A molded firework loading and dispensing device

A glue dispensing device and fireworks technology, applied to the surface coating liquid device, pyrotechnics, attack equipment, etc., to achieve the effect of isolating glue and air, improving the installation quality of lead wires, and simple device mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

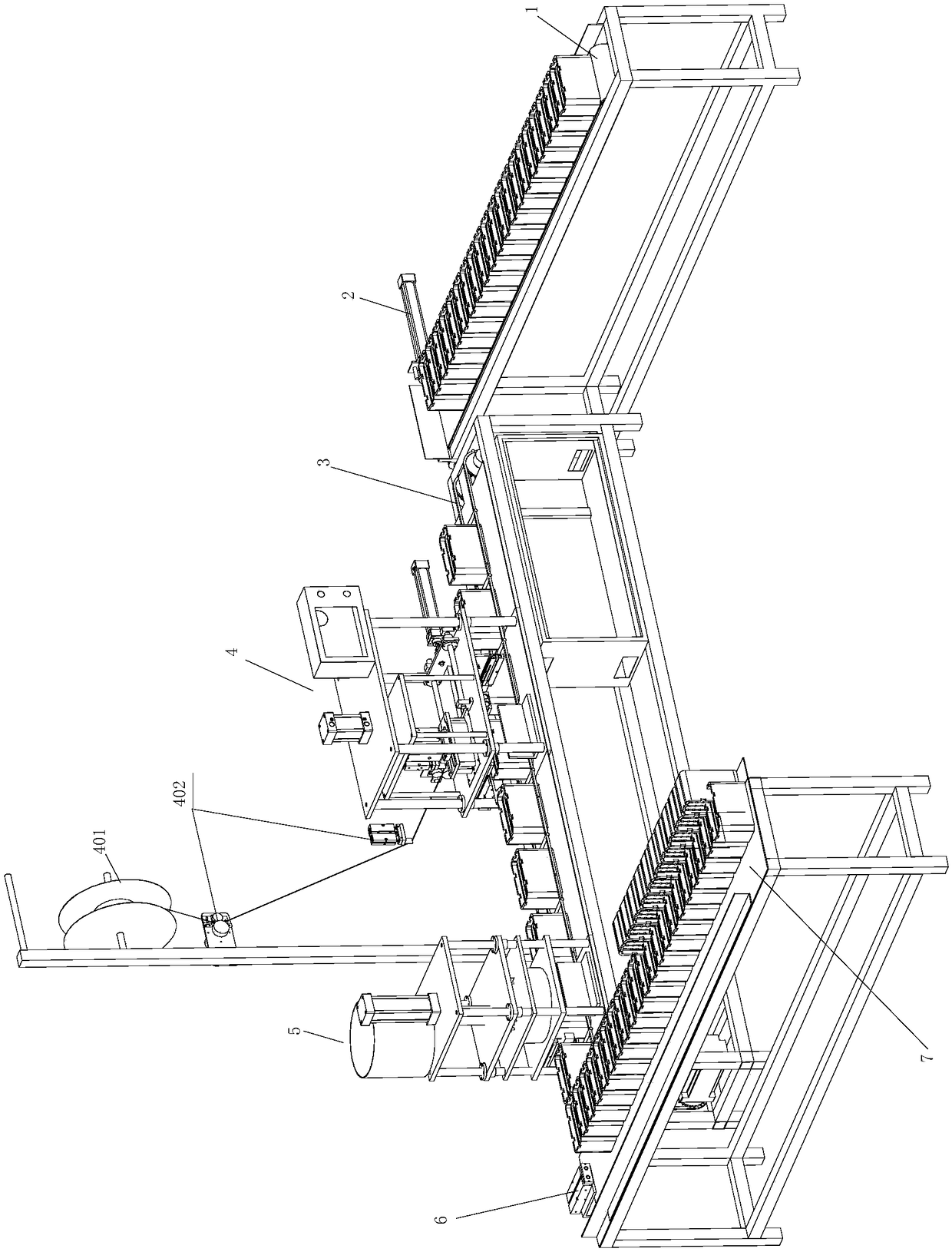

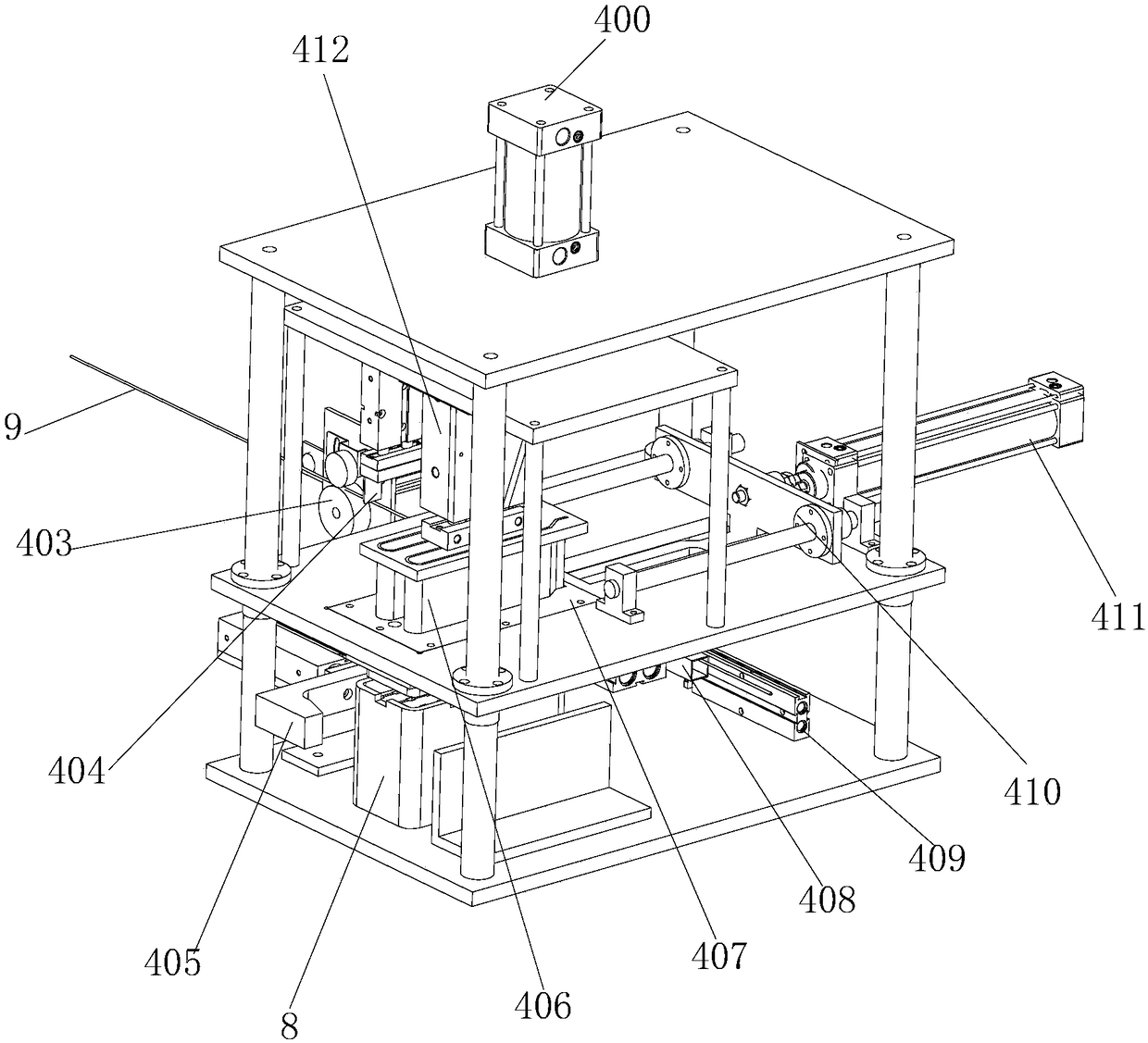

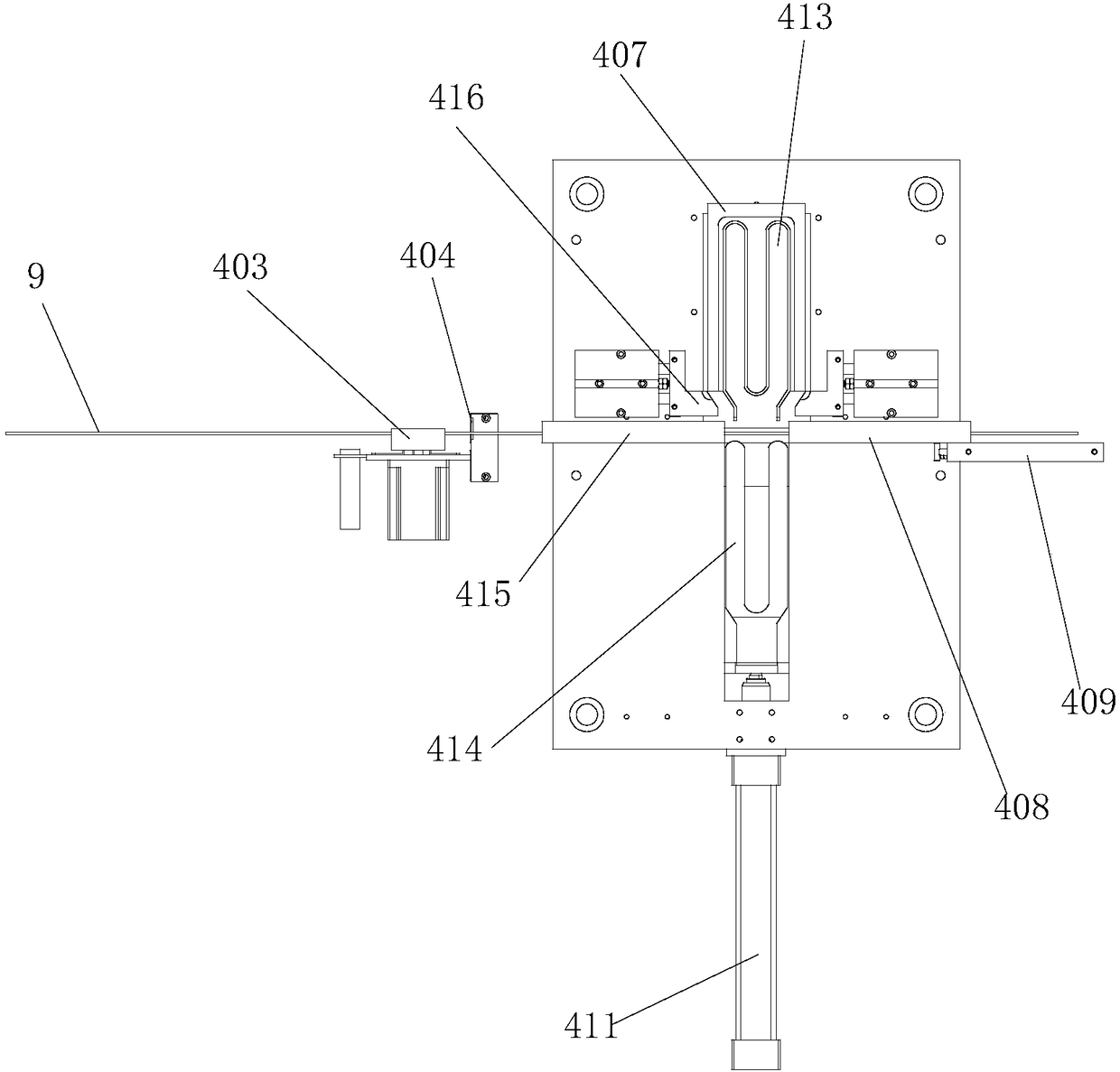

[0030] Embodiment 1: see attached Figure 1-8 , reflecting a specific structure of the present invention, the lead wire installation mechanism 4 of the molded fireworks is installed on the assembly line, and the assembly line includes the input conveyor belt 1, the positioning conveyor belt 3, and the output slide plate 7 of the molded fireworks 8 connected in sequence. The feed cylinder 2 sends the molded fireworks 8 from the input conveyor belt 1 to the positioning conveyor belt 3; the discharge cylinder 6 sends the molded fireworks 8 from the positioning conveyor belt 3 to the output slide 7. A lead wire installation mechanism 4 and a glue dispensing mechanism 5 are arranged on the positioning conveyor belt 3 . Between the lead wire installation mechanism 4 and the lead wire reel 401, there is an assembly 402 for smoke alarm and its fire alarm to cut off the lead wire

[0031] The lead wire installation mechanism 4 includes a correspondingly arranged folding die cavity, a fo...

Embodiment 2

[0043] Embodiment 2: see attached Figure 9 . The difference from Embodiment 1 is that the wiring groove 11 of the processed molded fireworks 10 is composed of five rows of grooves. The lead-in part 12 and the lead-out part 13 of the wiring groove 11 are respectively located at two opposite corners of the bottom of the molded fireworks 10 . In order to avoid that a plurality of protruding rods are inserted at the same time so that the lead wires are pulled at the same time to cause damage or even tear off. The protruding rods of the folding die include a primary protruding rod 15 and a secondary protruding rod 14, the primary protruding rod 15 is connected to the first reciprocating drive assembly (not shown in the figure), and the secondary protruding rod 14 is connected to the second folding rod. Lead the reciprocating drive assembly (not shown in the figure). During work, the primary protruding rod 15 is first inserted into the corresponding cavity 18, and then the secon...

Embodiment 3

[0044] Embodiment 3: see attached Figure 10 . The difference from Embodiment 1 is that the wiring groove 21 of the processed molded fireworks 20 is composed of six rows of grooves. In order to avoid that a plurality of protruding rods are inserted at the same time so that the lead wires are pulled at the same time to cause damage or even tear off. The protruding rods of the folding die include primary protruding rods 23 and secondary protruding rods 22 . The primary protruding rod 23 is located in the middle of all protruding rods.

[0045] During work, the primary convex rod 23 is first inserted into the corresponding concave cavity 25; then the secondary convex rod 22 is inserted into the corresponding concave cavity 25, and inserted in two steps to fold the lead plate into a U-shaped zigzag reciprocating shape; then the two corner pieces 24 jobs. All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com