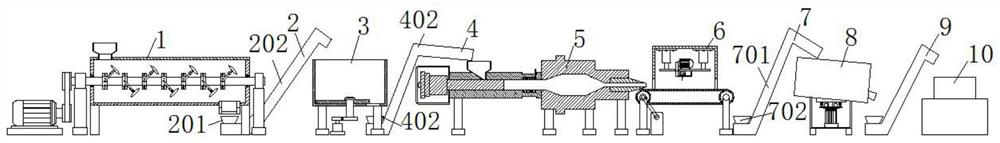

Production line of beef tendon seasoning noodle product and preparation method of beef tendon seasoning noodle product

A noodle product and production line technology, which is applied in the application field of beef tendon seasoned noodle products, can solve problems affecting the quality and taste of beef tendon seasoned noodle products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A. Weighing ingredients: add 55g of monosodium glutamate, 45g of beef powder, 45g of calcium carbonate, 55g of sweetener and 85g of preservative for every 2500g of flour;

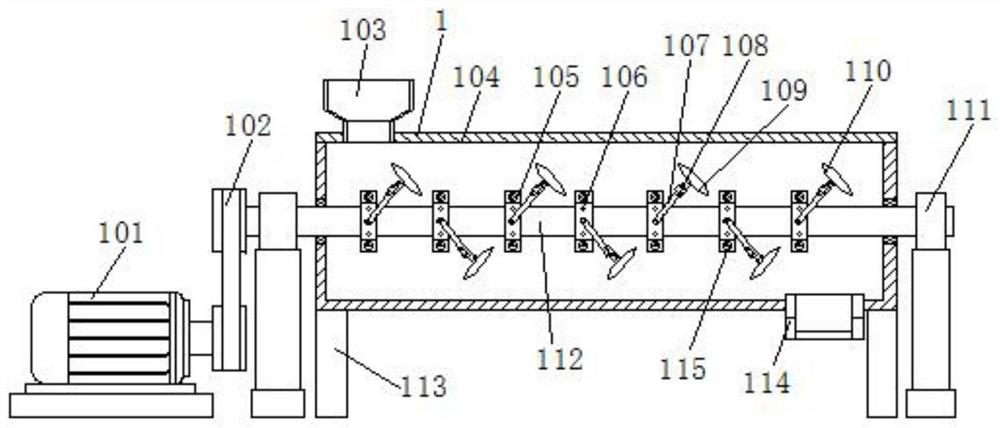

[0046] B. For powdering, put the above raw materials into the powdering assembly for thorough mixing. The stirring speed of the mixer is 60 rpm, stirring for 20 minutes, the stirring temperature is 0°C, and the raw material mixture is obtained after stirring evenly;

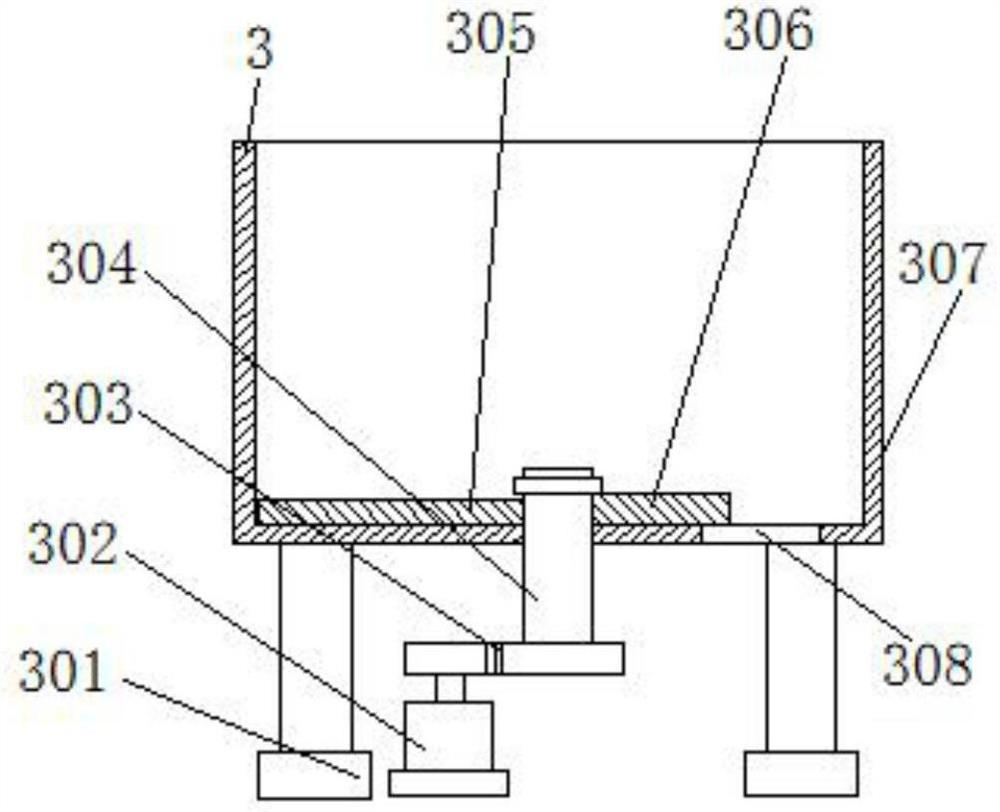

[0047] C. Powder lowering, the raw material mixture is lowered to the powder lowering component through the first lifting component, and the raw material mixture slowly enters the feeding cylinder of the aging molding component through the powder lowering component and the first lifting component;

[0048] D. Aging molding: The raw material mixture is continuously and evenly injected into the injection port of the aging molding component, and the aging reaction occurs and extruded;

[0049] E: cutting: the beef tendon seasoning noodle p...

Embodiment 2

[0054] A preparation method of beef gluten flavored noodle product, is characterized in that, comprises the following steps:

[0055] A. Weighing ingredients: add 60g of monosodium glutamate, 50g of beef powder, 50g of calcium carbonate, 60g of sweetener and 90g of preservative for every 2500g of flour;

[0056] B. Powdering, put the above raw materials into the powdering assembly and mix them thoroughly. The stirring speed of the mixer is 80 rpm, stirring for 25 minutes, the stirring temperature is 20°C, and the raw material mixture is obtained after stirring evenly;

[0057] C. Powder lowering, the raw material mixture is lowered to the powder lowering component through the first lifting component, and the raw material mixture slowly enters the feeding cylinder of the aging molding component through the powder lowering component and the first lifting component;

[0058] D. Aging molding: The raw material mixture is continuously and evenly injected into the injection port of ...

Embodiment 3

[0064] A. Weighing ingredients: add 65g of monosodium glutamate, 55g of beef powder, 55g of calcium carbonate, 65g of sweetener and 95g of preservative for every 2500g of flour;

[0065] B. Powdering, put the above raw materials into the powdering assembly for thorough mixing, the stirring speed of the mixer is 100 rpm, stirring for 30 minutes, the stirring temperature is 30°C, and the raw material mixture is obtained after stirring evenly;

[0066] C. Powder lowering, the raw material mixture is lowered to the powder lowering component through the first lifting component, and the raw material mixture slowly enters the feeding cylinder of the aging molding component through the powder lowering component and the first lifting component;

[0067] D. Aging molding: The raw material mixture is continuously and evenly injected into the injection port of the aging molding component, and the aging reaction occurs and extruded;

[0068] E: cutting: the beef tendon seasoning noodle pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com