Patents

Literature

35results about How to "Facilitate integrated production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

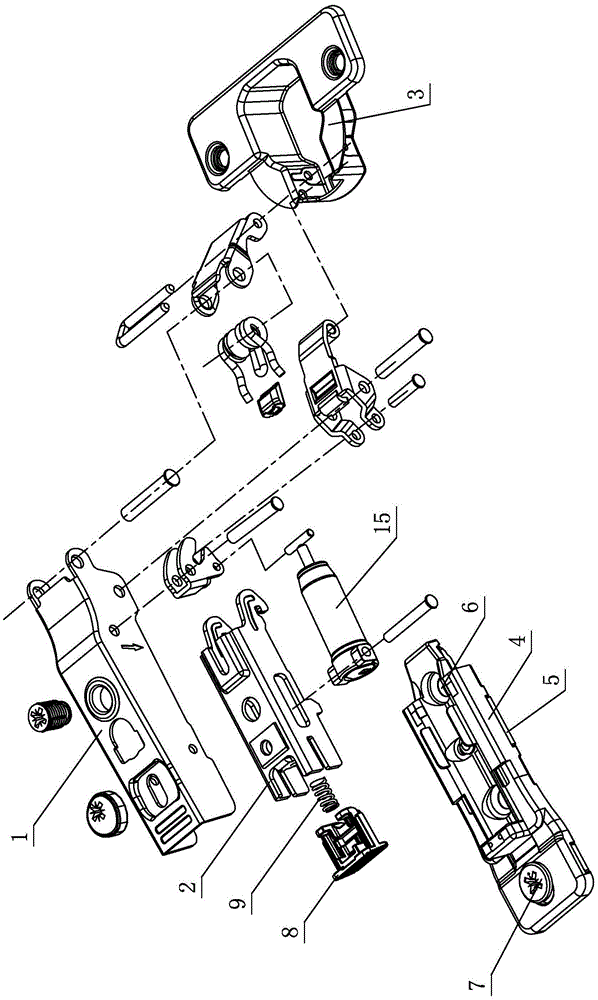

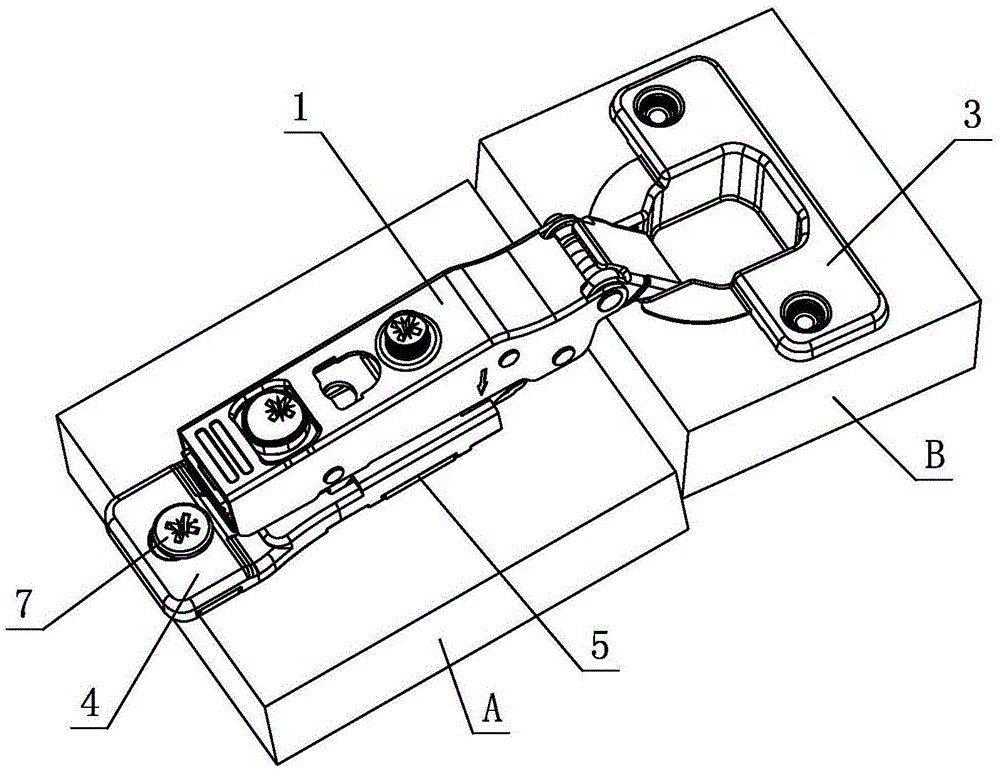

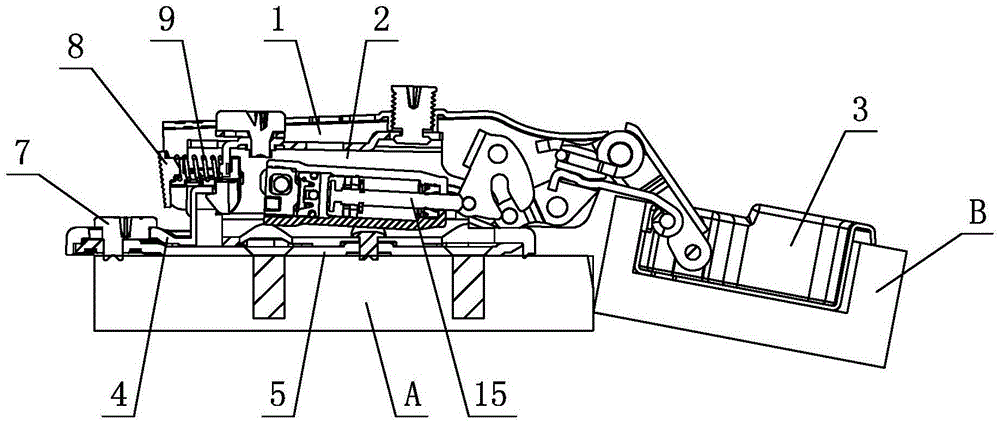

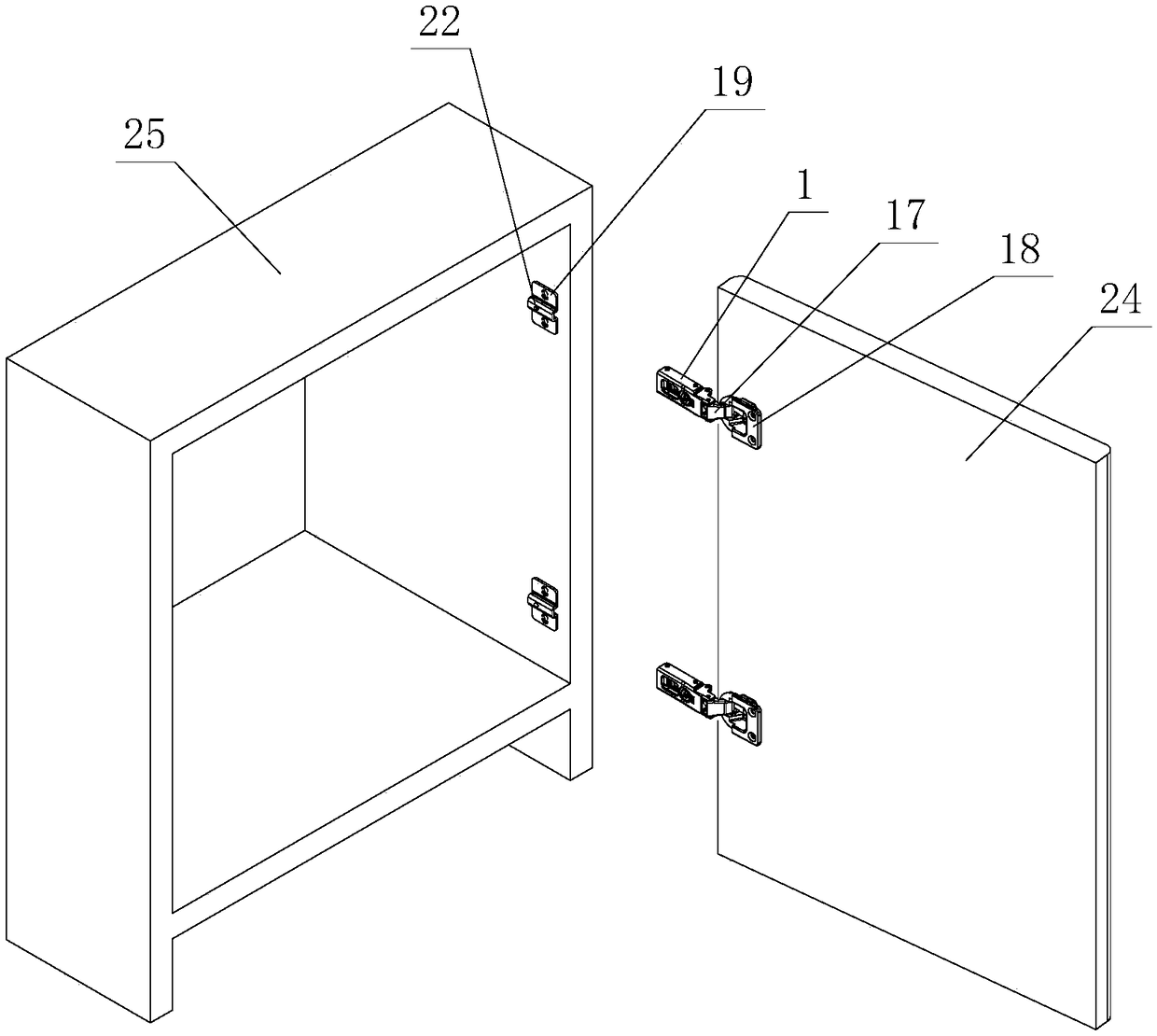

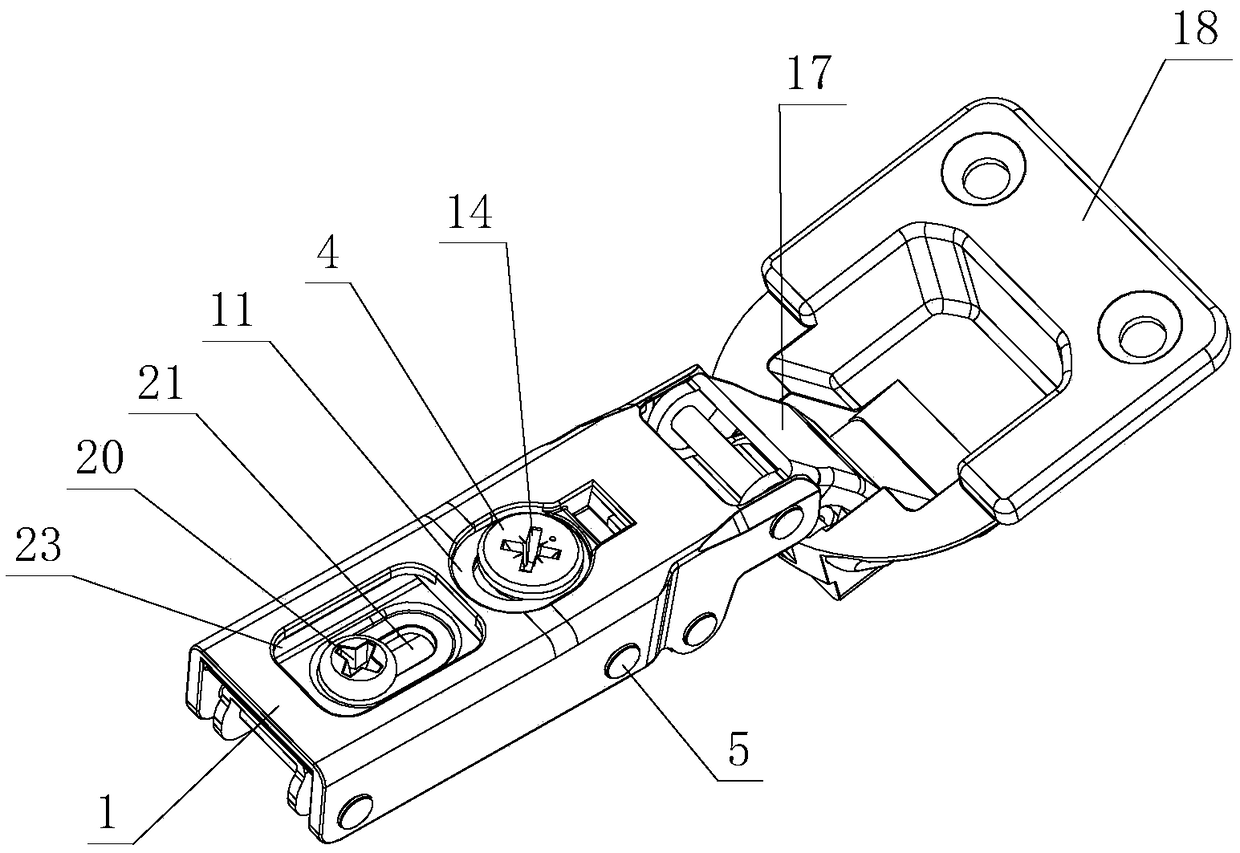

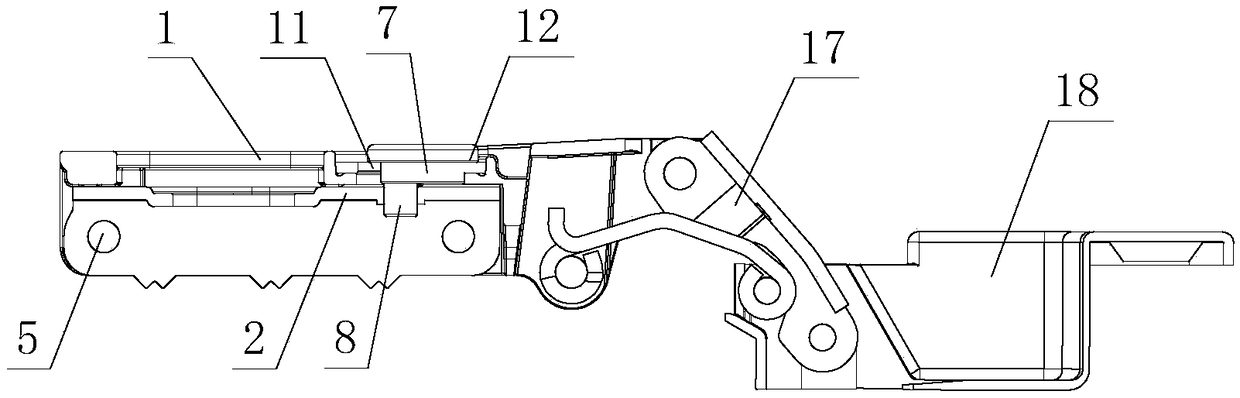

A fixed base for furniture hinges

Owner:伍志勇

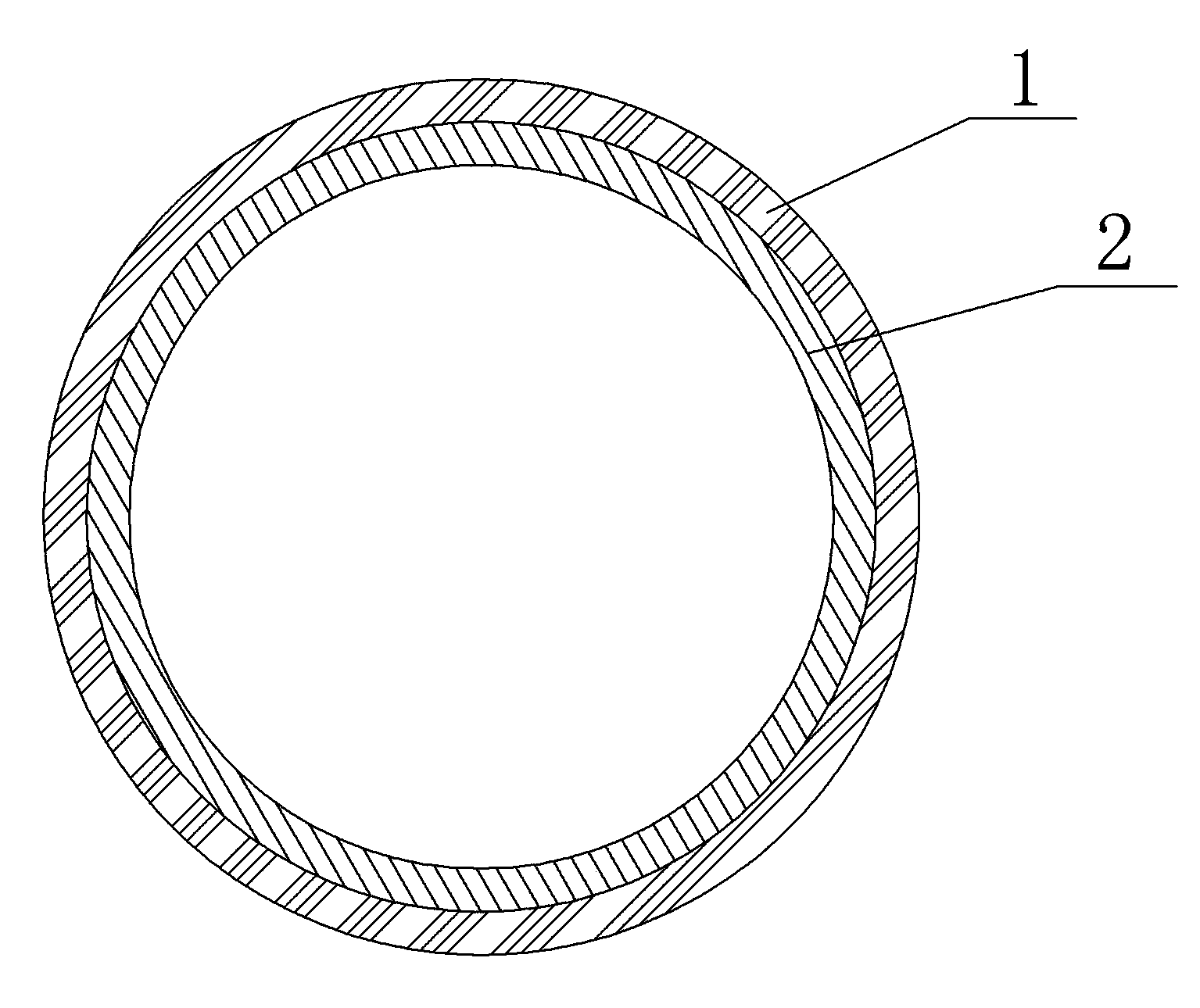

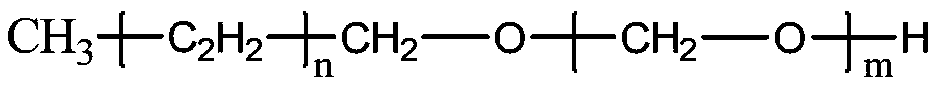

Double-layer composite tube and manufacturing method thereof

ActiveCN104019298AImprove stress resistanceFlow fastFlexible pipesLow-density polyethyleneWater quality

The invention discloses a double-layer composite tube and a manufacturing method thereof. The double-layer composite tube and the manufacturing method aim to solve the technical problems that black pigment is added into traditional HDPE tubes, accordingly inner walls are not smooth, water scale is prone to being generated, bacteria grow, and secondary pollution of water is caused. The double-layer composite tube comprises an inner layer and an outer layer, the inner layer is made of ultrahigh molecular weight polyethylene and ethylene-vinyl alcohol copolymers or low-density polyethylene, and the outer layer is made of high-density polyethylene, ethylene-vinyl alcohol copolymers and special melanin particles C of PE. The method includes the following steps of material proportioning and dehumidifying, material plastifying, material forming, vacuum sizing and spraying and cooling. The double-layer composite tube has the advantages of being good in toughness and flexibility, high in chemical stability, good in corrosion resistance, good in sealing performance, large in distribution power, long in service life, high in low temperature resistance, hygienic, free of toxin and the like. The manufacturing method is simple, easy to operate and capable of achieving integral production of the double-layer composite tube.

Owner:菏泽三垒塑业股份有限公司

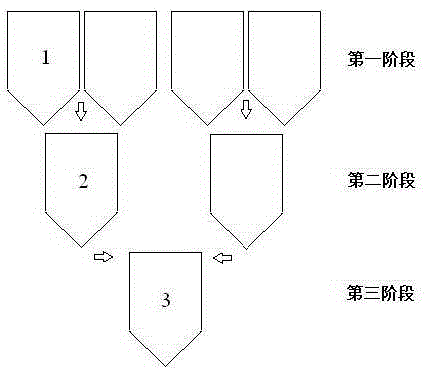

Method for rapid preparation of fruit and vegetable crisp grains by three-stage atmospheric pressure microwave spouting drying

The invention discloses a method for rapid preparation of fruit and vegetable crisp grains by three-stage atmospheric pressure microwave spouting drying, and belongs to the fruit and vegetable food treatment technical field. The method comprises the technological process for preparation of the fruit and vegetable crisp grains: carrying out fresh fruit and vegetable raw material pretreatment comprising selection, cleaning, grain-sized dicing, blanching and enzyme deactivation and color protection treatment, carrying out three-stage atmospheric pressure microwave spouting drying of the pretreated fruit and vegetable grains, and carrying out packaging storage. Compared with a single hot air drying, the adopted microwave drying technology has the energy saved by 50%-55% and the time shortened by 60%-65%; compared with a single-stage atmospheric pressure microwave spouting drying, the adopted technology has the energy saved by 20%-30% or more and the time shortened by 20%-30%. The pulse spouting is beneficial for improving the uniformity of material drying, and can improve the quality of the fruit and vegetable dried products; besides, the three-stage drying can effectively improve the material loading capacity and the utilization rate of energy consumption, and is beneficial for integrated application of the microwave drying technology and equipment in the fields of agricultural products and food processing.

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD +1

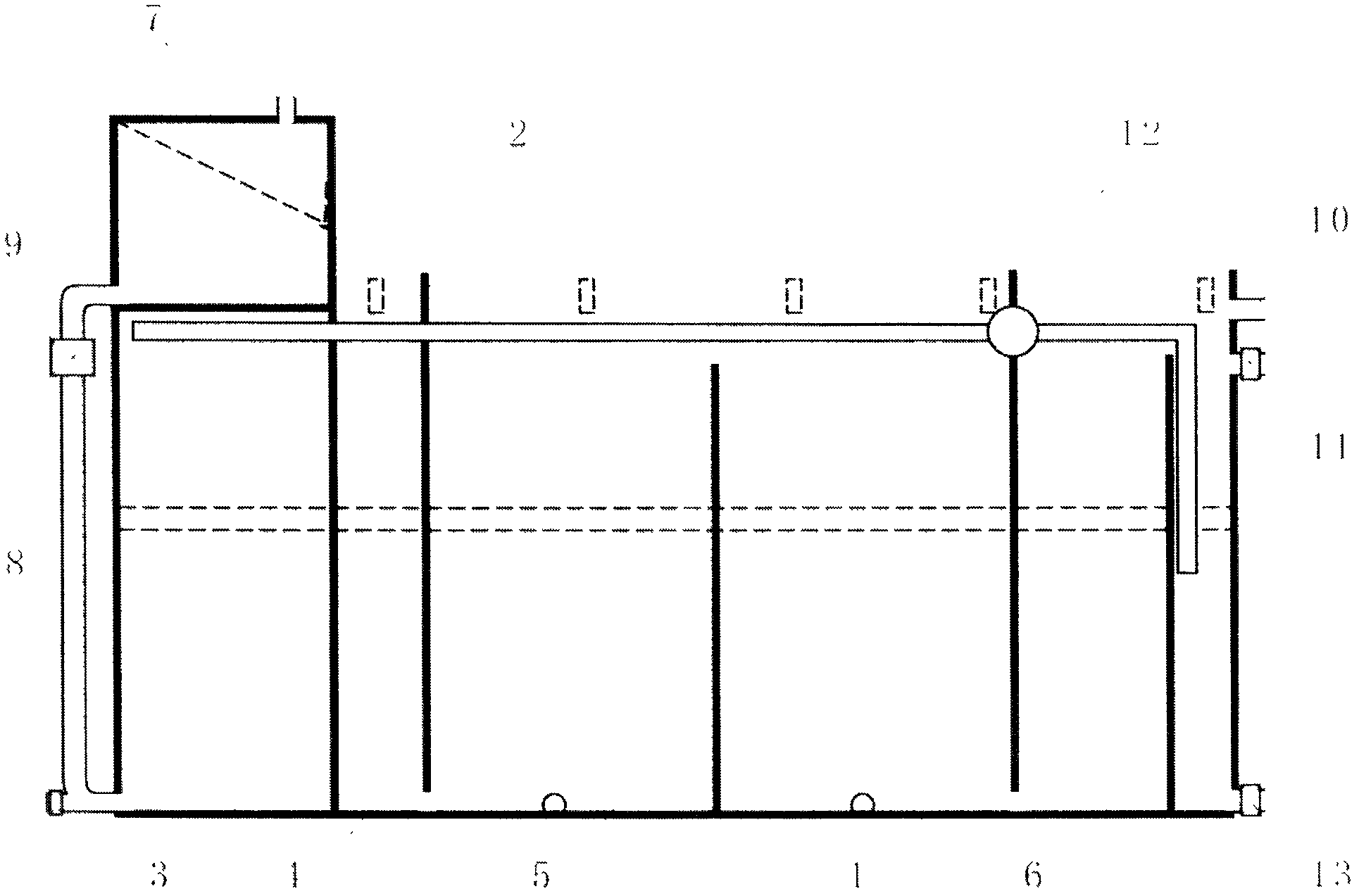

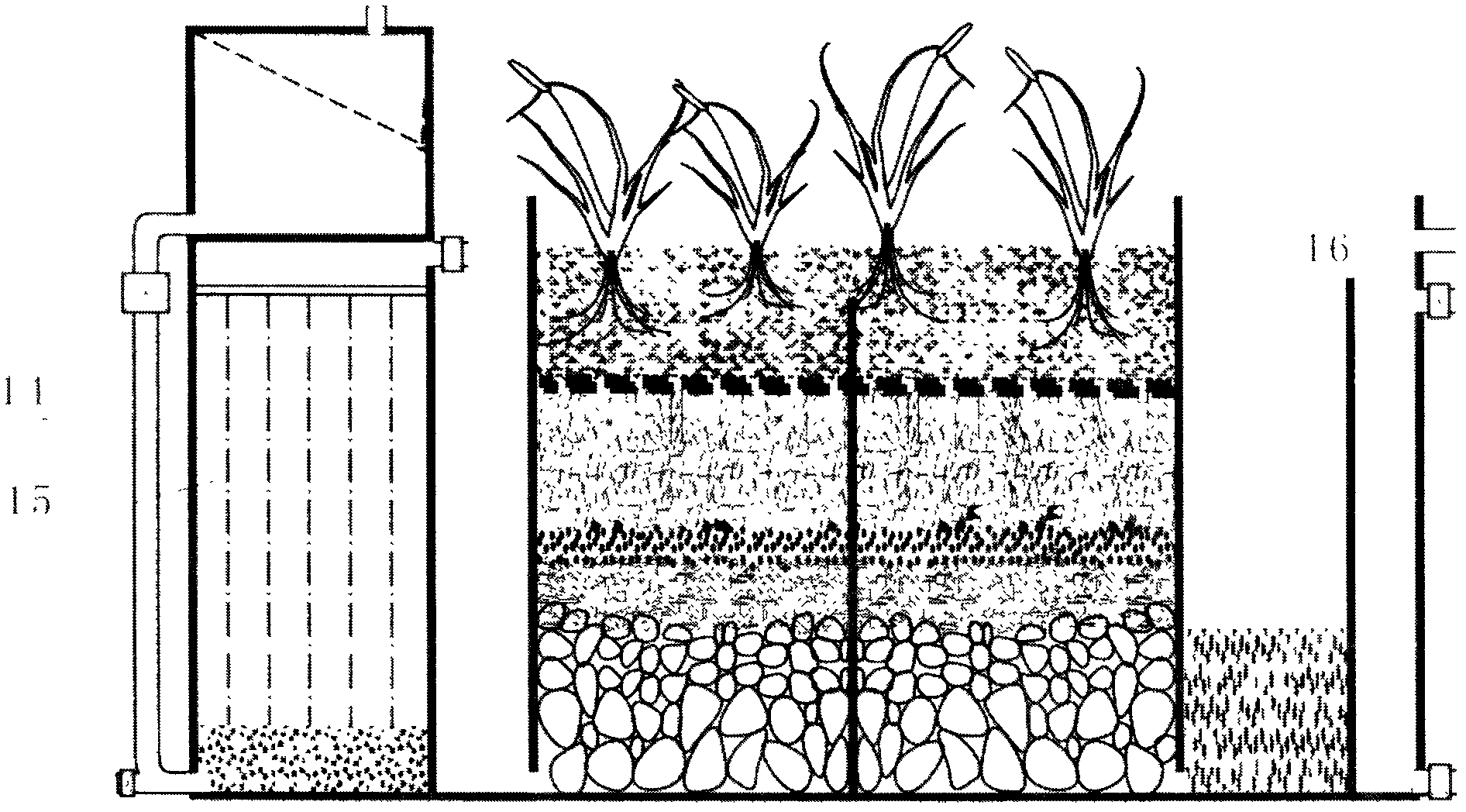

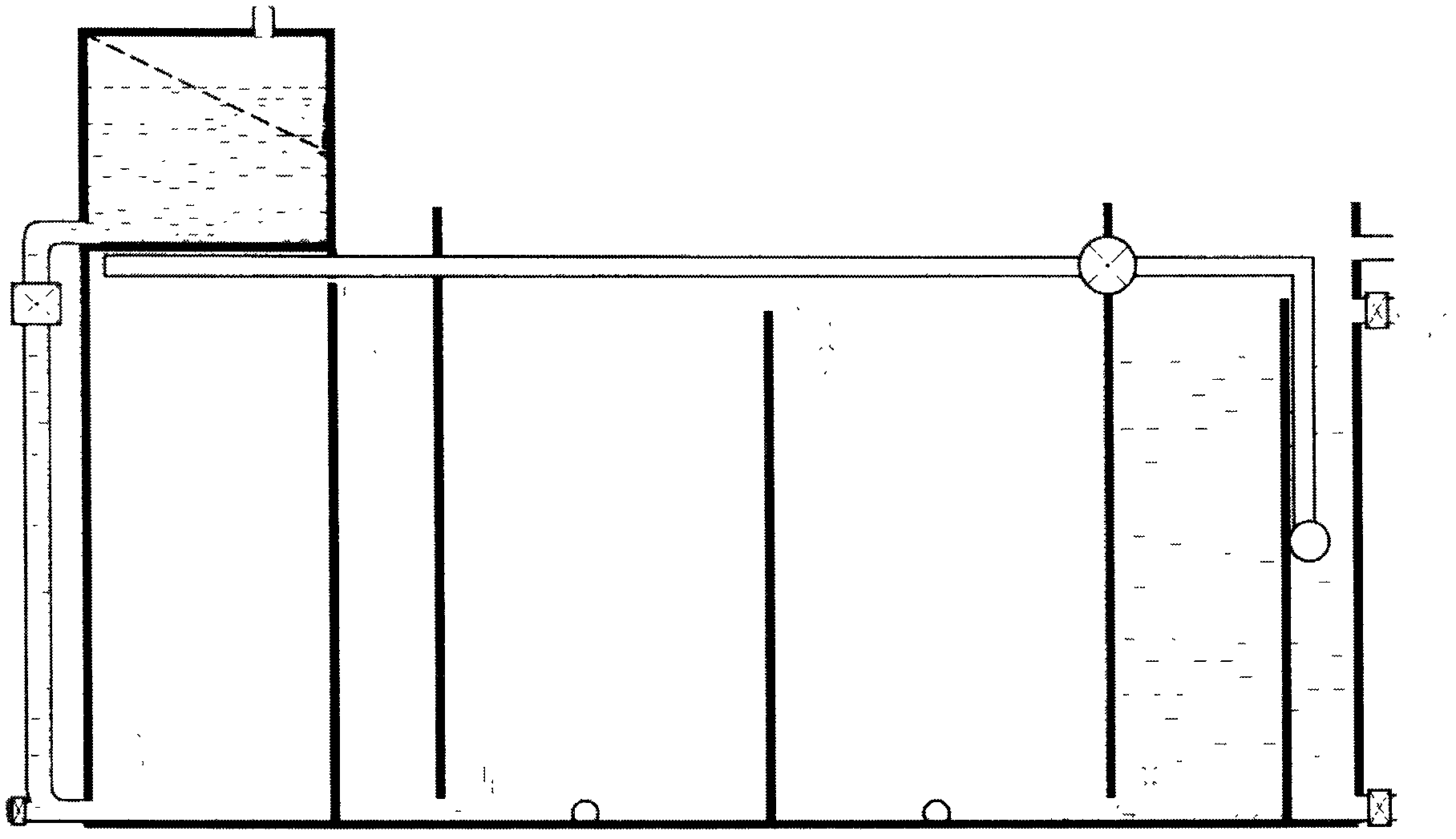

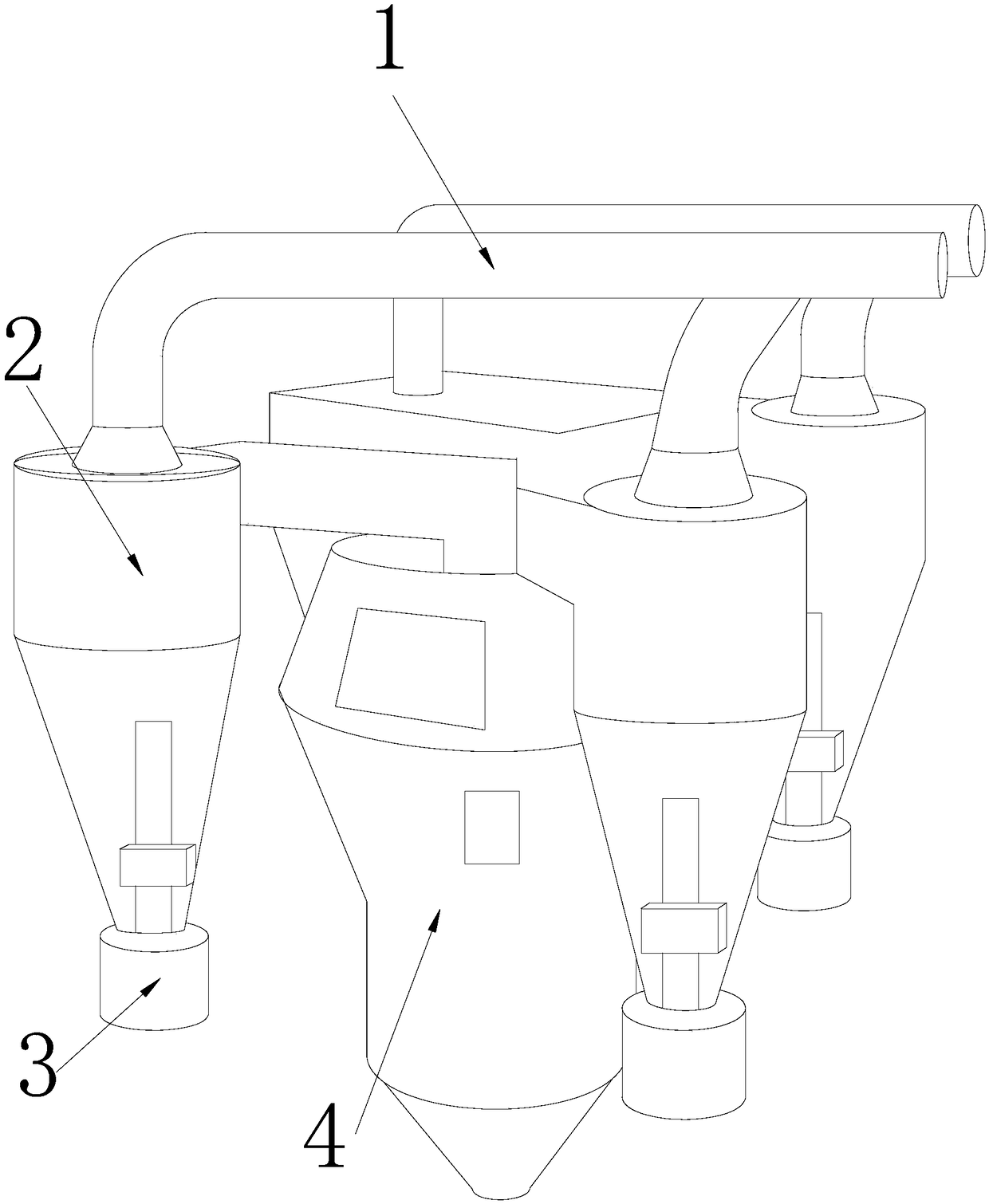

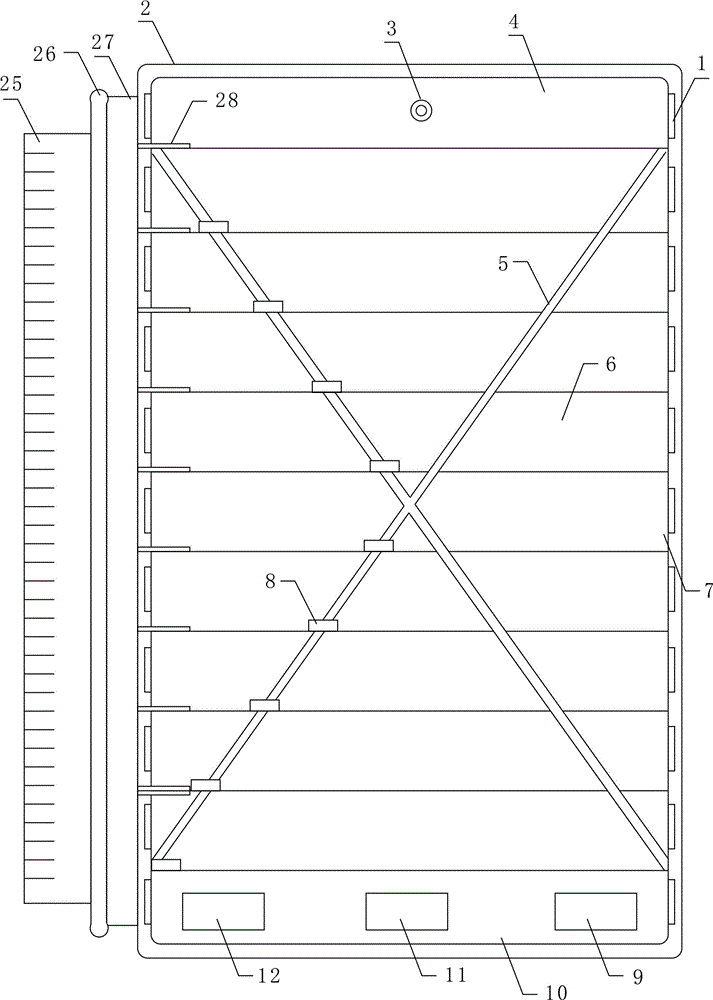

Distributed sewage integrated artificial wetland treatment facility and method

InactiveCN102627376AConducive to integrated productionSimple structureMultistage water/sewage treatmentConstructed wetlandWater discharge

The invention provides a distributed sewage integrated artificial wetland treatment facility and method. The distributed sewage integrated artificial wetland treatment facility comprises a high level water tank screening and filtering zone, a biological film treatment zone, a floating plant zone, a main wetland zone, a sand filtration sinking plant zone and a centralized water discharge zone, and a complete treatment water channels are formed in sequence, wherein the floating plant zone, the main wetland zone and the sand filtration sinking plant zone are separated to left and right parallel zones through partition boards, and a left treatment water channel and a right treatment water channel are formed. The method, provided by the invention, comprises the steps of: removing suspended dirt, treating the biological film, treating the wetland, filtering the sand, switching underflow and surface flow and configuring the plants of the main wetland zone. According to the invention, the facility only occupies 2-3 m<2> of floor, the purification efficiency reaches the standard, the facility can carry out integration production in a workshop, and the facility has the advantages of difficult blockage, easy management, convenience for maintenance and low operation cost.

Owner:SICHUAN UNIV

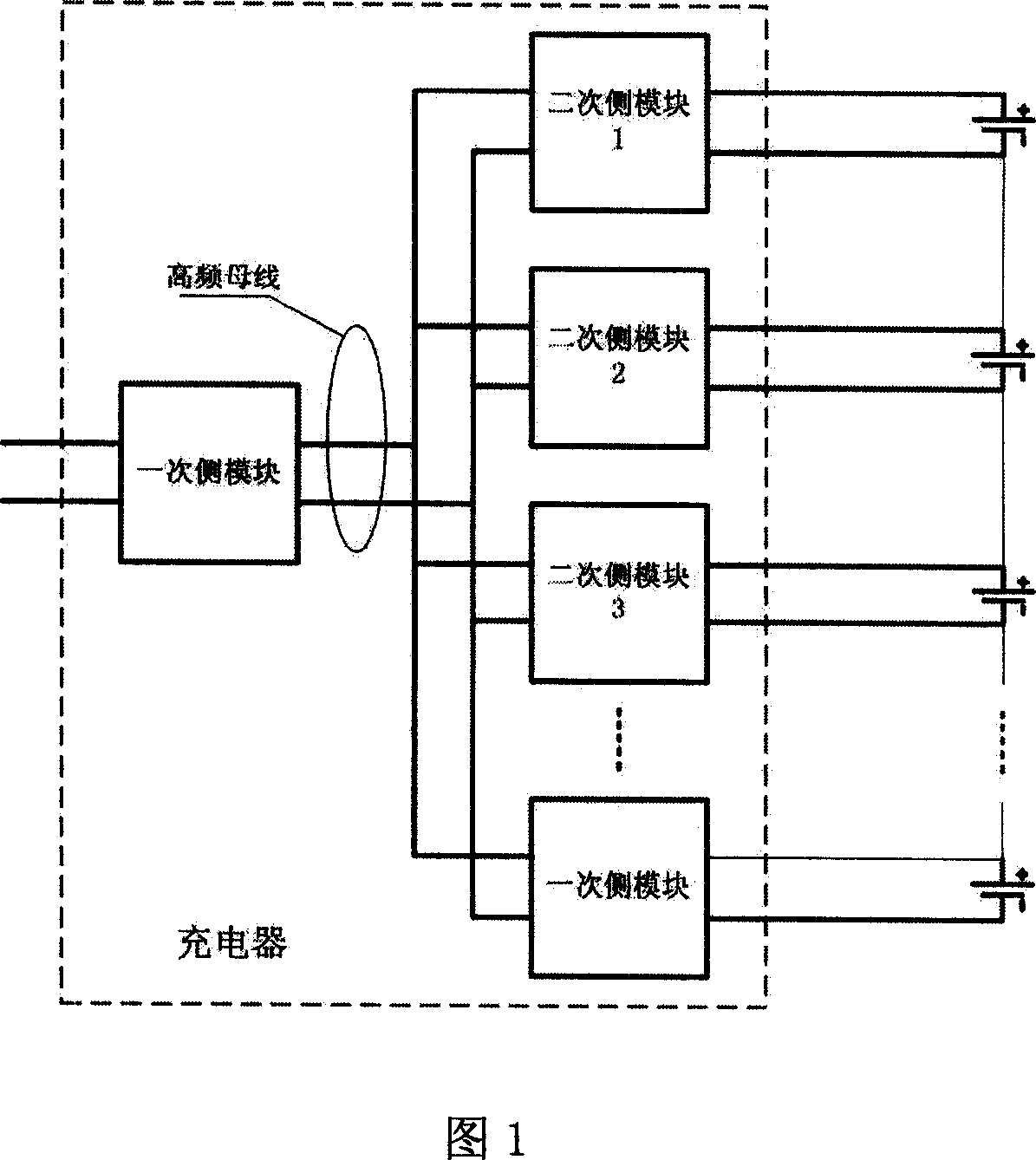

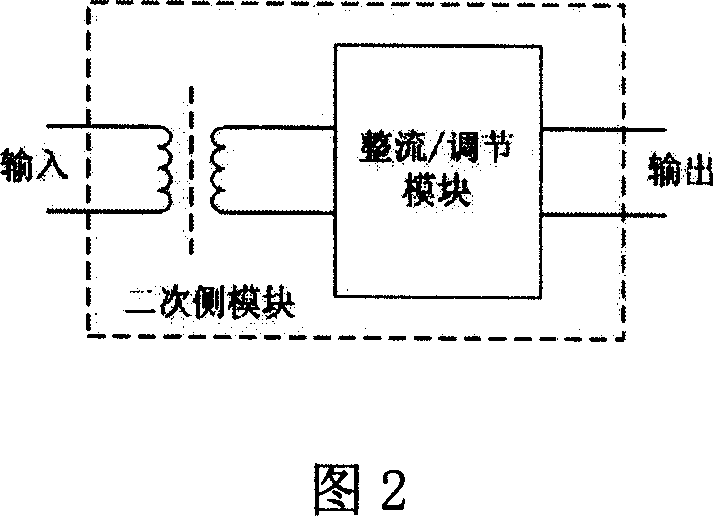

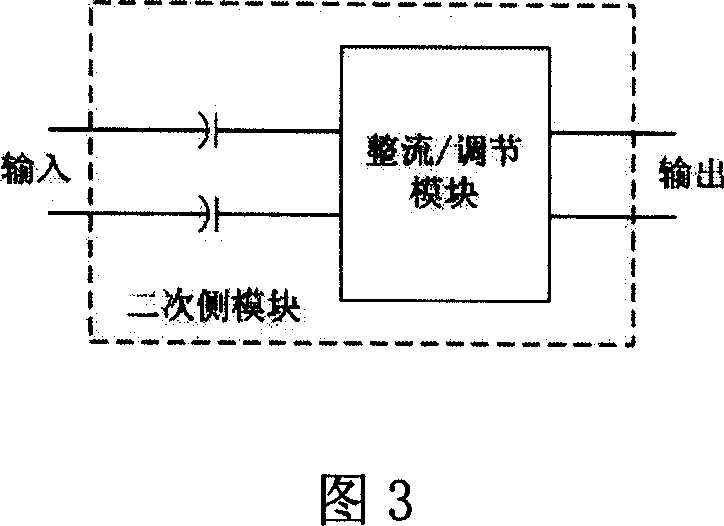

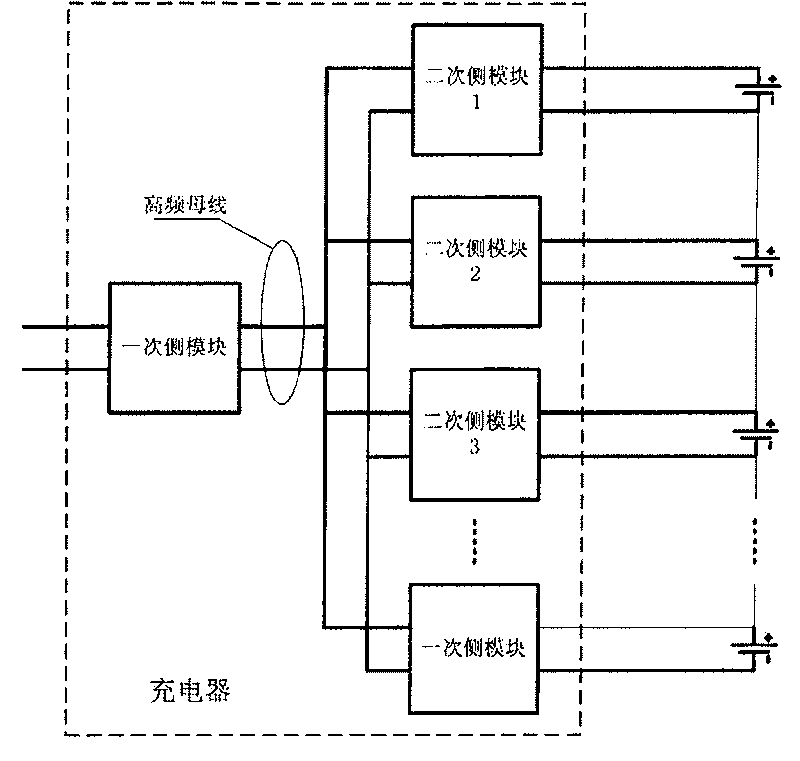

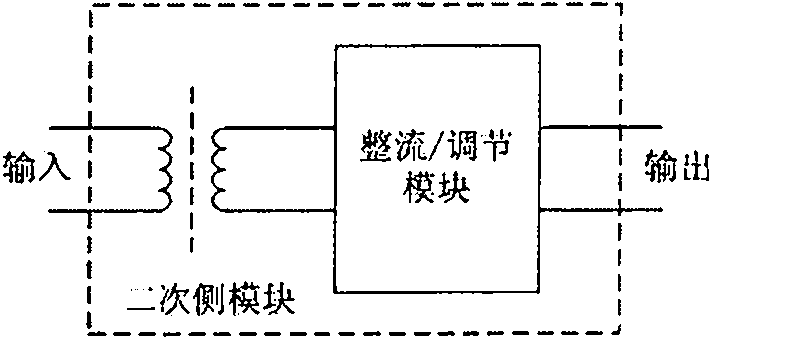

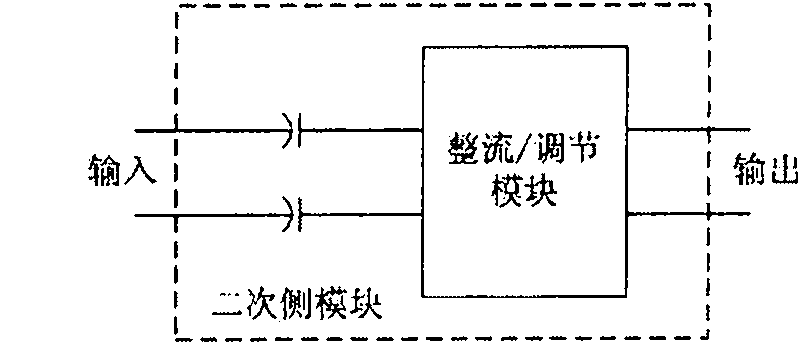

Accumulator charger based on high frequency bus

InactiveCN101051761AExtend your lifeLow costBatteries circuit arrangementsElectric powerElectrical devicesEngineering

The charging device is in use for charging accumulator (accu) adapted to mobile electric apparatus, emergency power supply, and light-volt energy sources. The charging device is capable of carrying out independent charging management for single accu in series connected accu pack, prolonging service life remarkably. The invention is hopeful to reduce cost of charger for charging single accu independently or series connected accu. Characters of structure are that high frequency (Hf) AC switch inverter adopted by module at primary side (PS) converts DC or AC in low frequency to output Hf AC. Module at secondary side (SS) includes isolation-coupled circuit (ICC), rectification / adjustment module. Being in one from transformer, piezoelectric, or condenser couplings, ICC outputs adjustable DC suitable for charge. Through AC bus in Hf, modules at PS and SS are connected. Inputted in parallel, multiple modules at SS charge accu respectively by outputted DC potentials insulated each other.

Owner:杭州迪源电气科技有限公司

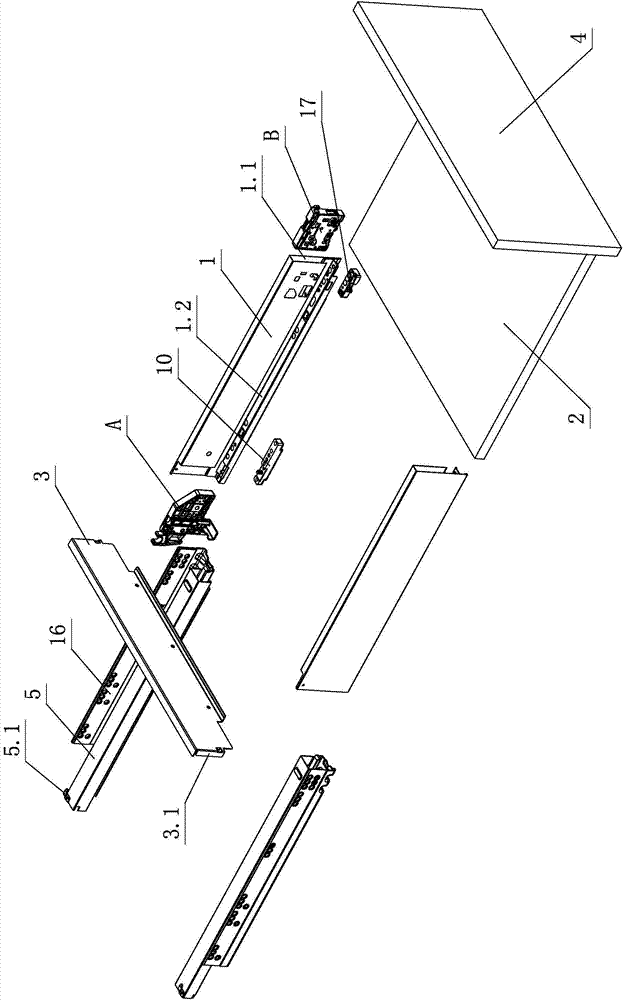

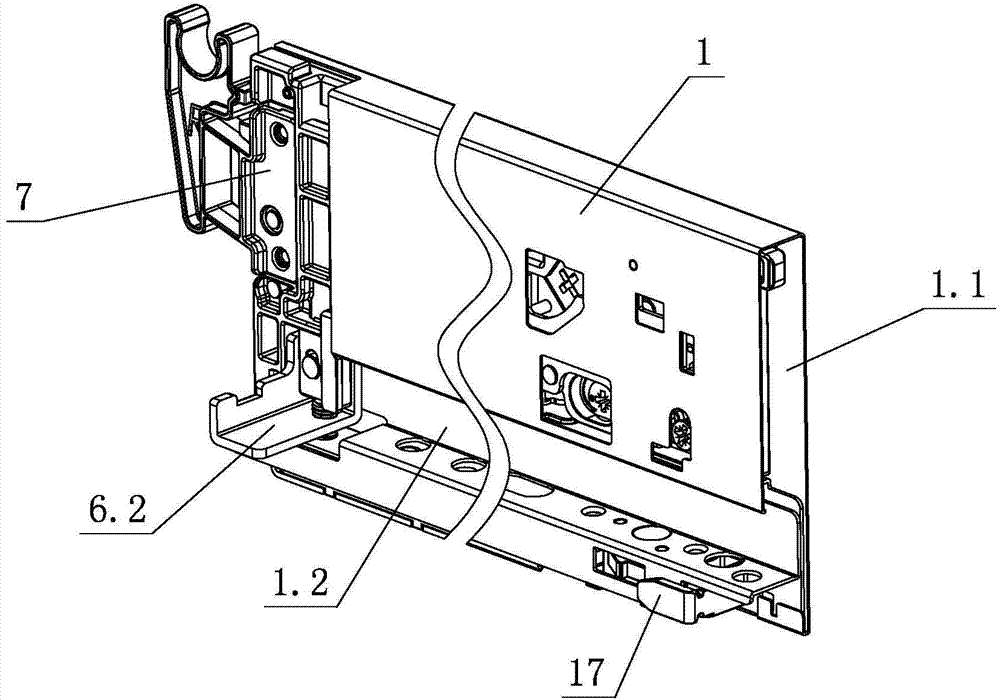

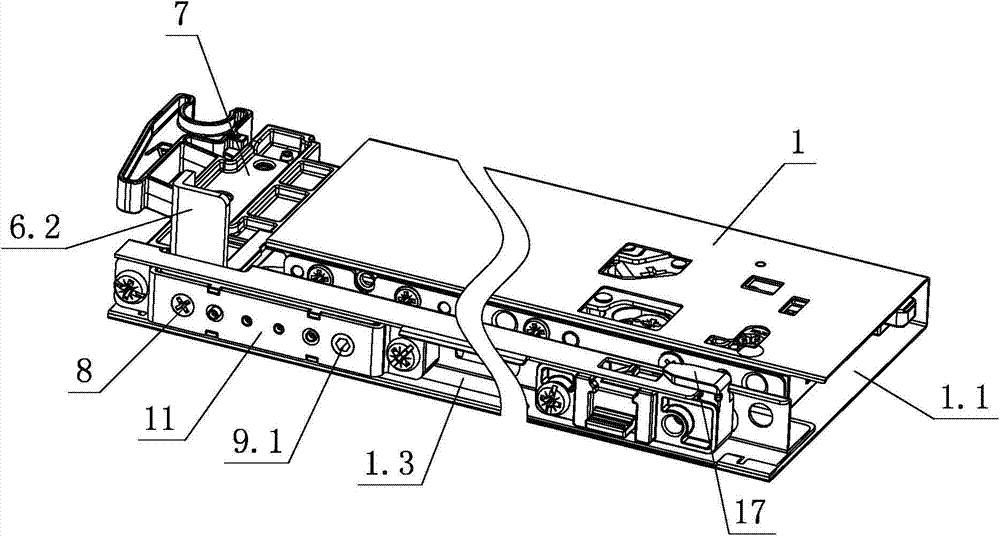

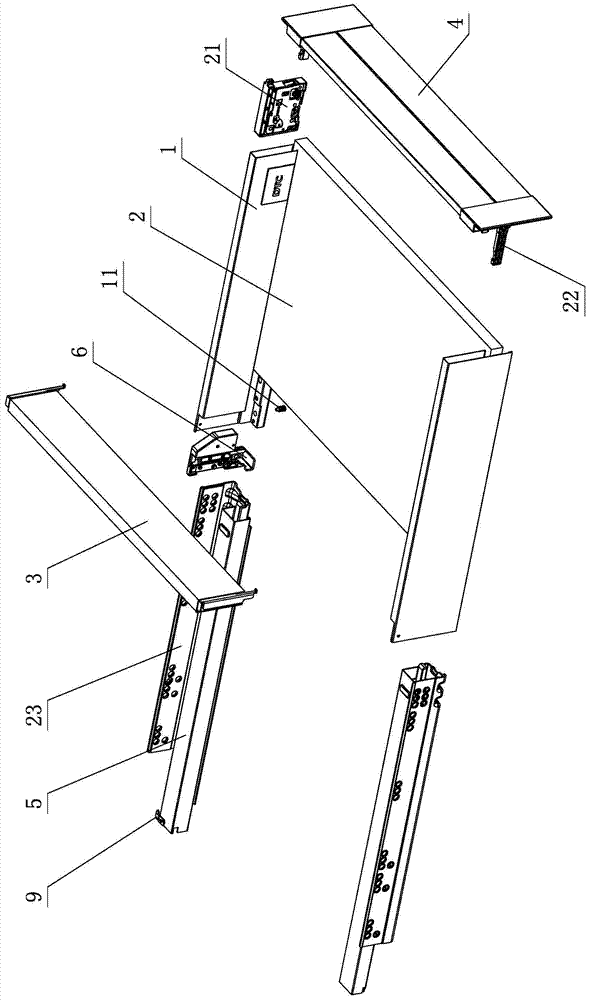

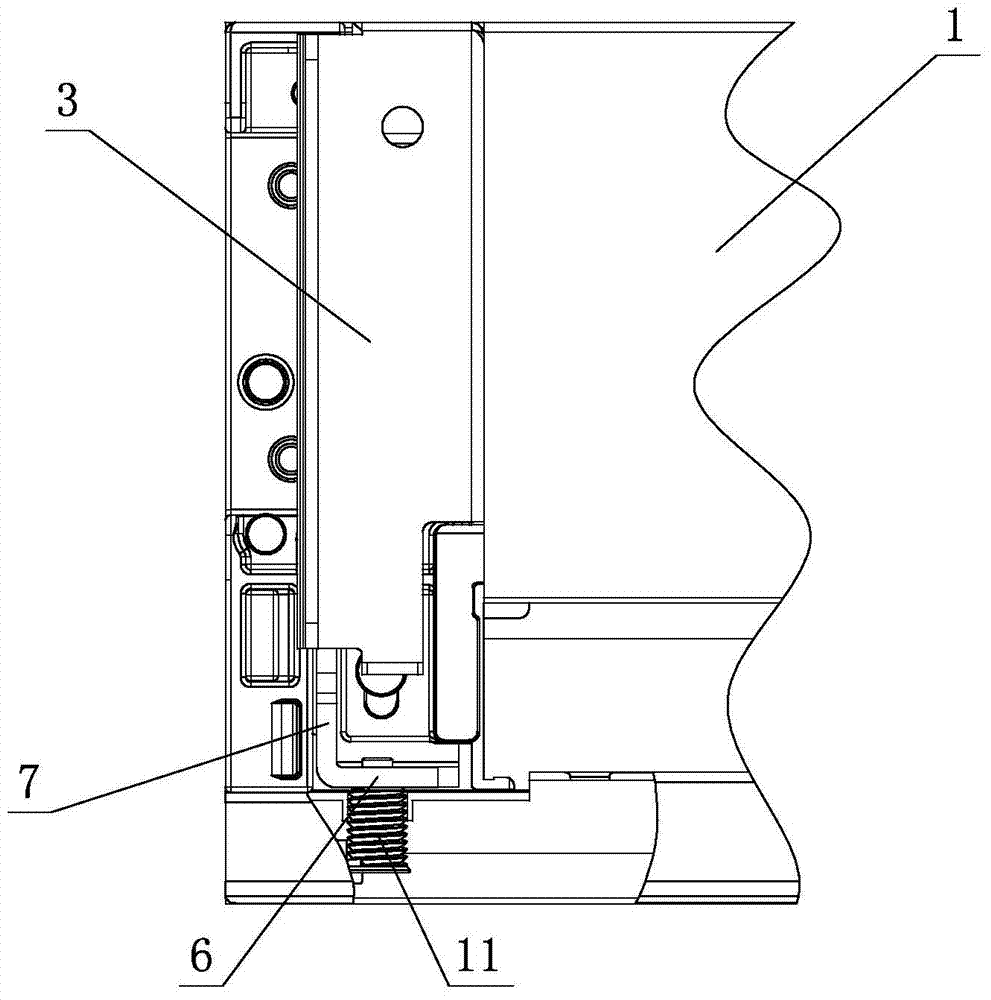

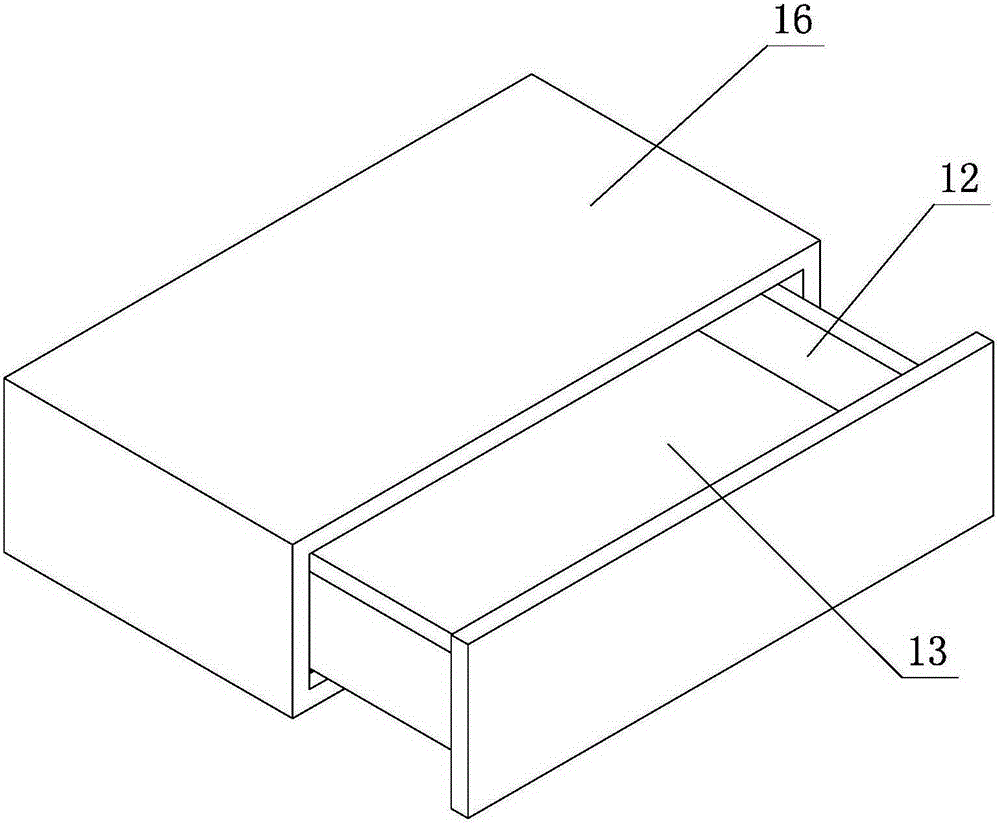

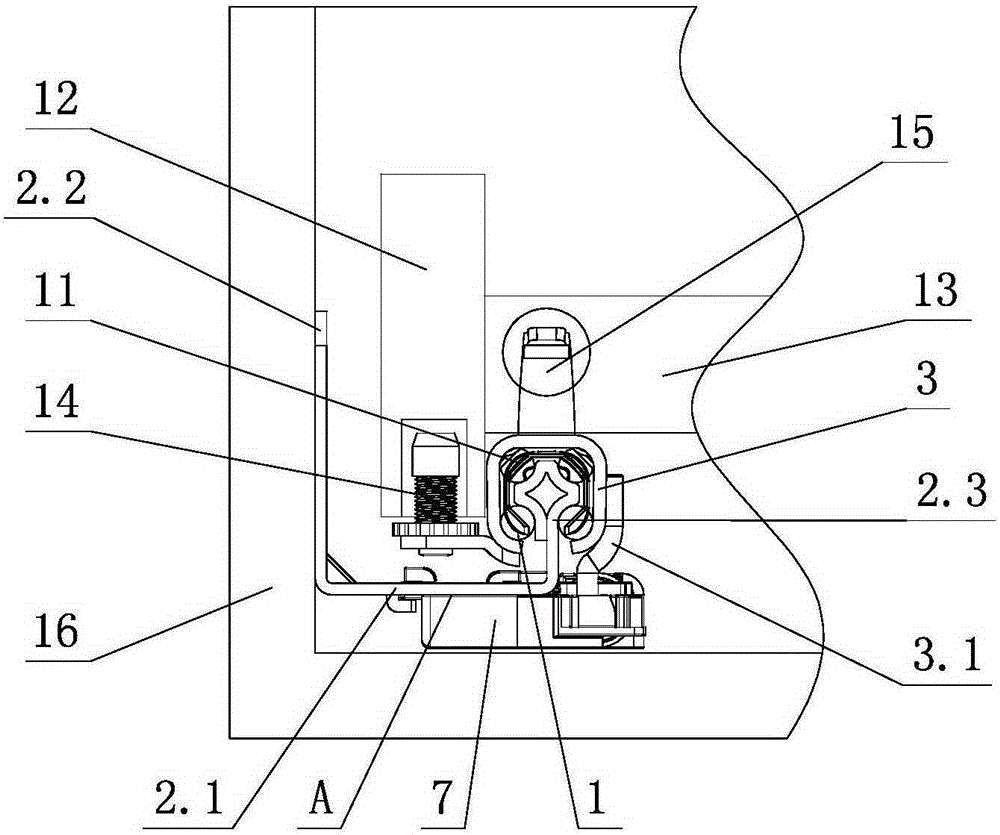

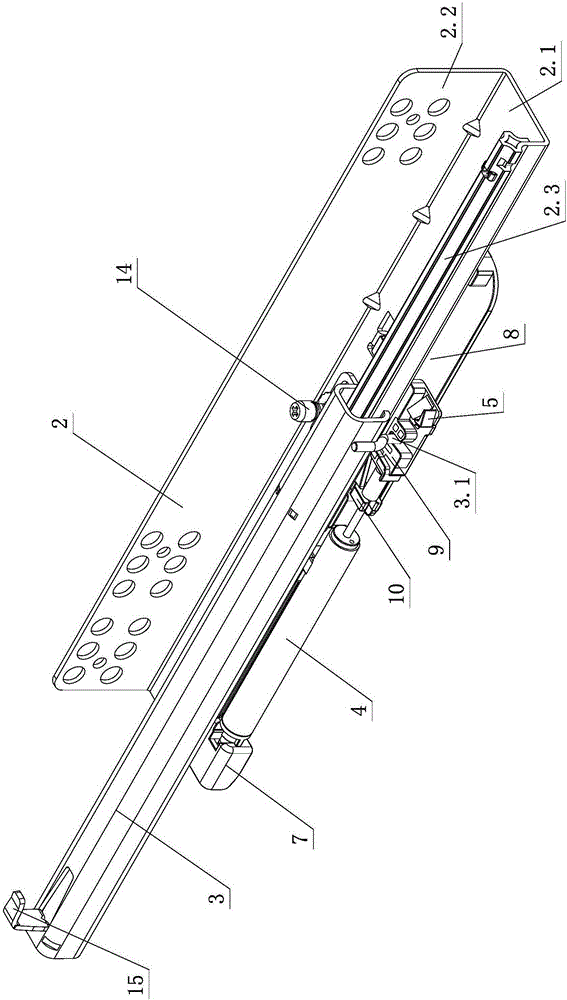

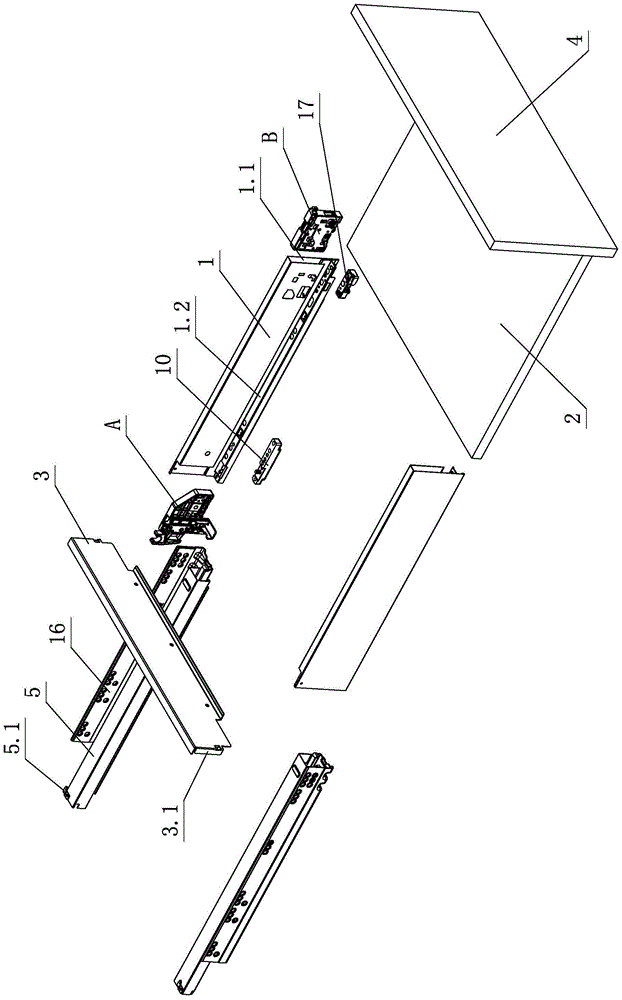

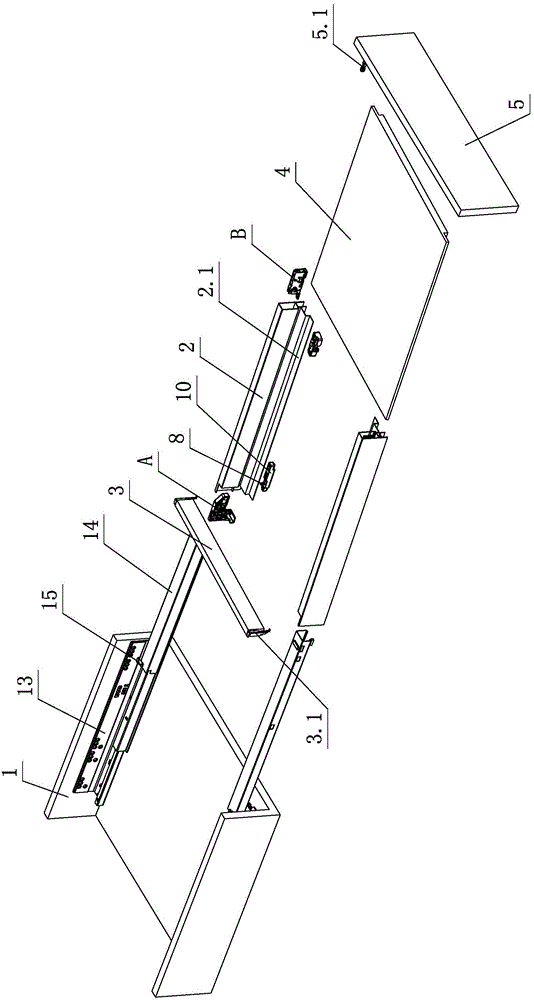

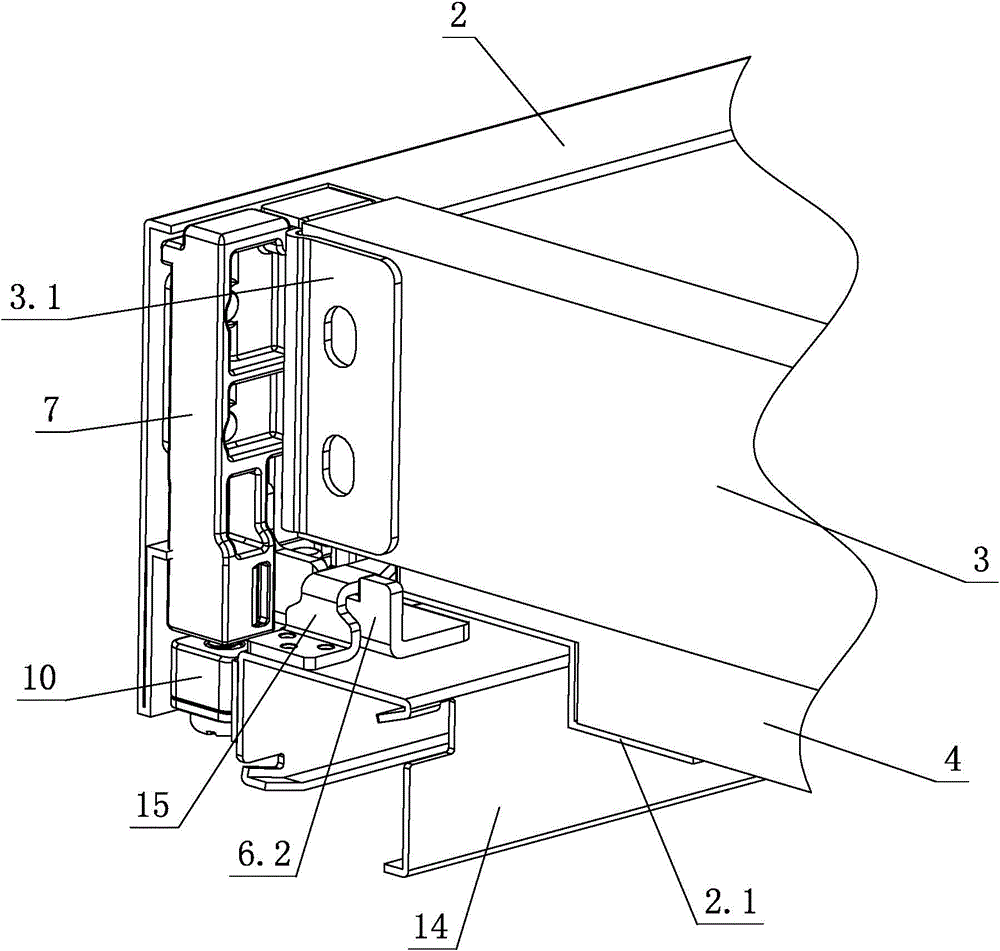

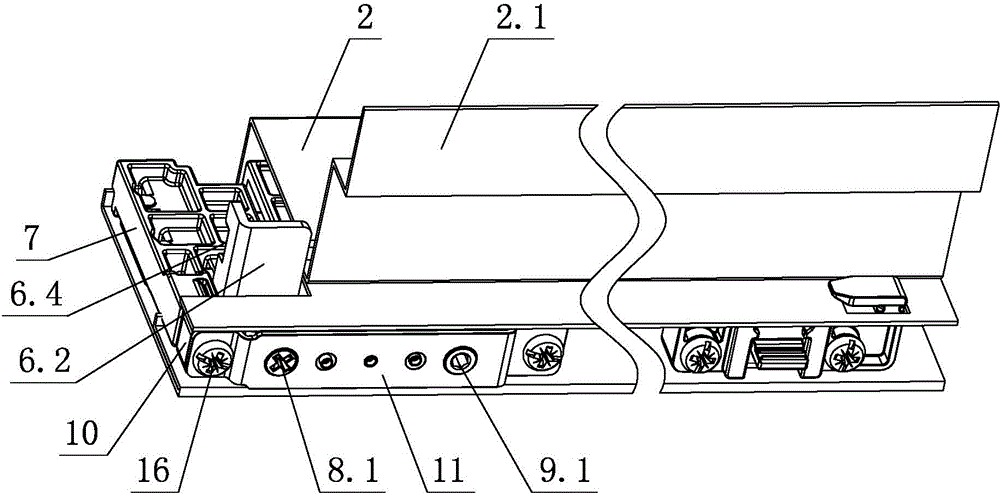

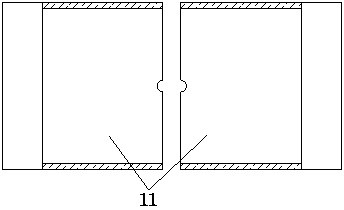

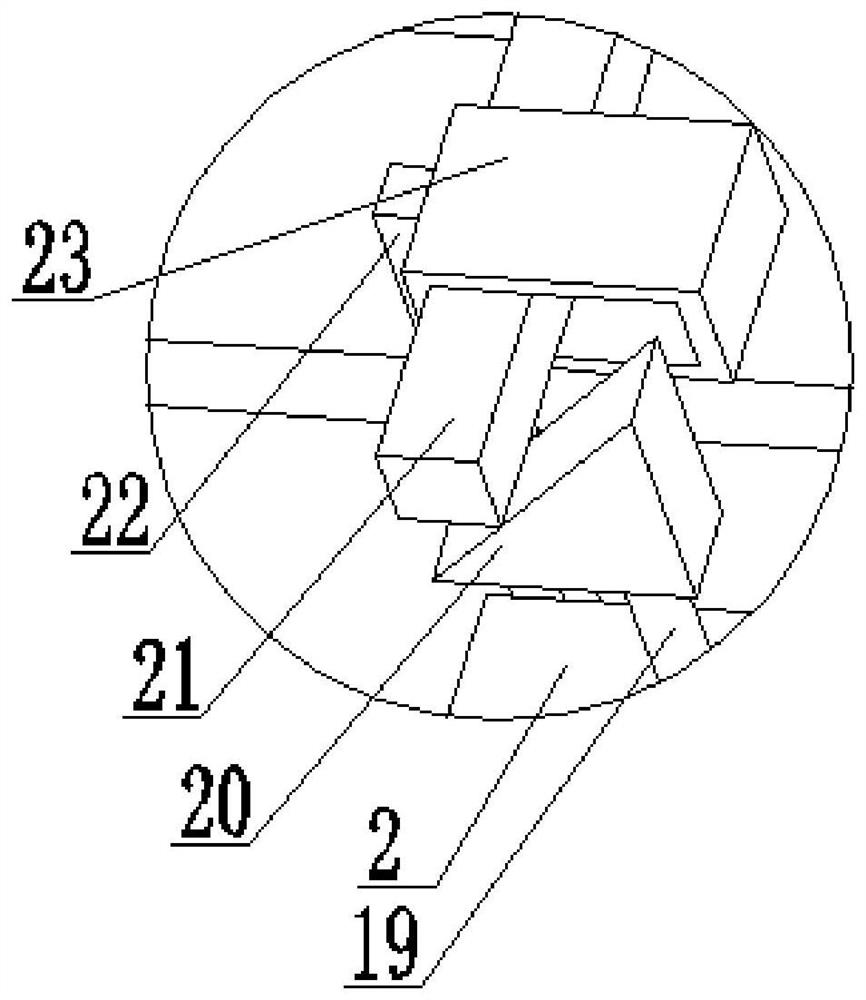

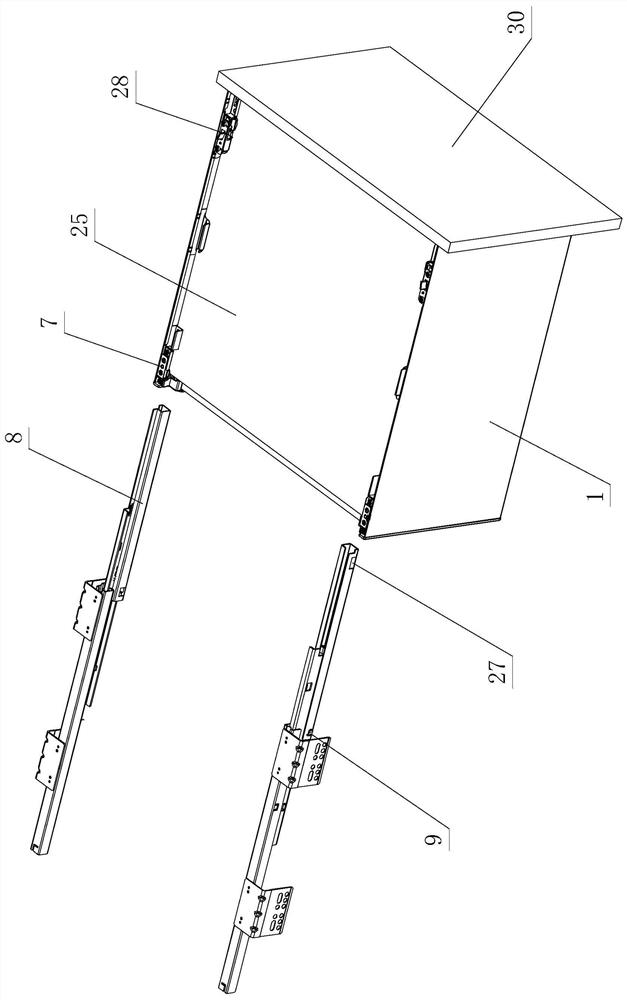

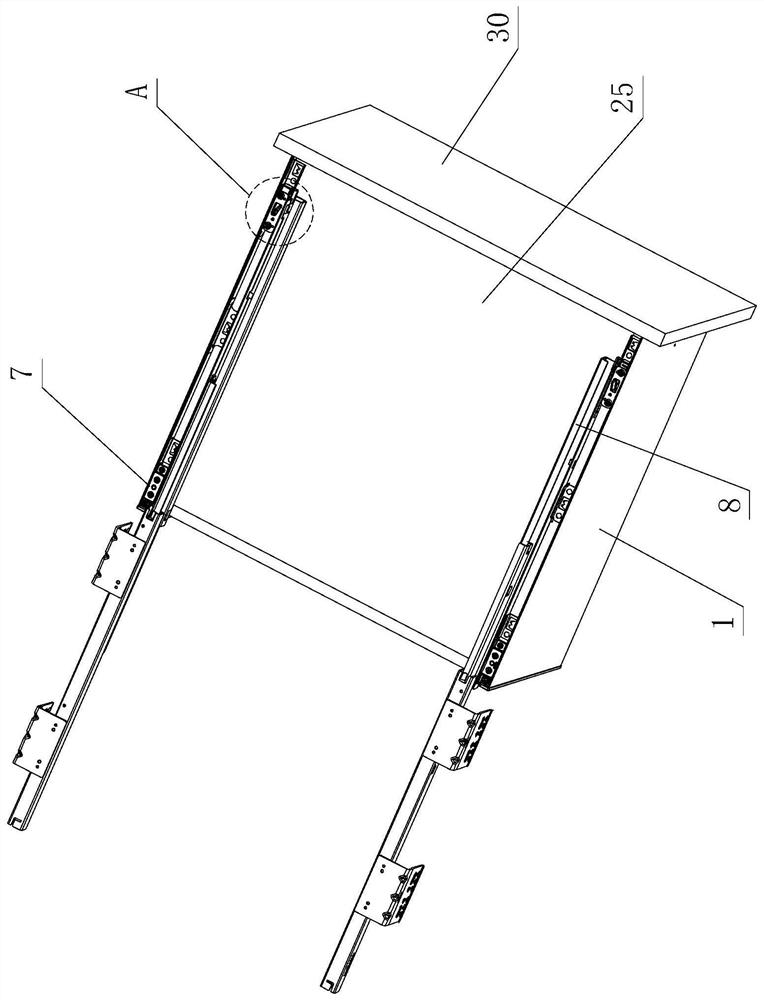

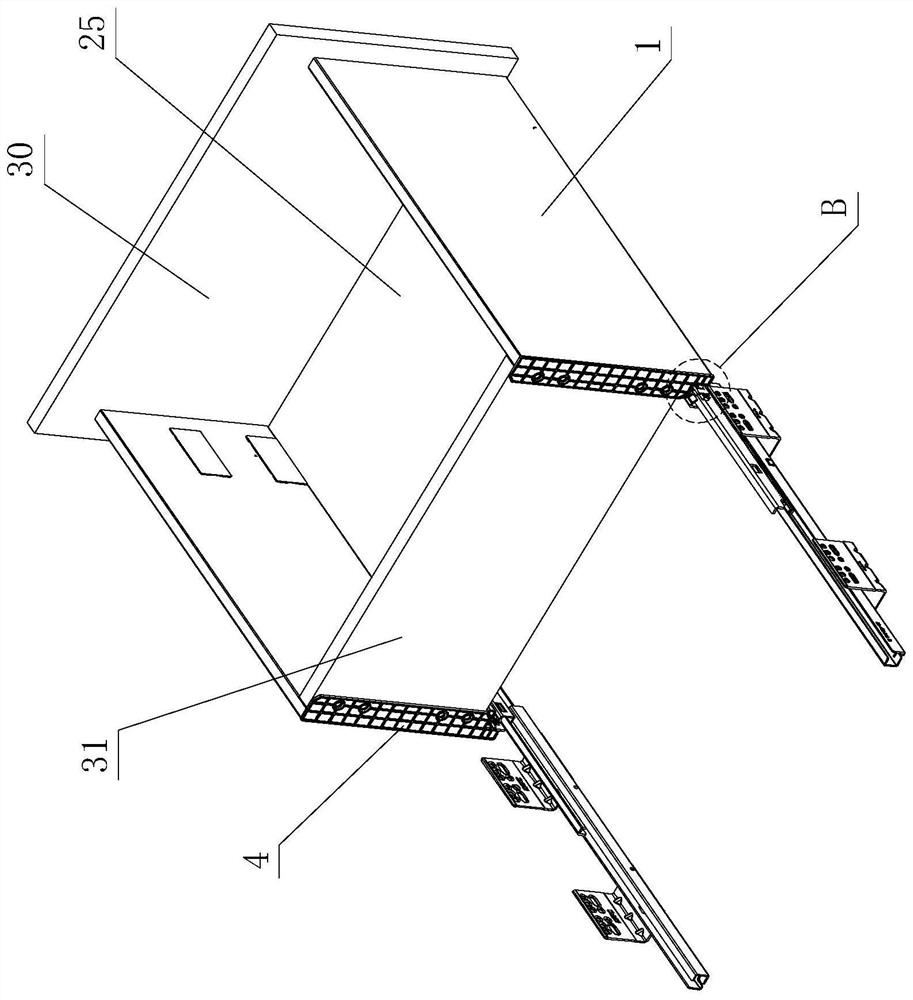

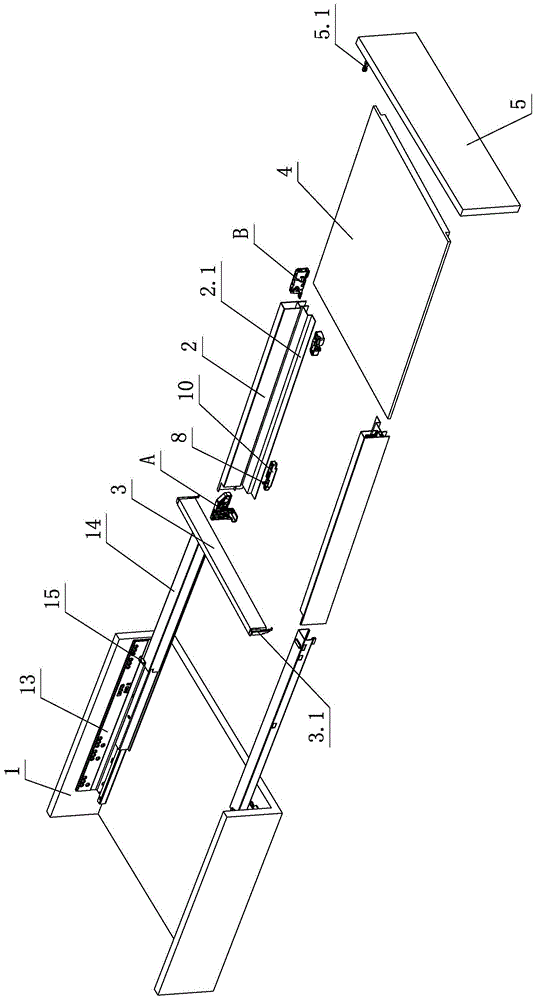

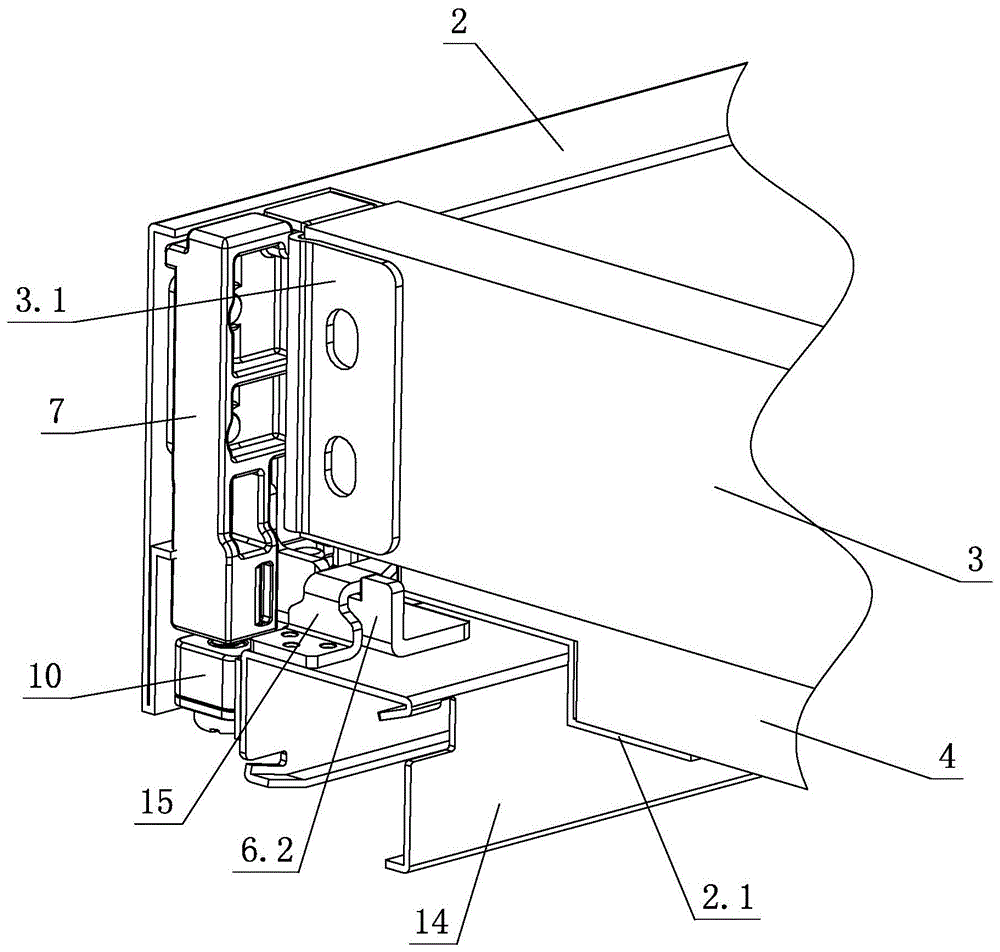

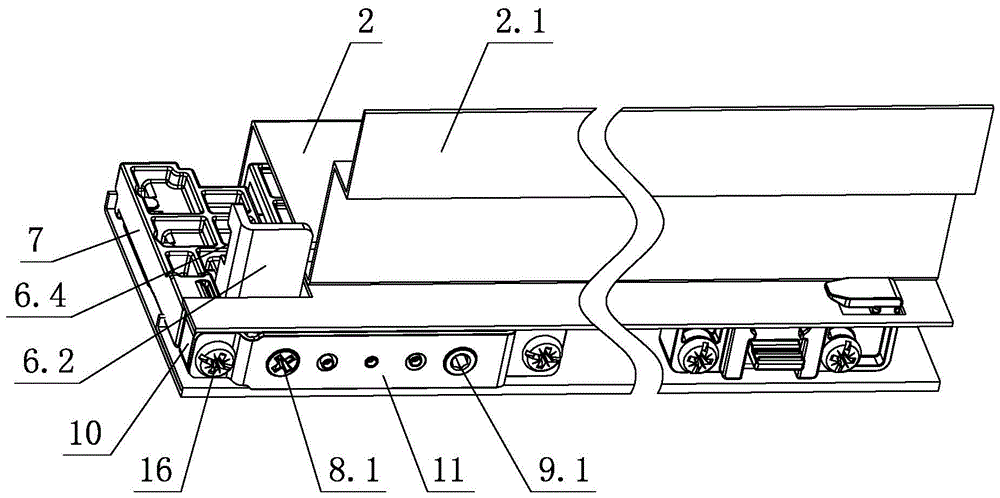

Adjusting mechanism of furniture drawer

An adjusting mechanism of a furniture drawer comprises side plates, a bottom plate, a back plate, a front plate and slide rail components used for opening and closing the drawer. Rear connectors and front connectors used for connecting the back plate with the front plate are arranged at the front end and the rear end of each side plate respectively, each slide rail component at least comprises a pull-out rail, a stabilizing portion is arranged at the rear end of each pull-out rail, a cavity is arranged in each side plate, each rear connector is fixedly arranged in the corresponding cavity and slidably provided with an adjusting element, and each adjusting element is supported on each pull-out rail and plays a positioning role on the corresponding stabilizing portion; an adjusting device is arranged in the lower region of the cavity of each side plate and at least provided with a screw gear part, and one end of each screw gear par is rotationally connected with the corresponding adjusting element in a threaded manner while the other end is rotationally positioned on each adjusting device. By gear drive, the side plates are enabled to move up and down relative to the adjusting elements, the inclination angle of the drawer relative the pull-out rails is adjusted, and practicality is high.

Owner:伍志勇

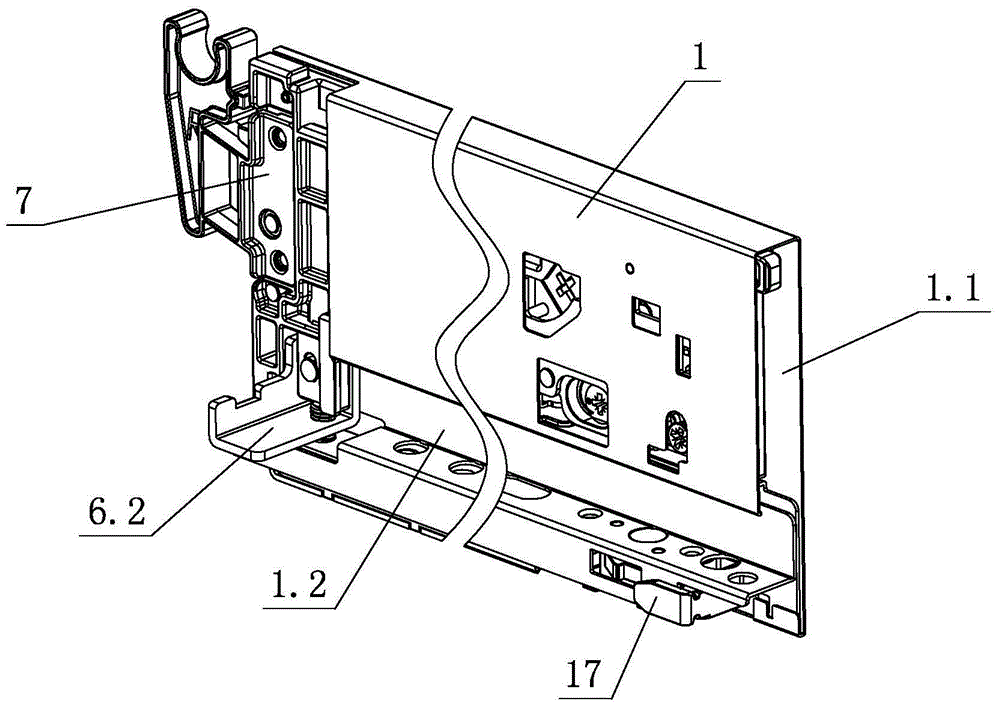

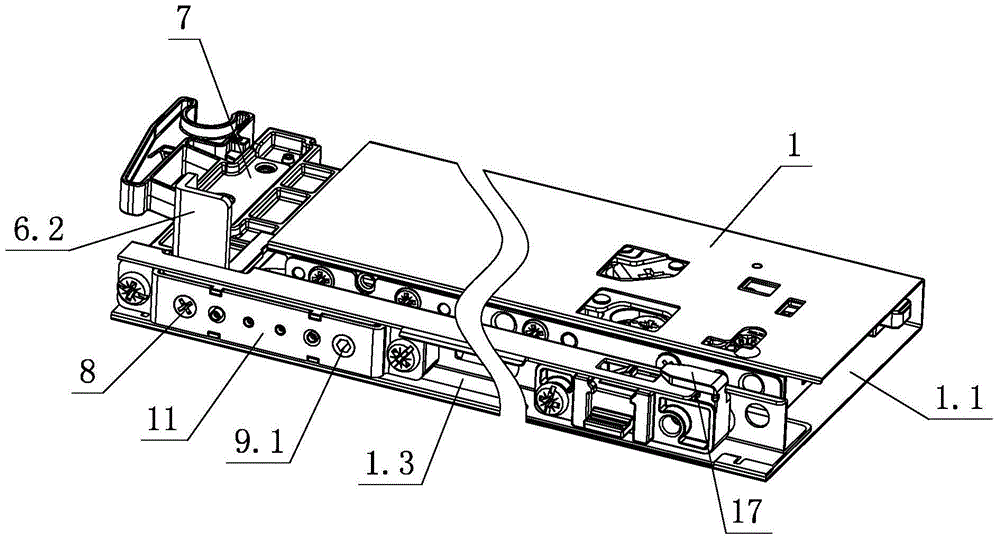

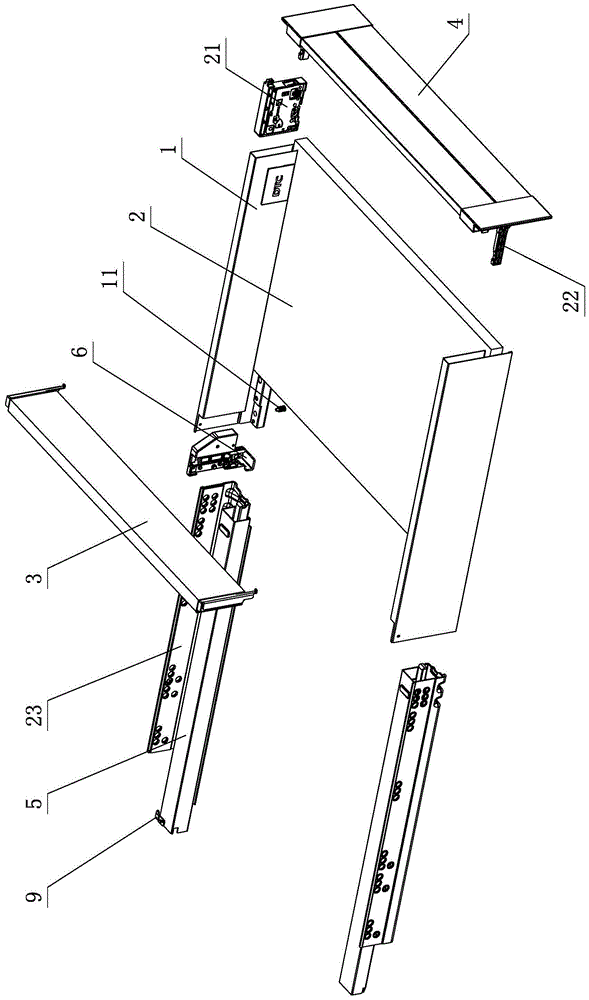

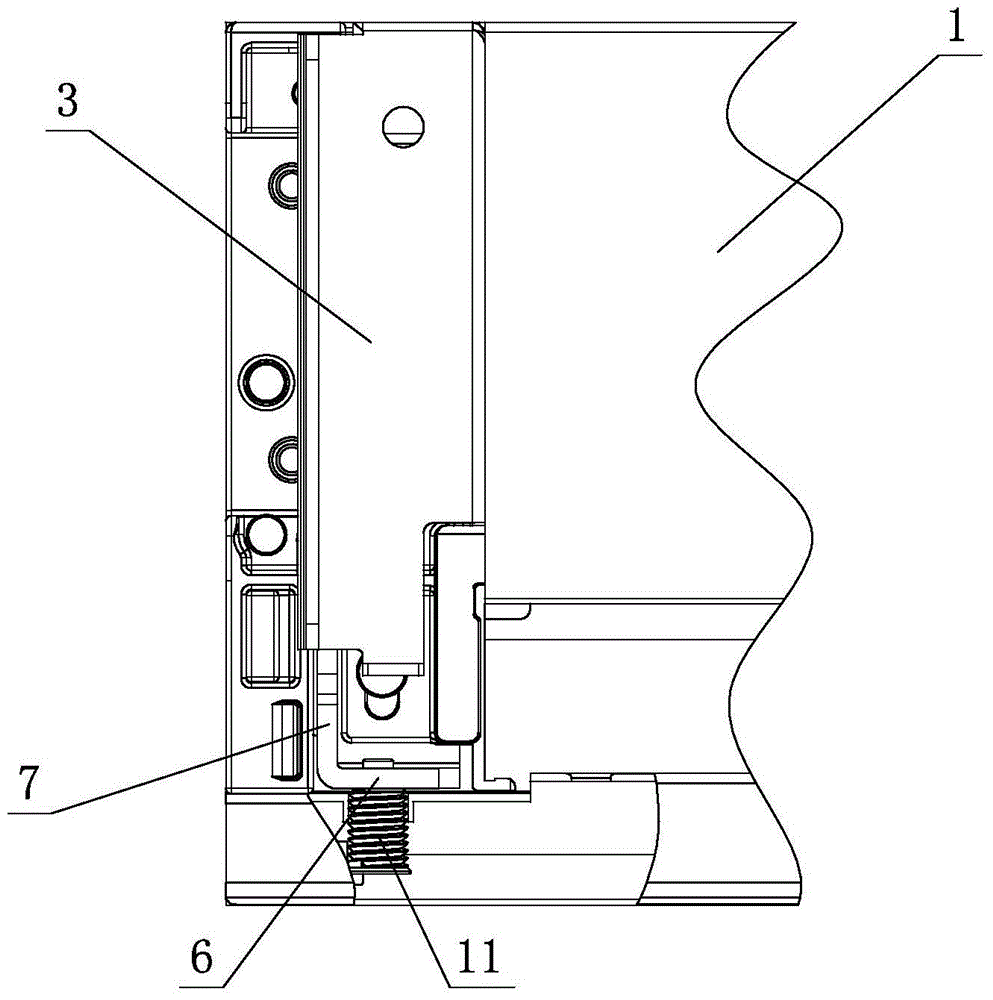

Furniture drawer hidden adjusting device

A furniture drawer hidden adjusting device comprises a frame, a base plate, a rear plate, a front panel and a sliding rail assembly. The adjusting device is arranged on the frame and used for adjusting rising and lowering of the frame relative to the sliding rail assembly. A bearing portion connected with a pulling rail of the sliding rail assembly in a matching mode is arranged on the adjusting device, and an operation part is arranged on a bottom area of the adjusting device facing the frame. The bearing part achieves vertical movement of the frame relative to the pulling rail by rotating or wrenching the operation part. By means of structure improvement, the operation part of the adjusting device is arranged in a U-shaped area of the frame in a hidden mode, and the hiding performance of the adjusting device is effectively improved. Meanwhile, a user can adjust the operation part of the adjusting device on the U-shaped area of the frame through a tool or manually to enable the guide portion of the adjusting device to move vertically and linearly relative to the guide matching portion of a rear connection device, finally adjustment of inclination position of the frame relative to the sliding rail assembly is achieved, and the practicability is high.

Owner:伍志勇

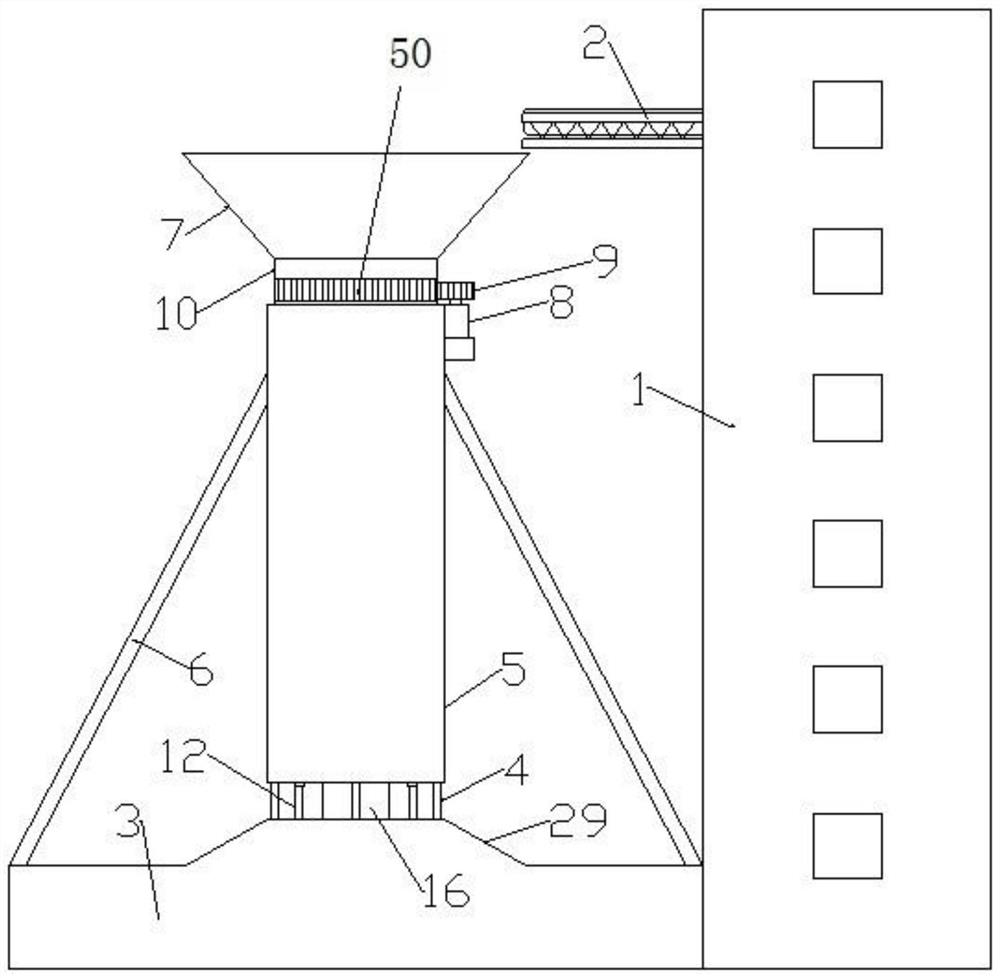

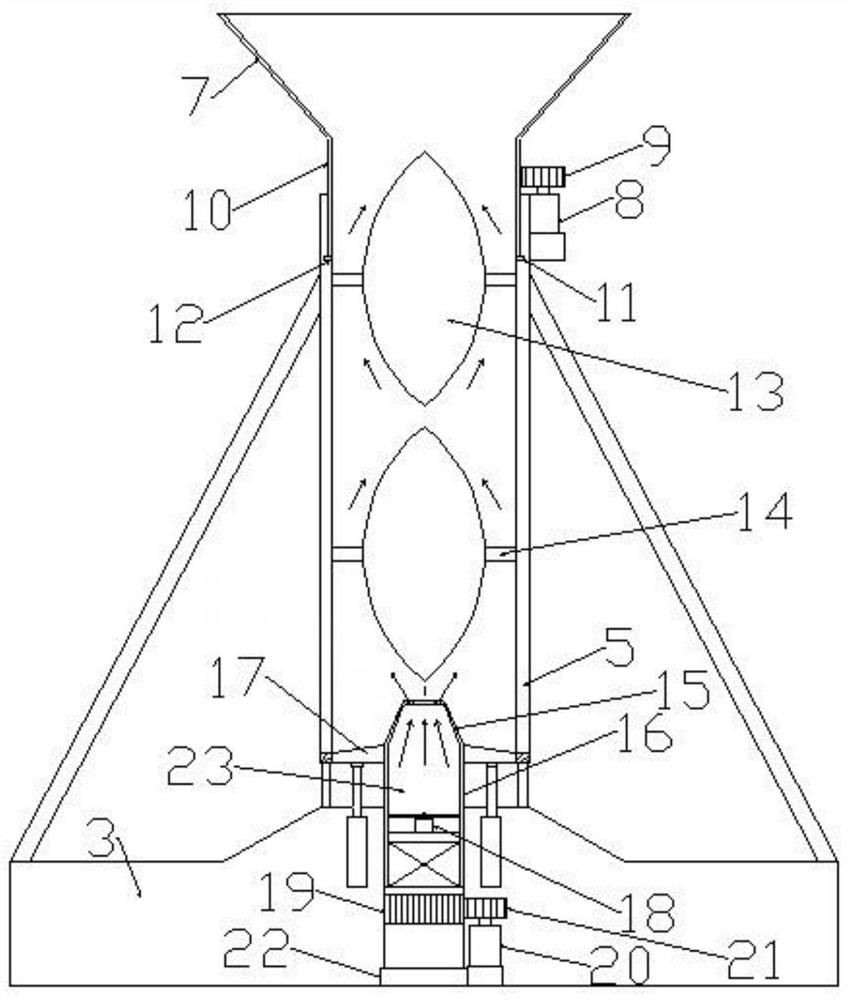

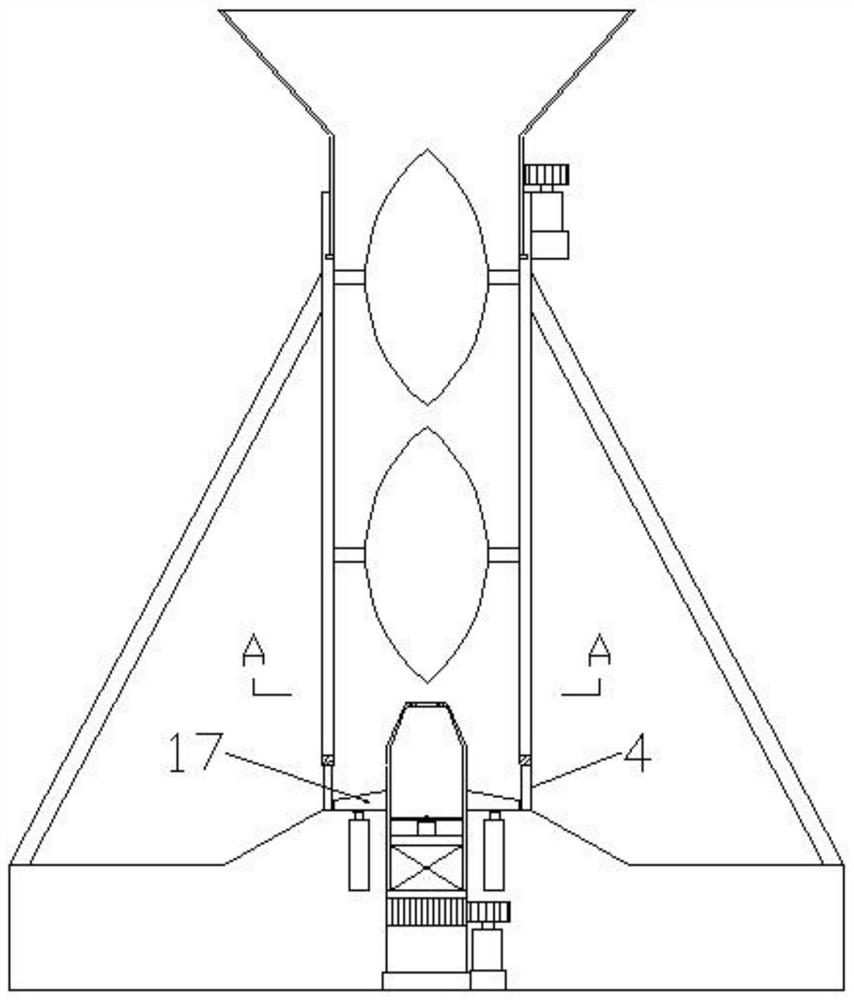

Microbial fertilizer vertical wind tunnel granulation blanking system and method

PendingCN113713712ARealize air cooling operationEvenly dispersedMaterial granulationMicroorganismEnvironmental engineering

The invention relates to a microbial fertilizer vertical wind tunnel granulation blanking system and method. The microbial fertilizer vertical wind tunnel granulation blanking system comprises a raised granulation preparation building and a discharging conveying belt arranged on one side of the top of the raised granulation preparation building and communicated with the interior of the raised granulation preparation building. A rotary rolling receiving hopper is arranged below the end of the discharging conveying belt in a bearing mode. The bottom of the rotary rolling material receiving hopper is connected with a wind tunnel granulation device, and a material receiving platform is arranged at the bottom of the wind tunnel granulation device. According to the invention, particles can be rapidly air-cooled, air is blown from bottom to top through the wind tunnel effect, the wind speed and wind power are accurately calculated according to the particle size of the particles, and wind tunnel cooling operation is effectively carried out while slow discharging is guaranteed; and the produced and prepared particles are uniformly and dispersedly discharged into a vertical cylinder at the bottom by utilizing a rotary discharging hopper type structure at the top, so that the particles at the top are prevented from being adhered, and meanwhile, top scattering and discharging operation is provided for the vertical cylinder of a wind tunnel structure.

Owner:ZHENGZHOU YONGFENG BIOLOGICAL FERTILIZER IND CO LTD

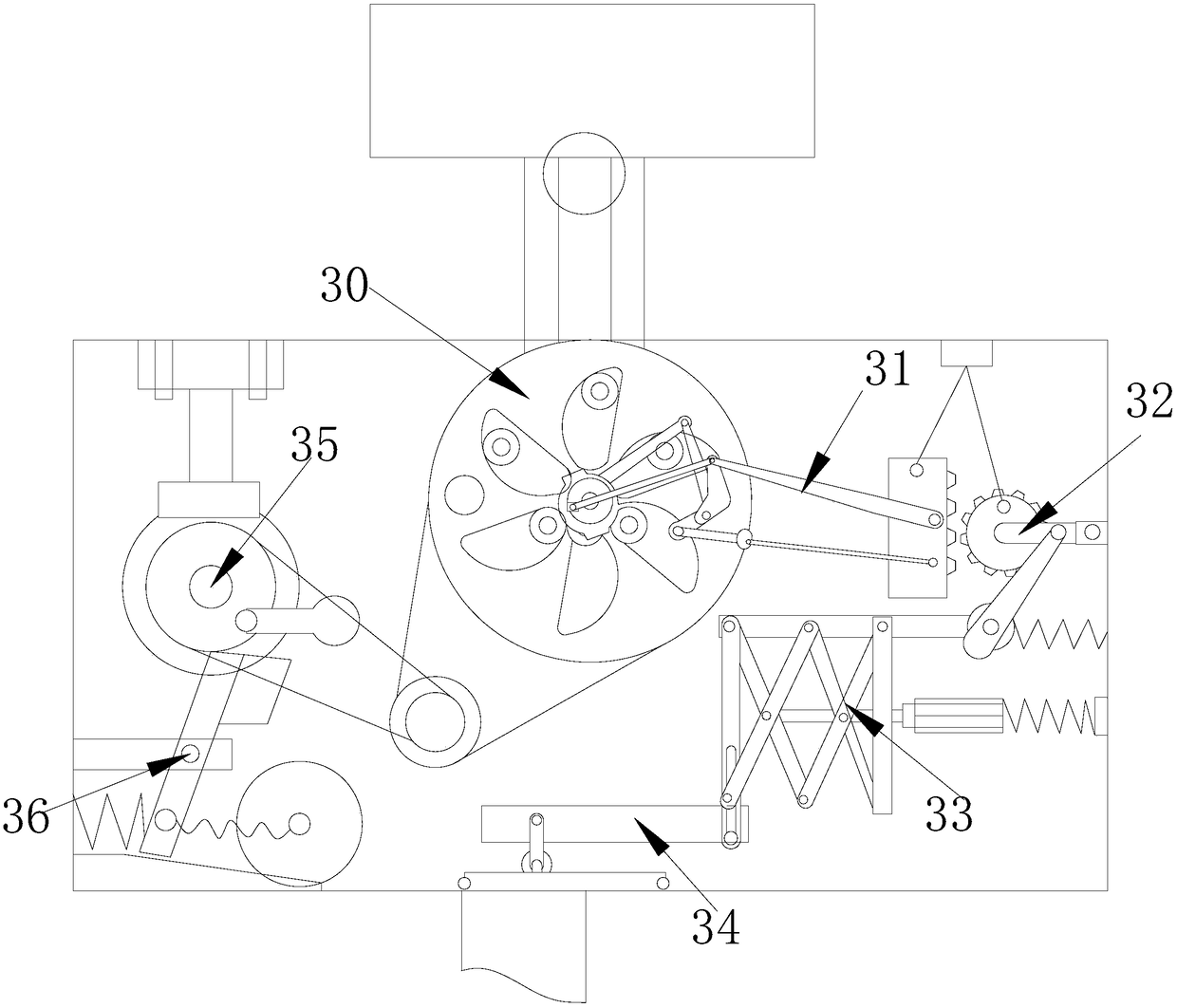

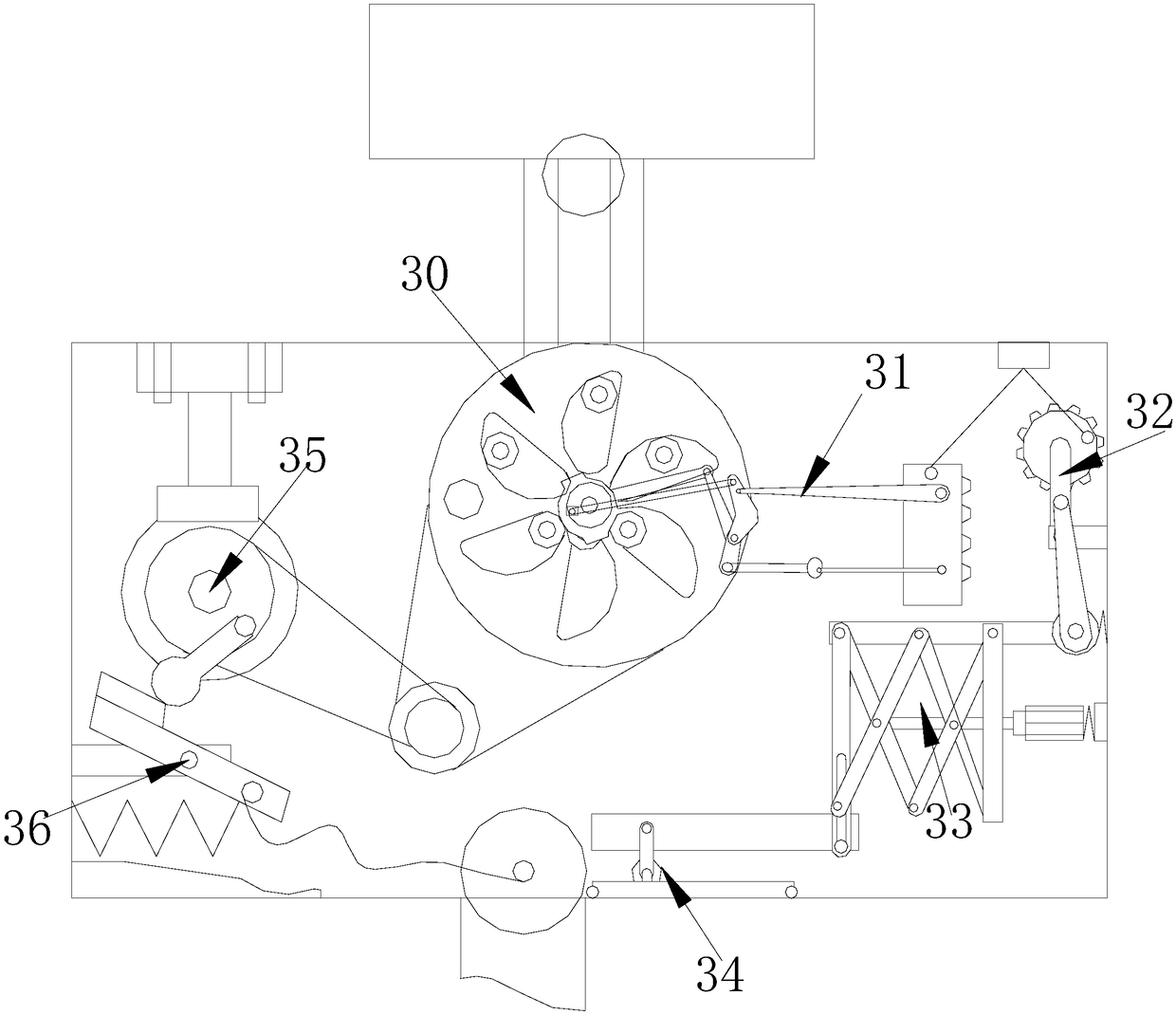

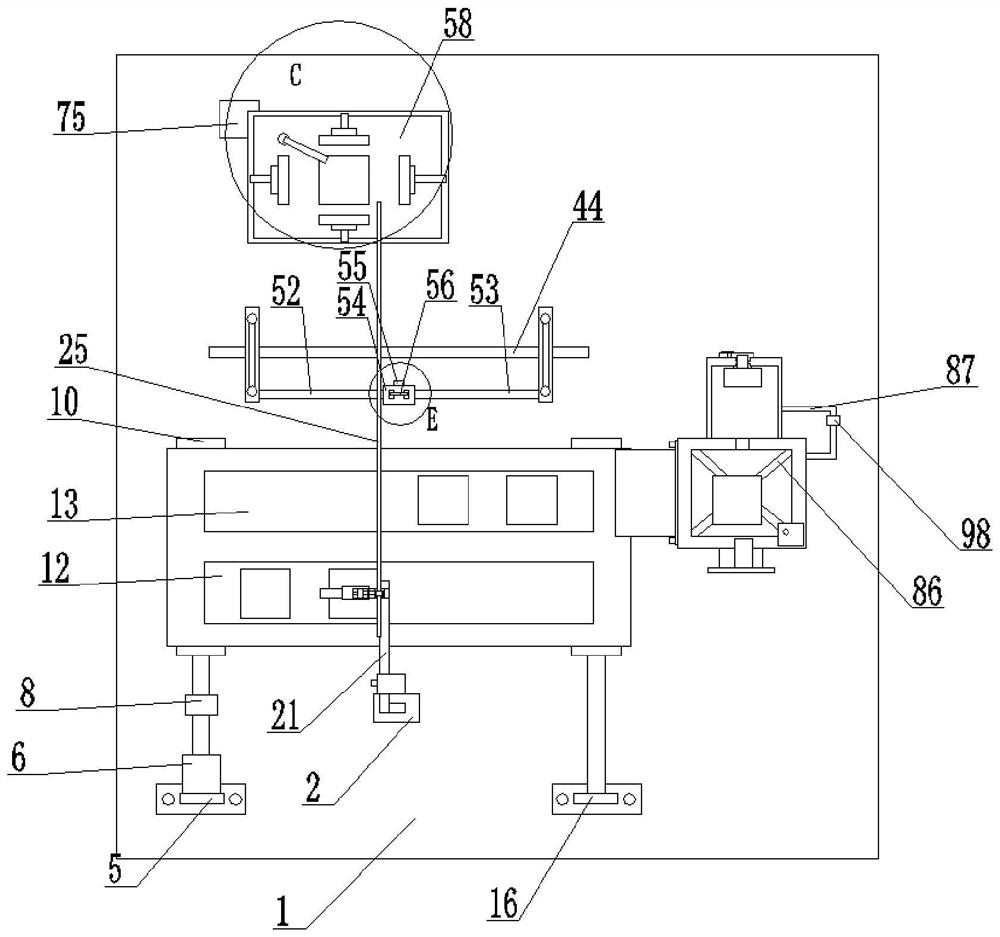

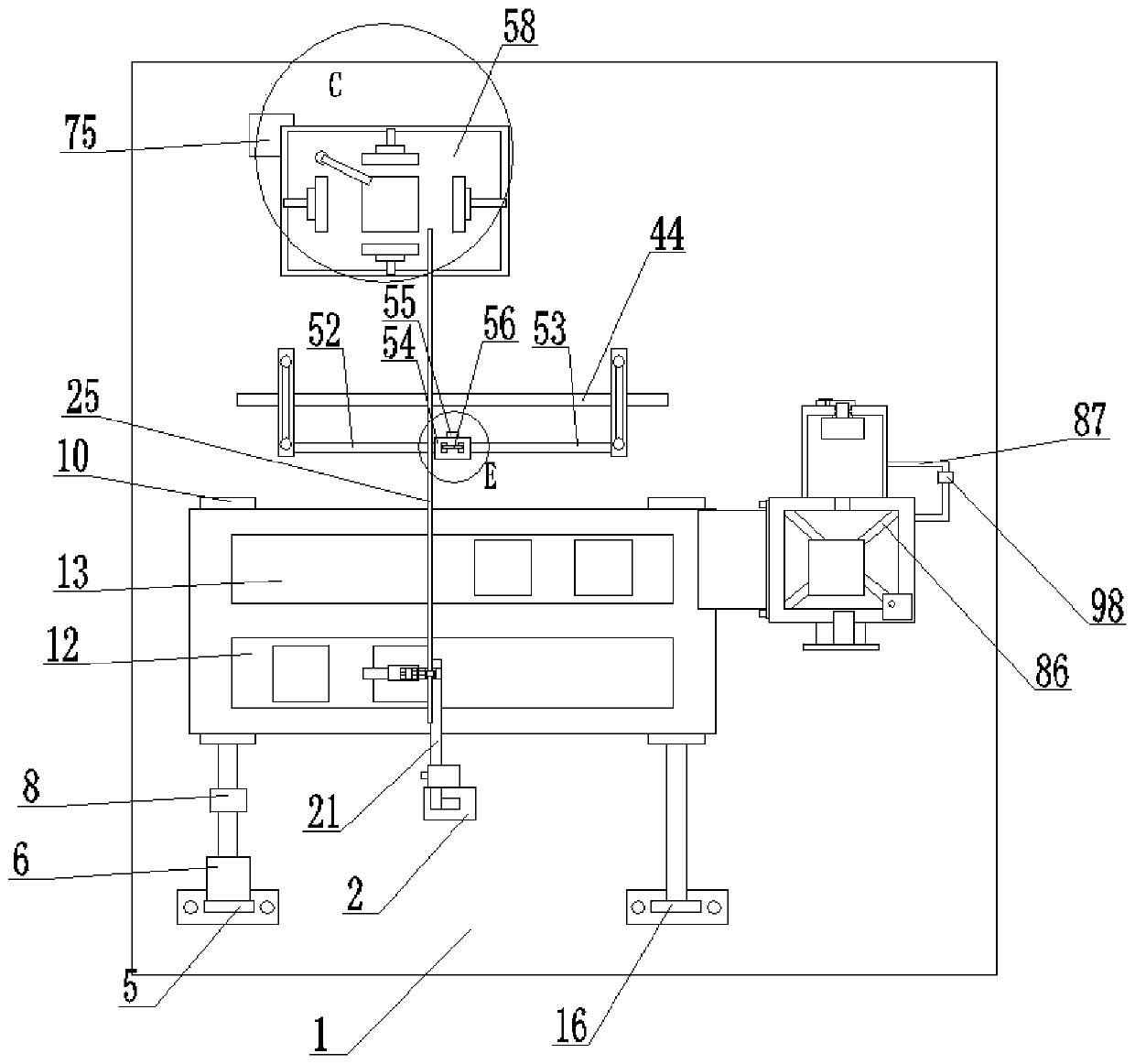

Battery carbon dust feeding device

InactiveCN108666592AClosely connectedSimple processPrimary cell manufactureDry cellsElectrical batteryEngineering

The invention discloses a battery carbon dust feeding device. The structure of the battery carbon dust feeding device comprises dust guide pipes, a dust feeding machine head, compaction devices and acontrol machine body, wherein the dust guide pipes are connected to the upper part of the dust feeding machine head; the dust feeding machine head is arranged on the outer side of the control machinebody and is connected with the compaction devices; the compaction devices are arranged at the bottom of the dust feeding machine head and are movably connected; a control machine body controller is connected onto the control machine body; and each compaction device comprises a rotating mechanism, a driving device, a swinging device, a pushing device, an opening and closing device, a transmission device and a compaction device body. According to the battery carbon dust feeding device, the compaction devices can be driven to move in a staggered manner so as to compact carbon dust while the carbon dust is fed, the compaction devices are tightly connected in a tandem working condition, and the manufacturing is relatively integrated and convenient for production.

Owner:莆田市山水牧歌贸易有限公司

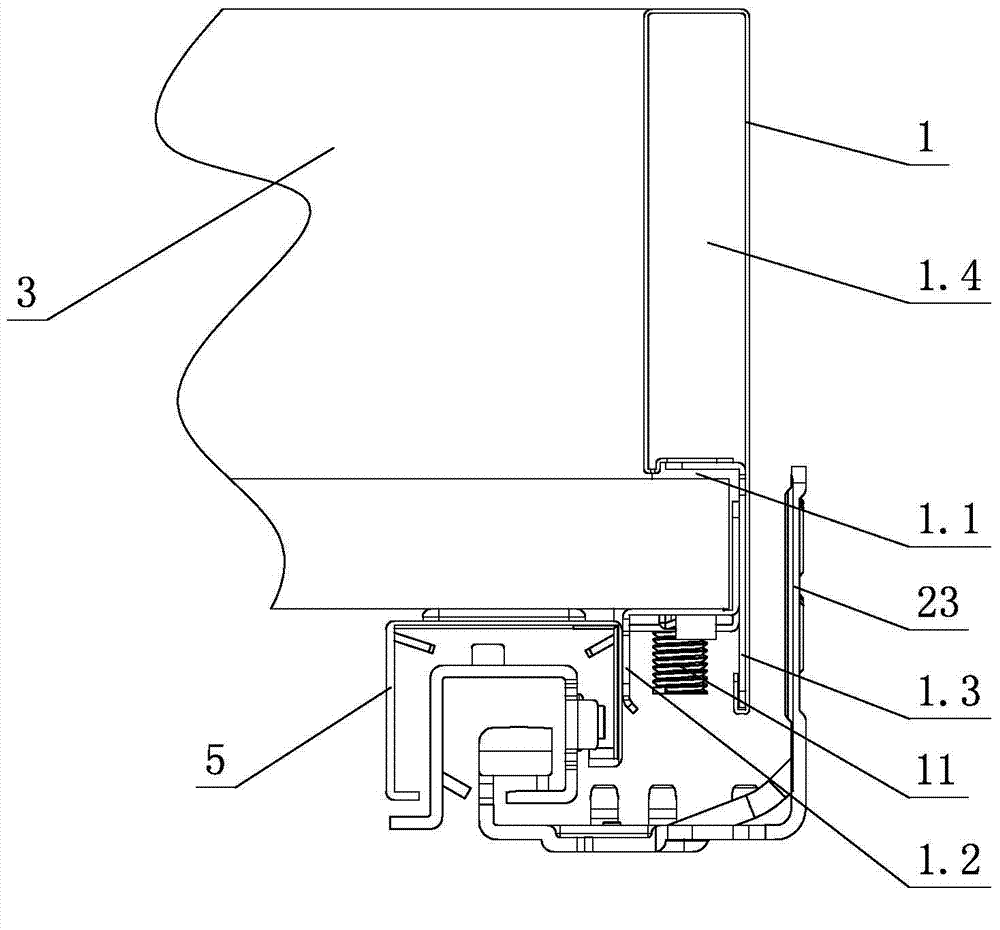

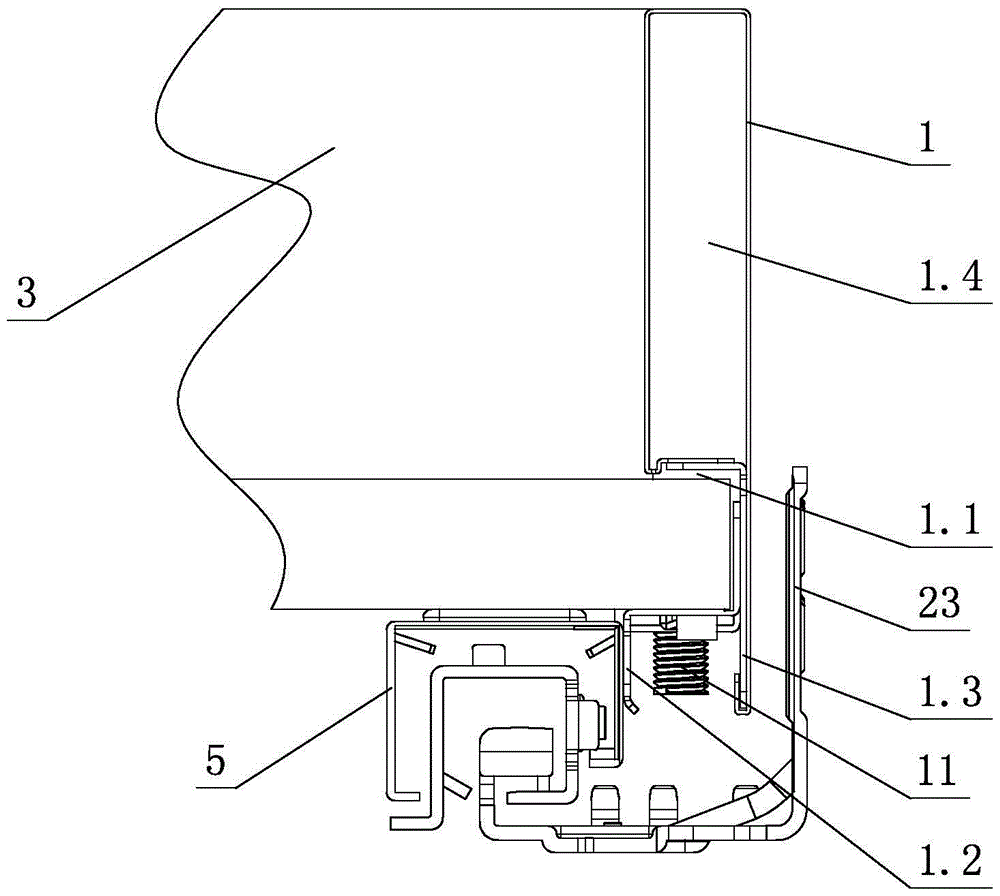

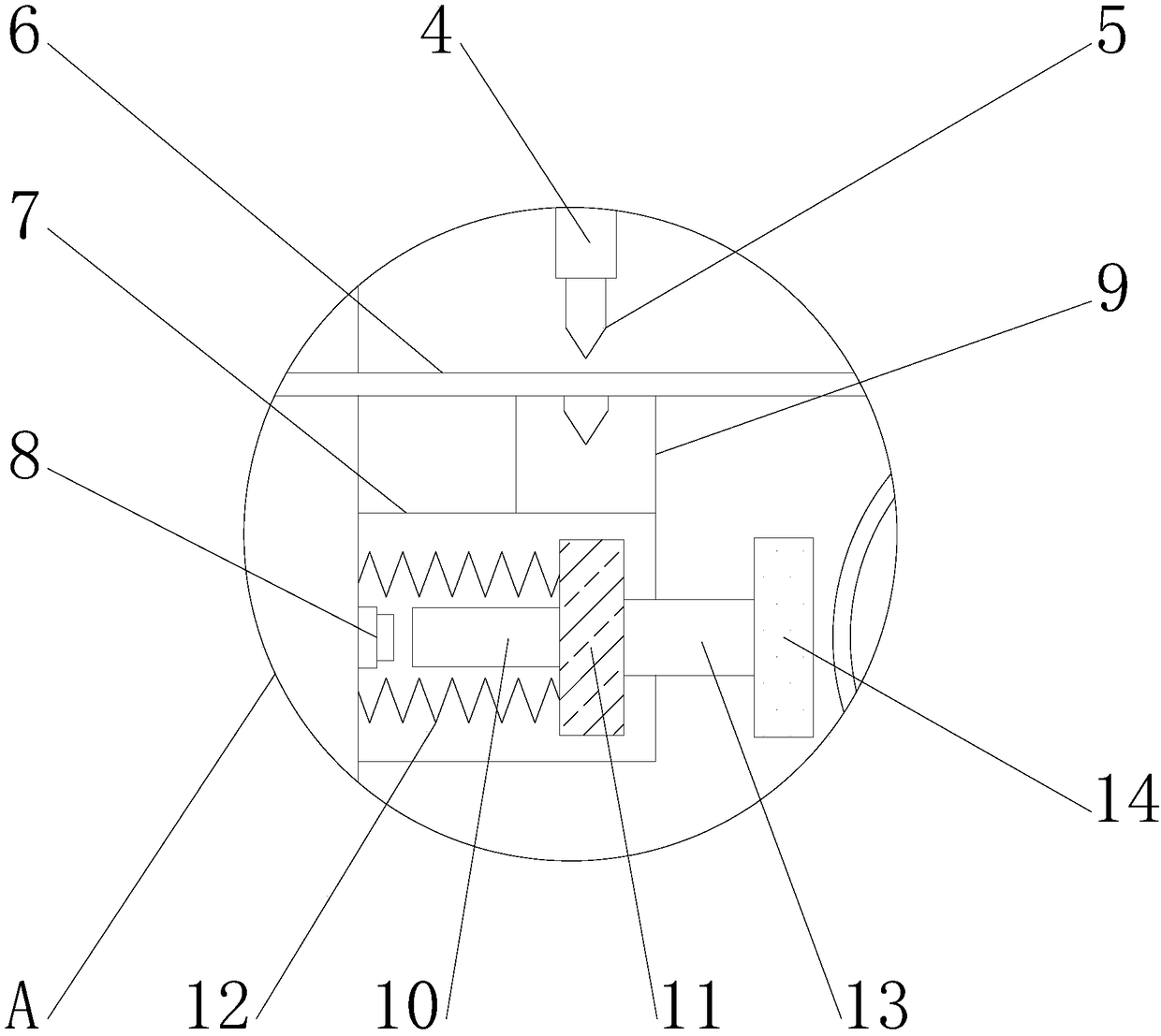

Damping anti-falling structure for furniture drawer

ActiveCN105231700AImplement buffer offAvoid the problem of easy fallingDrawersEngineeringSupport plane

The invention relates to a damping anti-falling structure for a furniture drawer. The damping anti-falling structure comprises a drawer main body, a cabinet main body, a fixed slide rail and a moveable slide rail, wherein a supporting part is arranged on the fixed slide rail; a damping anti-falling device is arranged at the bottom of the supporting part; a stirring part which at least interacts with the damping anti-falling device when the drawer main body is closed for a section of stroke is arranged on the moveable slide rail; the damping anti-falling device comprises a damper, an actuating element, a spring and a chute base; one end of the damper acts on the chute base while the other end at least acts on the actuating element when the drawer main body is closed for a section of stroke; one end of the spring is connected with the chute base while the other end is connected with the actuating element; a supporting plane is at least partially arranged at the bottom of the supporting part; the chute base is arranged on the supporting plane; a horizontal chute, a vertical chute and a chute surface are arranged on the chute base; a supporting chute is formed between the chute surface and the supporting plane; the actuating element is limited on the horizontal chute, the vertical chute and the supporting chute in a sliding form during the closing and opening process of the drawer main body, so that the sliding anti-falling arrangement for the actuating element is realized.

Owner:伍志勇

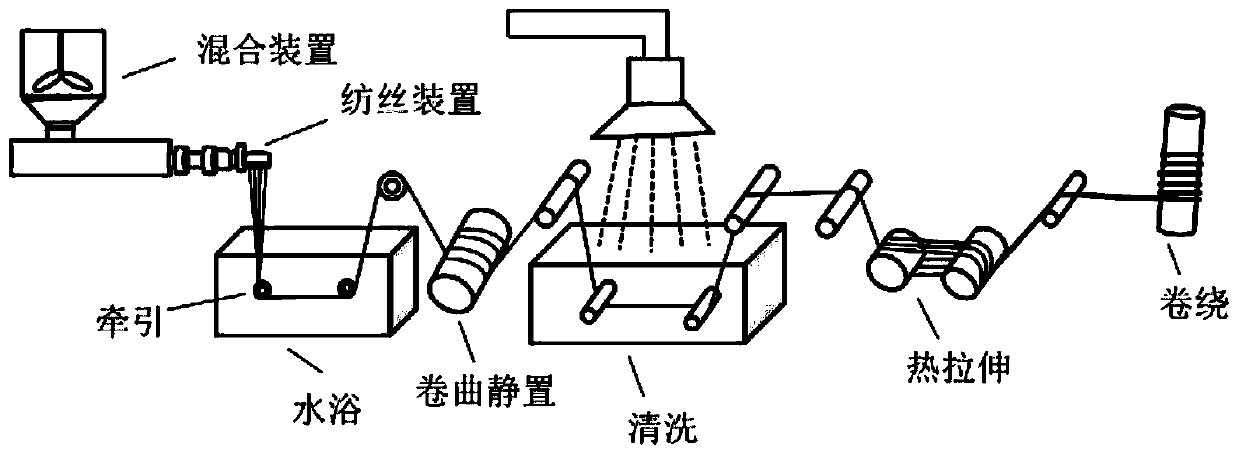

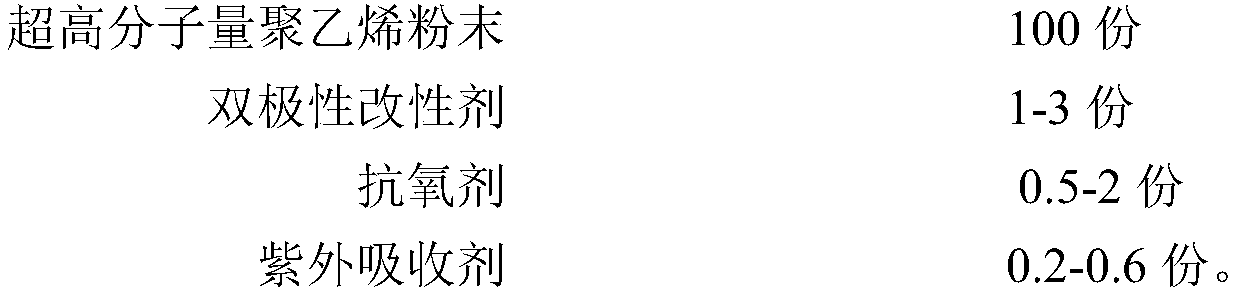

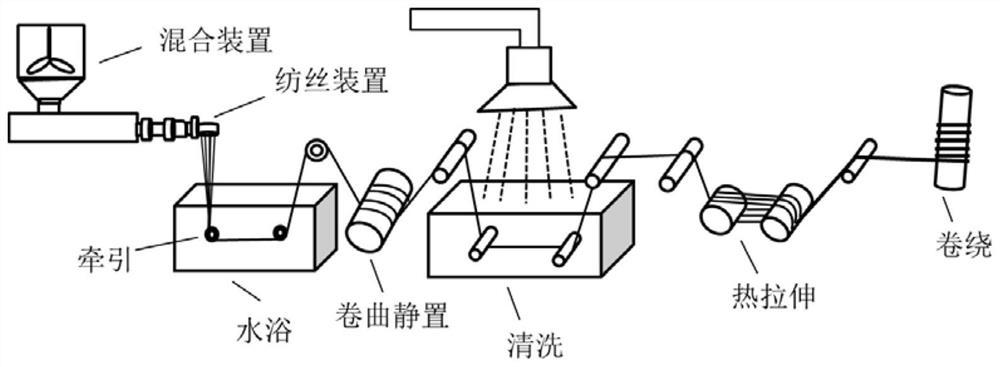

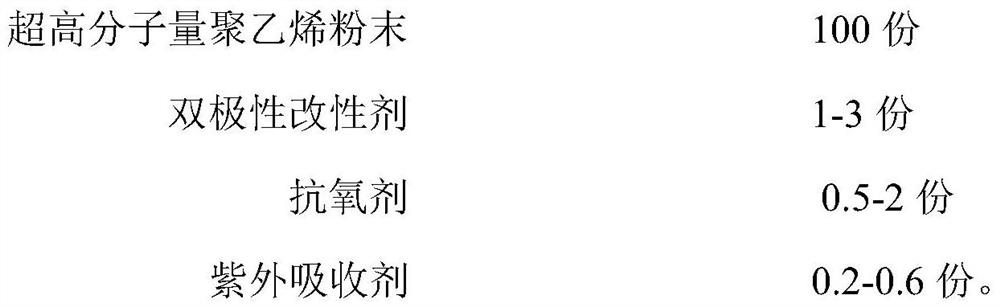

Method for modifying surface of ultra-high molecular weight polyethylene fiber

ActiveCN110541207AEasy to manufactureLow costMonocomponent polyolefin artificial filamentArtifical filament manufactureYarnFiber

The invention discloses a method for modifying the surface of an ultra-high molecular weight polyethylene fiber. The method comprises the specific steps that firstly, ultra-high molecular weight polyethylene fiber powder is added into a solvent, swelling pretreatmnet is conducted, then, a bipolar molecular modifying agent, an antioxidant and an ultraviolet absorbent are added into a swelling solution to obtain a swelling mixed solution, and the ultra-high molecular weight polyethylene fiber swelling mixed solution is evenly fed to a dual-screw extruder for gel spinning; a gel yarn is sprayed from a spinneret plate and enters a water bath tank to obtain primary cellosilk; the primary cellosilk is placed at the room temperature for 24-48 hours and washed in a clear water tank; through dryingand hyperthermal stretching, the modified ultra-high molecular weight polyethylene fiber is obtained. According to the method, on the premise of guaranteeing that the mechanical property of the ultra-high molecular weight polyethylene fiber is not lowered, the polarity of the surface of the fiber is improved, the good cohesiveness between the ultra-high molecular weight polyethylene fiber and a resin base is achieved, and the application range of the ultra-high molecular weight polyethylene fiber in the aspect of structural materials is enlarged.

Owner:NANJING UNIV OF TECH

Adjustment mechanism for furniture drawers

An adjusting mechanism of a furniture drawer comprises side plates, a bottom plate, a back plate, a front plate and slide rail components used for opening and closing the drawer. Rear connectors and front connectors used for connecting the back plate with the front plate are arranged at the front end and the rear end of each side plate respectively, each slide rail component at least comprises a pull-out rail, a stabilizing portion is arranged at the rear end of each pull-out rail, a cavity is arranged in each side plate, each rear connector is fixedly arranged in the corresponding cavity and slidably provided with an adjusting element, and each adjusting element is supported on each pull-out rail and plays a positioning role on the corresponding stabilizing portion; an adjusting device is arranged in the lower region of the cavity of each side plate and at least provided with a screw gear part, and one end of each screw gear par is rotationally connected with the corresponding adjusting element in a threaded manner while the other end is rotationally positioned on each adjusting device. By gear drive, the side plates are enabled to move up and down relative to the adjusting elements, the inclination angle of the drawer relative the pull-out rails is adjusted, and practicality is high.

Owner:伍志勇

Adjustable mechanism for drawer main body and furniture main body

The invention relates to an adjustable mechanism for a drawer main body and a furniture main body. The adjustable mechanism for the drawer main body and the furniture main body comprises a sliding rail assembly, the furniture main body and the drawer main body, wherein the sliding rail assembly is formed by fixed sliding rails and movable sliding rails through assembling, the fixed sliding rails are fixedly arranged on the left and right side walls of the furniture main body, and the drawer main body is detachably arranged on the movable sliding rails; the drawer main body comprises side plates, a rear back plate, a bottom plate and a front face plate, rear connecting devices for connecting with the rear back plate are arranged at the rear ends of the side plates, supporting portions are vertically arranged on the inner sides of the side plates in an extending manner, the bottom plate acts on the supporting portions, and the supporting portions act on the movable sliding rails; operating elements are arranged in the bottom areas of the side plates, each rear connecting device at least comprises an adjusting element, and fixed portions are arranged at the rear ends of the movable sliding rails; the adjusting elements are slidably arranged on the rear connecting devices, act on the movable sliding rails and are located and connected with the fixed portions, and the operating elements are matched and connected with the adjusting elements and are arranged in the bottom areas of the side plates. By rotating or pulling the operating elements, the position adjustment between the drawer main body and the furniture main body is realized.

Owner:伍志勇

Accumulator charger based on high frequency bus

InactiveCN101051761BExtend your lifeLow costBatteries circuit arrangementsElectric powerElectrical devicesEngineering

Owner:杭州迪源电气科技有限公司

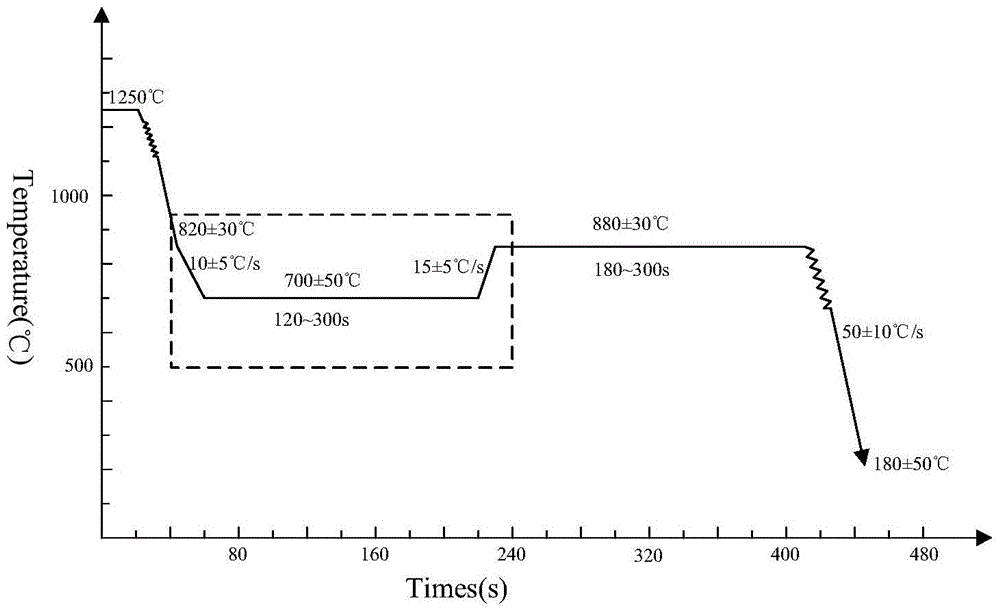

A short-process integrated manufacturing method for rolling and deep processing of high-strength steel automobile plates

A rolling and deep-processing short-process integrated manufacturing method of a high-strength steel automobile sheet includes following steps: heating raw materials in a heating furnace, performing controlled rolling including crude rolling and finish rolling, laminar cooling the rolled raw material, performing comprehensive blanking, heating the obtained sheet material, moulding and quenching the sheet material, performing a cutting process and a shot blasting process to obtain a finished product. The raw material is heated to more than 1250 DEG C in the heating furnace. A finish rolling temperature is 820 + / - 30 DEG C. The rolled sheet material is cooled to the temperature of 700 + / - 50 DEG C at a temperature decreasing rate of 10 + / - 5 DEG C / s, wherein the temperature is maintained for 2-5 min. The sheet material is heated to 880 + / - 30 DEG C at a temperature increasing rate of 15 + / - 5 DEG C / s in a continuous heating furnace with temperature maintenance for 3-5 min. The stamping and quenching member is subjected to stamping and quenching at the same time, wherein the flow velocity of cooling water in a stamping and quenching die is 50 + / - 10 DEG C / s. The stamped and quenched member is cooled to 180 + / - 50 DEG C / s to obtain a super-high strength steel part in a homogeneous martensitic structure, wherein the strength of extension can reach higher than 1500 MPa. The method can produce the high-strength steel automobile sheet at a high quality and a high efficiency, can reduce cost, can promote comprehensive utilization of secondary energy sources such as low-temperature waste heat and the like, can achieve integrated production from raw materials to the product, and can achieve energy saving, consumption reducing and environment protecting.

Owner:YANSHAN UNIV

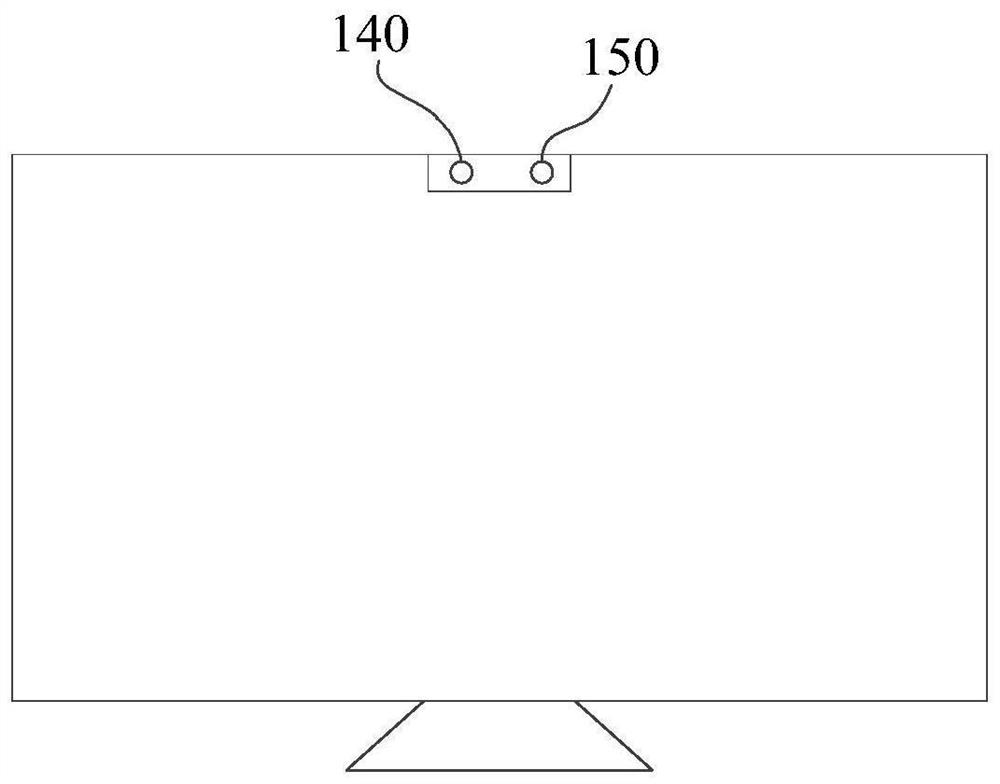

Hot-plugging type touch screen

ActiveCN104820525AFacilitate integrated productionGood radiation protection effectInput/output processes for data processingPolarizerPhase compensation

The invention provides a hot-plugging type touch screen. The hot-plugging type touch screen comprises a main screen and an outer sealing anti-vibration frame, wherein the outer sealing vibration-preventing frame sheathes the main screen and is used for preventing vibration; the main screen comprises a phase compensation layer, a PET layer, a polarizing piece, a transparent isolating point layer, a vibration-preventing buffering area, a reflective film plating layer, a signal transmission screen and a touch sensing screen; the PET layer is arranged at the front end of the phase compensation layer and is connected with the phase compensation layer by a circuit; the polarizing piece is arranged at the front end of the PET layer; the transparent isolating point layer is arranged at the front end of the polarizing piece; the vibration-preventing buffering area is arranged at the front end of the transparent isolating point layer; the reflective film plating layer is arranged at the front end of the vibration-preventing buffering area; the signal transmission screen is arranged at the front end of the reflective film plating layer; and the touch sensing screen is arranged at the front end of the signal transmission screen and is connected with the signal transmission screen by a circuit.

Owner:YANCHENG HUAXU OPTOELECTRONICS TECH CO LTD

Segmental anti-cracking touch screen

ActiveCN104820524AFacilitate integrated productionEasy maintenanceInput/output processes for data processingTouch SensesPolarizer

The invention provides a segmental anti-cracking touch screen. The segmental anti-cracking touch screen comprises a main screen, an externally sealed vibration-proof frame arranged outside the main screen in a sheathing manner, wherein the main screen comprises a phase compensation layer, a PET layer arranged at the front end of the phase compensation layer and connected with the phase compensation layer electrically, a polarizer arranged at the front end of the PET layer, a transparent isolation point layer arranged at the front end of the polarizer, a vibration-proof buffer area arranged at the front end of the transparent isolation point layer, a reflecting film coating arranged at the front end of the vibration-proof buffer area, a signal transmission screen arranged at the front end of the reflecting film coating, and a touch sensing screen arranged at the front end of the signal transmission screen and electrically connected with the signal transmission screen.

Owner:江苏智光创业投资有限公司

A method for surface modification of ultra-high molecular weight polyethylene fibers

ActiveCN110541207BEasy to manufactureLow costMonocomponent polyolefin artificial filamentArtifical filament manufactureFiberPolymer science

The invention discloses a method for surface modification of ultra-high molecular weight polyethylene. The specific steps are as follows: firstly add ultra-high molecular weight polyethylene powder into a solvent, perform swelling pretreatment, and then add bipolar molecular modification to the swelling solution. The swelling mixed solution is obtained by using additives, antioxidants and ultraviolet absorbers, and then the ultra-high molecular weight polyethylene swelling mixed solution is evenly fed to the twin-screw extruder for gel spinning; the gel filaments are sprayed from the spinneret into the The primary fiber filaments were obtained in a water bath; the primary fiber filaments were placed at room temperature for 24-48 hours, and then washed in a clear water tank; after drying, super-heated stretching was performed to obtain modified ultra-high molecular weight polyethylene fibers. On the premise of ensuring that the mechanical properties of ultra-high molecular weight polyethylene fibers do not decrease, the invention improves the polarity of the fiber surface, realizes good adhesion between ultra-high molecular weight polyethylene fibers and resin matrix, and expands the use of ultra-high molecular weight polyethylene fibers in structural materials. aspects of application.

Owner:NANJING TECH UNIV

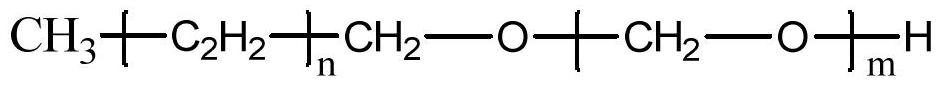

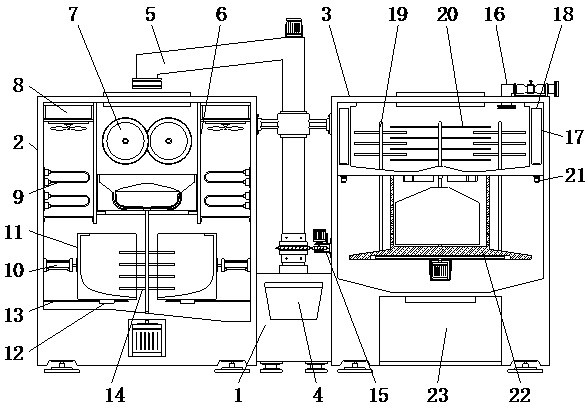

Antibacterial feed processing device for healthy livestock and poultry breeding and preparation process

InactiveCN112293775AFacilitate integrated productionImprove processing efficiencyFeeding-stuffWorking-up animal fodderBiotechnologyEngineering

The invention discloses antibacterial feed processing device for healthy livestock and poultry breeding and a preparation process. The antibacterial feed processing device comprises a storage box, a protective cover and a water inlet pipe, wherein the left side and the right side of the storage box are fixedly provided with a processing box and a granulating box respectively; the protective coveris fixedly installed in the processing box; the water inlet pipe is installed on the upper surface of the granulating box in a penetrating mode; a side stirring rod and a middle stirring rod are rotatably installed in a fermentation tank; a discharge port is reserved in the lower end of the granulating box; a collecting tank is installed in the protective cover; and a circular groove is formed inthe side surface of a granulating tank. According to the antibacterial feed processing device for healthy livestock and poultry breeding and the preparation process, a novel structural design is adopted, so that the device combines grinding, mixed fermentation and granulation processes in integrated equipment, and feed is convenient to produce; and a material conveying structure of a rotating structure is arranged in the device, so that materials are convenient to convey between processing structures, and the processing efficiency of the device is improved.

Owner:徐凯

Hot-swappable touch screen

ActiveCN104820525BFacilitate integrated productionEasy maintenanceInput/output processes for data processingPolarizerShock front

The present invention provides a hot-swappable touch screen, which includes a main screen and an outer sealed shockproof frame set outside the main screen for shockproof; the main screen includes a phase compensation layer, which is arranged at the front end of the phase compensation layer and connected to the phase compensation layer circuit PET layer, a polarizer arranged at the front end of the PET layer, a transparent isolation point layer arranged at the front end of the polarizer, an anti-shock buffer area arranged at the front end of the transparent isolation point layer, and a reflective film coating arranged at the front end of the anti-shock buffer area . A signal transmission screen disposed at the front end of the reflective film coating, and a touch sensitive screen disposed at the front end of the signal transmission screen and connected to the circuit of the signal transmission screen.

Owner:YANCHENG HUAXU OPTOELECTRONICS TECH CO LTD

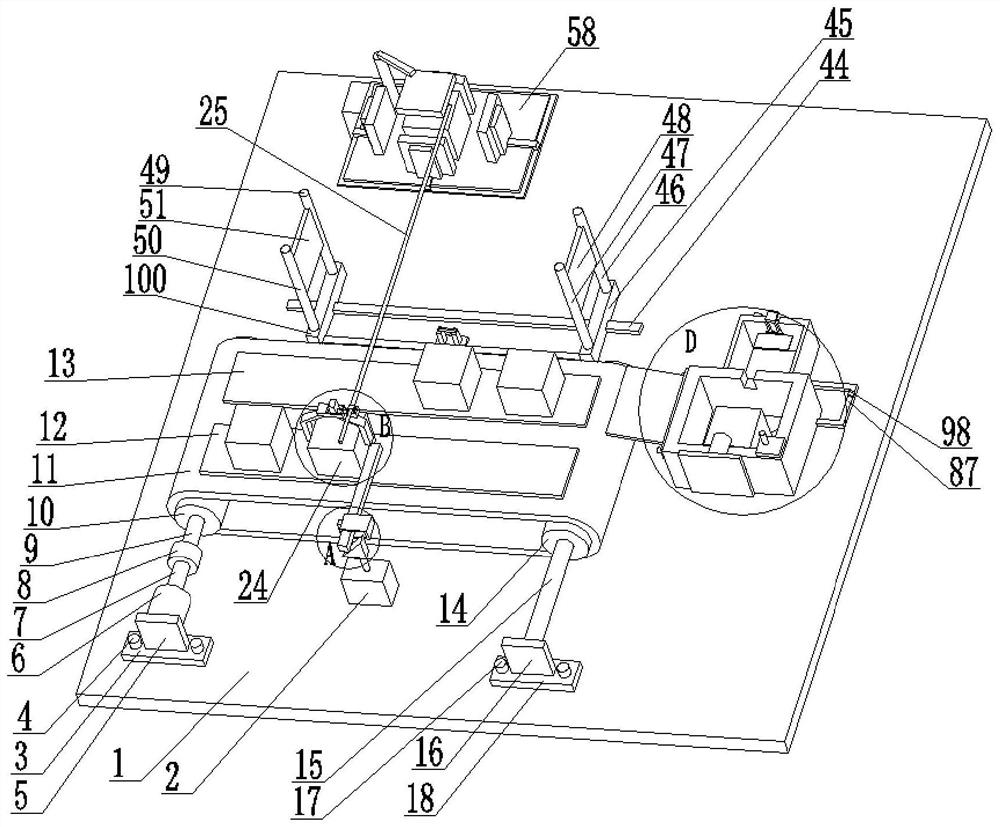

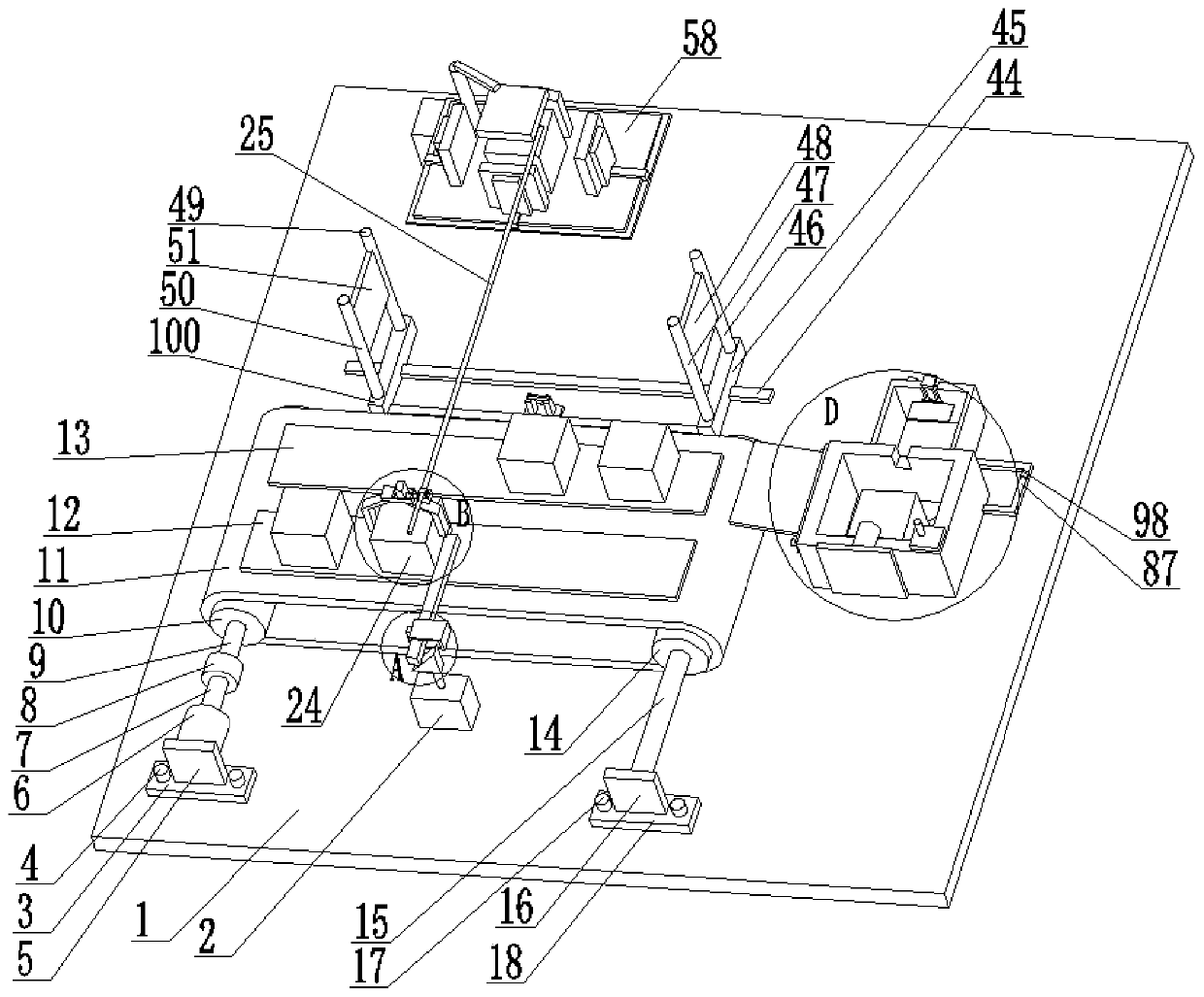

A vacuum automatic packaging forming machine

ActiveCN110979854BFirmly connectedEasy inspection and maintenancePackaging automatic controlPackaging under special atmospheric conditionsRotational axisDrive wheel

The invention provides a vacuum automatic packaging forming machine, which includes a substrate, a monitor, and a lower forming plate. The rear side of the top surface of the substrate is respectively fixed with a first bottom plate, a second series of bolt groups, and a first bottom plate. The second bottom plate, the power output end of the engine is provided with a rotating shaft, the rotating shaft is connected with the first shaft through a connector, the front end of the first shaft is provided with a driving wheel, the front end of the second shaft is provided with a driven wheel, the driving wheel, the driven wheel Contact and cooperate with the inner surface of the left and right ends of the conveyor belt respectively. The top surface of the conveyor belt is arranged with a storage belt to be measured and a storage belt to be packaged from front to back. Items whose volume is to be measured. The technical solution disclosed by the invention effectively solves the technical problems in the prior art that there is no automatic feeding capability and that the forces around the molding are different in size, which is beneficial to the popularization and application of the device.

Owner:爱博斯塑料(合肥)有限公司

A concealed adjustment device for a furniture drawer

A furniture drawer hidden adjusting device comprises a frame, a base plate, a rear plate, a front panel and a sliding rail assembly. The adjusting device is arranged on the frame and used for adjusting rising and lowering of the frame relative to the sliding rail assembly. A bearing portion connected with a pulling rail of the sliding rail assembly in a matching mode is arranged on the adjusting device, and an operation part is arranged on a bottom area of the adjusting device facing the frame. The bearing part achieves vertical movement of the frame relative to the pulling rail by rotating or wrenching the operation part. By means of structure improvement, the operation part of the adjusting device is arranged in a U-shaped area of the frame in a hidden mode, and the hiding performance of the adjusting device is effectively improved. Meanwhile, a user can adjust the operation part of the adjusting device on the U-shaped area of the frame through a tool or manually to enable the guide portion of the adjusting device to move vertically and linearly relative to the guide matching portion of a rear connection device, finally adjustment of inclination position of the frame relative to the sliding rail assembly is achieved, and the practicability is high.

Owner:伍志勇

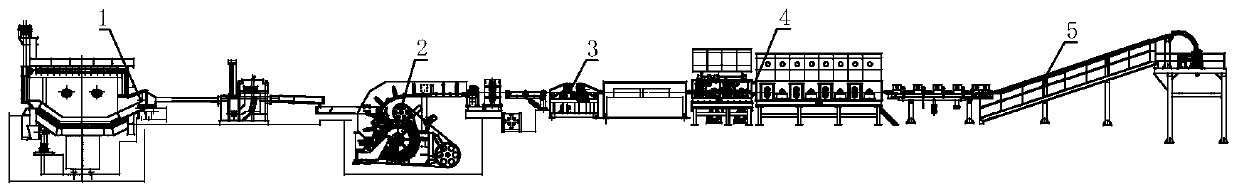

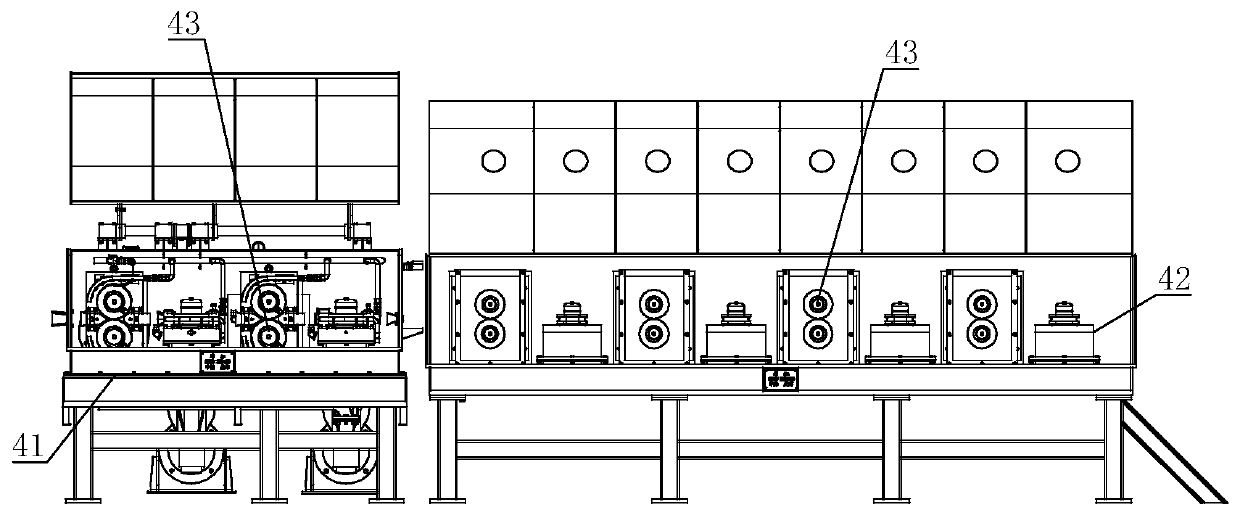

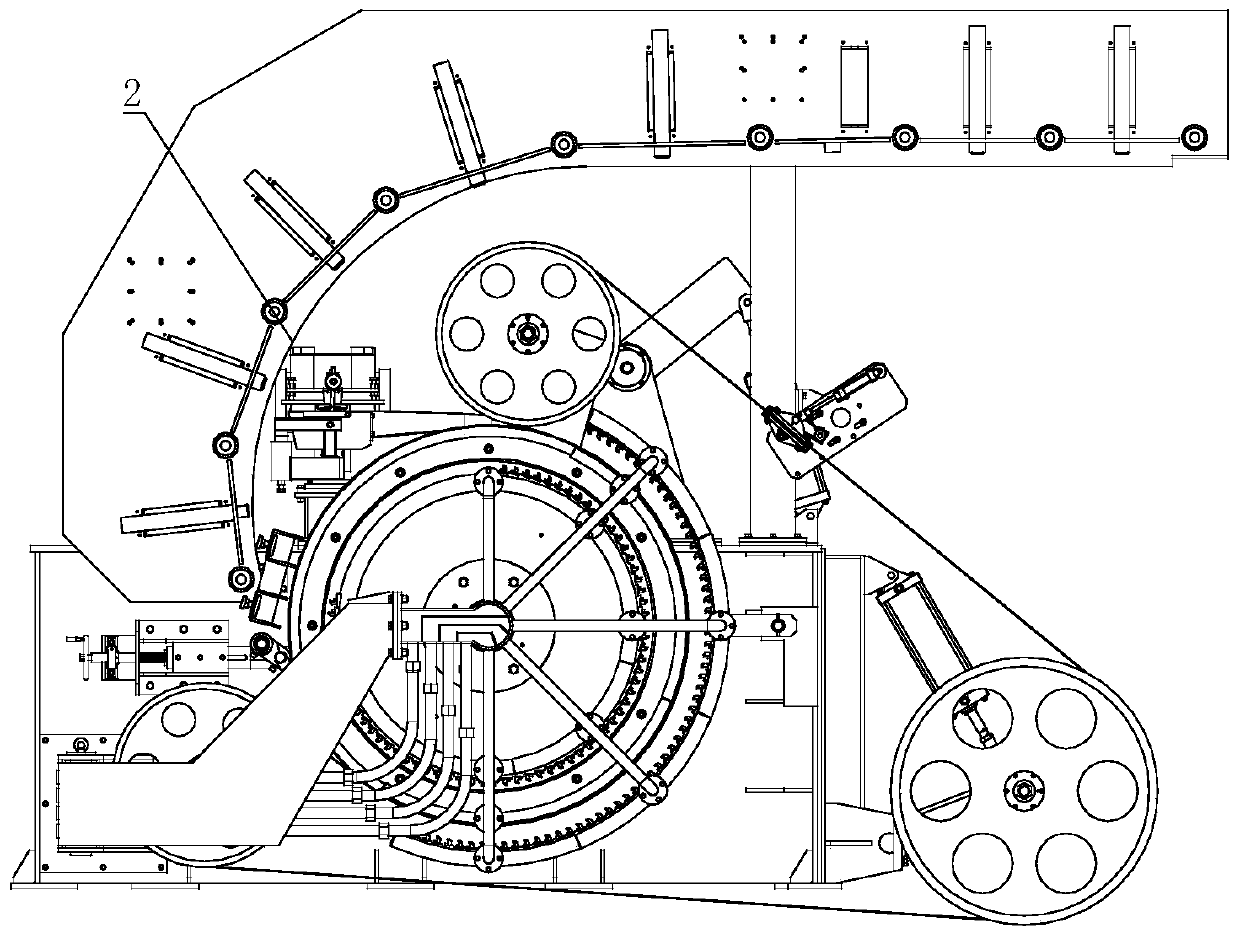

A 5356 aluminum alloy rod continuous casting and rolling production system

The invention relates to the field of aluminum alloy rod production, in particular to a 5356 aluminum alloy rod continuous casting continuous rolling production system. According to the technical scheme, the 5356 aluminum alloy rod continuous casting continuous rolling production system comprises a smelting system, a casting machine, a rolling pre-processing system, a rolling system and a windingsystem which are sequentially arranged. The rolling system comprises four rough rolling mills and eight fine rolling mills. The ends, away from the eight fine rolling miss, of the four rough rolling miss are close to the rolling pre-processing system. The ends, away from the four rough rolling mills, of the eight fine rolling mills are close to the winding system. A plurality of rollers are arranged at the four rough rolling mills and the eight fine rolling mills. Rolling grooves are formed in the rollers. Ovality of the rolling grooves sequentially decreases in the moving direction of a 5356aluminum alloy rod. The ovality of the rolling groove of the roller next to the winding system is zero. The invention provides a continuous casting continuous rolling production system capable of producing the 5356 aluminum alloy rod and enabling the 5356 aluminum alloy rod to be with the good lattice structure.

Owner:CHENGDU SHUHONG EQUIP MFG

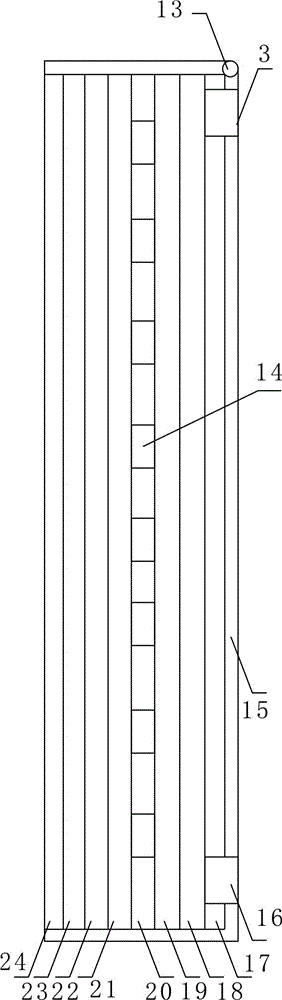

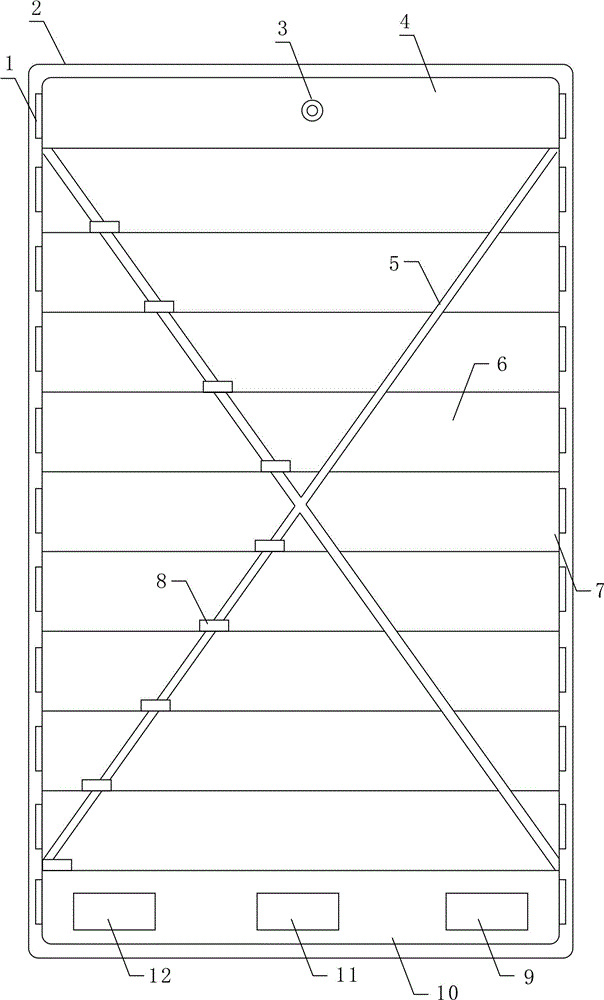

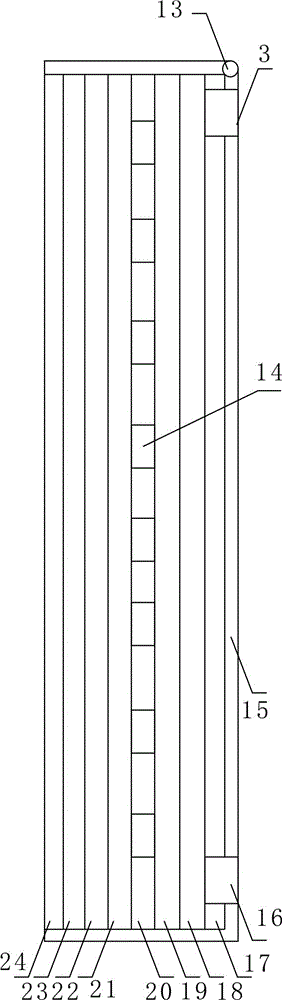

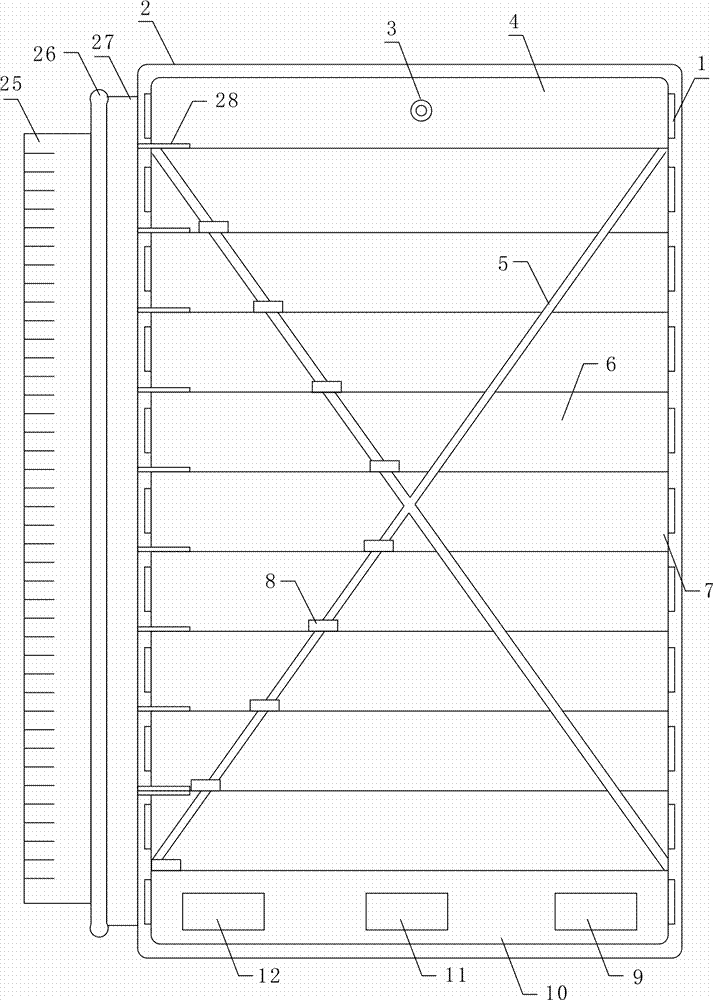

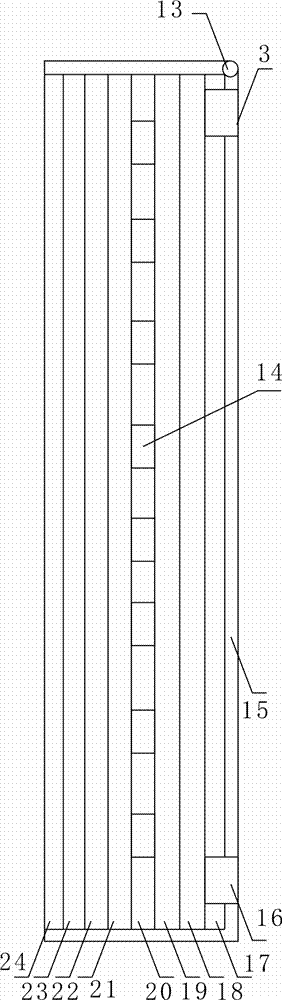

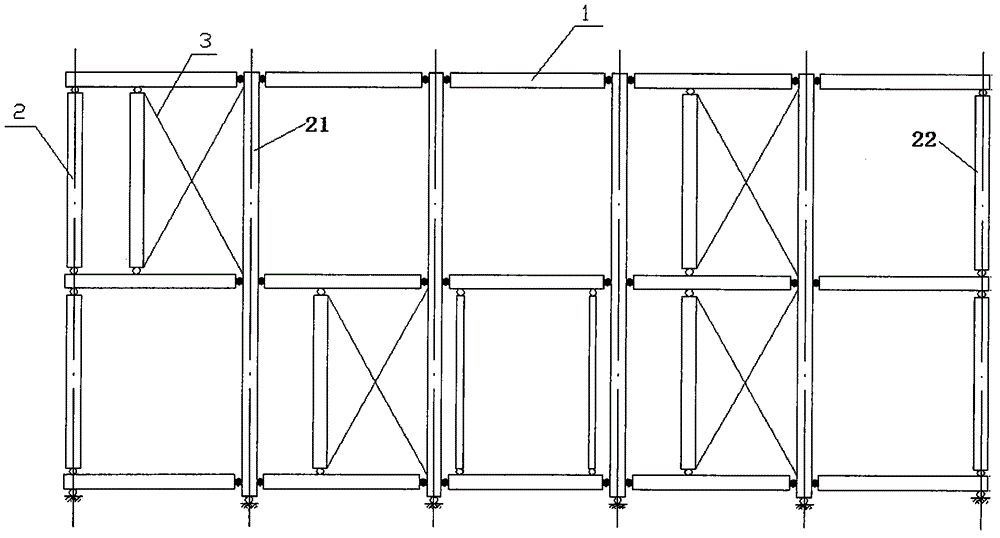

Partial layered assembling type steel-structure low-rise residential system

InactiveCN104675148ALow costImprove construction efficiencyBuilding constructionsDwelling buildingArchitectural engineeringPurchasing

The invention provides a partial layered assembling type steel-structure low-rise residential system which can lower material cost and increase building efficiency. The partial layered assembling type steel-structure low-rise residential system comprises a plurality of standing columns, crossbeams and support parts. The crossbeams are disposed on each layer among the standing columns. The support parts are disposed among the crossbeams. The standing columns include through columns and interlayer columns. The interlayer columns are disposed on the periphery pf the system. The through columns are disposed inside the system. The partial layered assembling type steel-structure low-rise residential system has the advantages that the beams, the columns and the support parts are standard components, factory integrated production is facilitated, and material purchasing cost is lowered; modularized building is used, the beams, columns and the support parts are connected through bolts, construction period is shortened, and building efficiency is increased.

Owner:北京津西赛博思建筑设计有限公司 +2

Vacuum automatic packaging forming machine

ActiveCN110979854AFirmly connectedEasy inspection and maintenancePackaging automatic controlPackaging under special atmospheric conditionsRotational axisDrive wheel

The invention provides a vacuum automatic packaging forming machine. The vacuum automatic packaging forming machine comprises a substrate, a monitor and a lower forming plate. A first bottom plate anda second bottom plate are fixed to the rear side of the surface of the top of the substrate through a first series bolt set and a second series bolt set. The power output end of an engine is providedwith a rotating shaft. The rotating shaft is connected with a first shaft through a connector. The front end of the first shaft is provided with a driving wheel. The front end of a second shaft is provided with a driven wheel. The driving wheel and the driven wheel are correspondingly in contact fit with the inner surfaces of the left end and the right end of a conveying belt. A to-be-measured storage belt and a to-be-packaged storage belt are arranged on the surface of the top of the conveying belt from front to back. The to-be-packaged storage belt and the to-be-measured storage belt are provided with a to-be-packaged-and-formed article and a packaged and formed article with the volume to be measured correspondingly. According to the technical scheme, the vacuum automatic packaging forming machine effectively solves the technical problems that in the prior art, the automatic feeding capacity is not achieved, and surrounding acting forces are not equal in value during forming are effectively solved. Popularization and application of the vacuum automatic packaging forming machine are facilitated.

Owner:汪秀英

Improved drawer adjusting structure

PendingCN111789423ALow production costSimplify the assembly processDrawersMetallic materialsEngineering

The invention provides an improved drawer adjusting structure which comprises a side plate, a cavity is formed in the side plate, and the lower portion of the side plate is integrally formed or provided with a connecting part in a split mode, wherein a rear connecting piece is arranged at the rear end of the cavity, the rear connecting piece is made of plastic, a movable piece is arranged on the rear connecting piece, the movable piece is made of plastic, an adapter piece made of a metal material is arranged on the movable piece, an adjusting assembly is arranged below the connecting part, andthe adjusting assembly is in driving connection with the adapter piece; the adjusting assembly is acted through a tool or manually, and the rear connecting piece is at least driven to move up and down relative to the movable piece and the adapter piece. According to the invention, the structure is improved; the driving stability between the adapter piece and the adjusting assembly can be improved, meanwhile, as the adjusting assembly is arranged below the connecting part in a hidden mode, the touch of a user can be avoided, the drawer is safer and more reliable in use and more exquisite and simpler in appearance, and the adjustment and positioning between the rear connecting piece and the movable piece and between the rear connecting piece and the adapter piece can be more stable, accurate and firm.

Owner:GUANGDONG DTC HARDWARE PRECISION MFG CO LTD

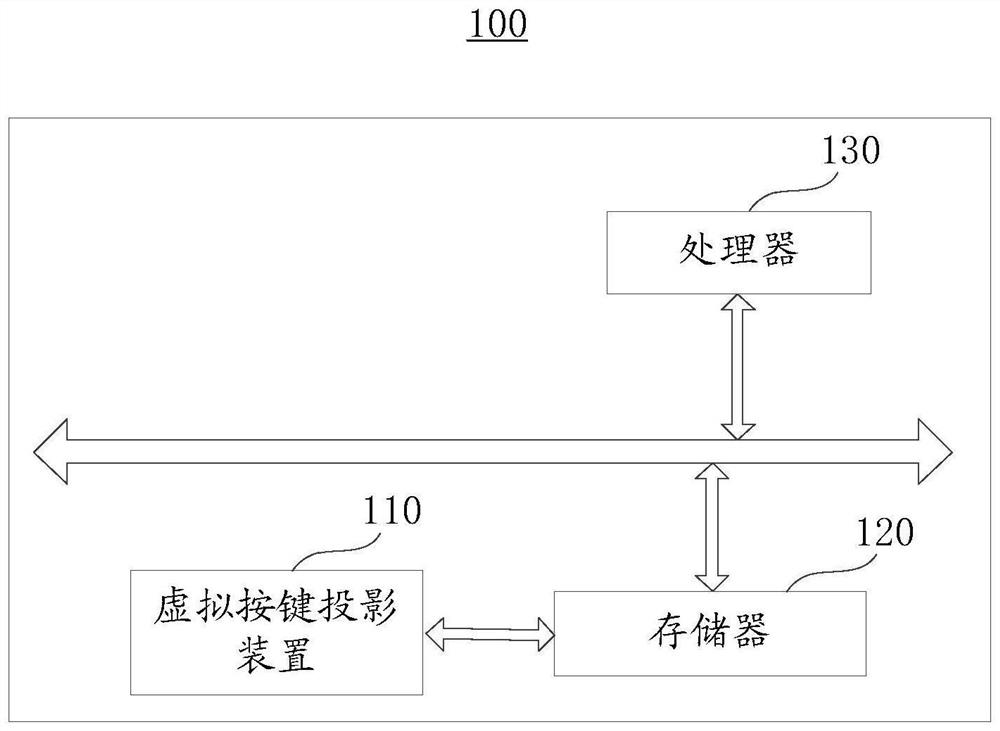

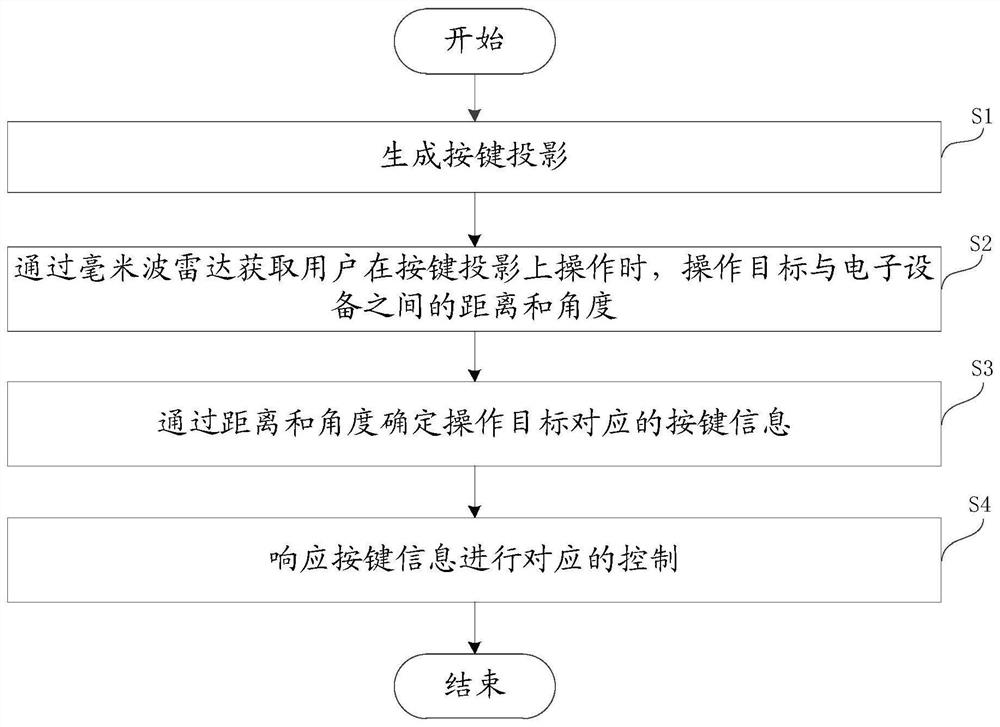

Virtual key projection method and device based on millimeter wave radar, and electronic equipment

PendingCN113822795AGuaranteed operating accuracyFacilitate integrated productionInput/output for user-computer interactionImage enhancementKey pressingTelecommunications

The embodiment of the invention provides a virtual key projection method and device based on millimeter wave radar, a storage medium and electronic equipment. The key projection is generated, the key information corresponding to the operation target is determined based on the distance and the angle between the operation target and the electronic equipment, and the distance and the angle are collected by the millimeter wave radar, and finally corresponding control is carried out according to the determined key information. According to the embodiment of the invention, physical keys of traditional electronic equipment are replaced, the operation accuracy of the generated virtual keys is ensured, integrated production of the electronic equipment is facilitated, the production and operation cost is reduced, and meanwhile, the use cost of a user is reduced.

Owner:HUIZHOU VISION NEW TECH CO LTD

Unloading device convenient for textile fabrics

The invention discloses an unloading device convenient for textile fabrics. The unloading device comprises a base, a box, an extension plate, a first electric push rod, a blade, the textile fabrics, abaffle plate, a switch, a top plate, a chute, a slide plate, a spring, a connecting plate, a scraper, a side plate, a fixed plate, a second electric push rod, a push plate, a support block, a limiting plate, a winding drum and a round plate. The unloading device convenient for the textile fabrics is simple in structure and convenient to operate; the textile fabrics are wound by the winding drum;through movement of the push plate, the winding and the unloading of the textile fabrics on the winding drum are facilitated, so that the problem of workload increment caused by manual unloading is solved, the working efficiency is improved, and the labor intensity is relieved; through contact with the surfaces of the textile fabrics by the scraper, the unloading device convenient for the textilefabrics facilitates removal of dust on the textile fabrics, effectively removes the dust, and improves the quality of the textile fabrics; and after the textile fabrics are wound, the unloading is performed through movement of the push plate, so that the operation procedures are reduced.

Owner:WUJIANG FUAILIANG TEXTILE

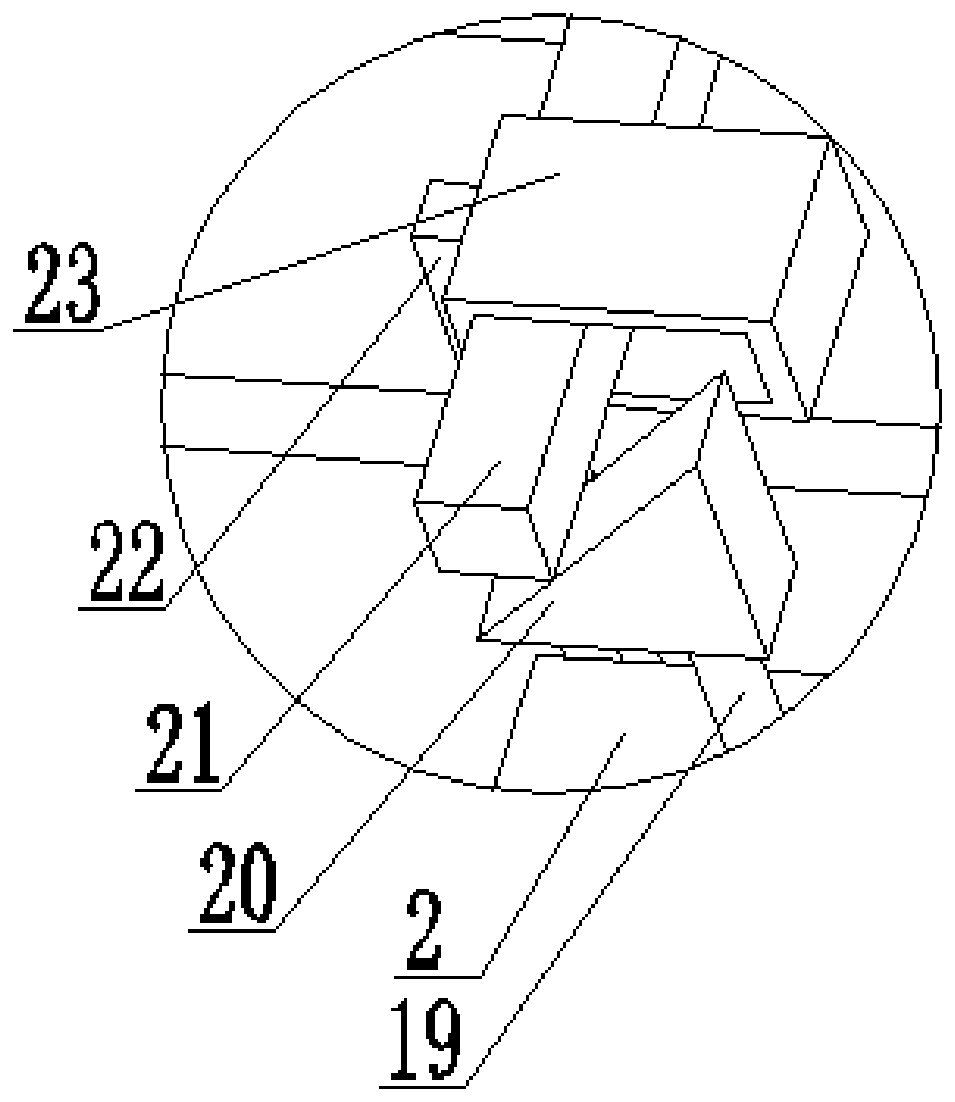

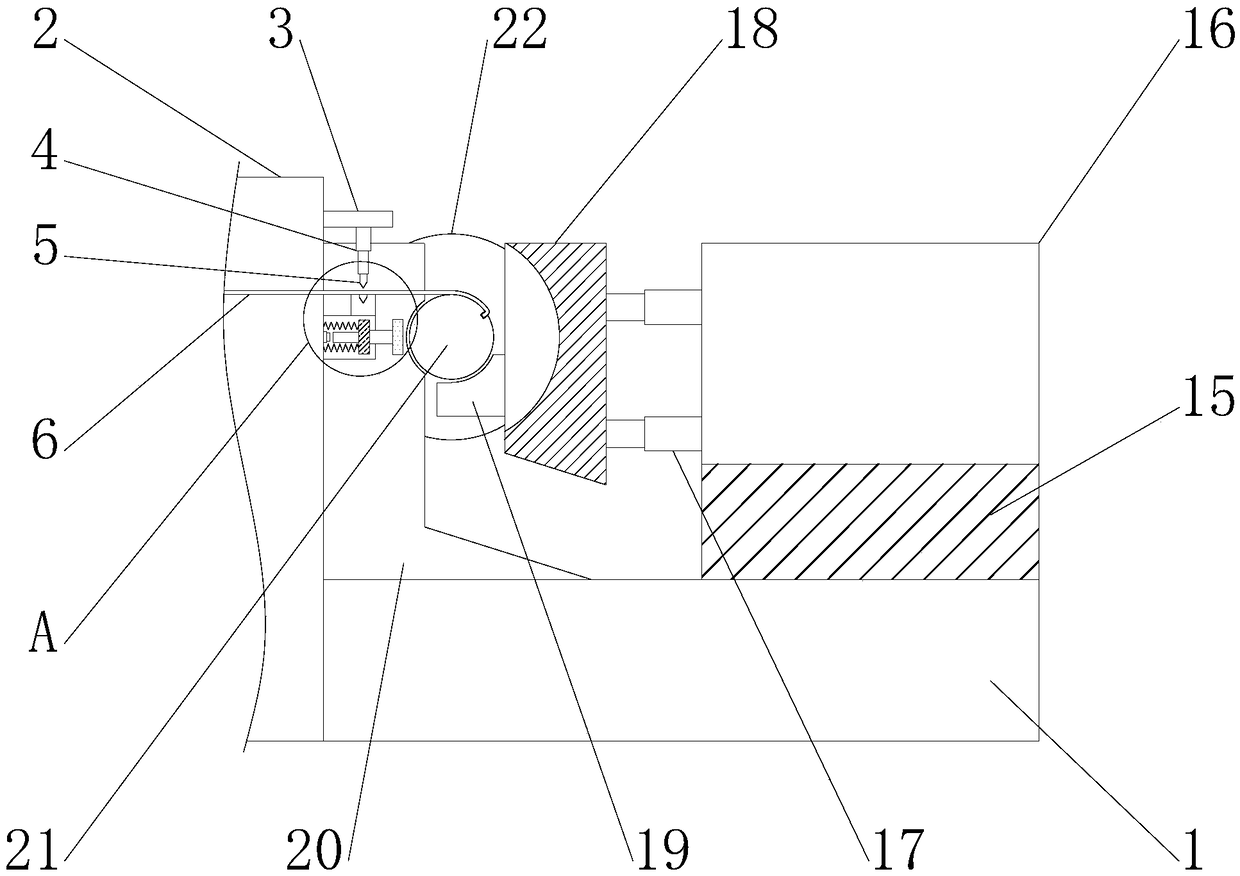

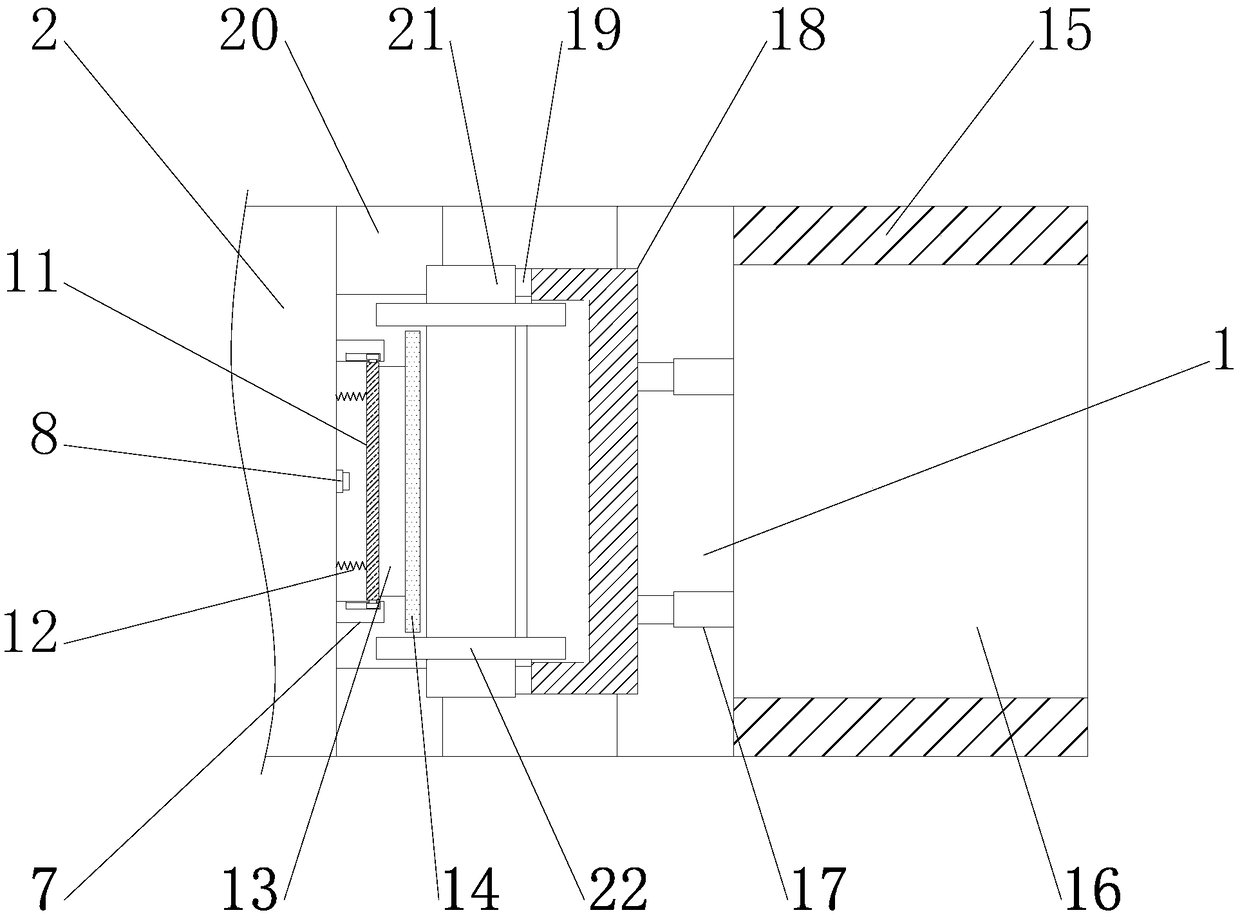

Simple and convenient adjustment structure of furniture hinge

PendingCN109458079AFacilitate integrated productionAvoid the disadvantages that can only be set on a fixed baseHingesEngineeringMechanical engineering

The invention relates to a simple and convenient adjustment structure of a furniture hinge. The furniture hinge at least includes a hinge arm and a connecting arm, the hinge arm is U-shaped, a slidingcavity is formed in the hinge arm, the connecting arm is arranged on the sliding cavity, and an eccentric adjusting member and a guiding member are arranged between the hinge arm and the connecting arm; the eccentric adjusting member rotates on the hinge arm in a positioned manner, and is in driven connection with the connecting arm during positioned rotating, and the guiding member is transversely arranged on the sliding cavity and the hinge arm; and the connecting arm does linear sliding on the sliding cavity through cooperation of the eccentric adjusting member and the guiding member. Through the improvement of the above structure, the disadvantage that an eccentric adjusting member in the prior art can only be arranged on a fixed base is overcome, the overall volume of the furniture hinge is reduced, the production cost is reduced, integrated production of the hinge is better facilitated, the compactness of connection of all components can be improved, the hinge look more beautiful, and practicability is high.

Owner:GUANGDONG DTC HARDWARE PRECISION MFG CO LTD

Adjustable mechanism of drawer body and furniture body

ActiveCN104643658BImprove concealmentFacilitate integrated productionDrawersEngineeringMechanical engineering

The invention relates to an adjustable mechanism for a drawer main body and a furniture main body. The adjustable mechanism for the drawer main body and the furniture main body comprises a sliding rail assembly, the furniture main body and the drawer main body, wherein the sliding rail assembly is formed by fixed sliding rails and movable sliding rails through assembling, the fixed sliding rails are fixedly arranged on the left and right side walls of the furniture main body, and the drawer main body is detachably arranged on the movable sliding rails; the drawer main body comprises side plates, a rear back plate, a bottom plate and a front face plate, rear connecting devices for connecting with the rear back plate are arranged at the rear ends of the side plates, supporting portions are vertically arranged on the inner sides of the side plates in an extending manner, the bottom plate acts on the supporting portions, and the supporting portions act on the movable sliding rails; operating elements are arranged in the bottom areas of the side plates, each rear connecting device at least comprises an adjusting element, and fixed portions are arranged at the rear ends of the movable sliding rails; the adjusting elements are slidably arranged on the rear connecting devices, act on the movable sliding rails and are located and connected with the fixed portions, and the operating elements are matched and connected with the adjusting elements and are arranged in the bottom areas of the side plates. By rotating or pulling the operating elements, the position adjustment between the drawer main body and the furniture main body is realized.

Owner:伍志勇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com