Positioning and clamping device for high-precision space vertical hole system turning

A technology of positioning and clamping and vertical holes, which is applied in the direction of positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of high operator skill level, no good solution, poor product quality stability, etc. Achieve the effect of lower skill level requirements, good fastening effect and good quality consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further elaborated below in conjunction with embodiment.

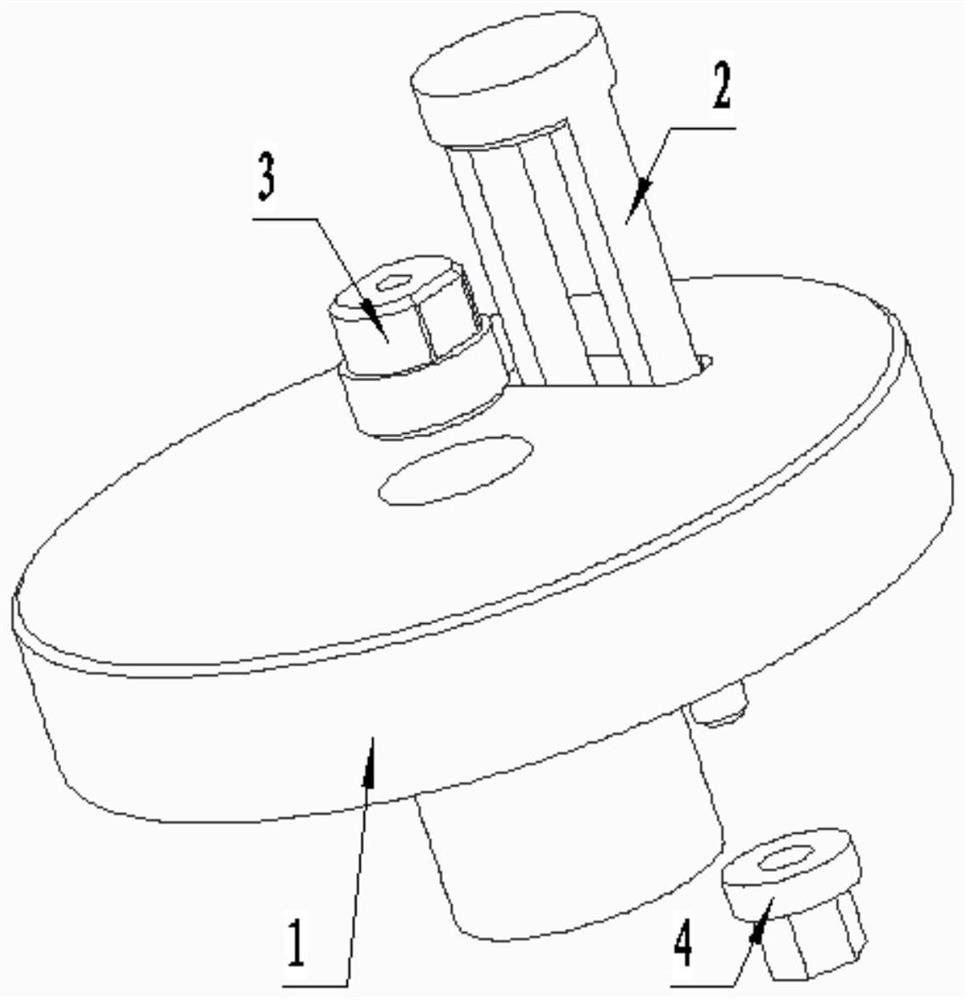

[0033] The invention provides a positioning and clamping device for high-precision space vertical hole system turning processing, which can realize automatic centering and orientation when the workpiece is clamped, and avoid "one-by-one alignment"; the use method of the device is simple and easy, and avoids four The complicated alignment process of jaw clamping. It truly realizes the high-quality, high-efficiency, and low-labor-intensity turning of the high-precision space vertical hole system of the cross lug assembly of the electromechanical actuator.

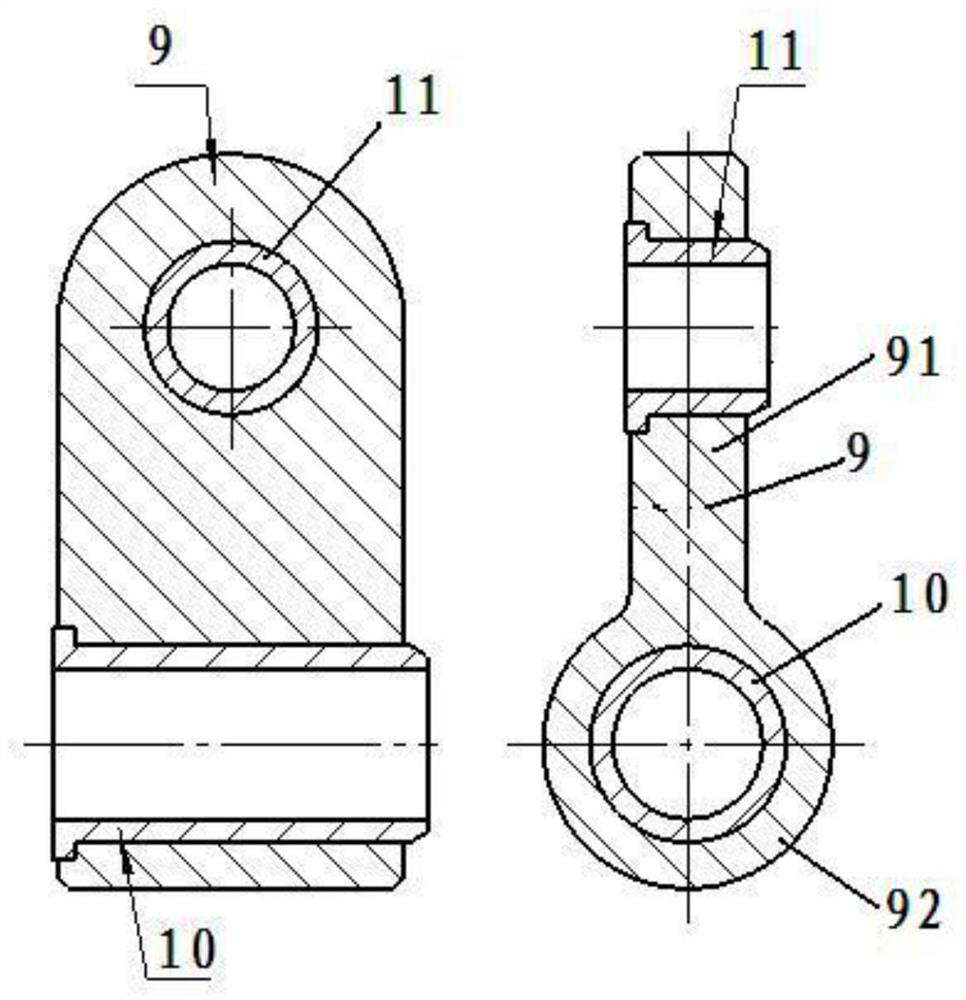

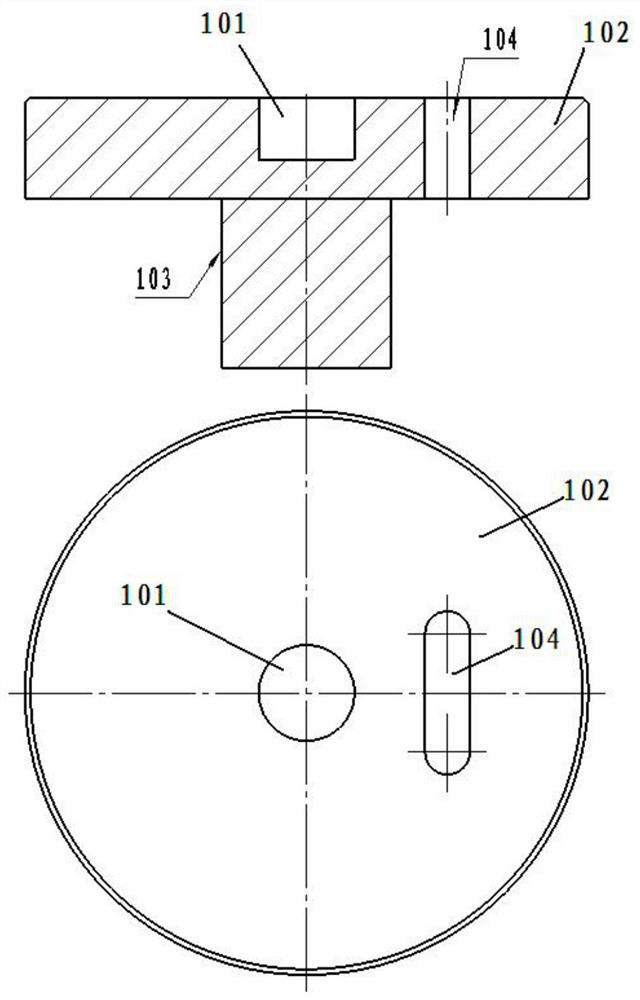

[0034] Positioning and clamping devices, including large copper sleeve positioning and clamping devices, small copper sleeve positioning and clamping devices and cross lugs; such as figure 1 As shown, the cross lug includes a steel base 9, a large copper sleeve 10, and a small copper sleeve 11; the cross lug is assembled by pressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com