof, and a mosaic block 2 is fixed on the adhesive layer 3 . Pointing material 1 is provided at the gap between the mosaic blocks 2 .

[0026] During processing, choose a fire-proof board with a rough surface as the base board 4, or firstly sand the two surfaces of the fire-proof board, apply an adhesive layer 3 on one of the surfaces, and then add the mosaic block 2 to it to carry out Finished product after drying. Thereafter, the grouting material 1 may be applied between the gaps of the mosaic blocks as needed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com