Semi-automatic channeling machine

A grooving machine, semi-automatic technology, applied in turning equipment, auxiliary devices, manufacturing tools, etc., can solve problems such as unstable quality, different depths of product grooves, and slow production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

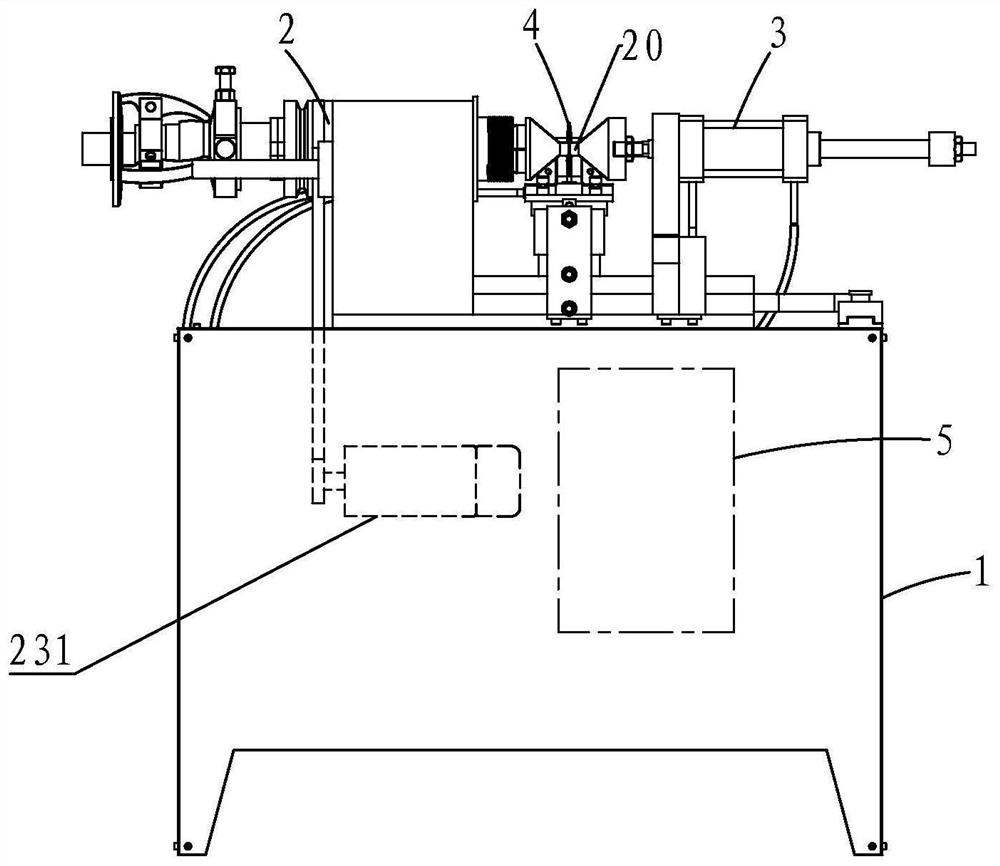

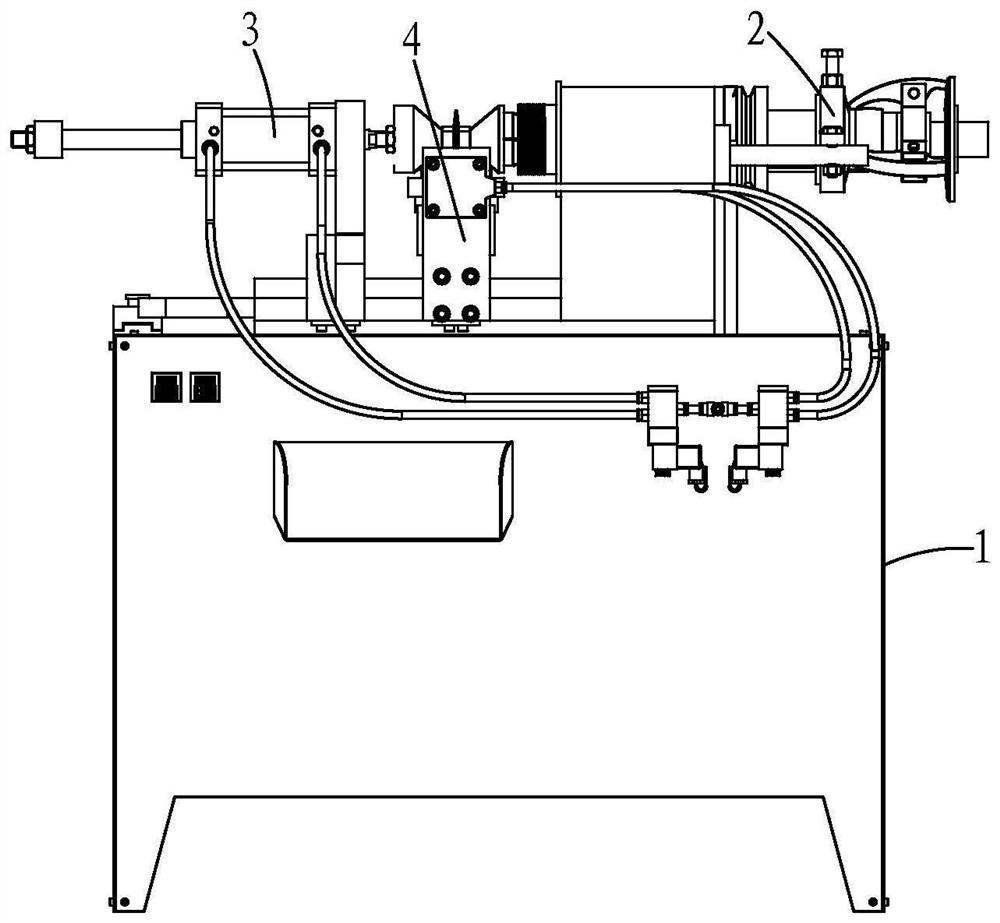

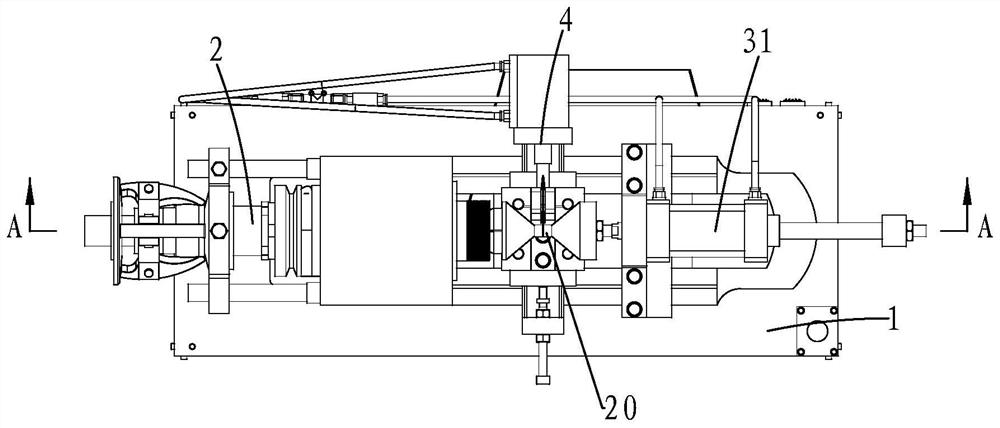

[0063] A kind of semi-automatic grooving machine of the present invention, comprises

[0064] Rack 1;

[0065]The instrument car assembly 2, the instrument car assembly 2 includes a mounting base 21, a rotating shaft 22 and a first drive module 23; one end of the rotating shaft 22 is protruded with a first thimble 24, and the axis of the first thimble 24 and the The axes of the rotating shaft 22 coincide; the first driving module 23 is connected to the rotating shaft 22, and the rotating shaft 22 is driven to rotate by the first driving module 23, thereby driving the first thimble 24 to rotate; the rotating shaft 22 Rotationally connected to the mounting base 21, and the first thimble 24 is located on one side of the mounting base 21, and the first thimble 24 is driven by the rotating shaft 22 to perform rotational movement; the mounting base 21 is fixedly connected On the frame 1; the instrument car assembly 2 is existing and can be purchased directly on the market.

[0066...

Embodiment 2

[0077] Embodiment two: on the basis of embodiment one,

[0078] The first drive module 23 includes a motor 231, a first pulley 232, a second pulley 233 and a belt 234; the motor 231 is electrically connected to the control device 5, and the motor 231 is installed on the frame 1; the first pulley 232 is fixedly sleeved on the output shaft of the motor 231; the second pulley 233 is fixedly sleeved on the rotating shaft 22; the belt 234 is sleeved on the first pulley 232 and the second pulley 233. The motor 231 is controlled by the control device 5 through an electric signal to drive the first pulley 232 to rotate, the belt 234 to drive the second pulley 233 to rotate, and then to drive the rotating shaft 22 to rotate, and finally to drive the pulley 232 to rotate. The first thimble 24 rotates.

[0079] The mounting base 21 defines a through hole 211 ; a first bearing 212 is nested in the through hole 211 ; the first bearing 212 is nested on the rotating shaft 22 .

[0080] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com