High-pressure vacuum die-casting process control system and method for efficient and high-quality aluminum alloy shock absorption tower

A vacuum die-casting and process control technology, applied in the field of die-casting process, can solve the problems affecting the high-quality and high-efficiency production of shock-absorbing towers, difficult to meet large-scale, long-term, and repetitive large-scale production needs, instability, etc. Process adaptive adjustment and intervention control, ensuring high-quality and efficient production, and improving the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

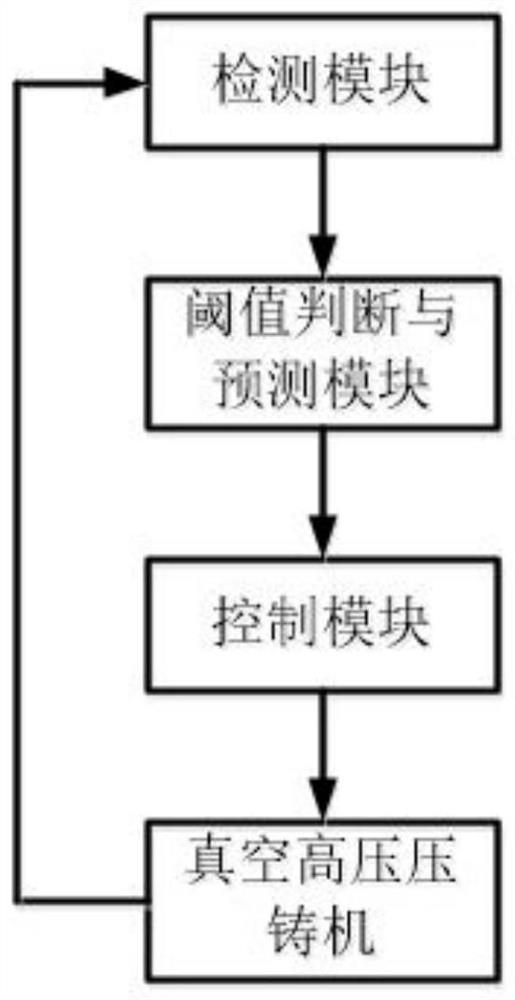

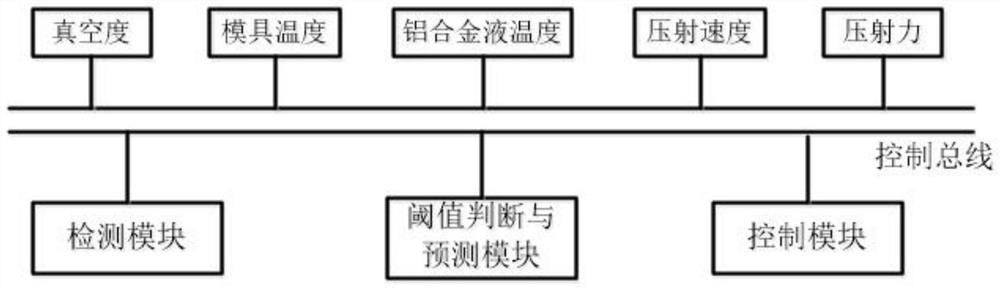

[0044] like Figure 1-Figure 5 As shown, a high-efficiency and high-quality aluminum alloy shock-absorbing tower high-pressure vacuum die-casting process control system includes a detection module, a threshold judgment and prediction module, and a control module, the detection module is connected with the threshold judgment and prediction module, and the threshold The judgment and prediction module is connected with the control module, and the detection module and the control module are respectively connected with the vacuum high pressure casting machine;

[0045] The detection module detects the vacuum degree, mold temperature, aluminum alloy liquid temperature, injection speed and injection force of the aluminum alloy shock-absorbing tower in the high-pressure vacuum die-casting machine in real time;

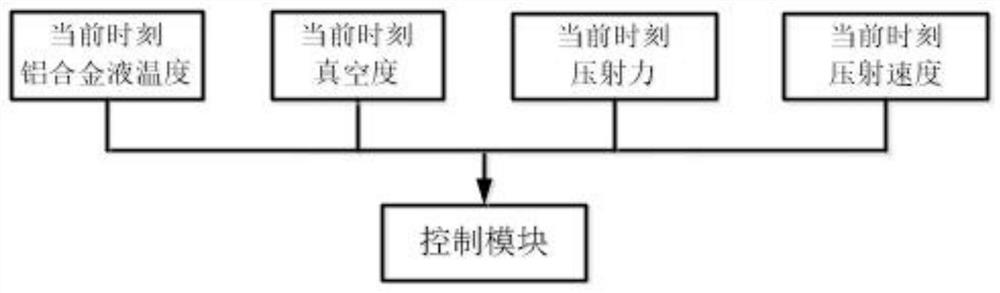

[0046] The threshold judgment and prediction module performs threshold judgment according to the vacuum degree and mold temperature signal provided by the detection module at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com