Rewinding and separating method for stainless steel pattern plate of work roll contactless steel plate

A non-contact, stainless steel technology, applied in the field of recoiling and decoiling of stainless steel checkered plates, can solve problems such as damage to the roller surface of the straightening machine, and achieve the effect of ensuring equipment safety, simple operation and excellent product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

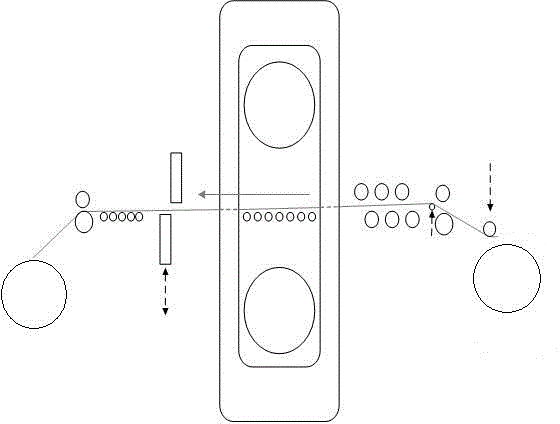

[0016] The invention includes the operation mode of the leveling and decoiling unit, the decoiler pressure roller threading, sheet building, coiling, steel passing, and tail flicking processes, wherein

[0017] 1. The leveling and detaching unit selects the rewinding mode to operate, and lifts the upper straightening roller to the leveling gap > 100mm during operation.

[0018] 2. The uncoiler pressure roller is used to complete the strip threading. When threading the strip, the strip head is flattened, and the deep bending roller is used to flatten the strip head. The flattened length of the strip head is more than 3m.

[0019] 3. Stop when the head of the strip steel reaches the exit side guide, lift the straight head roller to the highest level so that the gap between the straightening rolls is the largest (the strip steel is suspended in the gap between the rolls of the straightening machine after the strip is stretched).

[0020] 4. After continuing to thread the belt to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com