Patents

Literature

35results about How to "High quality and efficient production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

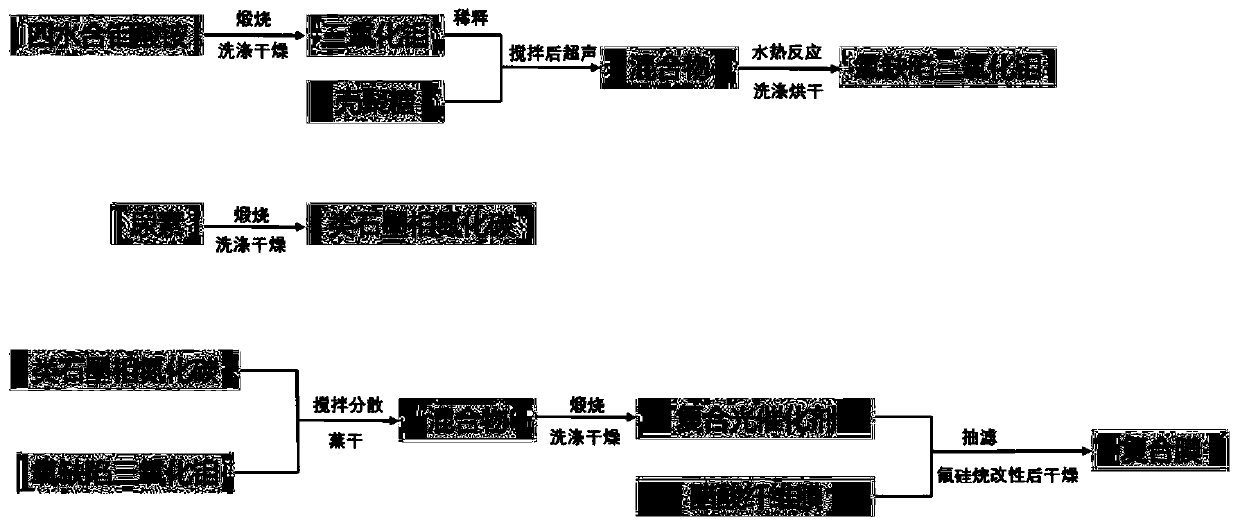

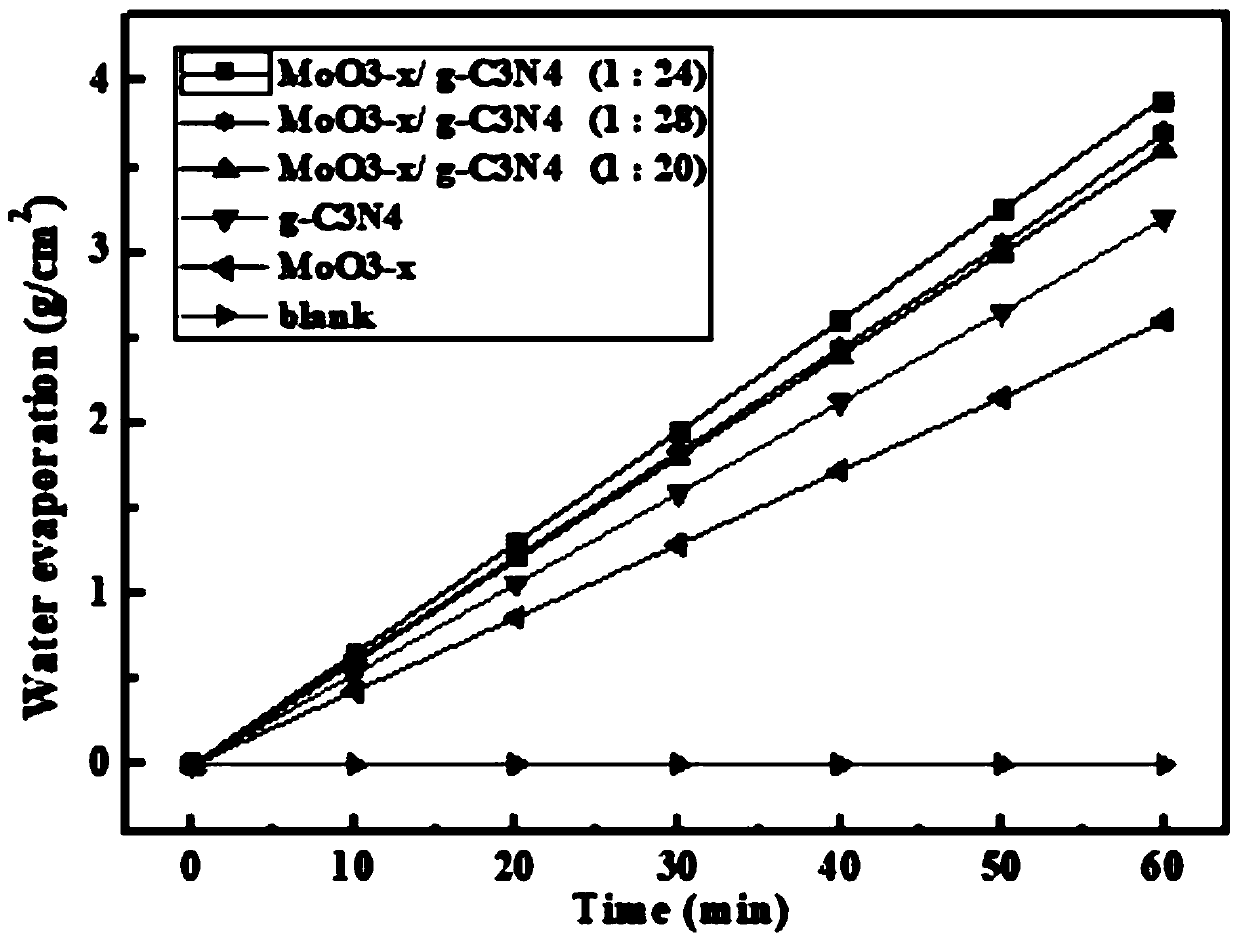

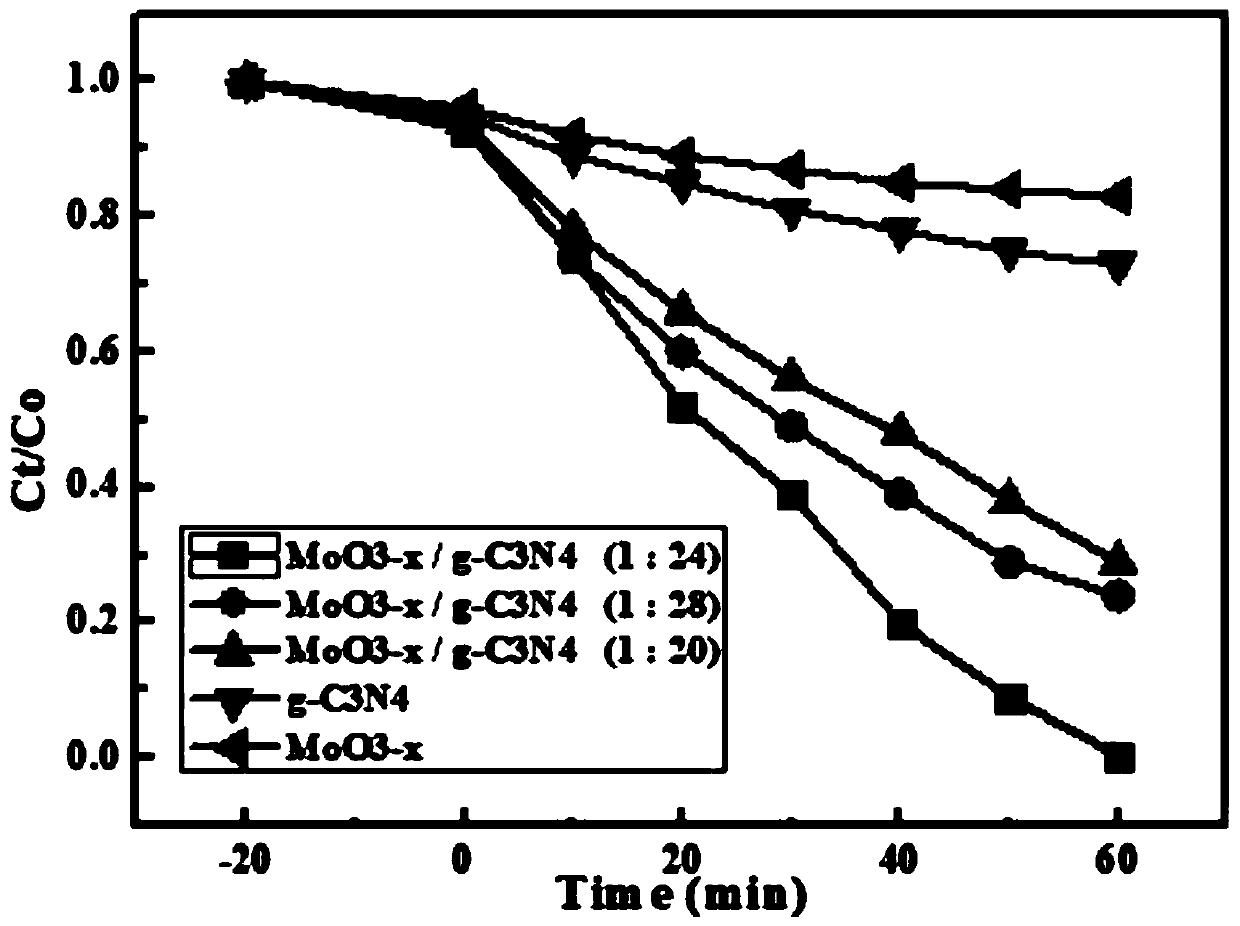

MoO<3-x>/g-C<3>N<4> composite photocatalytic material, and preparation method and application thereof

InactiveCN110227554AHigh photothermal conversion efficiencySpeed up vaporizationWater/sewage treatment by irradiationWater treatment compoundsHeterojunctionQuantum efficiency

The invention discloses a MoO<3-x> / g-C<3>N<4> composite photocatalytic material. The composite photocatalytic material is composed of a hydrophobically modified cellulose acetate membrane and a MoO<3-x> / g-C<3>N<4> compound supported on the cellulose acetate membrane, wherein the MoO<3-x> / g-C<3>N<4> compound is formed by connecting MoO<3-x> with g-C<3>N<4> via a Z-type heterojunction. The inventionalso discloses a preparation method for the above MoO<3-x> / g-C<3>N<4> composite photocatalytic material and the application of the composite photocatalytic material to degrading of VOCs in water bodies. The MoO<3-x> / g-C<3>N<4> composite photocatalytic material of the invention has high photothermal conversion efficiency and high quantum efficiency, and can improve the vaporization speed of waterand realize high-efficiency degradation of VOCs; and high-quality and high-efficiency production of clean water is successfully achieved through the synergistic effect of vaporization and degradation.

Owner:HOHAI UNIV

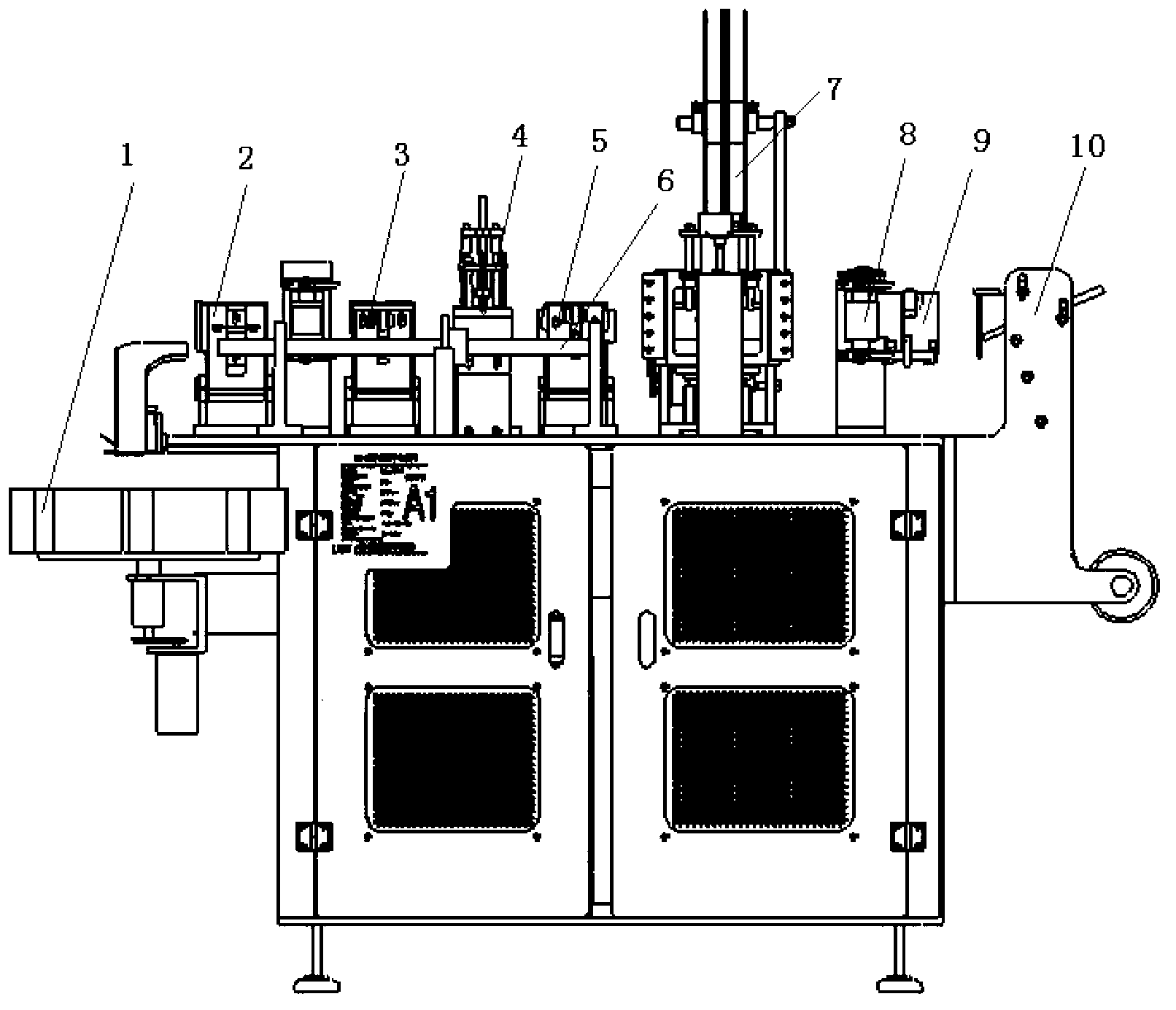

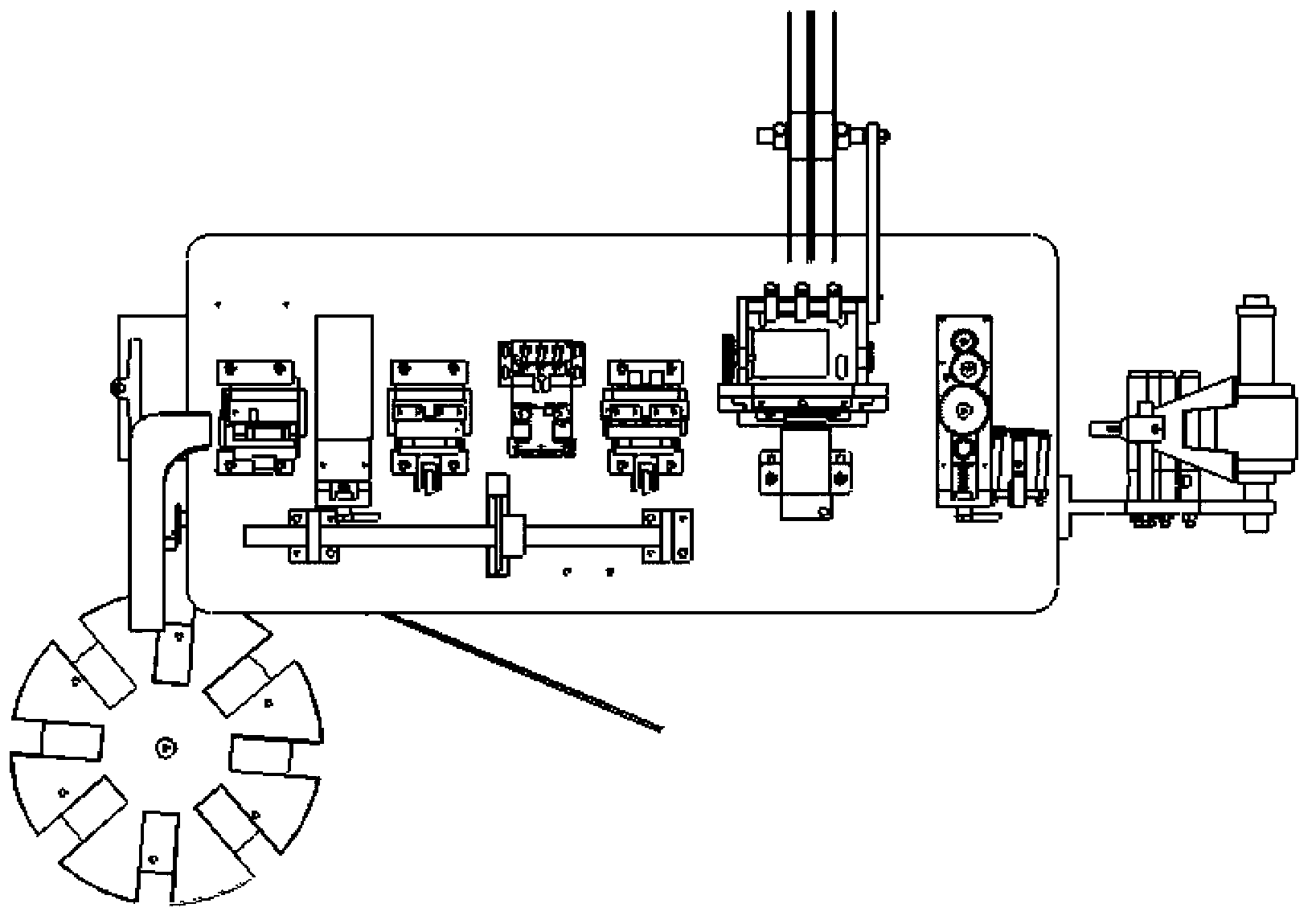

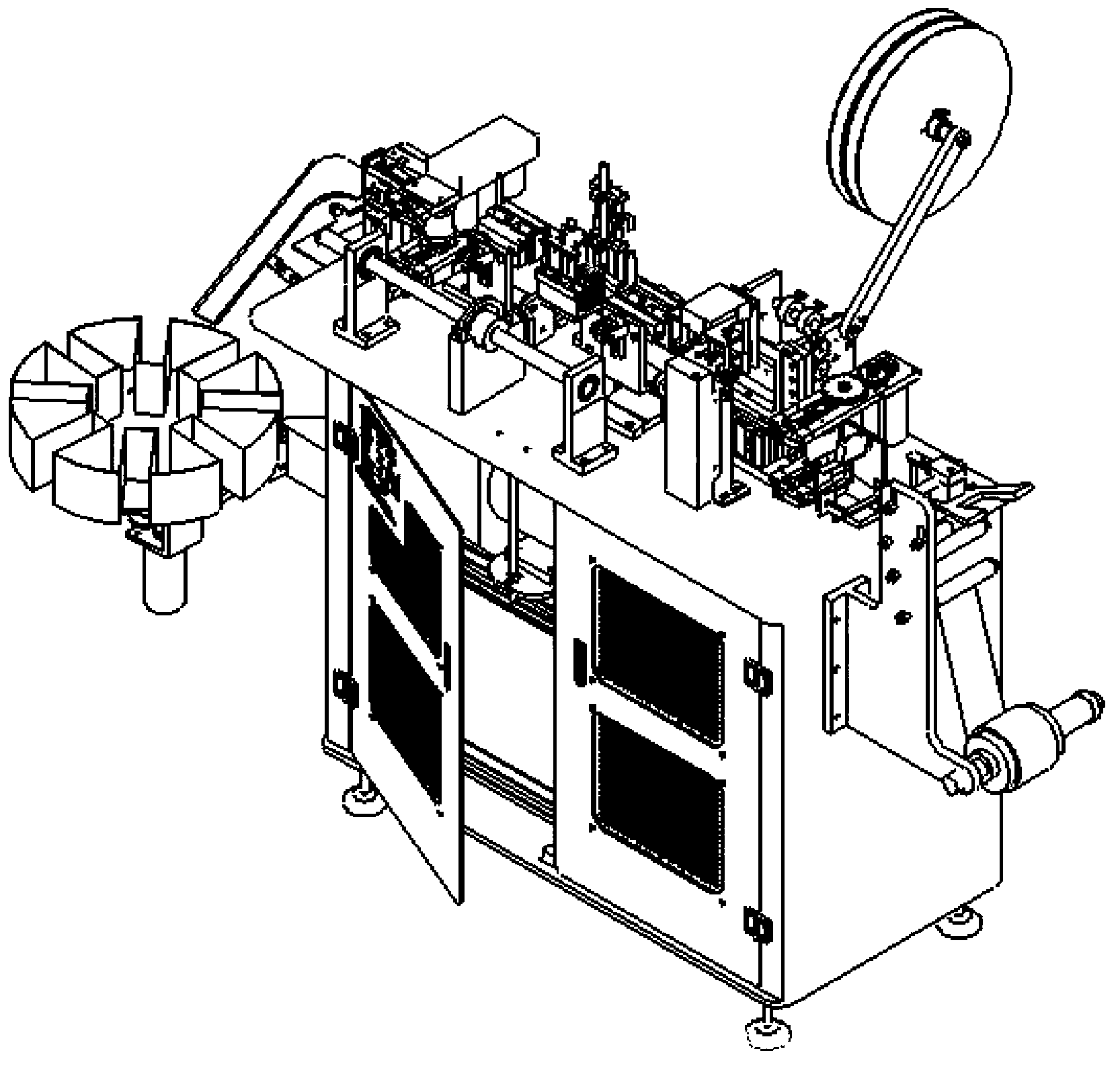

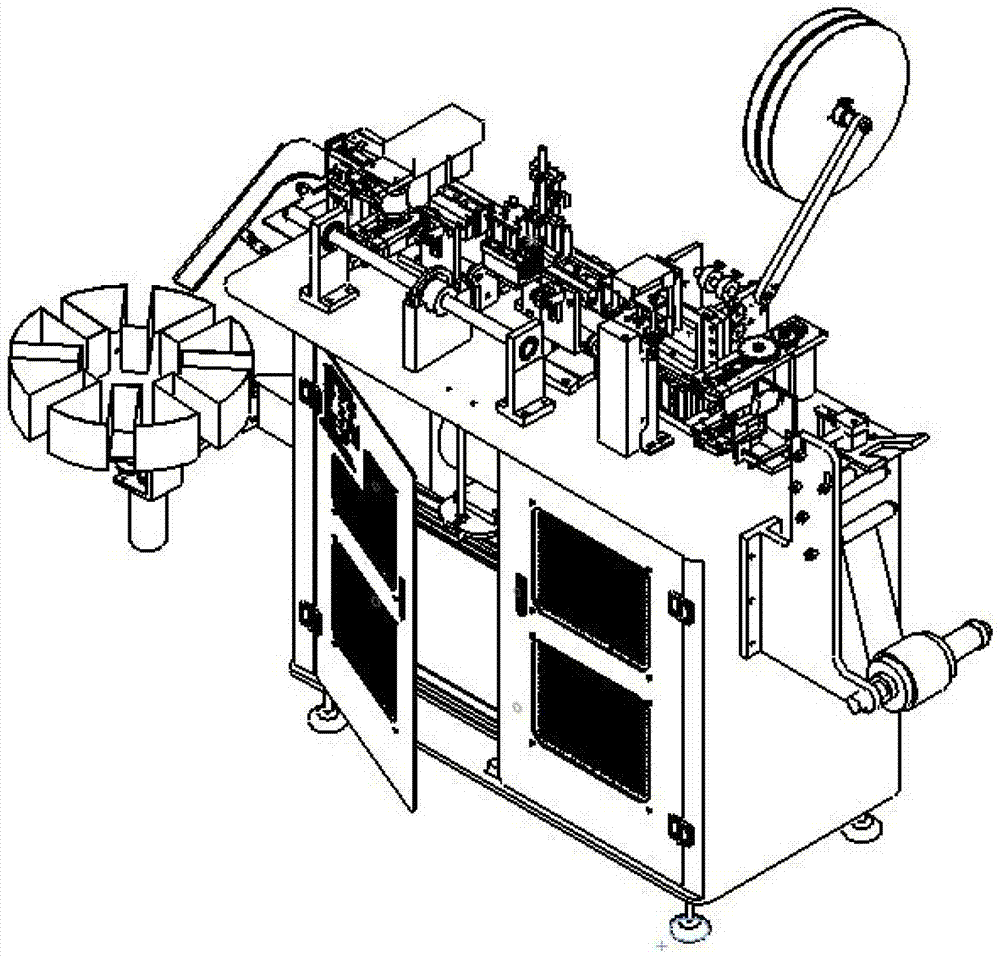

Efficient alcohol pad packer for finger-protective alcohol pad production

ActiveCN103287611AAvoid cross infectionFix technical deficienciesPaper article packagingWrapper twisting/gatheringAlcohol padsAutomation

The invention relates to an efficient alcohol pad packer for finger-protective alcohol pad production. The efficient alcohol pad packer comprises a workbench, a former, a light sensor, a packing paper feed mechanism, a liquid injection mechanism, a sealing mechanism and a finished product cutting mechanism. A core cutting and inserting mechanism and an epsilon-shaped core thermal sealing mechanism. The efficient alcohol pad packer has the advantages that the efficient alcohol pad packer is ingenious in design, simple in structure, high in practicality, and high in automation level, the advantages of original packers are inherited, the defects in the prior art are overcome, high-quality and efficiency production of the finger-protective alcohol pads and like products is achieved, process flow is simplified, equipment automation level is increased, and work efficiency is increased.

Owner:LIGHTS MEDICAL MFR

Chili cultivation method of planting chilies in one crop and harvesting chilies in three seasons

InactiveCN104620808AHigh quality and efficient productionPlant cultivationCultivating equipmentsGreenhouseCrop cultivation

The invention discloses a chili cultivation method of planting chilies in one crop and harvesting the chilies in three seasons. The method comprises the following steps that firstly, a seedling bed is prepared, small seedlings are cultivated, and large seedlings overwinter; secondly, early covering in spring, oversummer covering and delayed covering in autumn are carried out; thirdly, water, fertilizer and pesticide integrated management is carried out; fourthly, oversummer pruning is carried out. According to the greenhouse long-season chili cultivation method, the traditional spring and autumn two-crop cultivation mode of the chilies is created into the one-crop long-season cultivation mode, large seedling overwintering, covering, water, fertilizer and pesticide integrated management, oversummer pruning and other key technologies are integrated and created, the chilies are planted in one crop and harvested in spring, autumn and winter, and the high-quality and high-efficient production of the chilies of early covering in spring, early covering in autumn and delayed covering in autumn is achieved.

Owner:HUNAN VEGETABLE RES INST +1

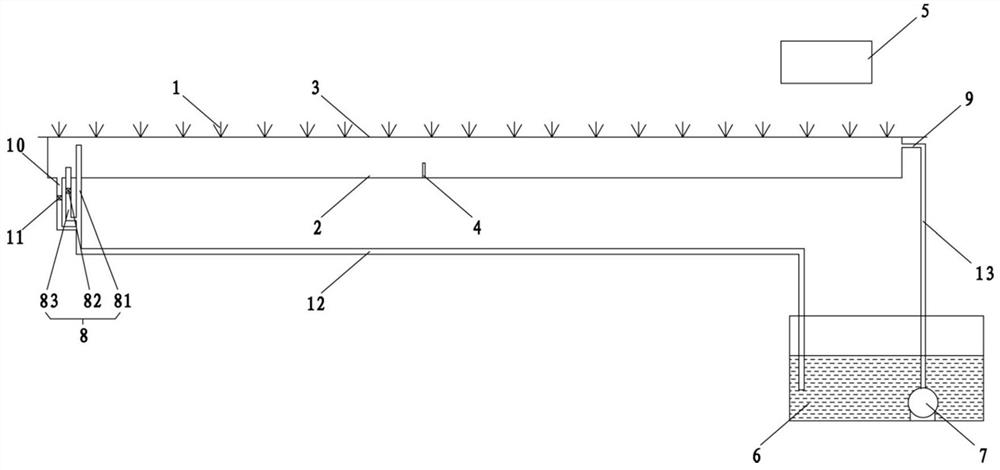

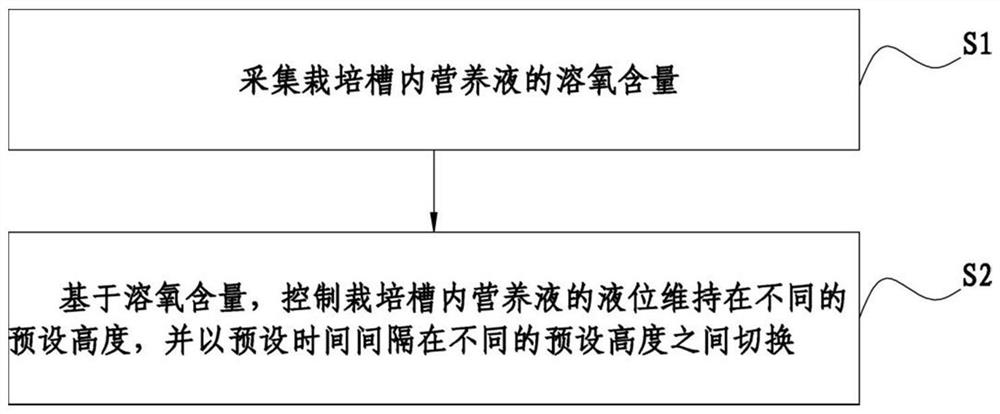

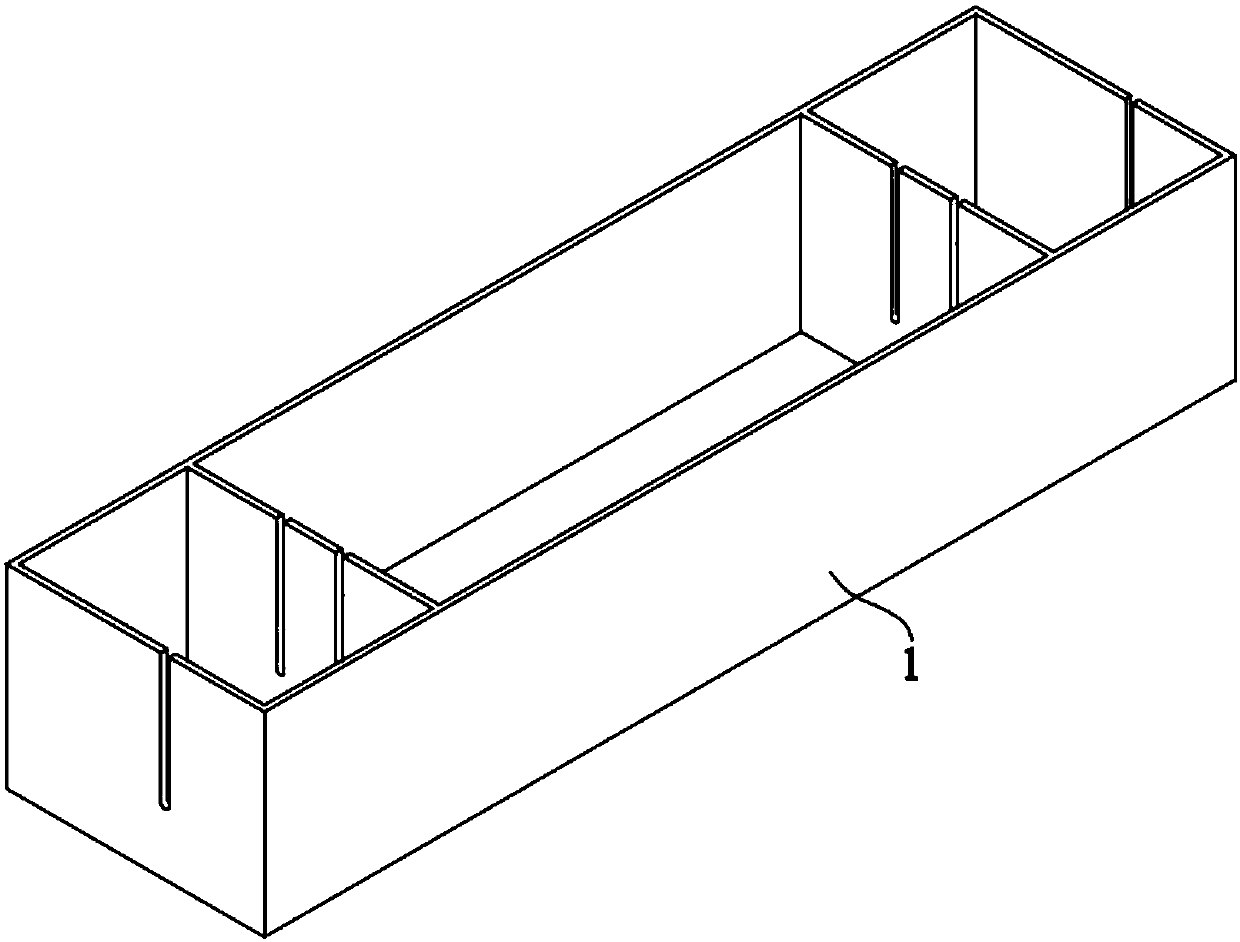

Crop soilless culture system and method

InactiveCN112005872AIncrease in sizeKeep aliveControlling ratio of multiple fluid flowsAgriculture gas emission reductionSoil scienceNutrition

The embodiment of the invention provides a crop soilless culture system and method, and the system comprises a cultivation tank which is used for containing and supplying a nutrient solution needed bythe growth of a crop; a dissolved oxygen collecting device used for collecting the dissolved oxygen content of the nutrient solution; and a liquid level adjusting device connected with the cultivation tank and used for controlling the liquid level of the nutrient solution in the cultivation tank to be maintained at different preset heights based on the dissolved oxygen content and switching between the different preset heights at preset time intervals. The system is simple in structure and low in cost; different nutrition absorption and metabolism functions can be given to crop roots on the basis of adjustment of the liquid level of a nutrient solution, normal absorption of water, fertilizer and oxygen by the crop roots is ensured, the annual output rate of soilless culture of crops is greatly increased, high-quality and high-efficiency production of the crops is achieved, and the soilless culture method is particularly suitable for soilless culture of green vegetables.

Owner:BEIJING RES CENT OF INTELLIGENT EQUIP FOR AGRI

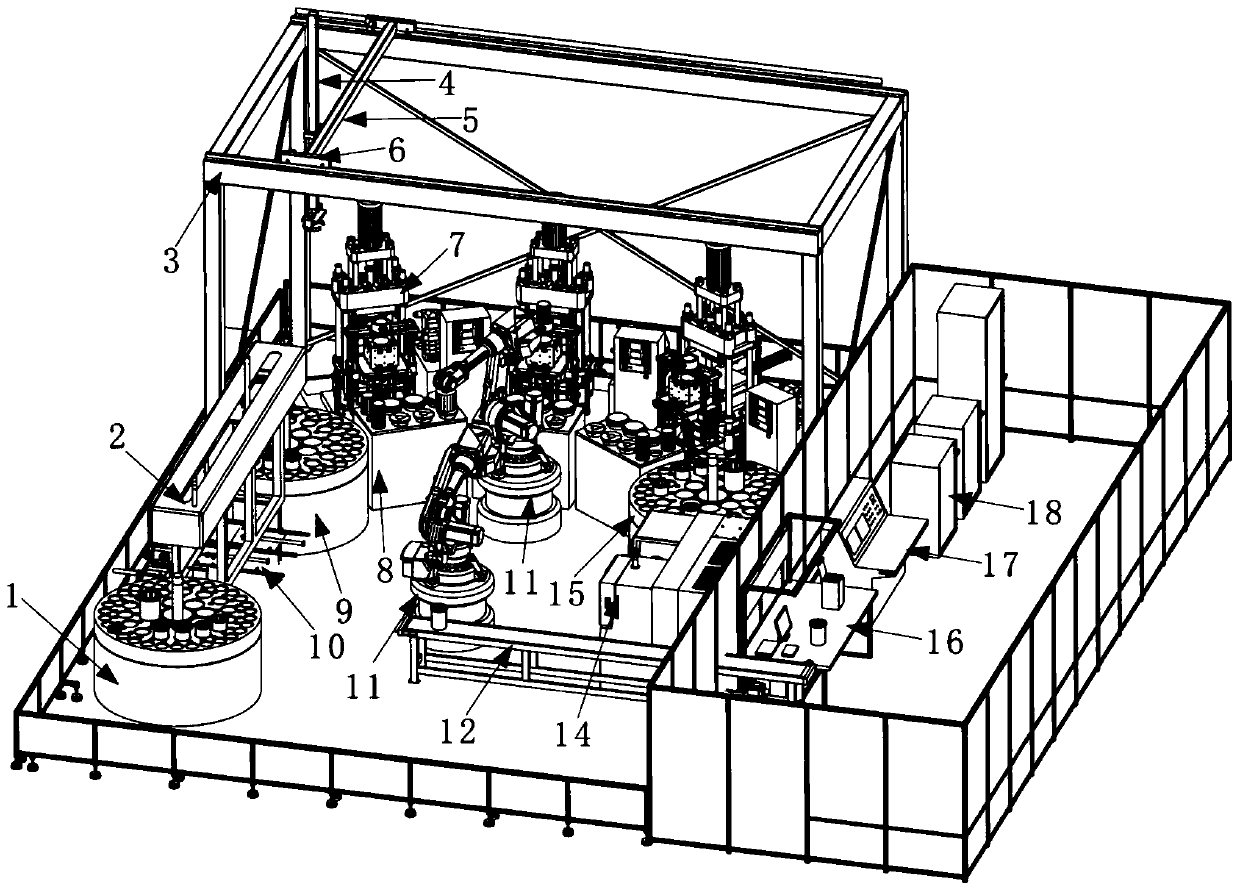

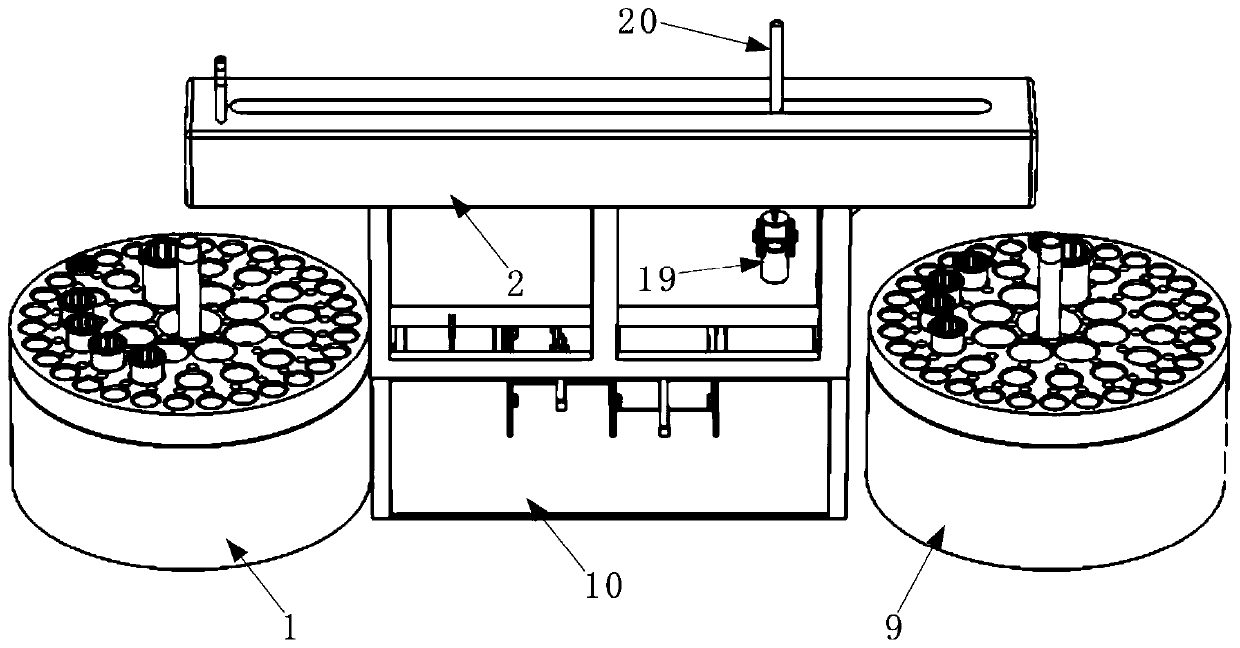

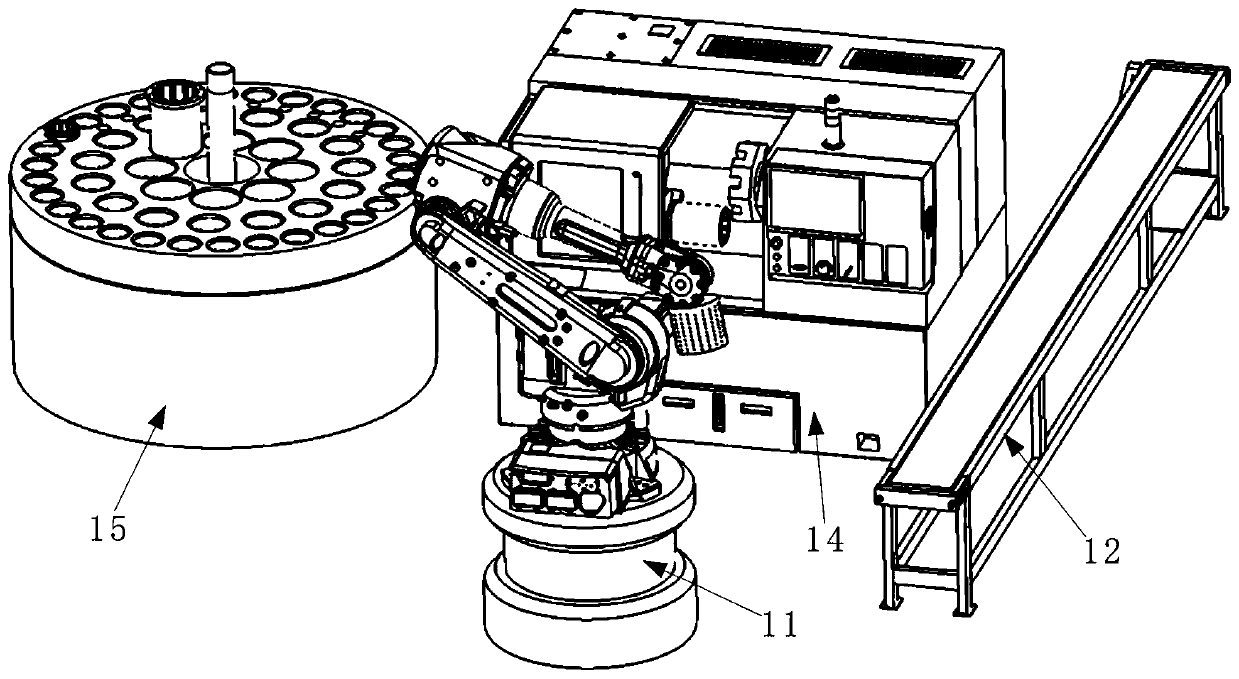

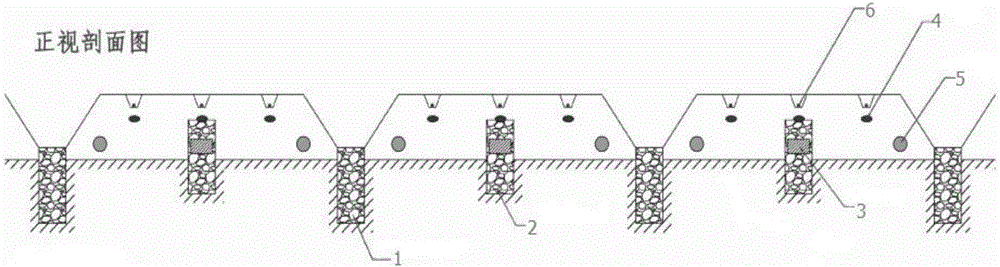

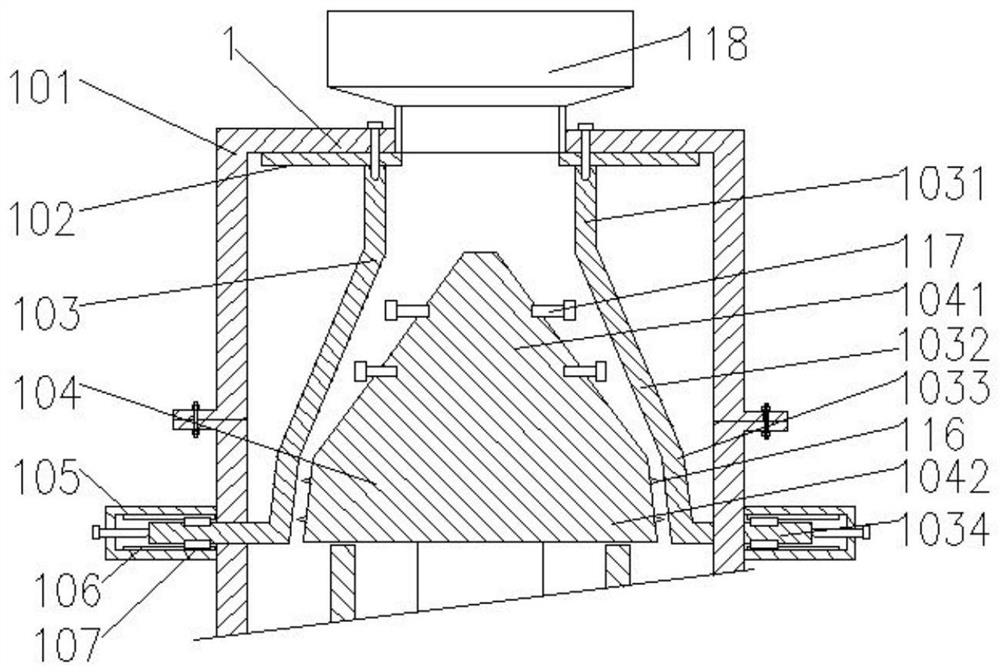

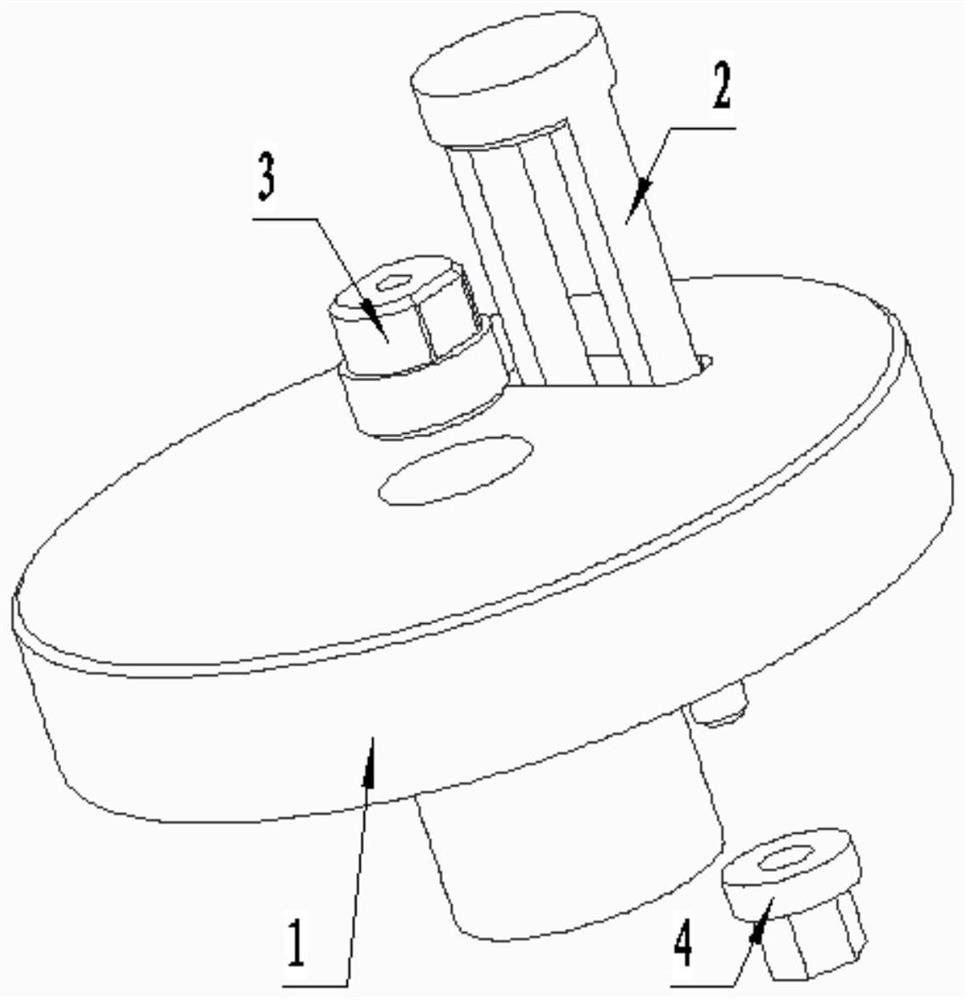

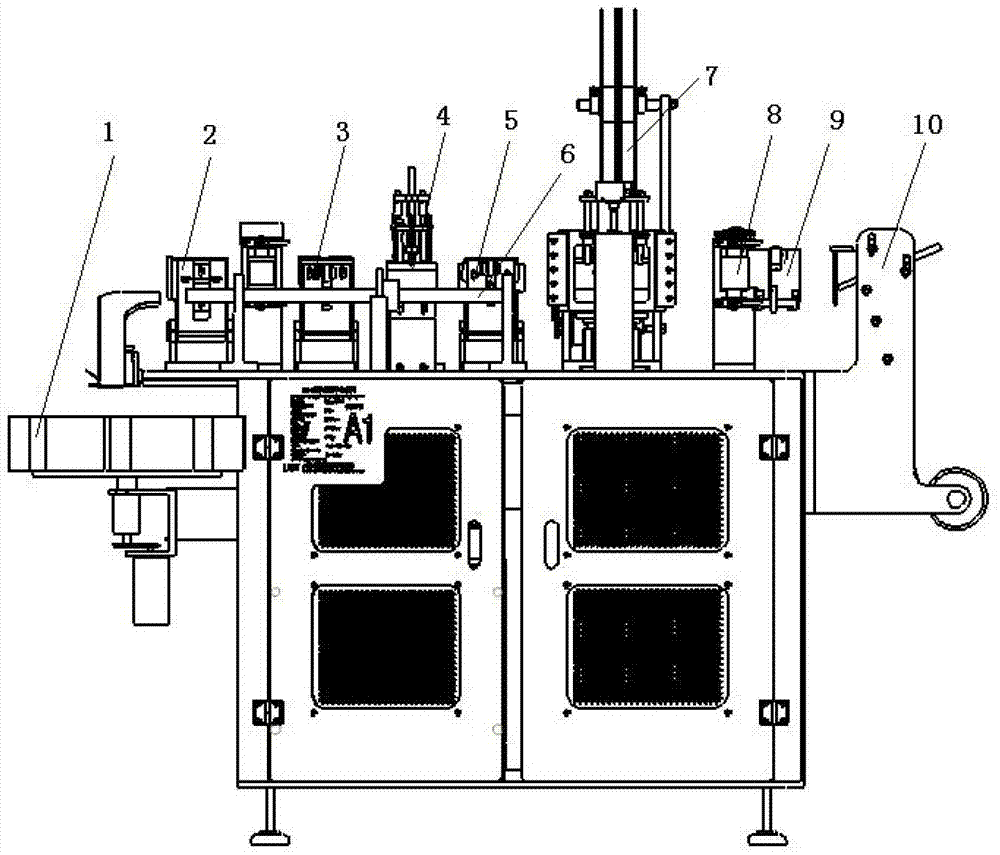

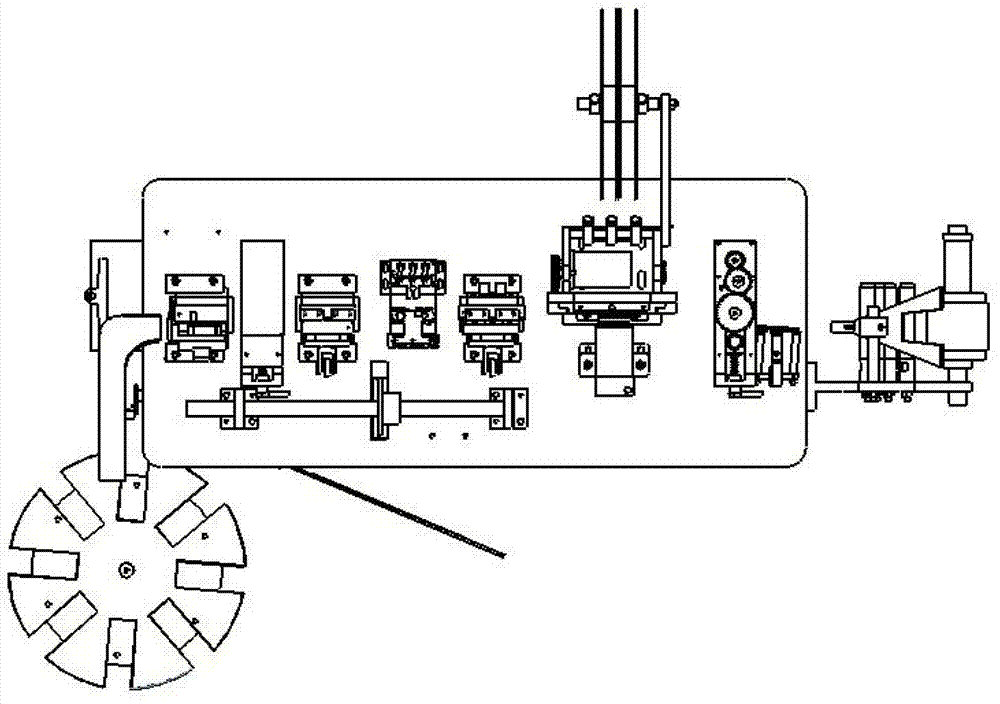

Efficient and high-quality intelligent manufacturing device and system for high-performance core base parts

ActiveCN110640971AHigh quality and efficient productionHigh degree of automationCleaning using liquidsMetal working apparatusIndustrial roboticsProcess engineering

The invention discloses an efficient and high-quality intelligent manufacturing device and system for high-performance core base parts. The manufacturing device comprises an automatic cleaning system,a molding vulcanization forming system, a precision machining system and an inspection and storage system, wherein the automatic cleaning system comprises a first rotary plate, a cleaning device anda second rotary plate which are installed in sequence; the molding vulcanization forming system comprises injection molding machining devices which are arranged in sequence; the inspection system comprises an inspection room, and the inspection room is provided with an inspection table, an input table and a storage device. According to the efficient and high-quality intelligent manufacturing device and system for the high-performance core base parts, through a complete intelligent production system, based on an industrial robot, various related production systems are connected in series, and intelligent production of the products is achieved. The efficient and high-quality intelligent manufacturing device has the advantages of being high in automation degree, high in production efficiency,high in product surface integrity, high in product reliability and consistency and the like. Therefore, intelligent manufacturing and production for general customers are achieved, and large-scaled,high-quality and efficient production of series products of the high-performance composite parts of many specifications and many varieties is achieved.

Owner:SOUTHWEST JIAOTONG UNIV +1

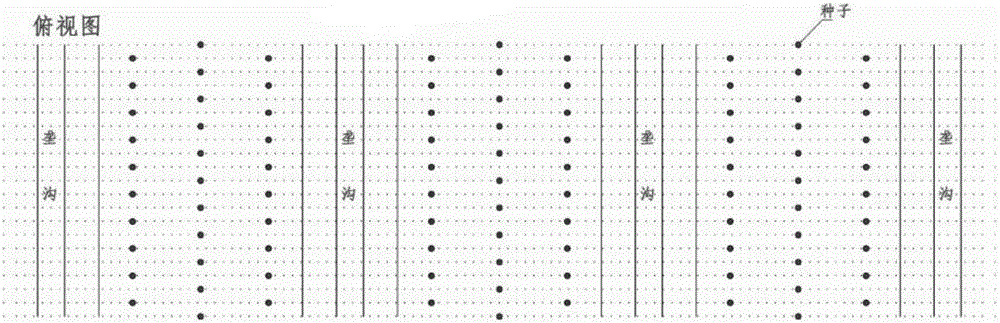

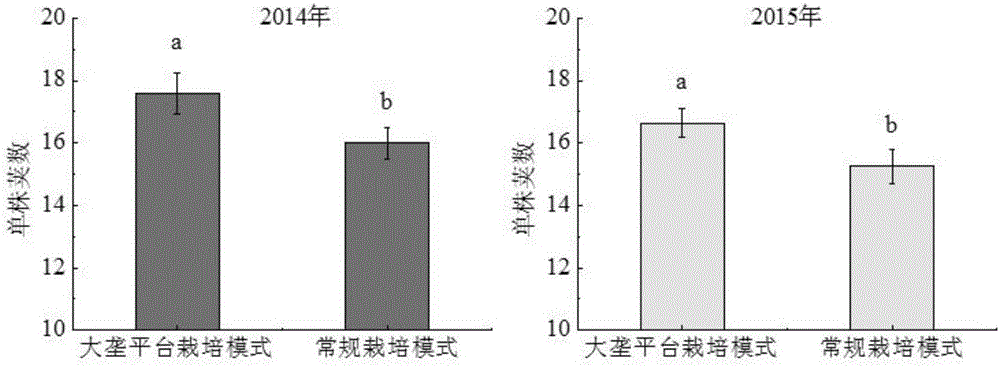

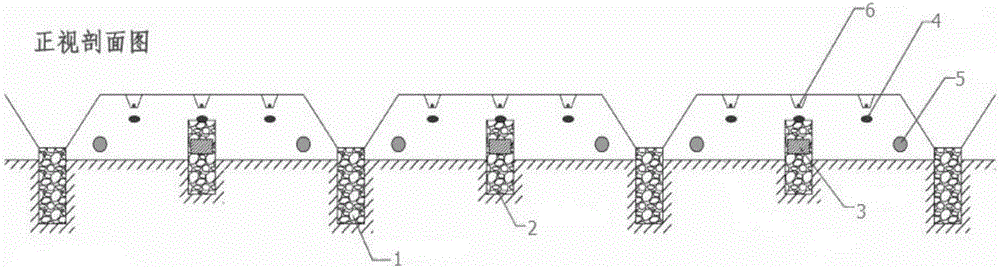

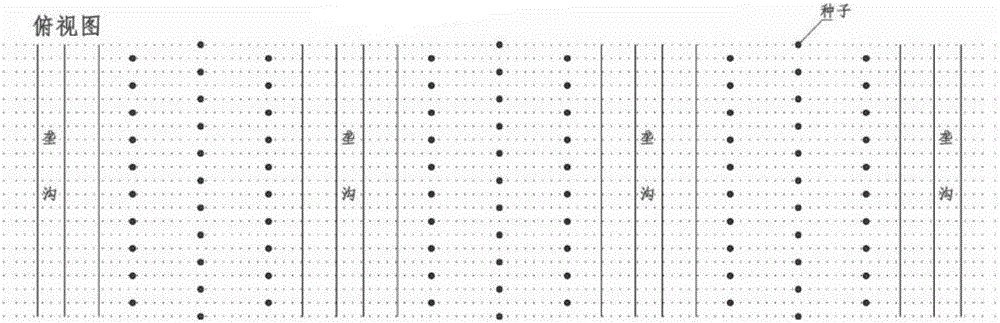

Large-ridge platform kidney bean cultivation method

ActiveCN106105723AGood soil and colony permeabilityStrong individual resilienceVegetative propogationPhotosynthesisScarification

The invention relates to a large-ridge platform kidney bean cultivation method, and belongs to the technical field of kidney bean cultivation. Soil preparation and ridging are performed in autumn, field ditches are arranged on the two sides of a ridge, a ridge platform is arranged on the ridge, the field ditches and the middle of the ridge platform are subjected to deep scarification, the land surface before ridging is adopted as the reference, the ridge deep scarification depth is 30-40 cm, and the deep scarification depth of the middle of the ridge is 15-30 cm; during soil preparation, the base fertilizer is applied to the middle of the ridge platform; the seed fertilizer is applied below the position of seed sowing; kidney bean seed sowing is performed on the ridge platform, seed sowing is performed on three rows, three seedling belts are formed, the seed sowing line spacing is 25-30 cm, the variety of kidney beans is erected or half-spreading type lodging-resistance high-yield kidney bean variety; the topdressing is applied to the outer sides of the seedling belts on the left and right sides of the ridge, and the topdressing is applied below the ridge platform. Due to the cultivation method of the combination of deep scarification, seed sowing and fertilizer application, the permeability is good, the stress resistance is strong, the production efficiency and fertilizer using efficiency of the kidney bean group photosynthesis are improved, and the high yield, high quality and efficient production can be achieved.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

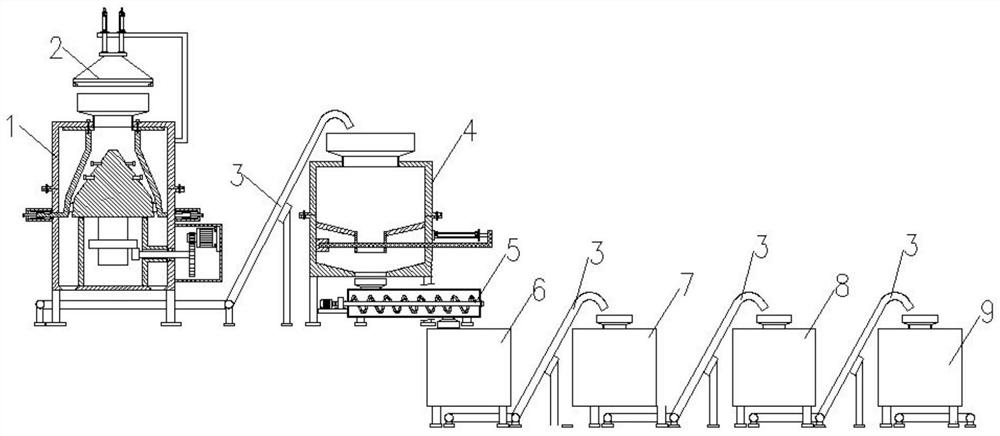

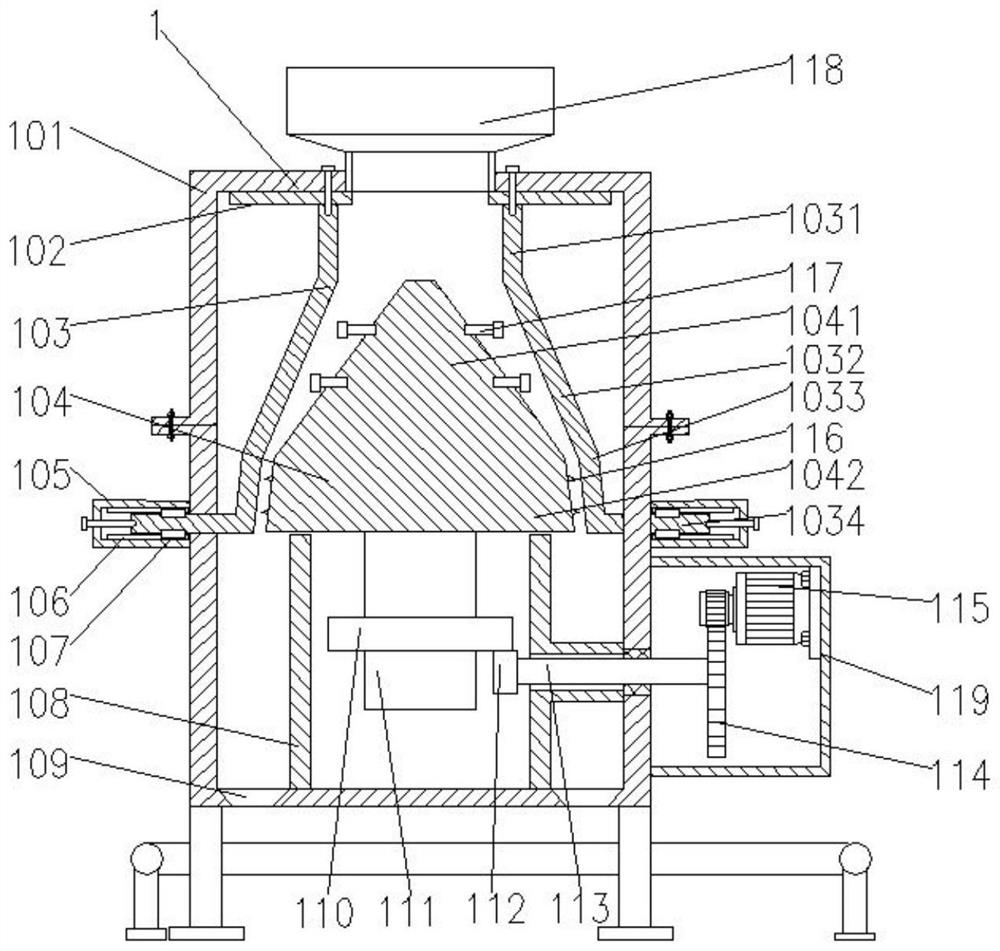

High-activity anti-condensation calcium hydroxide production equipment

PendingCN111661862AHigh quality and efficient productionThe process steps are simpleGrain treatmentsCalcium/strontium/barium oxides/hydroxidesCalcium hydroxideHigh activity

The invention discloses high-activity anti-condensation calcium hydroxide production equipment which comprises a crushing device, and a dust suction device is arranged above the crushing device; the lower end of the crushing device is connected with a storage tank through a lifting device, a spiral feeding device is arranged at the lower end of the storage tank, the stirring device is arranged atthe lower end of the spiral feeding device, and a filtering dehydration device, a drying device and a screening device are sequentially arranged at the side end of the stirring device through the lifting device; the crushing device comprises a crushing chamber, a first hopper and a first discharging opening are formed in the upper end and the lower end of the crushing chamber correspondingly, a rotary extrusion column is arranged in the middle in the crushing chamber, an extrusion plate is movably arranged on the periphery of the rotary extrusion column, and the rotary extrusion column is usedin cooperation with the extrusion plate; and the circumferential upper end and the circumferential lower end of the rotary extrusion column are respectively provided with an extrusion pin shaft and aspine part. The process steps are optimized, integration is carried out, design arrangement is optimized, and calcium hydroxide can be efficiently produced with high quality.

Owner:湖南蓝伯化工有限责任公司

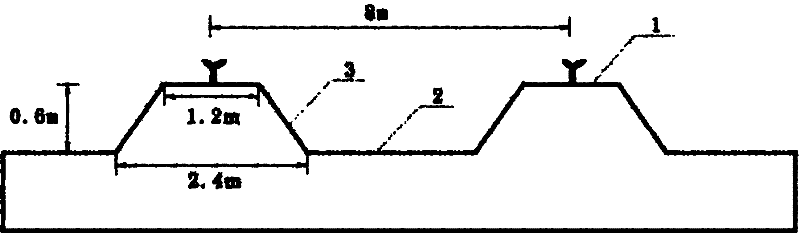

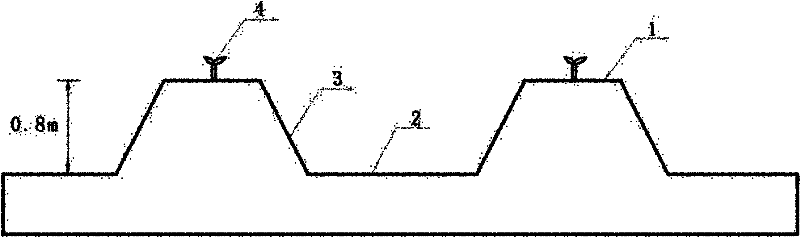

High-ridge cultivation method of Chinese gooseberries

ActiveCN102177828BAvoid the effects of growthImprove quality indicatorsCultivating equipmentsActinidiaWater table

The invention discloses a high-ridge cultivation method of Chinese gooseberries, which comprises steps of flattening soil; ridging, wherein space between ridges is controlled to be 6-8m, the height of the ridges is 0.5-0.6m, the ridges are formed by using improved surface soil and ladder-shaped, and ridges are smashed; planting, wherein the upper parts of the ridges are dug to be used for planting, and strong Chinese gooseberry seedlings are chosen to be planted; planting the seedlings in the center parts of furrows, tamping earthing soil, and fully watering seedlings with rooting water; after the surface soil of the ridge furrows and an organic fertilizer are mixed, digging the mixture of the surface soil and the organic fertilizer out and piling to the ridge sides to make the height of the ridges reach 0.9 m to 1 m; and fertilizing and earthing up according to the growth conditions of the Chinese gooseberry seedlings. The high-ridge cultivation method is simple in operation. The purpose of limiting the root region can be achieved by reducing the cost, the influence of overhigh ground water level to the Chinese gooseberry growth is avoided and the fruit quality is greatly enhanced.

Owner:上海农夫果园

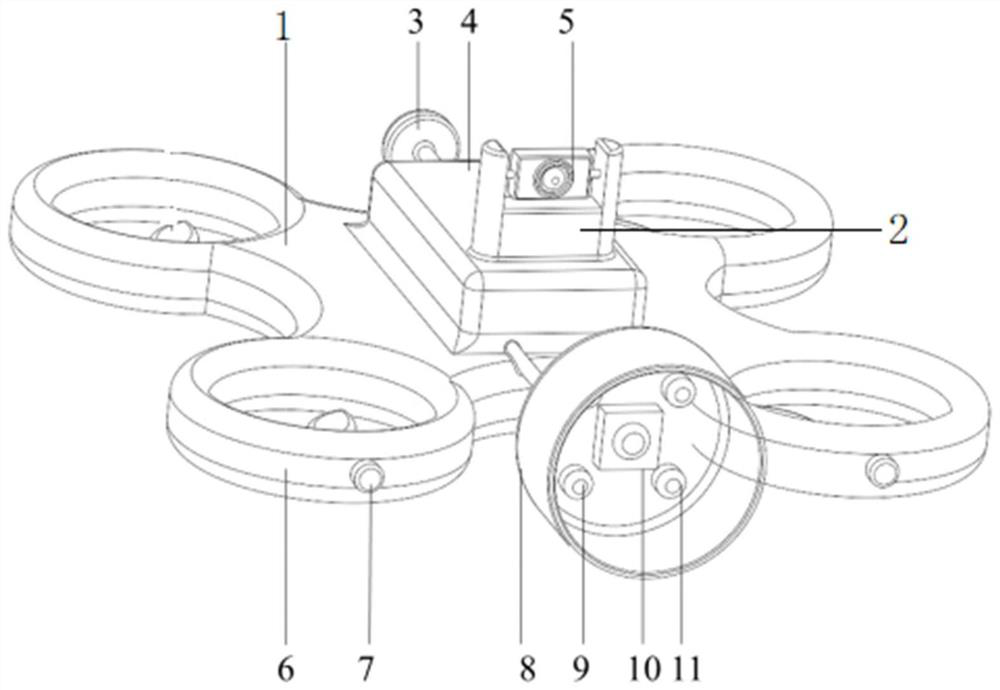

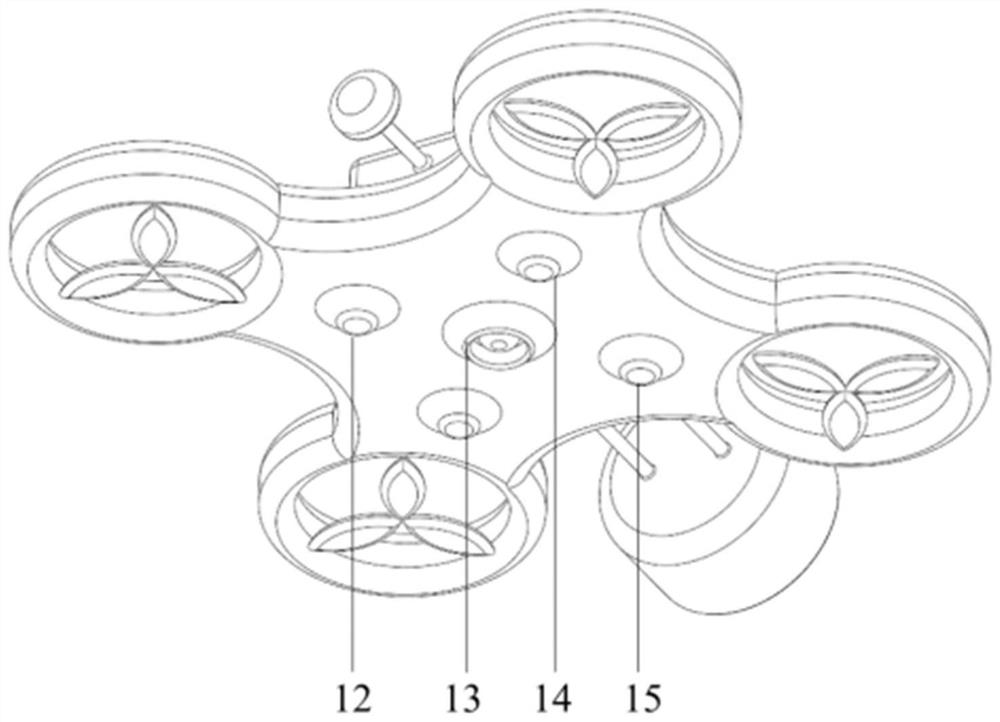

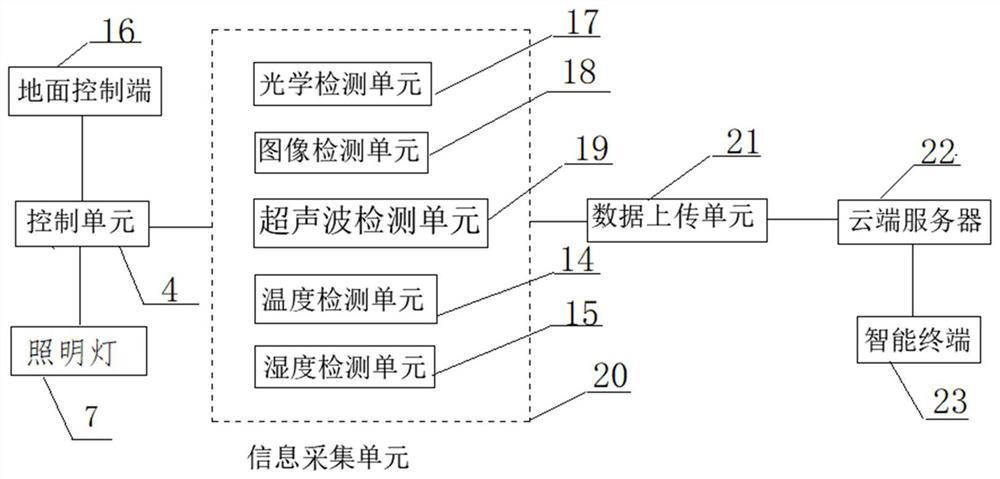

Miniature intelligent flight detector for fruit quality in growth

The invention provides a miniature intelligent flight detector for fruit quality in growth. The miniature intelligent flight detector comprises an aircraft, and is characterized by comprising a control unit, an information acquisition unit and a data uploading unit which are arranged on the aircraft, wherein the control unit is connected with the aircraft and used for controlling flight of the aircraft, the control unit is in communication connection with a ground control end, the control unit is sequentially connected with an information acquisition unit and a data uploading unit, and the data uploading unit is in communication connection with a cloud server. Digital and internet-of-things quality detection and control in fruit growth are achieved by monitoring a plurality of quality state parameters in fruit growth in real time, and the purpose of high-quality and efficient production is achieved.

Owner:CHINA AGRI UNIV

Production method for forging axle for railway vehicle by adopting continuous casting billet

ActiveCN112916788AGuarantee internal qualityHigh quality and efficient productionMetal-working apparatusFurnace typesHeating furnaceRadial forging

The invention discloses a production method for forging an axle for a railway vehicle by adopting a continuous casting billet, and belongs to the field of preparation methods of axles for railway vehicles. According to the novel technological process of the axle for the railway vehicle, a plurality of blank axles can be efficiently produced at a time. According to the method, an LZ50 continuous casting round billet is placed in a heating furnace to be heated and then subjected to 4-5-pass forging cogging through a high-speed forging machine, at the initial pass, forging with the rolling reduction smaller than or equal to 20 mm is adopted, it is guaranteed that the rolling reduction of two passes is 120-150 mm subsequently, the final forging temperature is controlled to be 850-900 DEG C, the diameter of the billet subjected to forging cogging is 345-360 mm, then the billet is transferred to a radial forging machine, small-rolling-reduction multi-pass forging is adopted in the forging process of the radial forging machine, a connected blank axle with the qualified size is obtained, and a single blank axle for the railway vehicle is obtained after saw cutting and segmentation. The method has the characteristics of being short in production process, high in forming size precision and high in production efficiency.

Owner:建龙北满特殊钢有限责任公司

Kiwifruit planting method capable of increasing yield and improving quality

InactiveCN107567927AWide range of applicationsReduce manufacturing costCultivating equipmentsFertilizer mixturesNitrogen fertilizerRoot system

The invention discloses a kiwifruit planting method capable of increasing yield and improving quality. The method includes the steps that loose and fertile neutral soil with a long sunshine duration,sufficient sunshine, a deep soil layer, a high altitude and good drainage conditions is selected and deeply dug by 35 cm, wherein the pH value of the soil is 7; 200-240 kg of slow-release nitrogen fertilizer is applied to the soil per mu; seedlings which are 40-60 cm high, develop normally without disease and pest damage and have well-developed roots are selected and cultivated in the treated soil, water is supplemented after transplanting, and phosphate fertilizer and potash fertilizer are applied every month; leaf fertilizer is applied 1-3 times in the fruiting period, wherein the leaf fertilizer is sprayed to leaves at nightfall of sunny days. According to the method, as the abuse of chemical fertilizer and antibiotics is avoided, soil can be improved, planted kiwifruits are rich in nutrition and high in yield, the survival rate of the planted kiwifruits reaches up to 99.8%, and the kiwifruits are fresh and sweet and good in color.

Owner:YINGSHANG QINGFENG AGRI & ANIMAL HUSBANDRY DEV CO LTD

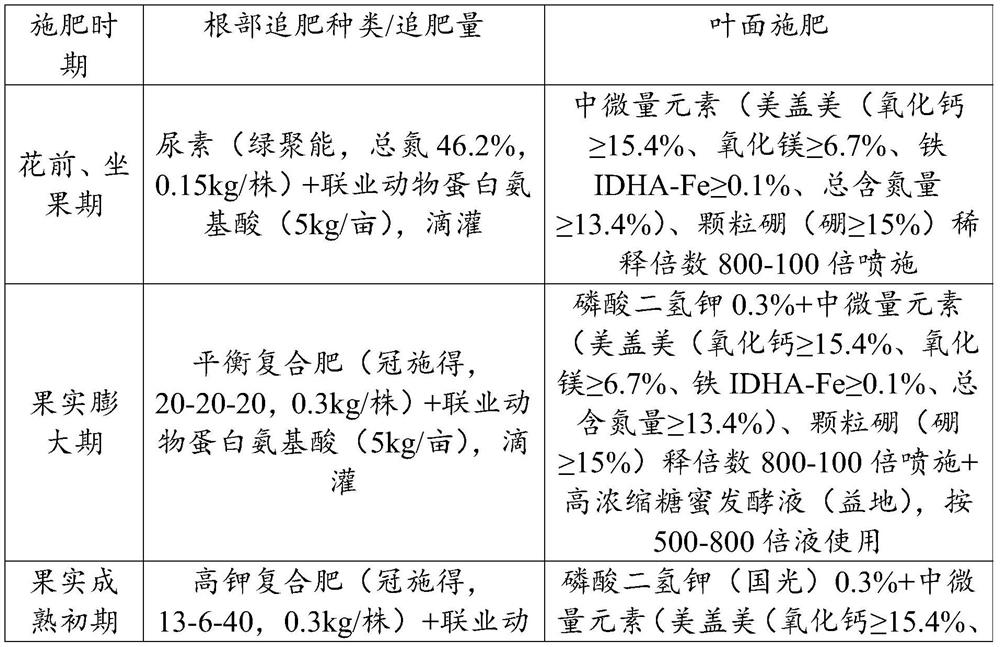

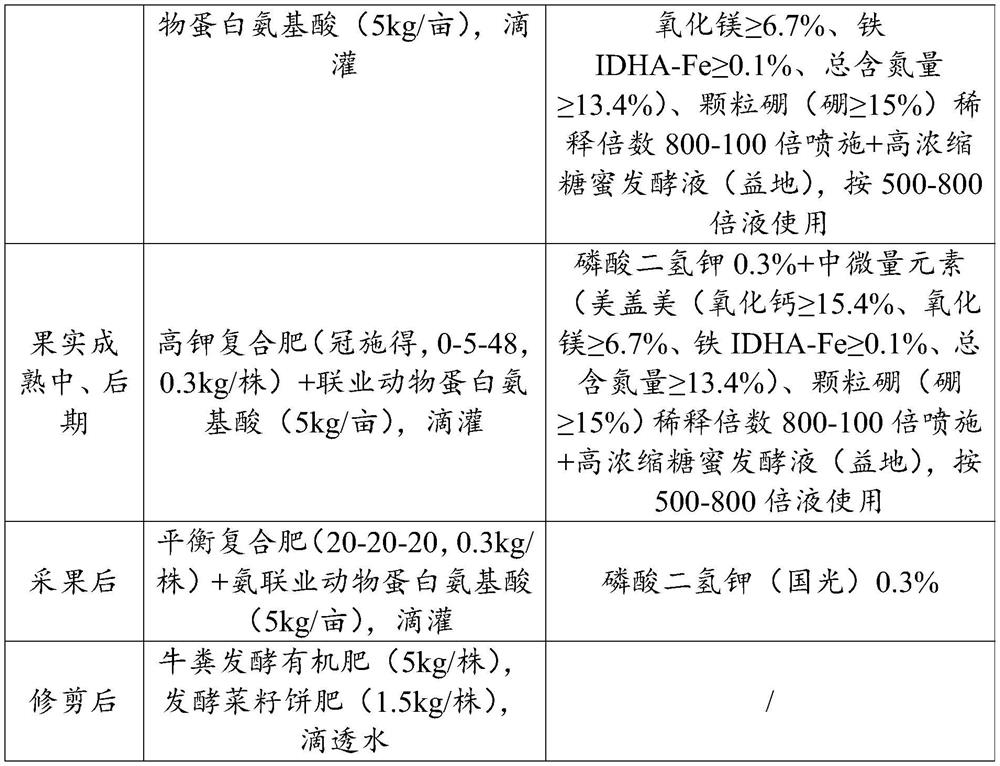

Fertilization management method of adult cocktail grapefruit and growing method of cocktail grapefruit containing same

ActiveCN112314140BGrow fastImprove stress resistanceFertilising methodsCultivating equipmentsFruit maturationFruit set

The invention provides a fertilization management method of adult cocktail grapefruit and a planting method of cocktail grapefruit comprising the same, and relates to the technical field of agricultural planting. The fertilization management method adopts a gradient during the entire planting process of adult cocktail grapefruit, specifically during the fruit setting period before flowering, the fruit expansion period, the early fruit ripening period, the middle and late fruit ripening period, the fruit picking period and the pruning period. Nitrogen reduction, gradually increasing potassium fertilization mode for fertilization management, thereby effectively improving the fruit quality of cocktail grapefruit, and realizing the high-quality and efficient production of cocktail grapefruit.

Owner:JINHUA VOCATIONAL TECH COLLEGE

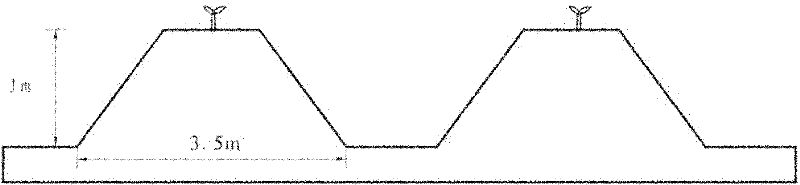

Wide-ridge platform Vigna radiate L.Wilclzek cultivation method

InactiveCN106105724AGood soil and colony permeabilityStrong individual resilienceVegetative propogationPhotosynthesisSoil preparation

The invention relates to a wide-ridge platform Vigna radiate L.Wilclzek cultivation method, and belongs to the Vigna radiate L.Wilclzek cultivation technical field; the method comprises the following steps: autumn ploughing and ridging, building furrows on two sides of the ridge, building a ridge platform for the ridge, respectively deep ploughing the furrows and the ridge platform middle portion, using the field surface before ridging as reference, the furrow subsoiling depth is 30-40cm, and the ridge platform middle subsoiling depth is 15-30cm; applying base fertilizer in middle of the ridge platform in soil preparation; applying seed manure under sowing positions; sowing Vigna radiate L.Wilclzek on the ridge platform in 3 lines, forming 3 seedling strips, wherein the sowing line space is 25-30cm, and the Vigna radiate L.Wilclzek variety is an erection or semiprostrate lodging resistance high yield Vigna radiate L.Wilclzek kinds; respectively applying additional fertilizer outside the seedling strips on the left and right sides of the ridge, and applying additional fertilizer under the ridge platform. The cultivation method combines subsoiling, sowing with fertilizer application, is good in permeability and strong in stress resistance, thus improving Vigna radiate L.Wilclzek colony photosynthesis production efficiency and fertilizer utilization rate, and realizing Vigna radiate L.Wilclzek highyield high-quality high efficiency production.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

Air heater for foam plastic production

InactiveCN108562044AHigh quality and efficient productionHeating fastStorage heatersEngineeringCopper

The invention discloses an air heater for foam plastic production, and belongs to the technical field of air heating devices. The air heater comprises a hollow tube body, the two ends of the tube bodycorrespondingly communicate with an air inlet and an air outlet, the tube body is made of pure copper, and a plurality of axial heat exchange grooves are formed in the inner wall of the tube body; and a blocking column is further arranged in the tube body to fill the hollow area of the tube body, a heating device is arranged on the outer wall of the tube body, and a temperature detection device is arranged at the air outlet. According to the air heater, heat generated by the external heating device can be rapidly transferred to the interior of the tube body through the tube body with the purecopper material, air can be fully contacted with the inner wall of the tube body through the heat exchange grooves, so that high-efficiency heat exchange is achieved, and the air is guaranteed to beheated to a preset temperature in a short time.

Owner:高密市美佳硕机械科技有限公司

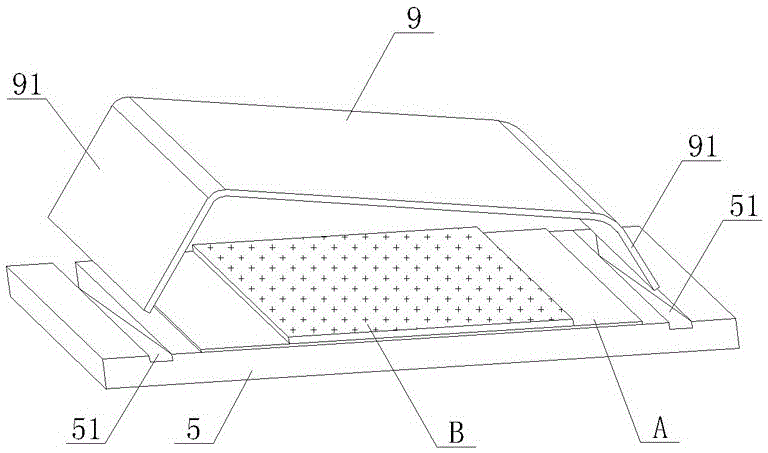

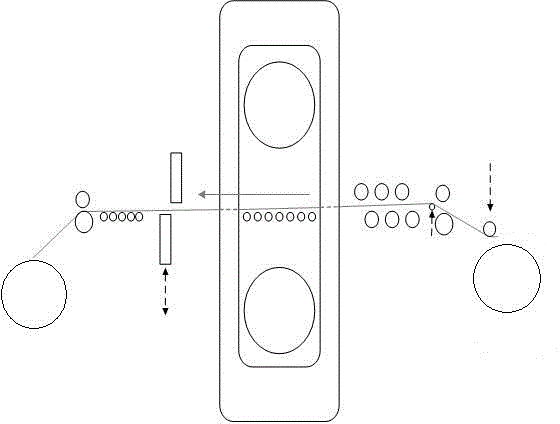

Flow-casting production equipment for zirconium oxide substrates

PendingCN106738197ASatisfy high-efficiency and high-quality productionFlat surfaceShaping conveyorsEngineeringThermocouple

The invention discloses flow-casting production equipment for zirconium oxide substrates. The flow-casting production equipment is characterized in that a flow-casting bearing plate made of a stainless steel plate material is laid on the surface of a working platform, a film band paid off by a pay-off mechanism is taken up by a take-up mechanism after passing through the surface of the working platfrom, a flow-casting device is arranged at the end, close to the pay-off mechanism, of the working platform, a plurality of drying chambers are arranged on the working platform, the multiple drying chambers communicate with one another, a closed drying space is formed on the working platform, a first exhaust pipe is arranged at the front end in the closed drying space, a second exhaust pipe is arranged in the middle position in the closed drying space, glass baffles are arranged in the drying chambers and shield the film band passing through the drying chambers, the glass baffles are horizontally arranged in an inclined mode in the transverse direction, and a resistance wire heater with a thermocouple is installed at the bottom of the flow-casting bearing plate. According to the flow-casting production equipment, efficient high-quality production of the zirconium oxide substrates can be achieved, and the produced zirconium oxide substrates are free of cracking, flat in surface and even in thickness.

Owner:陈振宁

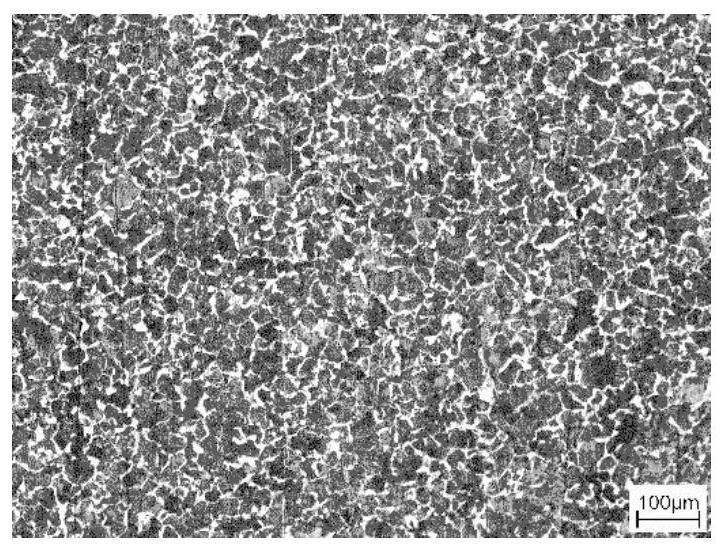

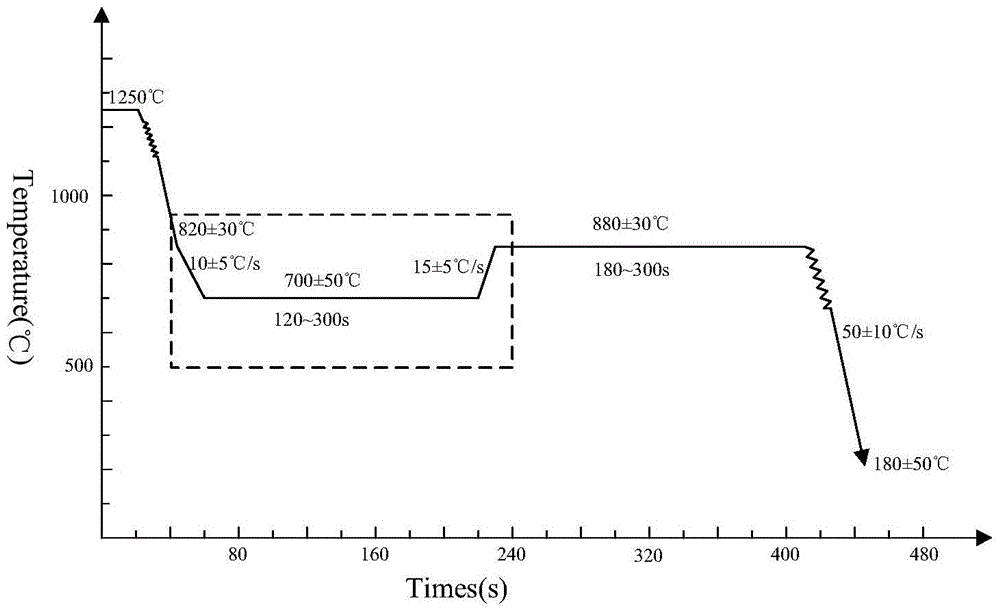

A short-process integrated manufacturing method for rolling and deep processing of high-strength steel automobile plates

A rolling and deep-processing short-process integrated manufacturing method of a high-strength steel automobile sheet includes following steps: heating raw materials in a heating furnace, performing controlled rolling including crude rolling and finish rolling, laminar cooling the rolled raw material, performing comprehensive blanking, heating the obtained sheet material, moulding and quenching the sheet material, performing a cutting process and a shot blasting process to obtain a finished product. The raw material is heated to more than 1250 DEG C in the heating furnace. A finish rolling temperature is 820 + / - 30 DEG C. The rolled sheet material is cooled to the temperature of 700 + / - 50 DEG C at a temperature decreasing rate of 10 + / - 5 DEG C / s, wherein the temperature is maintained for 2-5 min. The sheet material is heated to 880 + / - 30 DEG C at a temperature increasing rate of 15 + / - 5 DEG C / s in a continuous heating furnace with temperature maintenance for 3-5 min. The stamping and quenching member is subjected to stamping and quenching at the same time, wherein the flow velocity of cooling water in a stamping and quenching die is 50 + / - 10 DEG C / s. The stamped and quenched member is cooled to 180 + / - 50 DEG C / s to obtain a super-high strength steel part in a homogeneous martensitic structure, wherein the strength of extension can reach higher than 1500 MPa. The method can produce the high-strength steel automobile sheet at a high quality and a high efficiency, can reduce cost, can promote comprehensive utilization of secondary energy sources such as low-temperature waste heat and the like, can achieve integrated production from raw materials to the product, and can achieve energy saving, consumption reducing and environment protecting.

Owner:YANSHAN UNIV

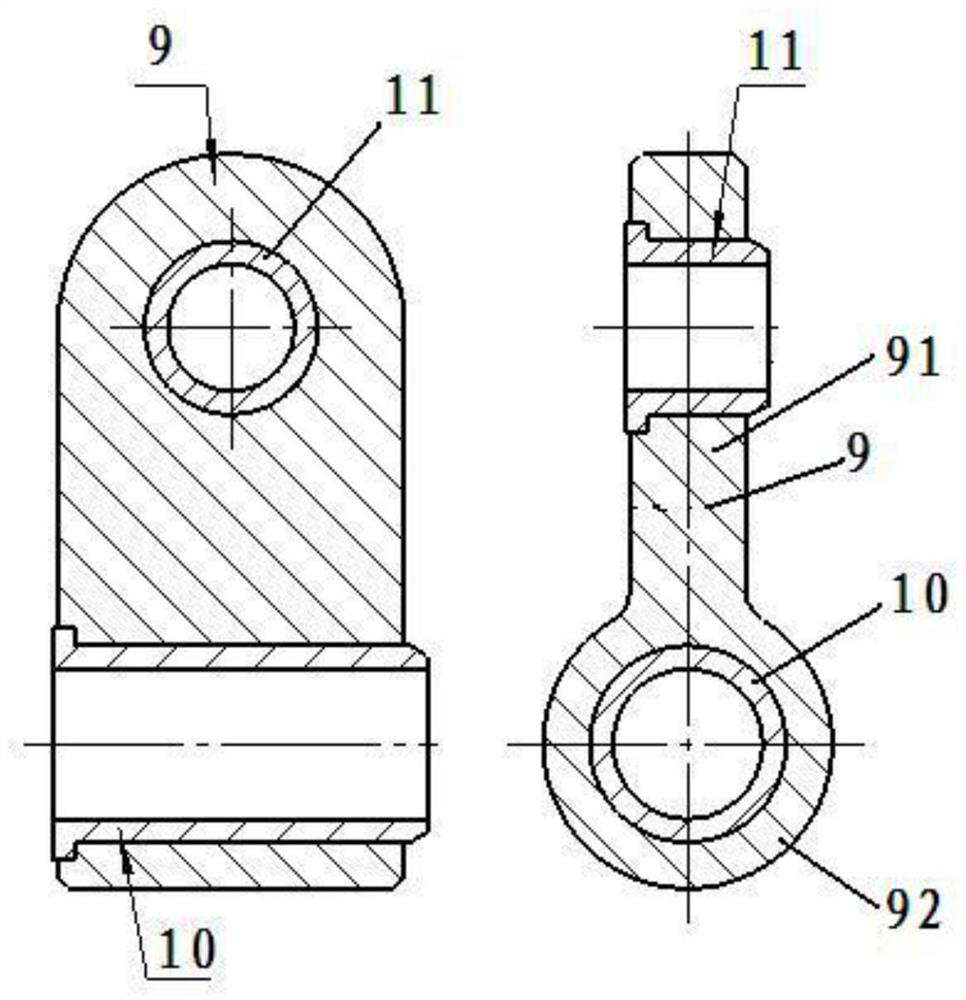

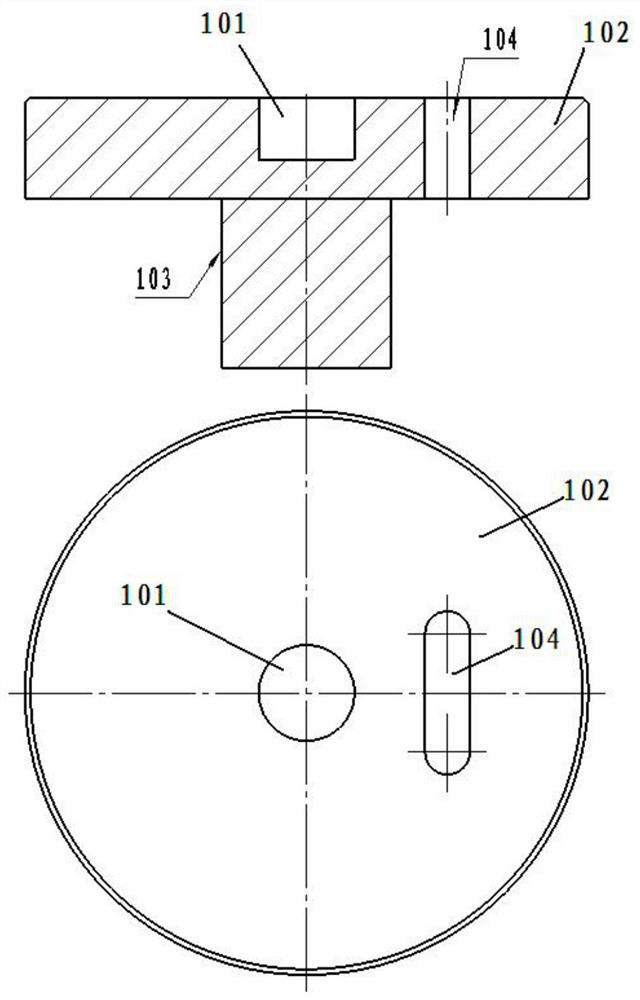

Positioning and clamping device for high-precision space vertical hole system turning

InactiveCN111941109ARealize automatic centeringAvoid "One-by-One Correction"Positioning apparatusMetal-working holdersEngineeringCentring

The invention relates to a positioning and clamping device for high-precision space vertical hole system turning, and belongs to the field of turning positioning design. The positioning and clamping device comprises a large copper bush positioning and clamping device, a small copper bush positioning and clamping device and a cross lug, wherein the cross lug comprises a steel substrate, a large copper sleeve and a small copper sleeve, the steel substrate comprises a plate-shaped structure and a cylindrical structure, the plate-shaped structure is arranged on the outer wall of the cylindrical structure in the radial direction of the cylindrical structure, the plate-shaped structure and the cylindrical structure are integrally formed, the large copper bush and the small copper bush are both of a hollow cylindrical structure, the large copper bush is coaxially pressed in the cylindrical structure in the axial direction, the small copper bush is pressed on the plate-shaped structure, the large copper bush positioning and clamping device is used for vertically clamping the steel substrate and turning the large copper bush, and the small copper bush positioning and clamping device is usedfor horizontally clamping the steel substrate and turning the small copper bush. According to the positioning and clamping device, automatic centering and orienteering during workpiece clamping are achieved, and high-quality, high-efficiency and low-labor-intensity turning of a high-precision space vertical hole system of the cross lug is achieved.

Owner:北京实验工厂有限责任公司

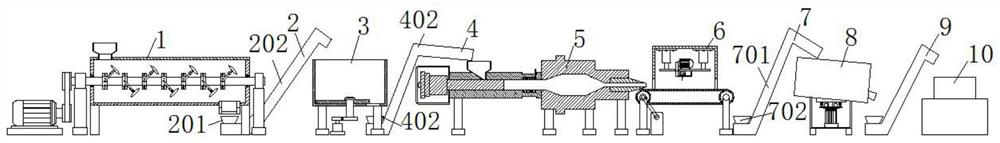

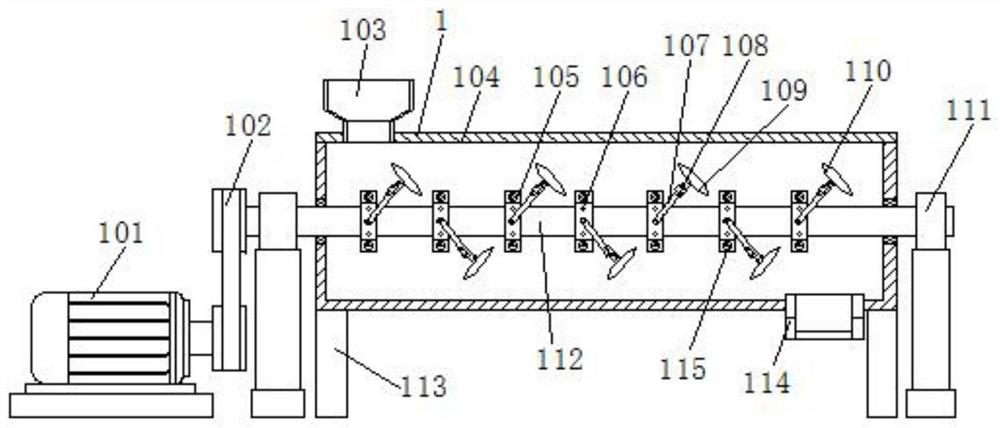

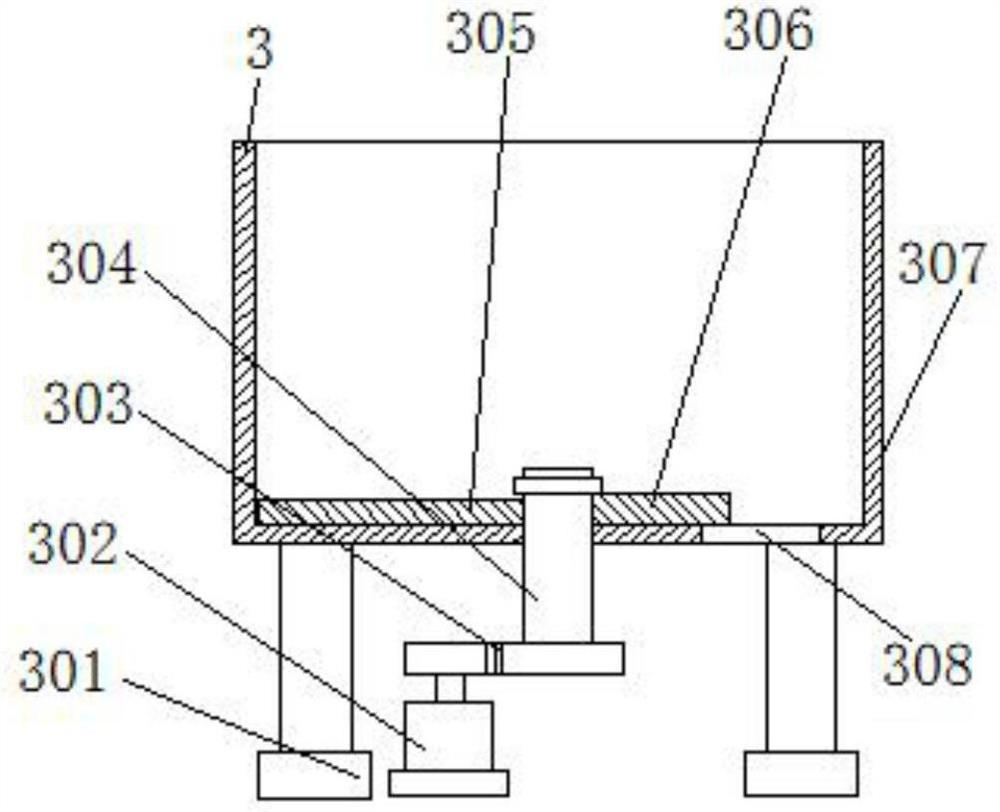

Production line of beef tendon seasoning noodle product and preparation method of beef tendon seasoning noodle product

PendingCN113383935AHigh quality and efficient productionThe process steps are simpleFood shapingGrain treatmentsProduction lineProcess engineering

The invention discloses a production line of a beef tendon seasoning noodle product and a preparation method of the beef tendon seasoning noodle product. The production line comprises a flour beating assembly, a first lifting assembly, a flour discharging assembly, a second lifting assembly, a curing and molding assembly, a cutting assembly, a third lifting assembly, a material stirring assembly, a fourth lifting assembly and a packaging assembly, wherein the curing and molding assembly comprises a feeding cavity; a feeding barrel is arranged at the upper end of the feeding cavity; a piston rod is arranged in the feeding cavity; a molding cavity is formed in the side end of the feeding cavity; a channel is formed between the feeding cavity and the molding cavity; the channel is connected with an exhausting assembly; and a discharging nozzle is arranged at the side end of the molding cavity. According to the production line of the beef tendon seasoning noodle product and the preparation method of the beef tendon seasoning noodle product, provided by the invention, technological steps are optimized and the production line is integrally designed and arranged; and a production formula is unique and the beef tendon seasoning noodle product can be produced at high efficiency and high quality.

Owner:湖南国湘食品有限公司

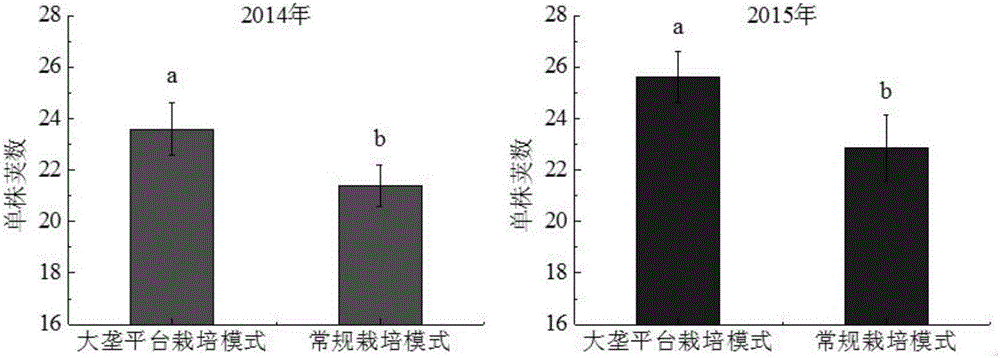

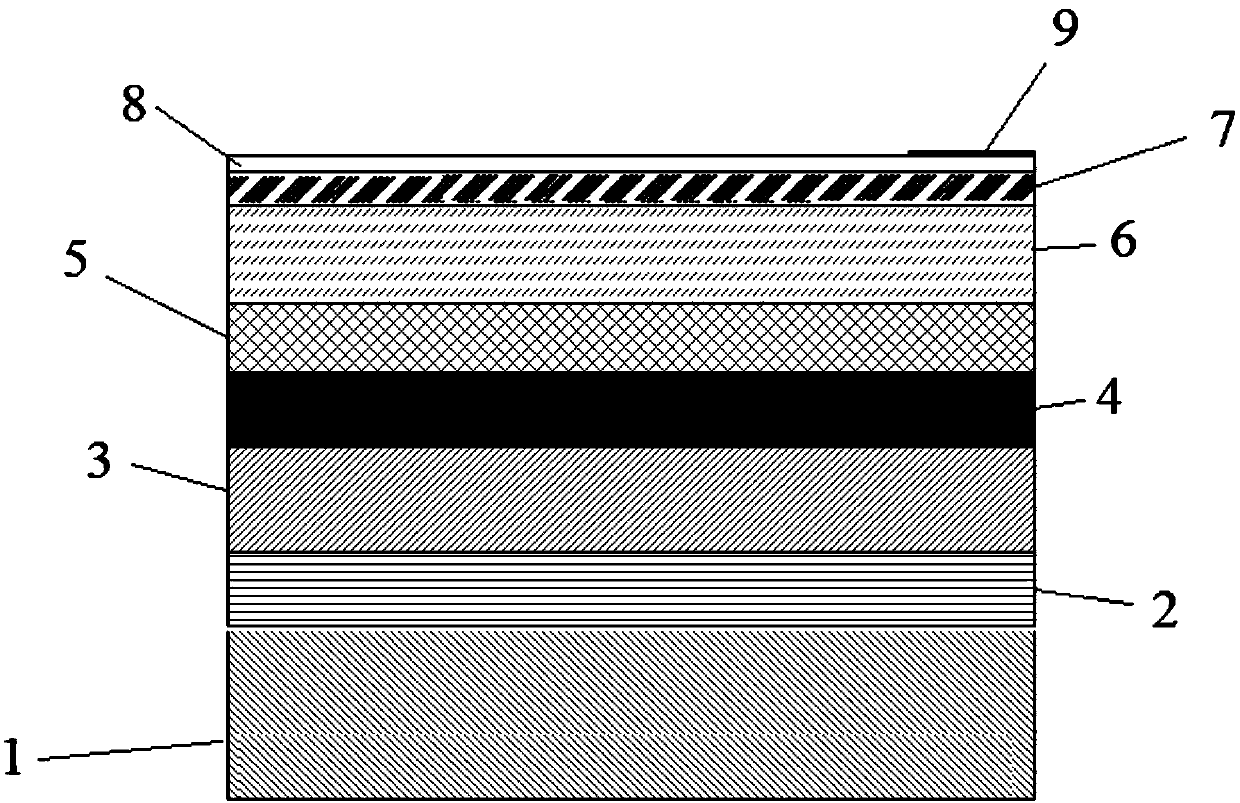

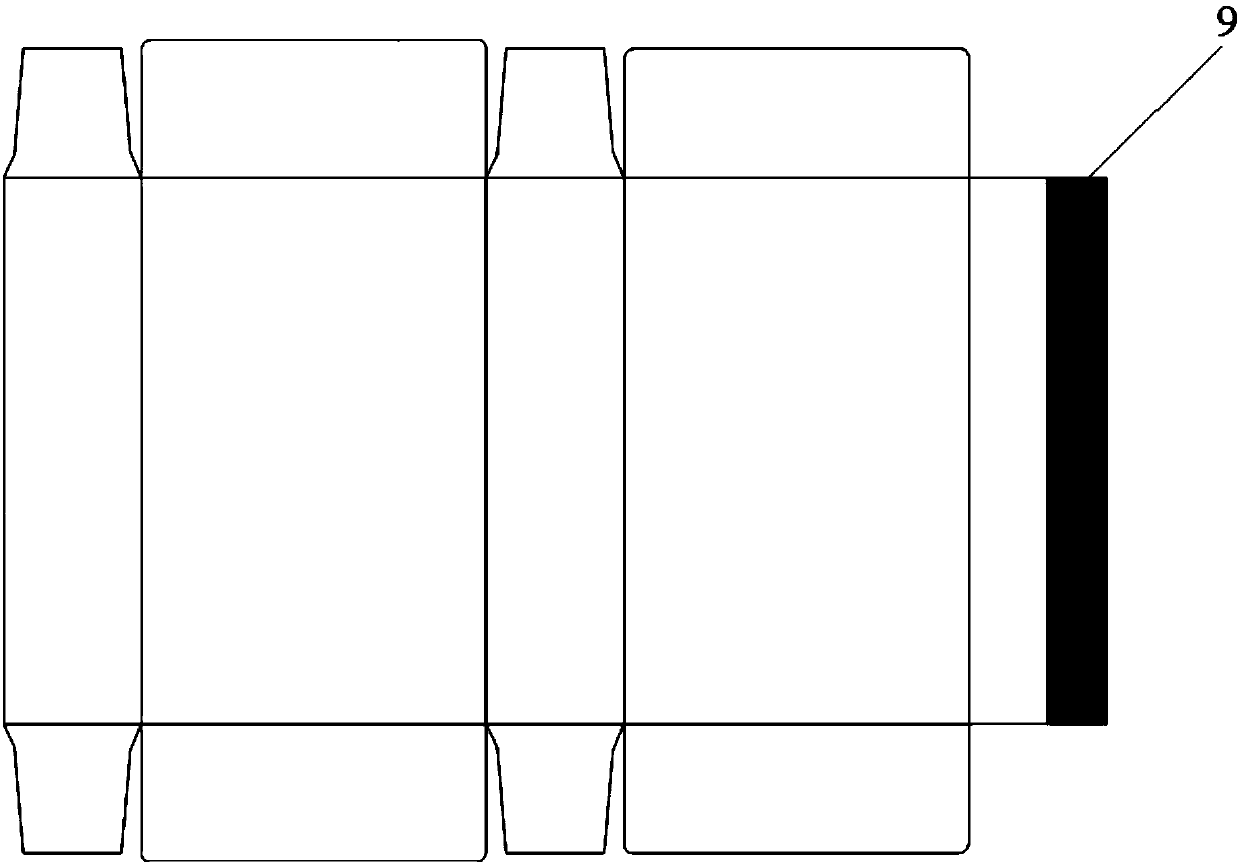

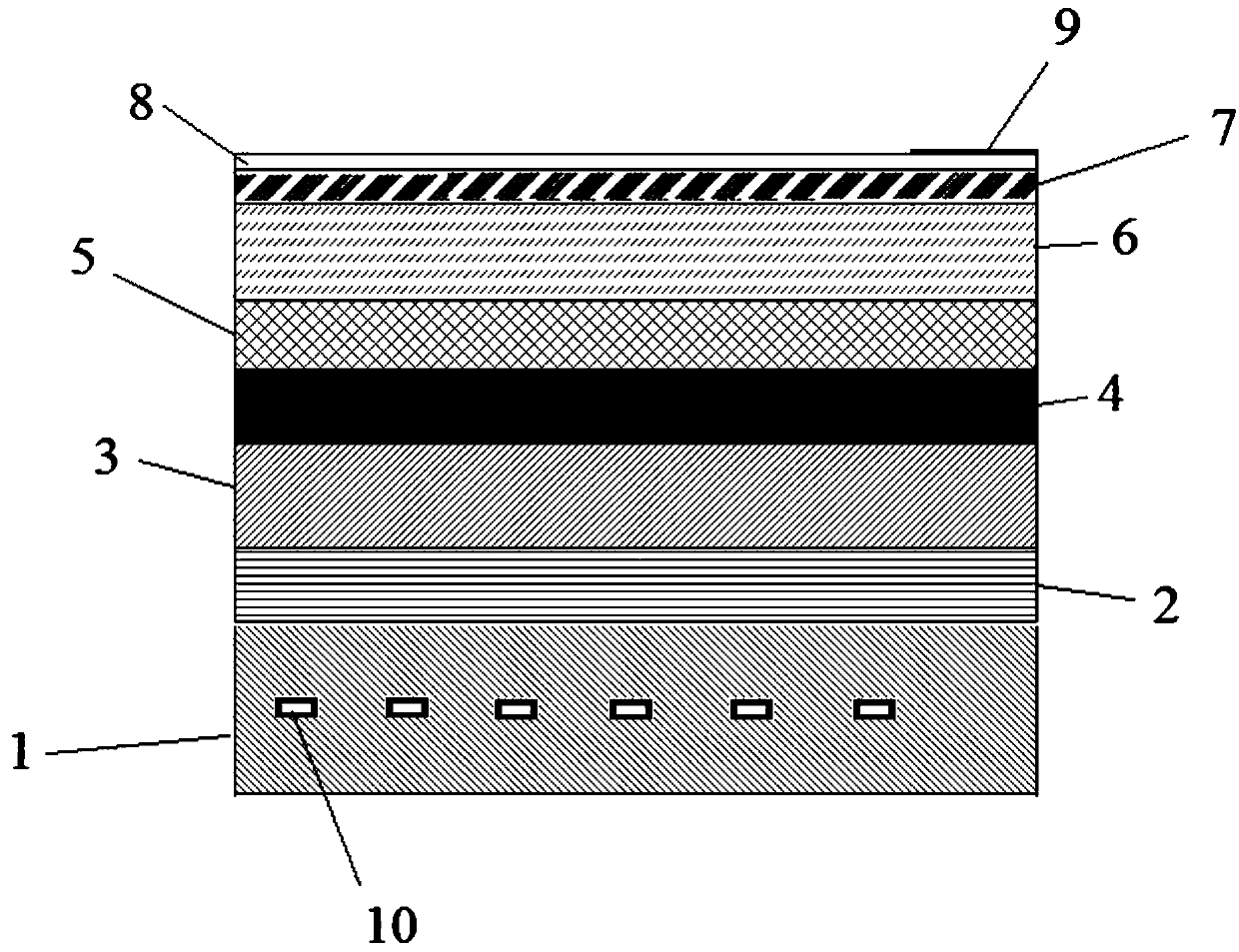

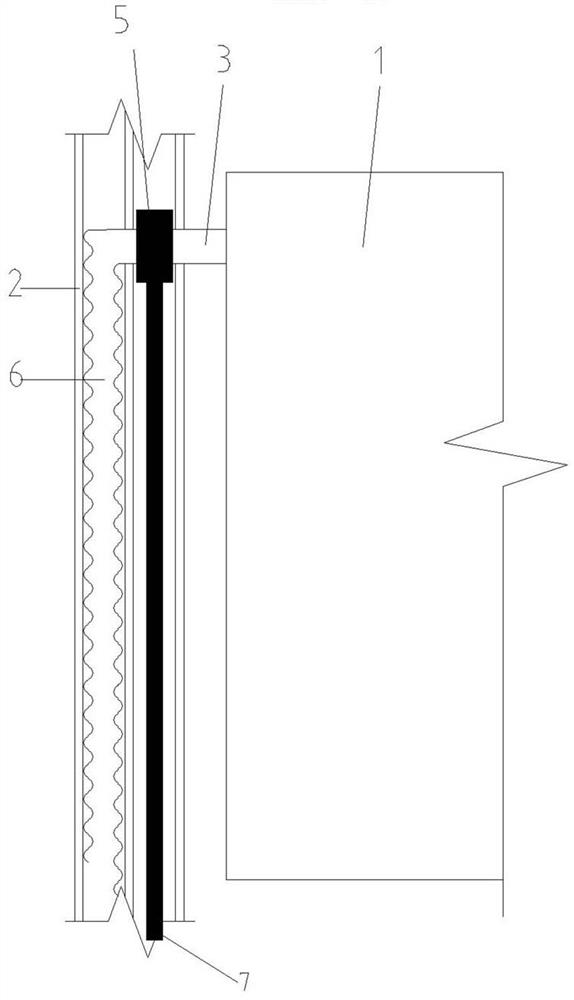

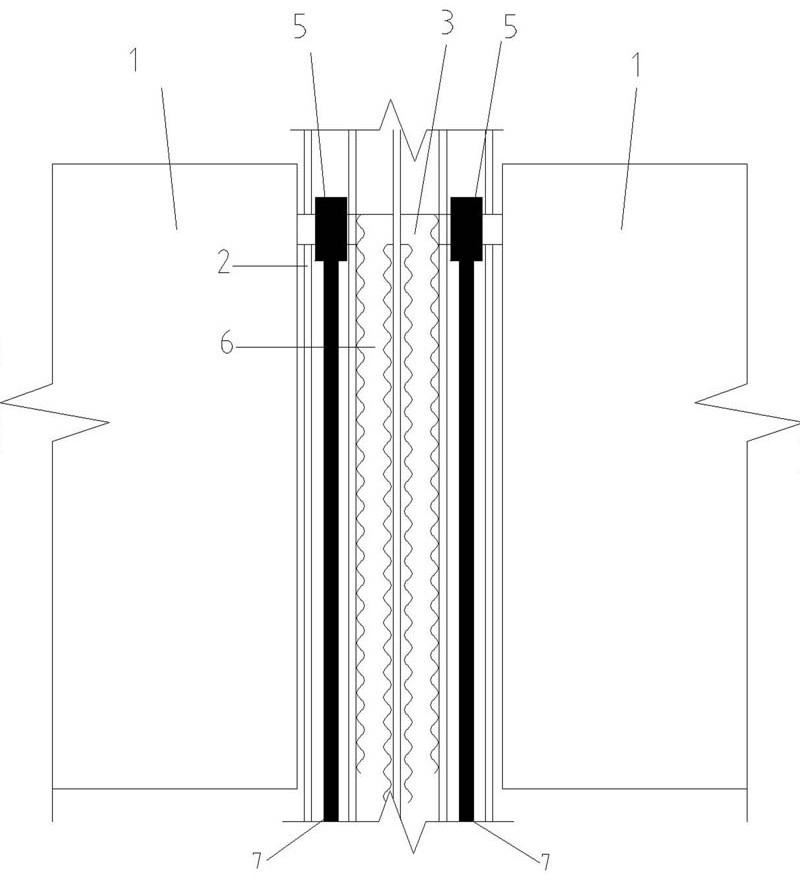

High-firmness and high-blocking anti-fake packaging box

The invention relates to a high-firmness and high-blocking anti-fake packaging box. The high-firmness and high-blocking anti-fake packaging box is formed through box sticking of a packaging paperboard. The high-firmness and high-blocking anti-fake packaging box is characterized in that the packaging paperboard comprises a paperboard body (1), a first glue sticking layer (2), an aluminum film plating layer (3), a second glue sticking layer (4), a holographic laser anti-fake layer (5), a BOPP film layer (6), a crylic acid glue layer (7) and a PET thin film layer (8) which are sequentially composited from bottom to top, and a first plasma bonding face (9) is formed at a sealed position of the packaging paperboard through machining. Compared with the prior art, the packaging paperboard has theadvantages that the sticking firmness is high, the mechanical strength is high, blocking is high, and the anti-fake effect is outstanding.

Owner:上海新洲包装印刷有限公司

Efficient high-speed diamond wire saw manufacturing device and manufacturing method

PendingCN111501079AUniform and effective adhesionHigh quality and efficient productionElectrolysis componentsElectrolytic coatingsComposite materialElectrical and Electronics engineering

The invention belongs to the technical field of diamond wire saw manufacturing, and particularly relates to an efficient high-speed diamond wire saw manufacturing device and a manufacturing method. The manufacturing device comprises a sand loading slot, wherein a wire inlet end and a wire outlet end of the sand loading slot are separately equipped with magnetic conductive wheels which are made ofa magnetic conductive material; a diamond bus passes through the sand loading box and is wound on the magnetic conductive wheels; strong magnetic blocks are separately mounted on the outer side partsof the two magnetic conductive wheels; magnetic fields which are formed by the strong magnetic blocks are distributed on the magnetic conductive wheels, and act on the diamond bus; and under action ofthe magnetic fields, nickel-plated diamond particles in a plating solution are quickly, effectively and uniformly adsorbed and coated on the diamond bus. The process can greatly improve production efficiency, so that wire speed can be increased to 90 meters / minute from 10-30 meters / minute; and the nickel-plated diamond particles in the plating solution can be reduced to 500-1000 / ml from 3000-5000 / ml, so that operations are convenient, the cost is reduced, product performances are guaranteed very well, and use requirements are met.

Owner:江苏三超金刚石工具有限公司

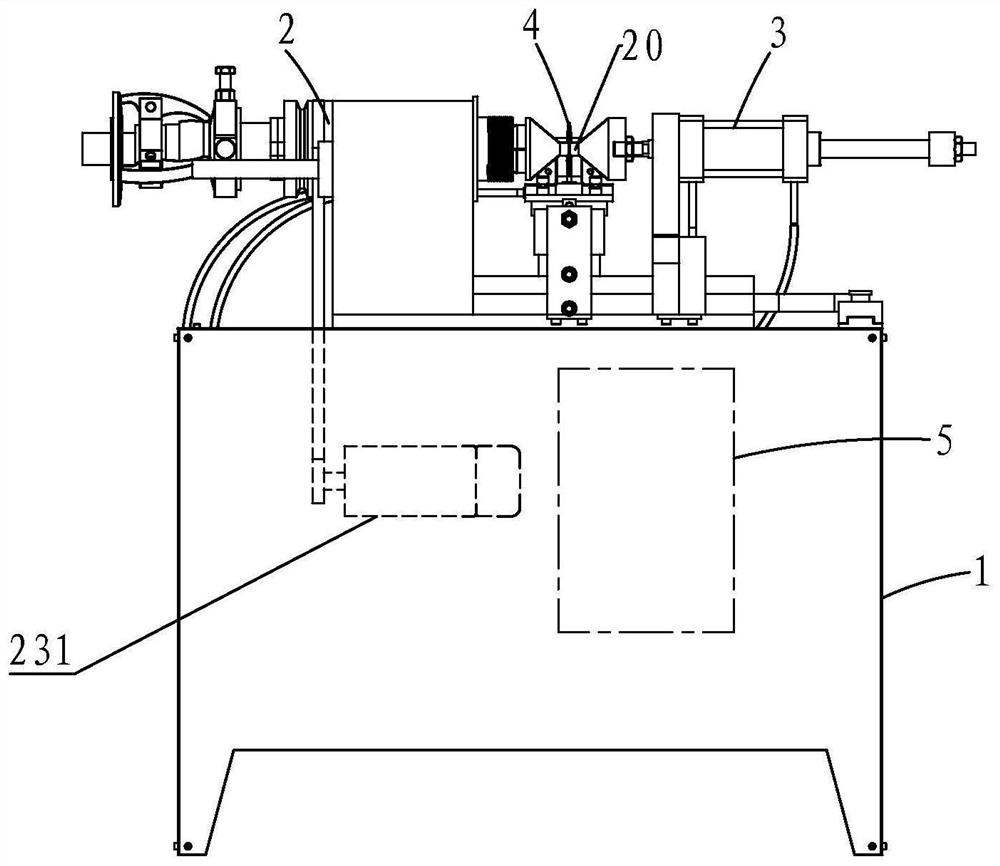

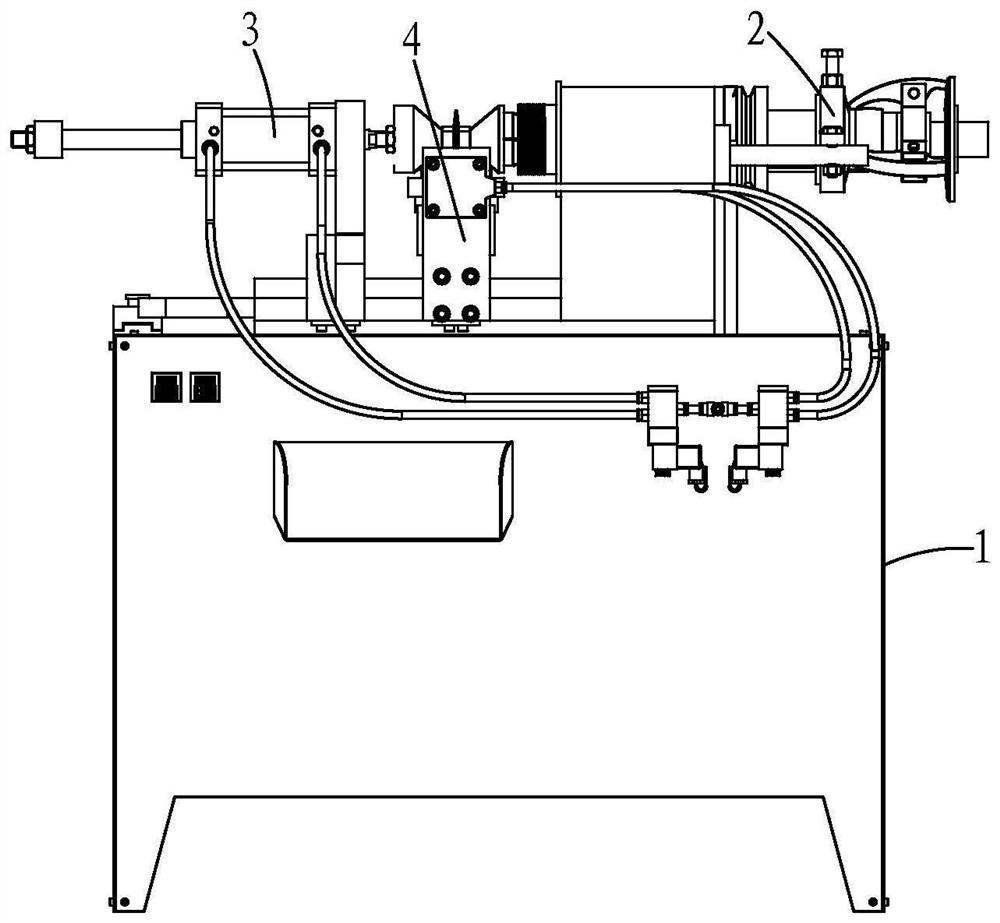

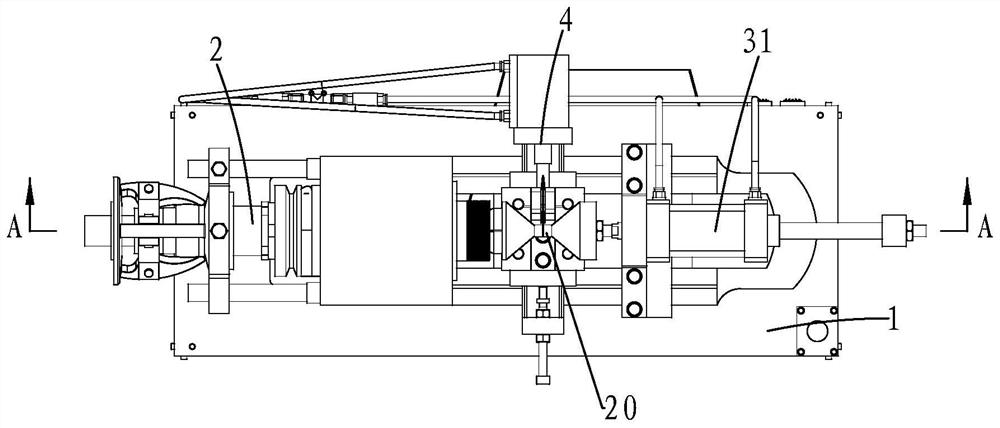

Semi-automatic channeling machine

InactiveCN111842934AImprove productivityGuarantee product qualityAuxillary equipmentTurning machinesInstrument trolleySemi automatic

The invention provides a semi-automatic channeling machine. The semi-automatic channeling machine comprises a rack, an instrument trolley assembly, am ejector pin assembly, a channeling tool rest assembly and a control device; a direct head of a groove to be machined is arranged between a first ejector pin and a second ejector pin, a second driving module is controlled by the control device to drive the second ejector pin to push the direct head tightly, then the control device controls the channeling tool rest assembly to move for groove machining, when the groove of the product is machined in place, a limiting device pushes against a tool rest, is simultaneously sensed by a sensing device and then fed back to the control device, and finally the control device controls a channeling tool rest group and the ejector pin assembly to reset and stop to finish machining. In the whole process, all machining procedures are all mechanical except manual material placement and starting, the groove structure is automatically machined, the productivity is improved, the product quality is ensured, and production achieves the high-efficiency and high-quality effects.

Owner:FUZHOU ZHENXIE PIPE

Lightweight concrete perforated plate profile and its preparation process

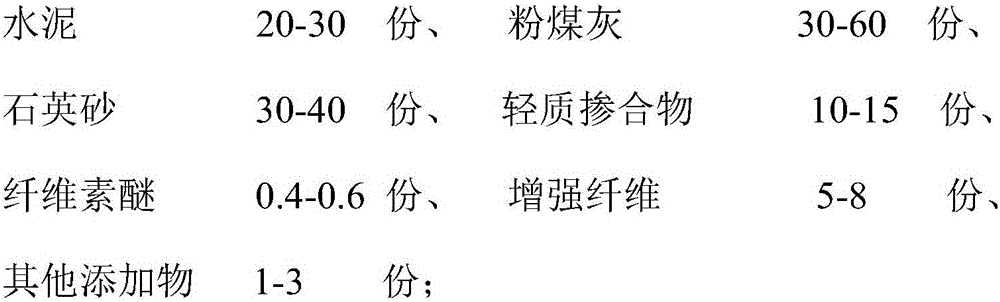

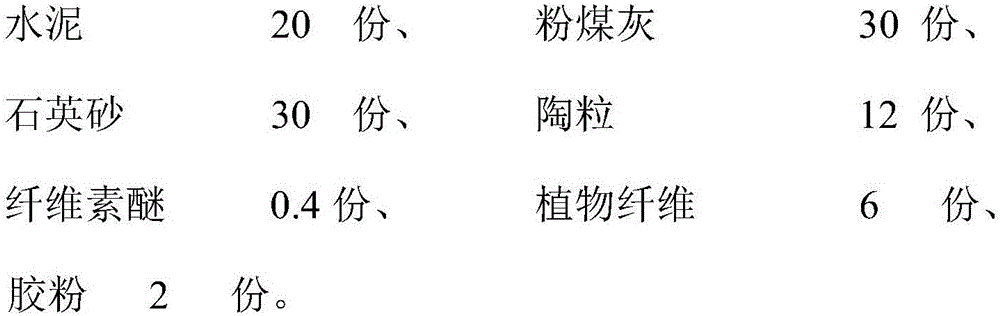

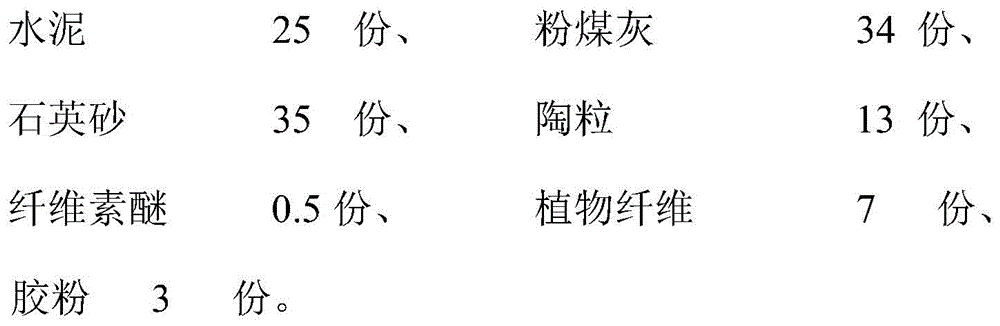

ActiveCN104129947BImprove and increase bearing strengthImprove and enhance ease of useSolid waste managementCelluloseMasterbatch

The invention discloses a lightweight concrete porous plate section bar, which characterized in that a concrete mixture is used as a working masterbatch. The working masterbatch comprises the following materials by weight: 20-30 parts of cement, 30-60 parts of fly ash, 30-40 parts of quartz sand, 10-15 parts of a lightweight blend, 0.4-0.6 part of cellulose ether, 5-8 parts of plant fiber and 1-3 parts of other additives. The preparation technology is as below: first conducting a first dry stirring on the raw materials for even mixing, then adding 10-18 parts of water for a secondary even mixing; and then conducting plasticity extrusion moulding by a vacuum extruder and a porous extrusion mold. The invention uses regenerated industrial wastes by a large proportion of, reduces the dosage of cement, reduces the cost and is beneficial to saving of resource and energy and environmental protection.

Owner:房晓磊

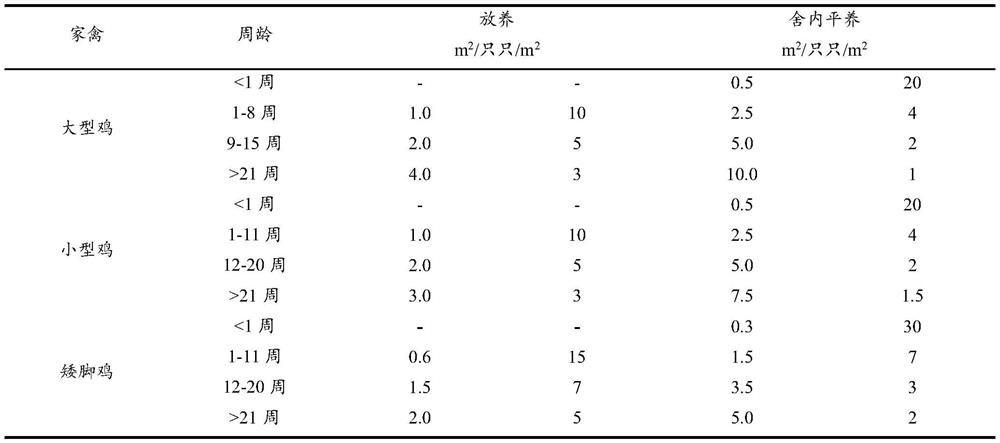

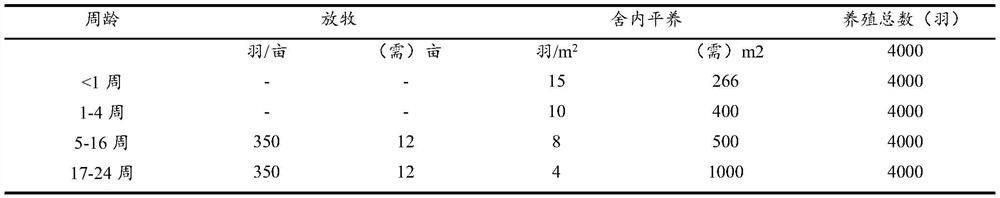

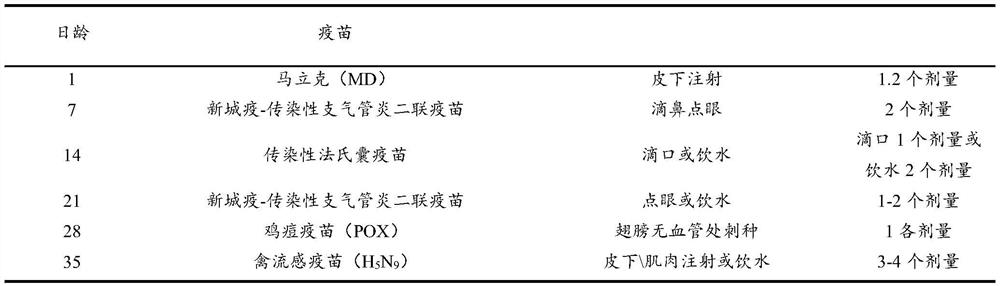

Ecological stocking breeding method for poultry

PendingCN114586738AHigh quality and efficient productionEfficient recycling and utilizationAnimal husbandryGrazingPoultry product

The invention provides an ecological stocking breeding method for poultry. The ecological stocking breeding method comprises the step of performing ecological stocking on the poultry by adopting a rotational grazing vehicle as a mobile animal house for outdoor poultry breeding, the flowing area of the rotational grazing vehicle is a wide grassland or a flat artificial forest farm; the poultry variety is a variety with excellent environmental stress resistance; the rotational grazing vehicle is divided into an upper layer and a lower layer and is provided with a fermentation bed, a heat preservation lamp, a fan, an ultraviolet lamp, an air conditioner, a disinfection facility and an incinerator. High-quality, healthy and organic poultry products can be produced under outdoor ecological environments such as forest and grassland, mobile breeding can be carried out by using the rotational grazing vehicle, automatic breeding equipment and solar green energy are arranged inside and outside the compartment, high-efficiency and high-quality production is realized under reasonable breeding density and scientific breeding technology management, and the method is suitable for large-scale popularization and application. The breeding waste is scientifically fermented and digested in situ, so that the effective circulation and utilization of the ecological environment are realized.

Owner:SOUTHWEST FORESTRY UNIVERSITY

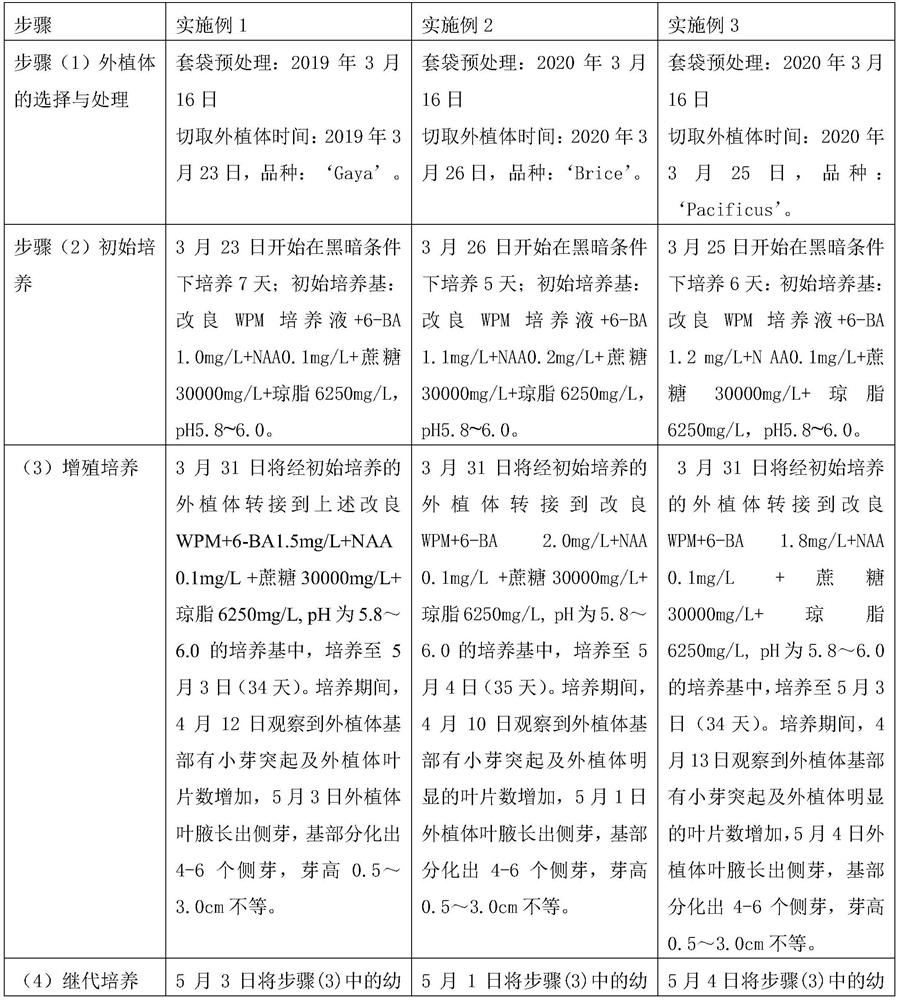

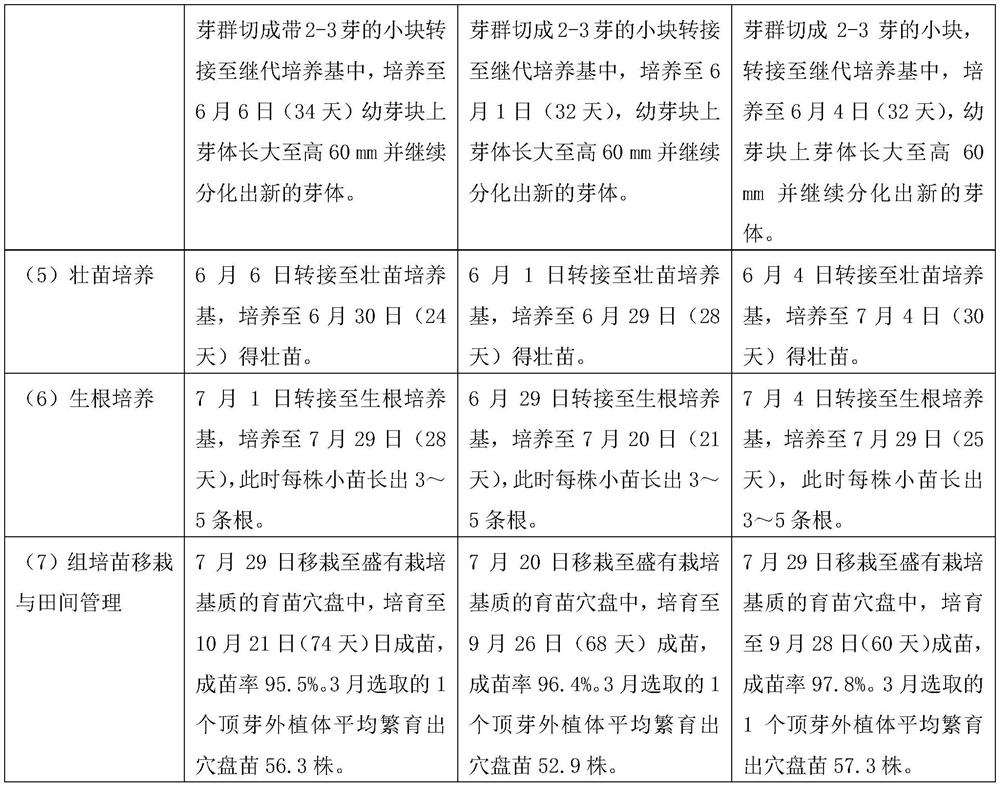

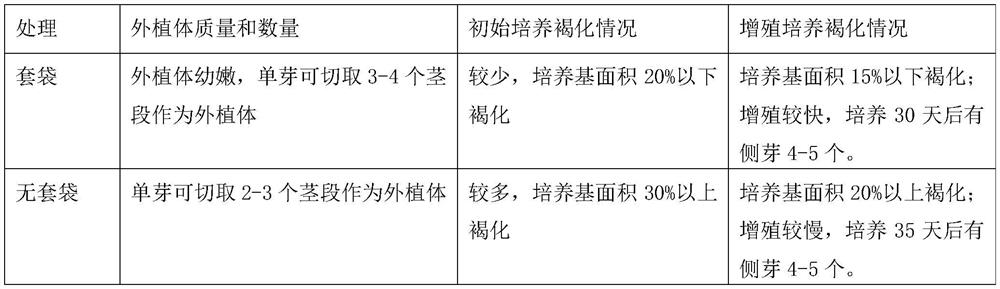

Large-scale production method for plug seedlings of nepenthes in middle Yunnan region

ActiveCN114403002AImprove cultivation efficiencyKeep tender and cleanPlant tissue cultureHorticulture methodsFluorescent lightCulture mediums

A large-scale production method for plug seedlings of nepenthes in the middle Yunnan region is characterized in that more than 50 high-quality plug seedlings are bred from one terminal bud explant in March to October in the same year through compact connection and technical measure integration of seven steps of explant pretreatment, initiation, proliferation, subculture, seedling strengthening and rooting culture, tissue culture seedling transplanting and field management; through explant pretreatment, an improved WPM culture medium with low salt content is selected, so that the problems of low survival rate of initial culture, serious browning and slow growth of explants in subsequent group culture links are solved; an LED combined light source I and an LED combined light source II are adopted in the multiplication culture link and the strong seedling culture link respectively, compared with a traditional fluorescent lamp, energy is saved by 43.7%-53%, and meanwhile the multiplication multiple and the strong seedling rate are improved by 38.1% and 28.0% respectively; in the links of rooting culture, tissue culture seedling transplanting and field management, the beneficial weather conditions of relatively damp and hot summer in the middle Yunnan region are fully utilized, and the production cost is reduced.

Owner:FLOWER RES INST OF YUNNAN ACAD OF AGRI SCI +1

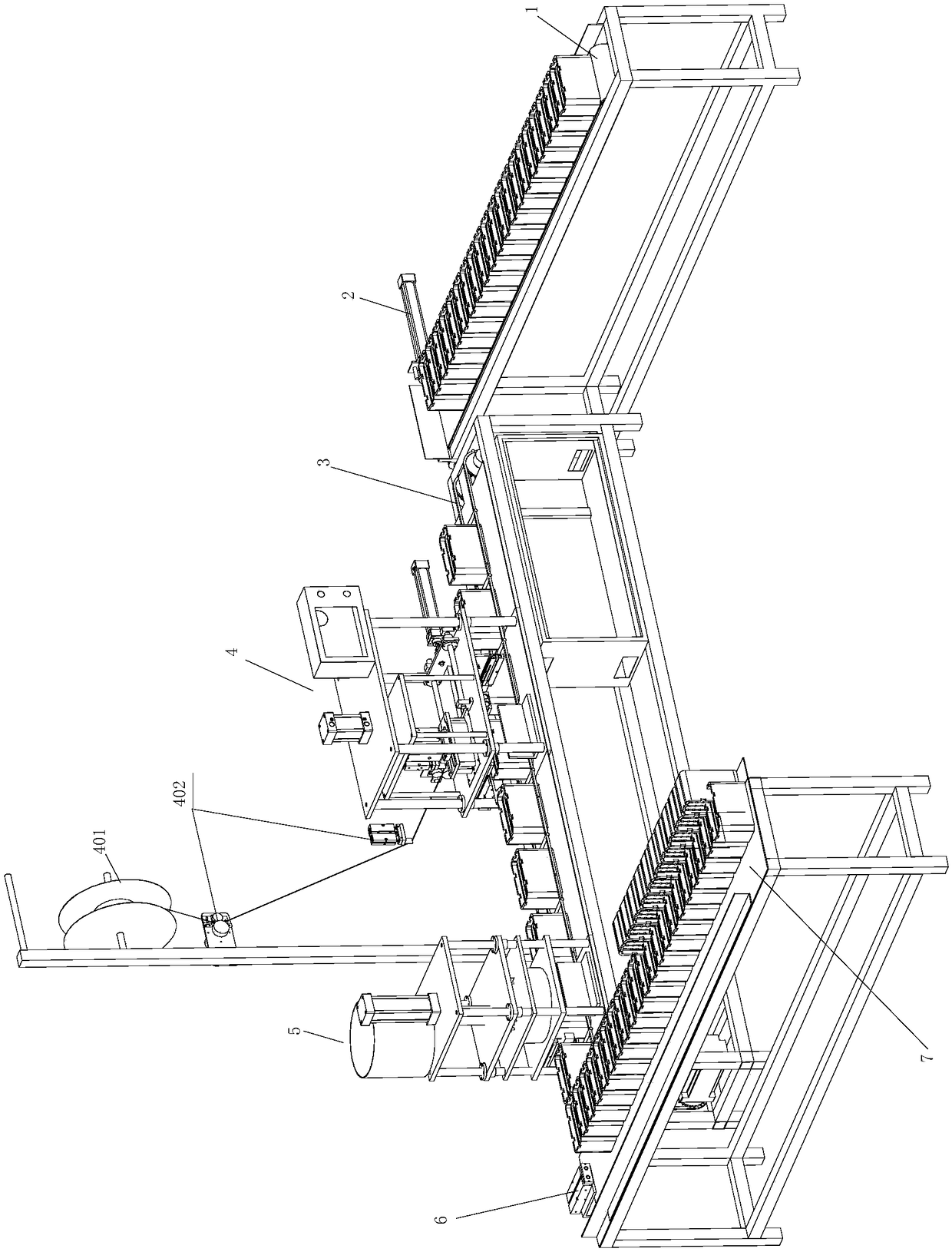

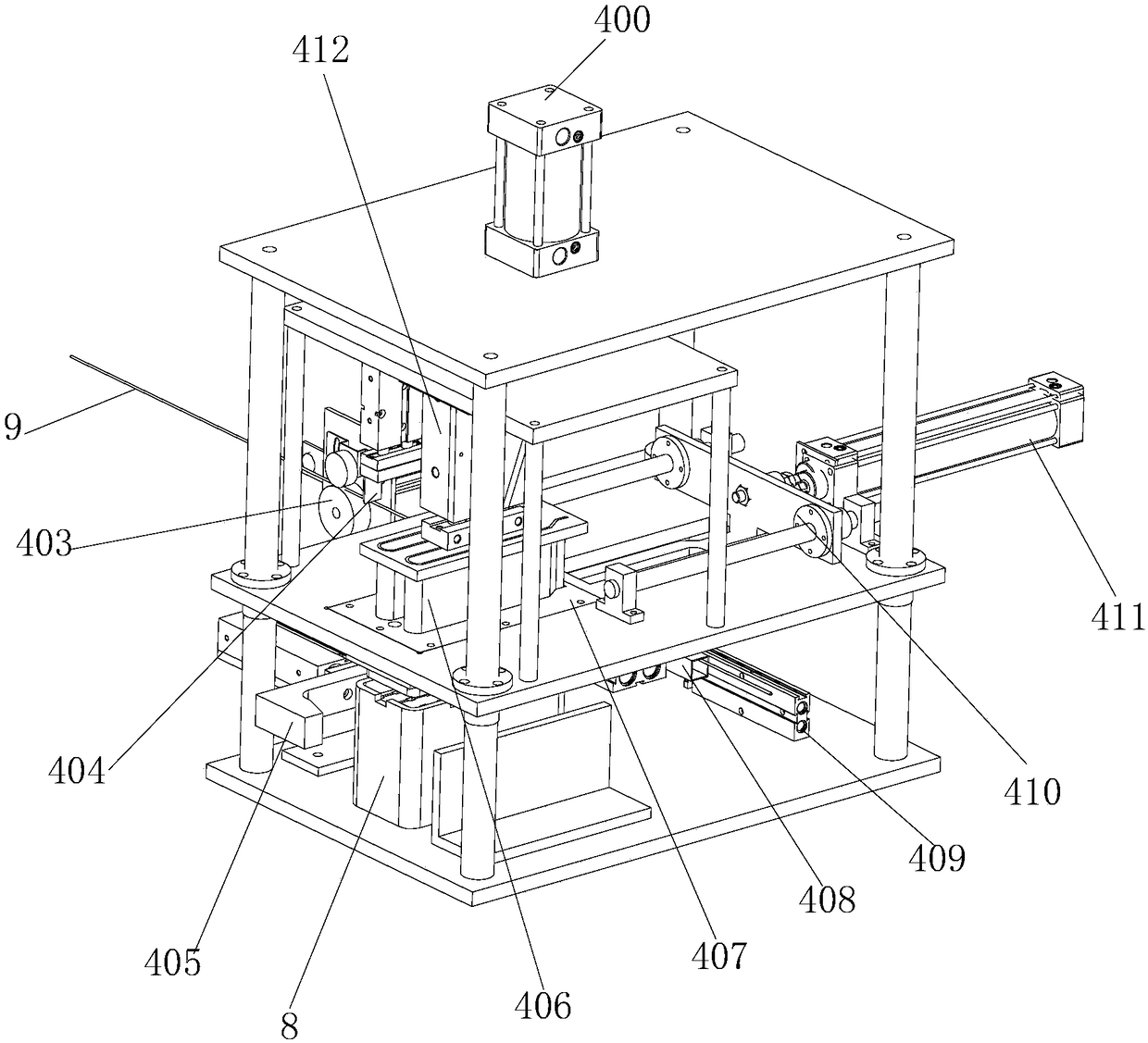

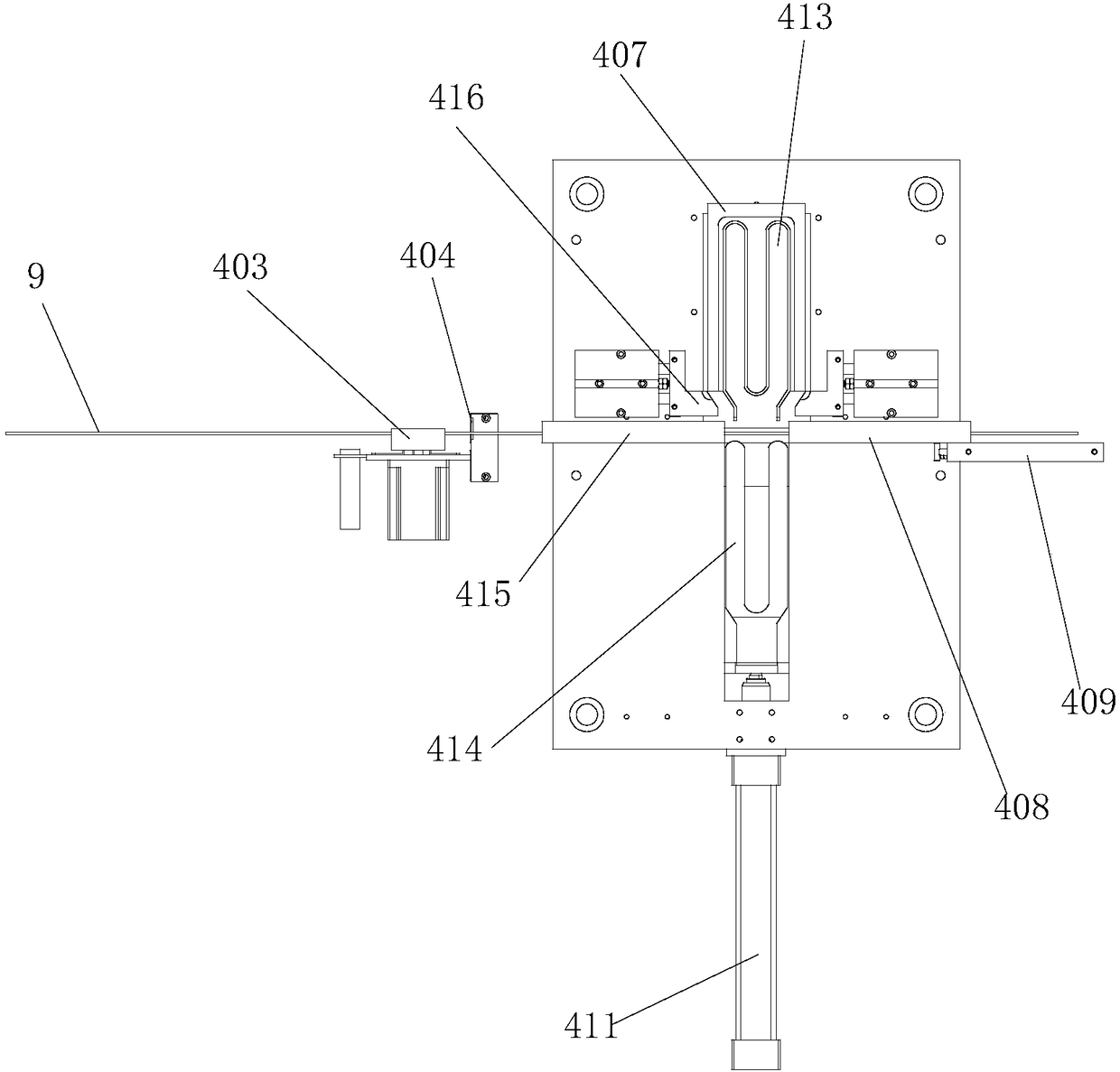

A molded firework loading and dispensing device

ActiveCN107218854BLiquid level stabilityUniform dispensing volumeLiquid surface applicatorsCoatingsFireworksEngineering

The invention discloses a lead wire mounting and dispensing device of molded fireworks. The lead wire mounting and dispensing device comprises a lead wire mounting mechanism and a dispensing mechanism which are sequentially distributed on a transmitting mechanism. The lead wire mounting and dispensing device disclosed by the invention can be used for efficiently and reliably completing lead wire mounting and dispensing work of the molded firework, and efficiently and reliably completes lead wire mounting and dispensing work of one product once, has processing speed adaptive to and matched with other processes in large-scale assembly line production of the molded fireworks, protects the lead wire and greatly improves lead wire mounting quality. The dispensing mechanism can effectively prevent a glue path from being blocked, dispensing dose is uniform and adjustable, glue is reliably isolated from air in a glue supply process, and concentration of the glue is uniform. The whole device is simple in mechanism, is matched and coordinated smoothly, is convenient to operate, regulate and maintain, is low in cost, and is durable and wearable; and special requirements of the molded fireworks are met, and high-quality efficient automatic assembly line production is realized.

Owner:LIUYANG YIHELONG FIREWORKS GRP +1

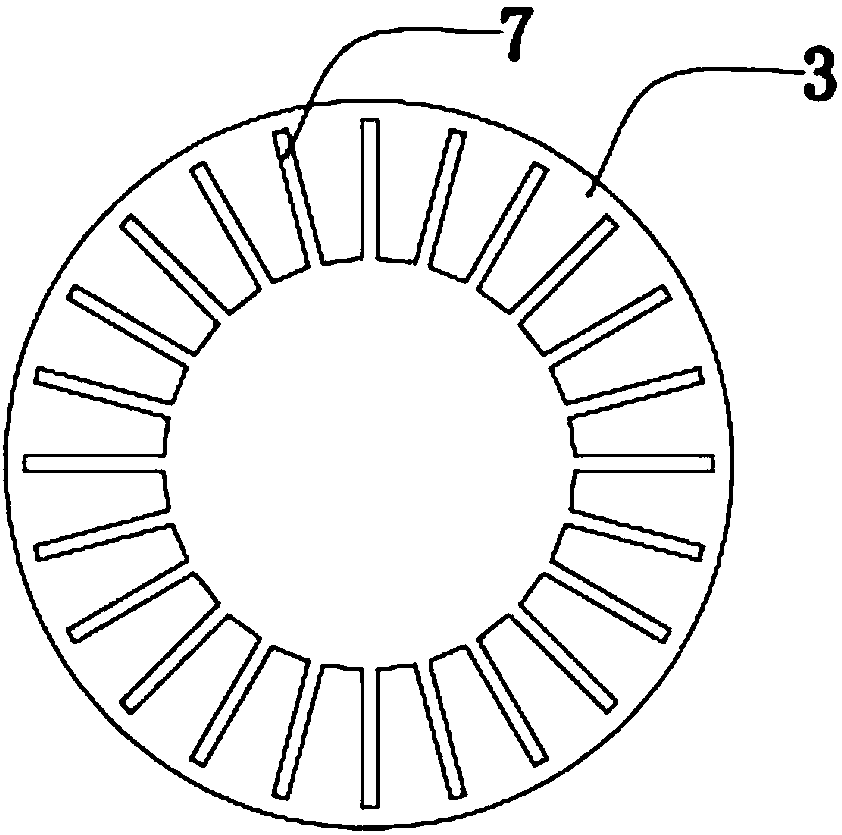

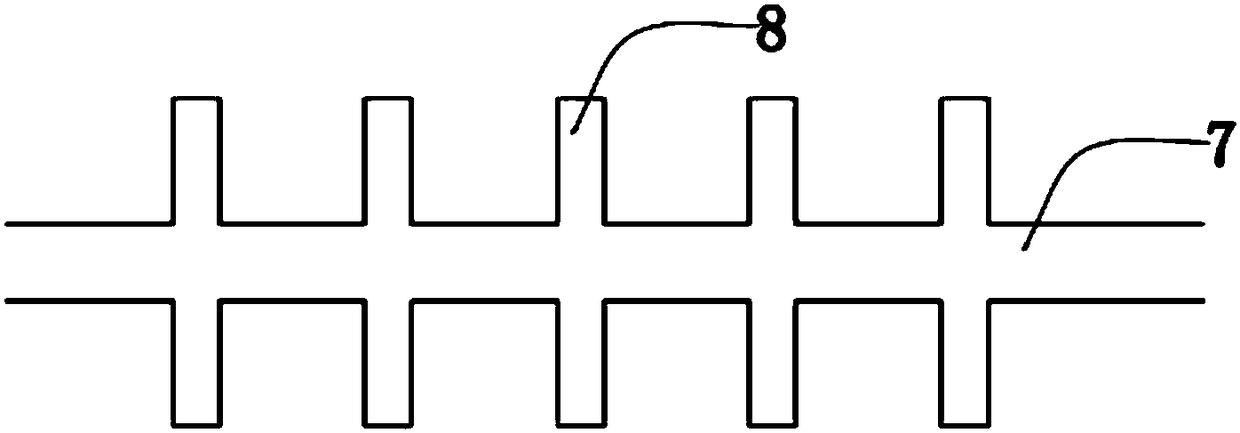

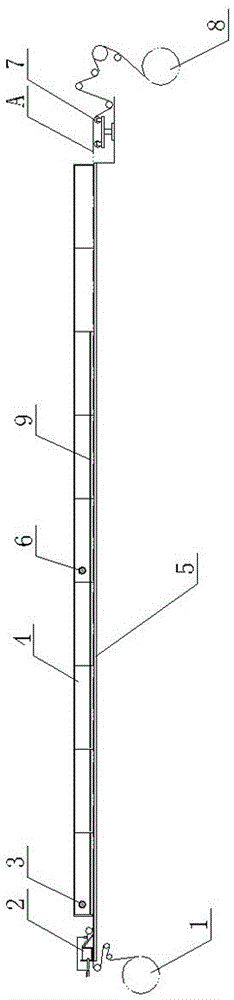

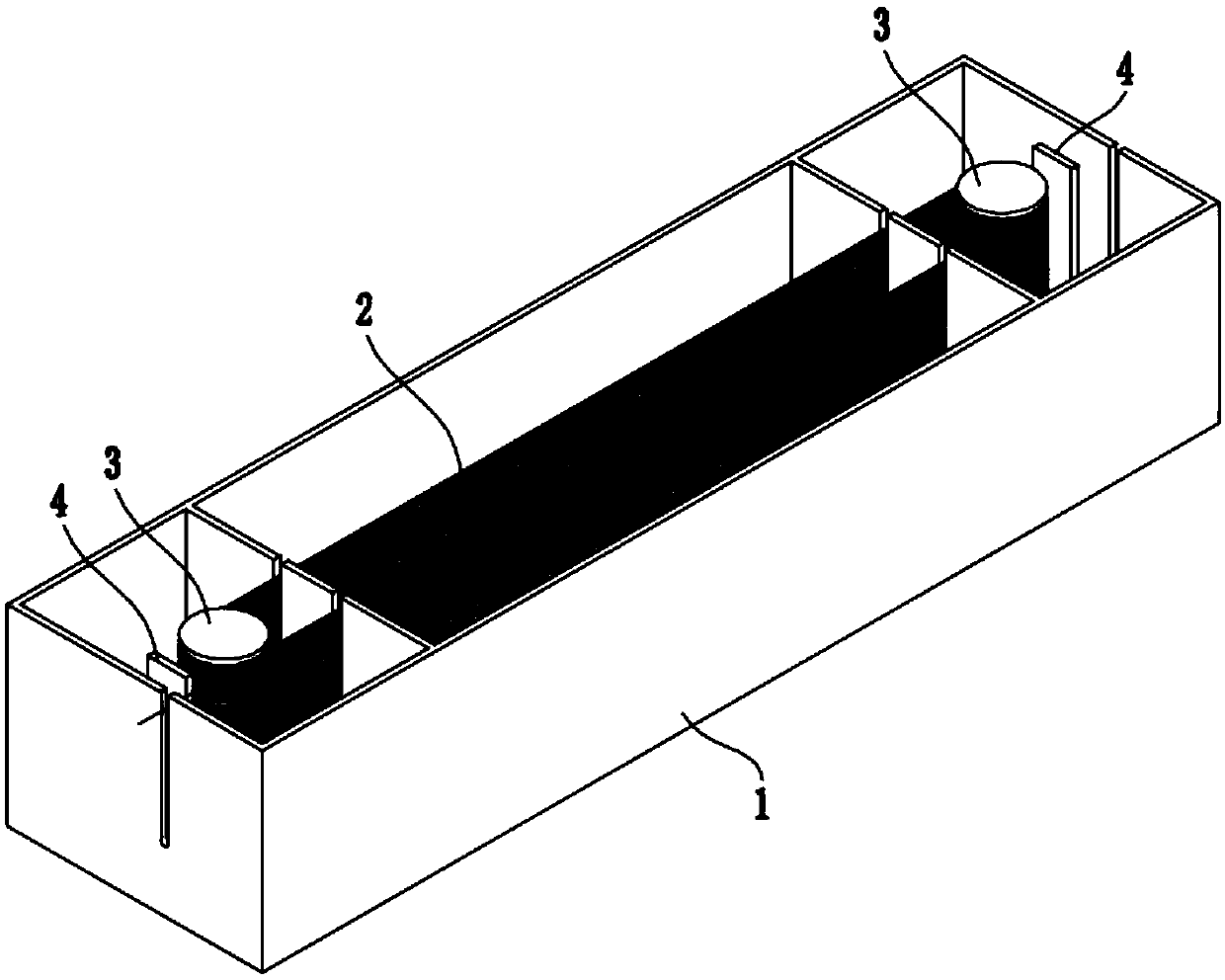

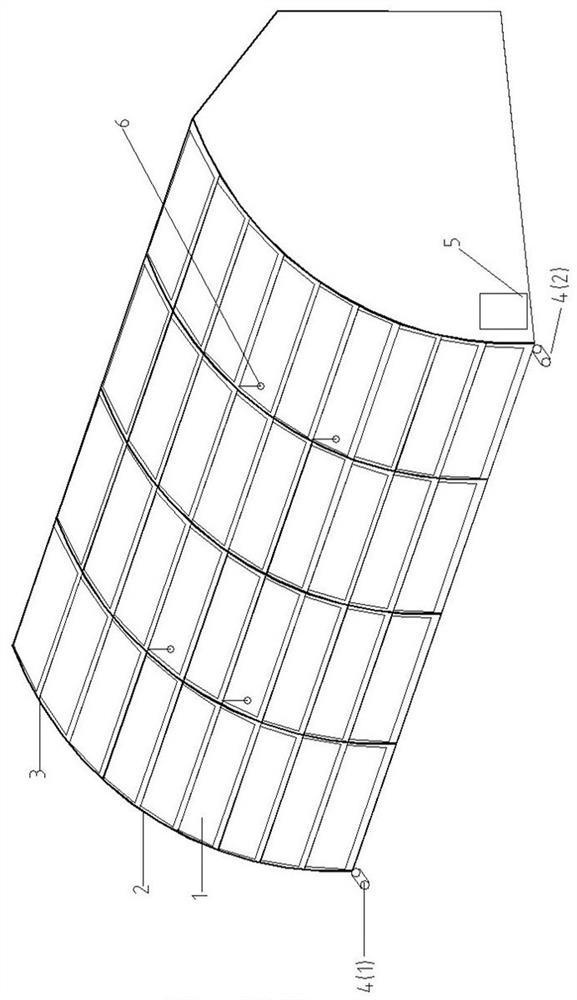

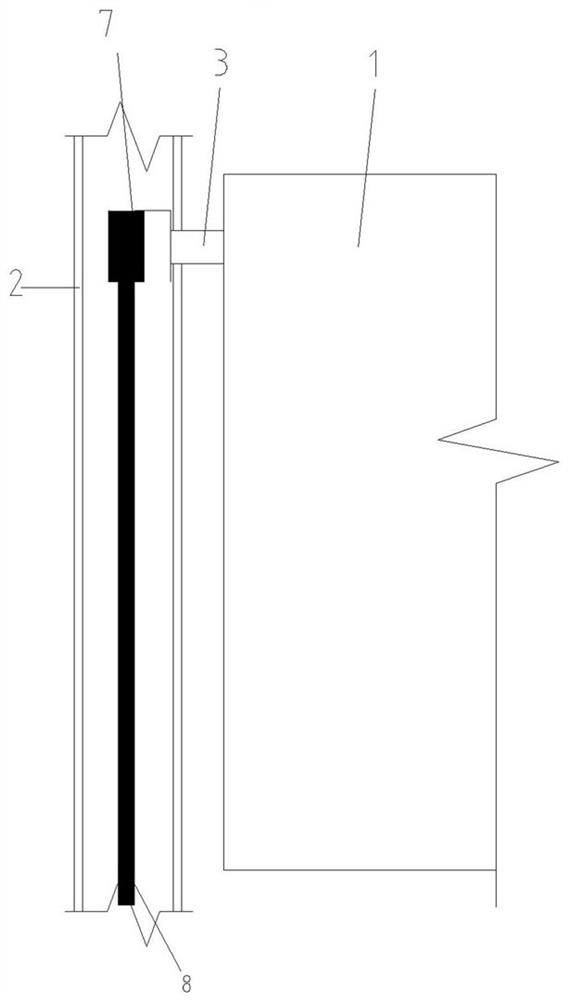

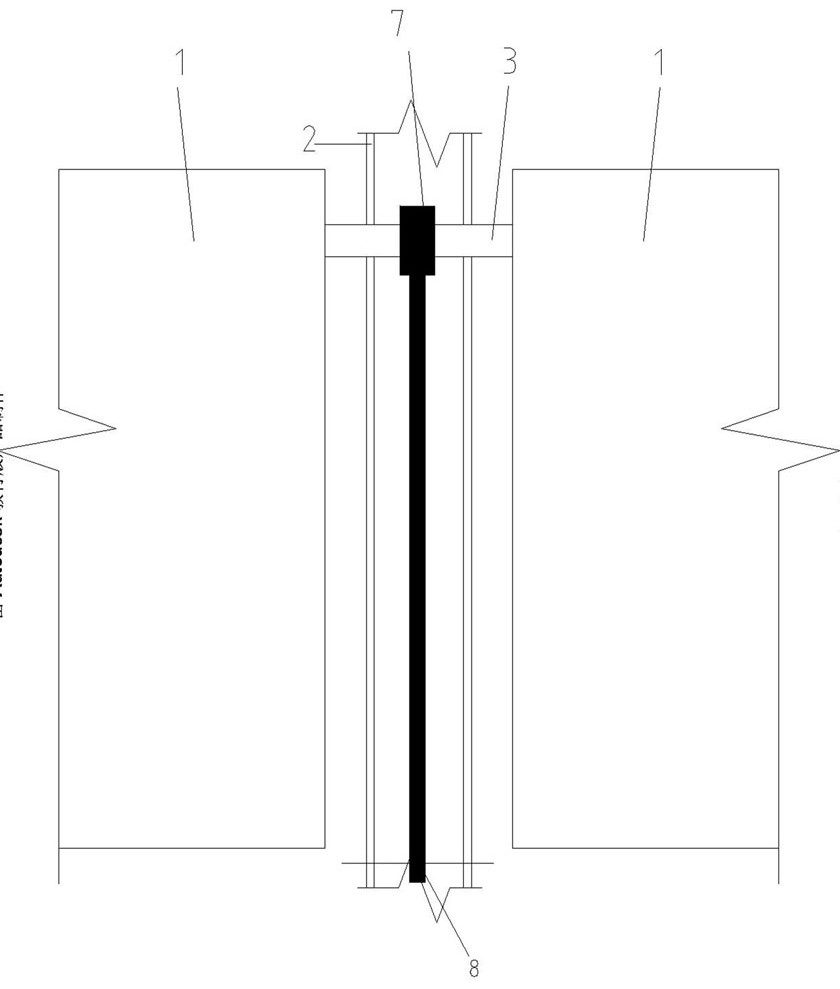

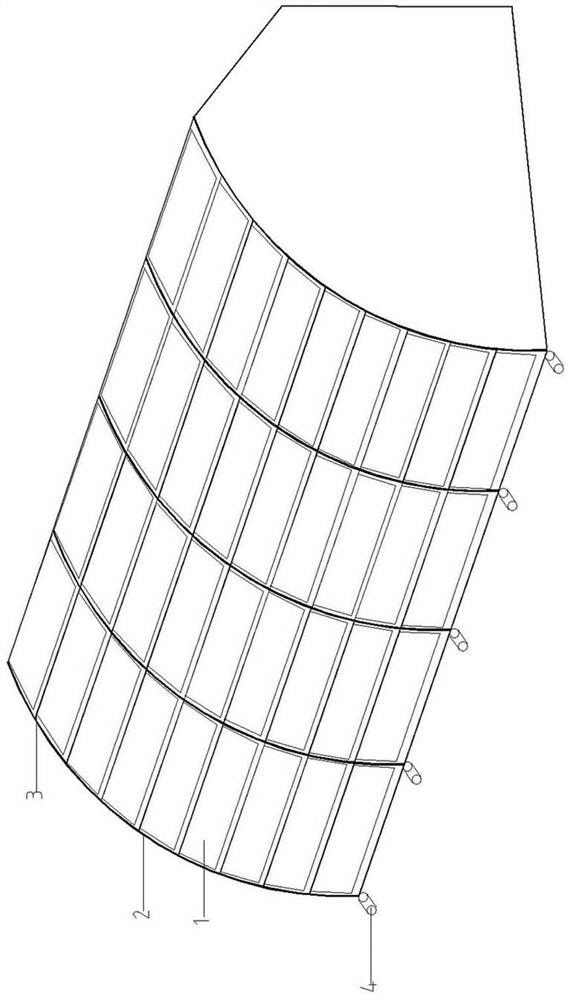

Solar double-sided photovoltaic power generation internal shading system for greenhouse

PendingCN112640703ASolve the problem of high comprehensive operation and maintenance costsHigh quality and efficient productionClimate change adaptationRenewable energy machinesCurrent loadElectric machine

The invention discloses a solar double-sided photovoltaic power generation internal shading system for a greenhouse. rotating shafts (3) are mounted on side frames of double-sided photovoltaic modules (1) and are fixed on a support (2); the support (2) consists of mounting channels of gears (7) and chains (8), and a direct-current wire laying channel (9); the end parts of the rotating shafts (3) are provided with the gears (7), the chains (8) in the support (2) are controlled to move through a first motor (4 (1)) or a second motor (4 (2)), and the gears (7) rotate to open or close the double-sided photovoltaic modules (1) to achieve shading; and when solar radiation exists and the shading requirement is met, electric energy generated by the double-sided photovoltaic modules (1) is stored in a storage battery pack (12) through an inversion control all-in-one machine (11), the storage battery pack (12) is connected with a direct-current load (13), and the inversion control all-in-one machine (11) can achieve alternating-current output and directly input into an alternating-current load (14).

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

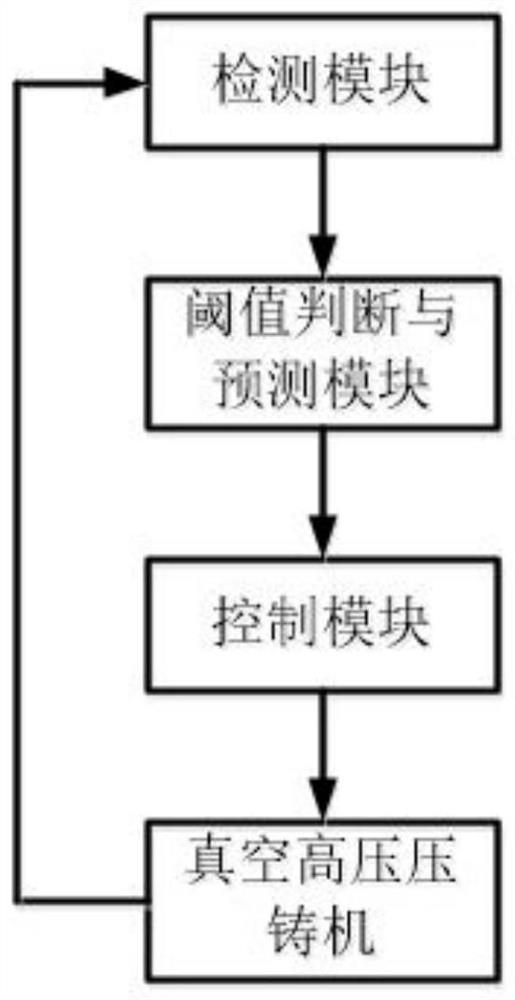

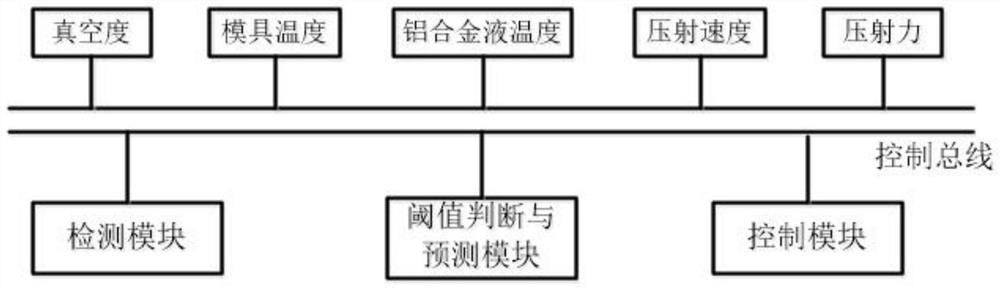

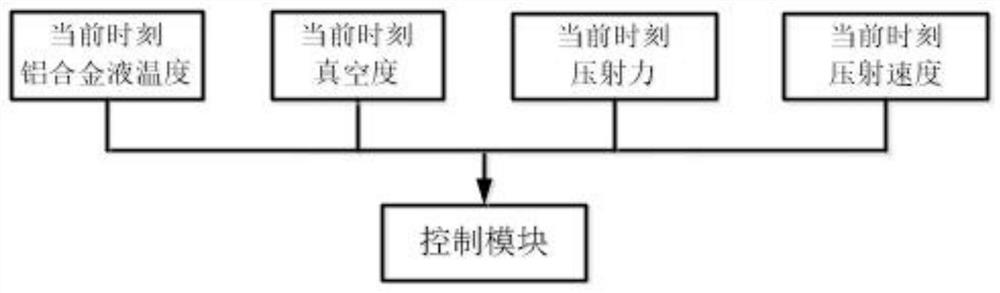

High-pressure vacuum die-casting process control system and method for efficient and high-quality aluminum alloy shock absorption tower

ActiveCN114632922AHigh quality and efficient productionImprove stabilityPressure castingControl system

The invention discloses an efficient and high-quality aluminum alloy damping tower high-pressure vacuum die-casting process control system and method.The system structurally comprises a detection module, a threshold value judgment and prediction module and a control module, the detection module is connected with the threshold value judgment and prediction module, the threshold value judgment and prediction module is connected with the control module, and the control module is connected with the control module. The detection module and the control module are respectively connected with the vacuum high-pressure casting machine; the detection module detects the vacuum degree, the mold temperature, the aluminum alloy liquid temperature, the injection speed and the injection force of the aluminum alloy damping tower on the high-pressure vacuum die-casting machine in real time. The stability of the vacuum high-pressure die-casting process can be improved, self-adaptive adjustment and intervention control of the process are achieved, and high-quality and high-efficiency production of the shock absorption tower is ensured.

Owner:HUNAN UNIV

Efficient alcohol pad packer for finger-protective alcohol pad production

ActiveCN103287611BAvoid cross infectionFix technical deficienciesPaper article packagingWrapper twisting/gatheringEngineeringAlcohol pads

The invention relates to an efficient alcohol pad packer for finger-protective alcohol pad production. The efficient alcohol pad packer comprises a workbench, a former, a light sensor, a packing paper feed mechanism, a liquid injection mechanism, a sealing mechanism and a finished product cutting mechanism. A core cutting and inserting mechanism and an epsilon-shaped core thermal sealing mechanism. The efficient alcohol pad packer has the advantages that the efficient alcohol pad packer is ingenious in design, simple in structure, high in practicality, and high in automation level, the advantages of original packers are inherited, the defects in the prior art are overcome, high-quality and efficiency production of the finger-protective alcohol pads and like products is achieved, process flow is simplified, equipment automation level is increased, and work efficiency is increased.

Owner:LIGHTS MEDICAL MFR

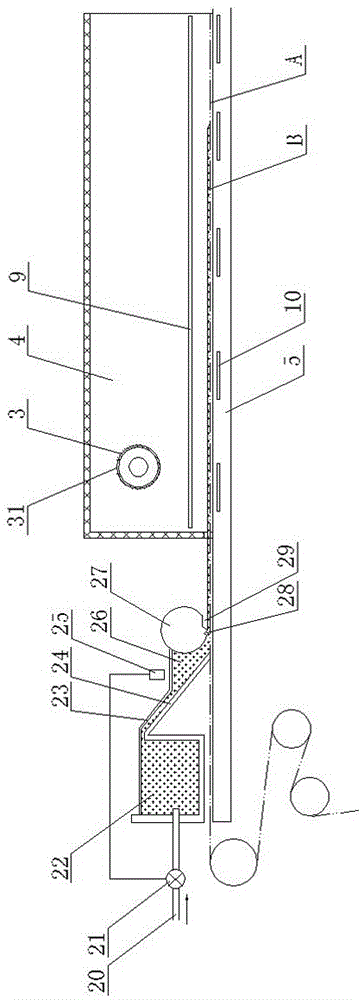

Solar internal shading system for greenhouse

PendingCN112640704ASolve the problem of high comprehensive operation and maintenance costsHigh quality and efficient productionClimate change adaptationRenewable energy machinesEngineeringHeat conservation

The invention discloses a solar internal shading system for a greenhouse. PVT modules (1) are fixed to a support (2) through rotating shafts (3), the end parts of the rotating shafts (3) are provided with gears (5), chains (7) in the support (2) are controlled to move through motors (4), and the gears (5) rotate to open or close the PVT modules (1). In solar photo-thermal utilization, cold water enters an array formed by the PVT modules (1) through a cold water inlet pipe (8) in the support (2), absorbs solar radiant heat and then water enters a hot water outlet pipe (10), hot water is stored in a heat preservation water tank (19), a stop valve (11), a gate valve (12), a handle butterfly valve (13), a Y-shaped filter (14), a temperature sensor (15), a pressure gauge (16), a flow meter (17), a water pump (20) and a check valve (21) are arranged on a medium flow channel of the support (2), and the heat preservation water tank (19) controls tap water supplementing through a floating ball valve (18).

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Rewinding and separating method for stainless steel pattern plate of work roll contactless steel plate

ActiveCN103272881BHigh quality and efficient productionAbility to meetWork rollStructural engineering

The invention relates to a rewinding and separating method for a stainless steel pattern plate of a work roll contactless steel plate, and belongs to the metallurgy field. The method comprises the procedures as follows: selecting an operation mode through a flattening and separating unit, threading a strip steel, tensioning the strip steel, winding the strip steel, penetrating the strip steel and performing tailing disposal, wherein the flattening and separating unit selects a rewinding mode for operation, and a straightener roll gap is larger than 60 mm; an unwinding machine press roll is used for threading the strip steel, a deep bending roll is used for flattening a strip steel head part, and the flattening length is larger than 3 m; a vehicle is stopped when the strip steel head part reaches an outlet side guide position, and the straight head roll is lifted to the highest, so that the tensioned strip steel is suspended in the straightener roll gap; the strip steel head part is wound and tensioned at an outlet pinch roll; the tension strip steel is guaranteed to be suspended in the straightener roll gap; the winding tension per unit is smaller than 2Kg / mm <2>; the winding steel penetrating speed is smaller than 60m / min; and a pinch roll and the straight head roll at a tailing disposal inlet are put down timely, the flattened tail part is 2-3m long, and the tailing disposal speed is 15 m / min. The method can prevent the surface of the steel plate from being scratched in rewinding and separating processes of a hot-rolled stainless steel pattern plate steel coil.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com