Lithium battery cap pressure welding device

A lithium battery and cap technology, which is applied in the field of lithium battery cap pressure welding devices, can solve the problems of low cap production efficiency, low safety performance, poor product quality, etc., and achieves good practical performance, good quality reliability, and improved production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

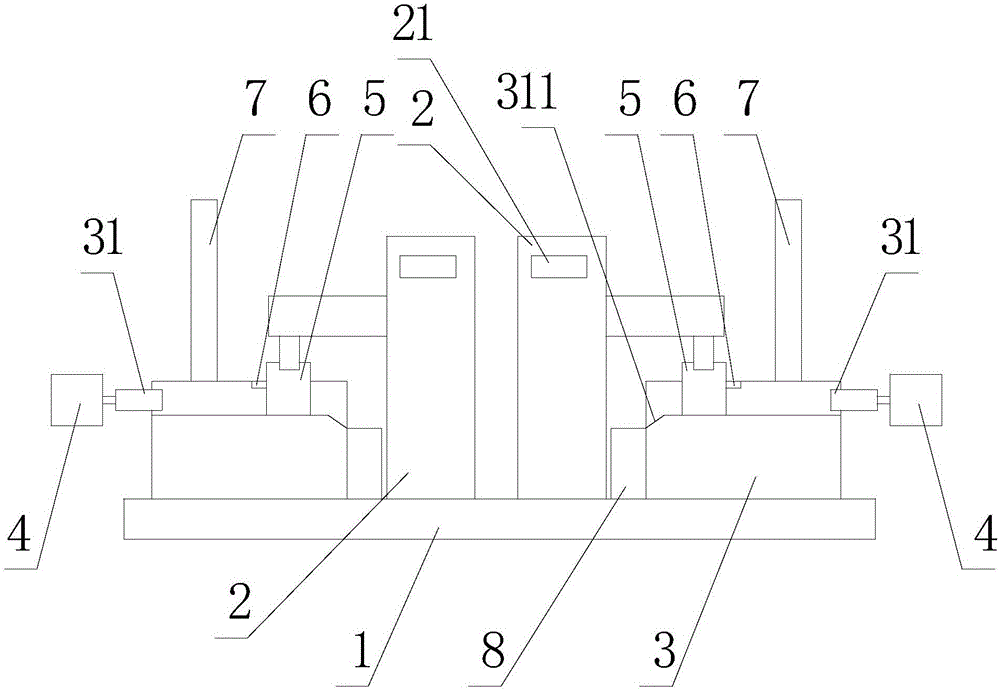

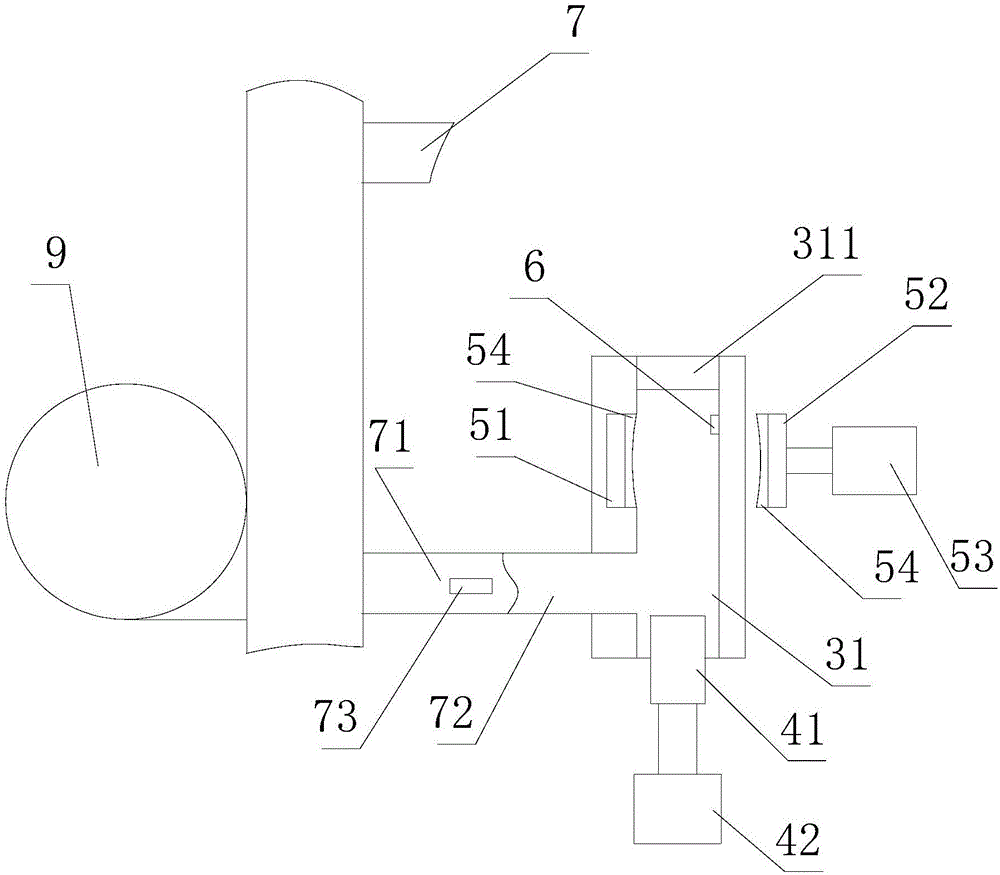

[0018] Such as figure 1 , figure 2 As shown, the lithium battery cap welding device includes a frame 1 and two bonding devices 2 fixedly connected to the frame 1, and the frame 1 at the bottom of the two bonding devices 2 is fixedly connected with a fixing device 3. The fixing device 3 is a base provided with a through groove 31 at the top, and the feeding section of the through groove 31 is provided with a pushing device 4 for pushing the cap to the bottom of the pressure welder 2, and on the frame 1 A locking device 5 that locks the pushed cap in the through groove 31 is movably connected, and the locking device 5 includes a fixed block 51 fixed at one end of the fixing device 3, and a sliding block movably connected at the other end of the fixing device 3. 52, the slider 52 is movably connected to the frame 1 through the first cylinder 53, and the slider 52 is driven by the first cylinder 53, so that the slider 52 and the fixed block 51 clamp the cap in the through groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com