A short-process integrated manufacturing method for rolling and deep processing of high-strength steel automobile plates

A manufacturing method and technology for automobile sheets, which are applied in the field of rolling and deep processing, can solve problems such as large changes in mechanical properties, high strength of hot-rolled coils, and difficulties in cold processing, and achieve the effects of promoting comprehensive utilization, accelerating industrial upgrading, and increasing benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

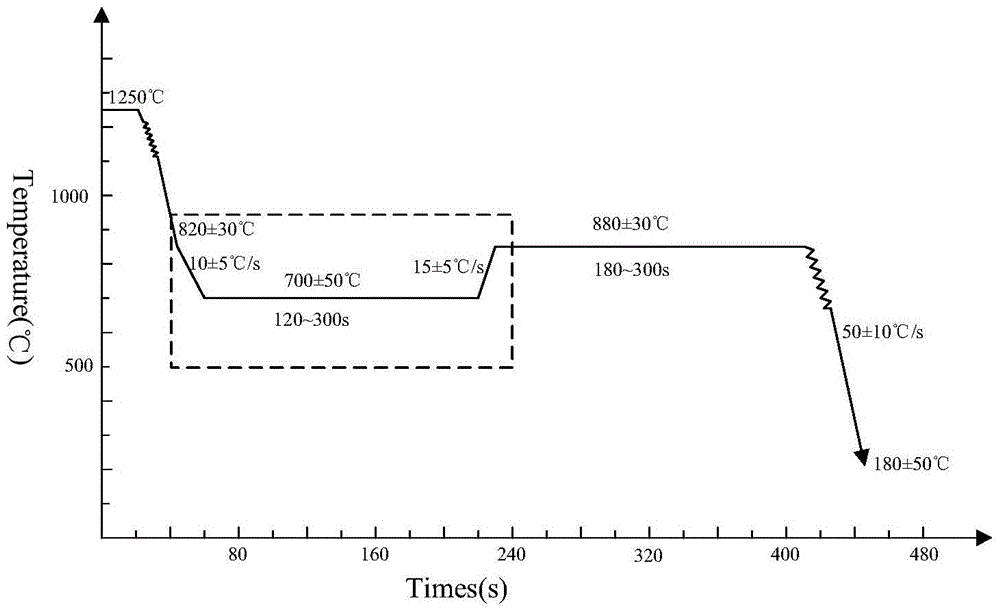

[0021] The raw materials are put into a heating furnace with a heating temperature of 1250°C. After conventional rough rolling and finish rolling, the final rolling temperature is 790°C.

[0022] Cool to 650°C at a slow cooling rate of 5°C / s, and hold at 650°C for 2 minutes to form a stable pearlite structure in the high-strength steel automobile sheet.

[0023] The high-strength steel automobile sheet is cut into the shape and size required by the stamping and quenching die through the shearing device, and the cut sheet is transferred to the continuous heating furnace by the high-temperature intelligent manipulator for heating.

[0024] In a continuous heating furnace, heat to 850°C at a heating rate of 10°C / s and hold for 3 minutes to ensure that the entire structure of the stamping and quenching part is transformed into austenite, and the grains are not too coarse. Then, the stamping and quenching parts are transferred from the continuous heating furnace to the stamping and...

Embodiment 2

[0029] The raw material is put into the heating furnace, the heating temperature is 1250°C, after conventional rough rolling and finish rolling, the final rolling temperature is 820°C.

[0030] Cool to 700°C at a slow cooling rate of 10°C / s, and hold at 700°C for 3 minutes to form a stable pearlite structure in the high-strength steel automotive sheet.

[0031] The high-strength steel automobile sheet is cut into the shape and size required by the stamping and quenching die through the shearing device, and the cut sheet is transferred to the continuous heating furnace by the high-temperature intelligent manipulator for heating.

[0032] In a continuous heating furnace, heat to 880°C at a heating rate of 15°C / s and hold for 4 minutes to ensure that the entire structure of the stamping and quenching parts is transformed into austenite, and the grains are not too coarse. Then, the stamping and quenching parts are transferred from the continuous heating furnace to the stamping and...

Embodiment 3

[0037] The raw materials are put into a heating furnace with a heating temperature of 1250°C. After conventional rough rolling and finish rolling, the final rolling temperature is 850°C.

[0038] Cool to 750°C at a slow cooling rate of 15°C / s, and hold at 750°C for 5 minutes to form a stable pearlite structure in the high-strength steel automobile sheet.

[0039] The high-strength steel automobile sheet is cut into the shape and size required by the stamping and quenching die through the shearing device, and the cut sheet is transferred to the continuous heating furnace by the high-temperature intelligent manipulator for heating.

[0040] In a continuous heating furnace, heat to 910°C at a heating rate of 20°C / s and hold for 5 minutes to ensure that the entire structure of the stamping and quenching part is transformed into austenite, and the grains are not too coarse. Then, the stamping and quenching parts are transferred from the continuous heating furnace to the stamping an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com