Microbial fertilizer vertical wind tunnel granulation blanking system and method

A vertical technology of microorganisms and fertilizers, which is applied in the field of microbial fertilizer preparation, can solve the problems of easy reaction changes and inability to meet fast and efficient air-drying operations, and achieve the effect of accelerating the effect of air cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

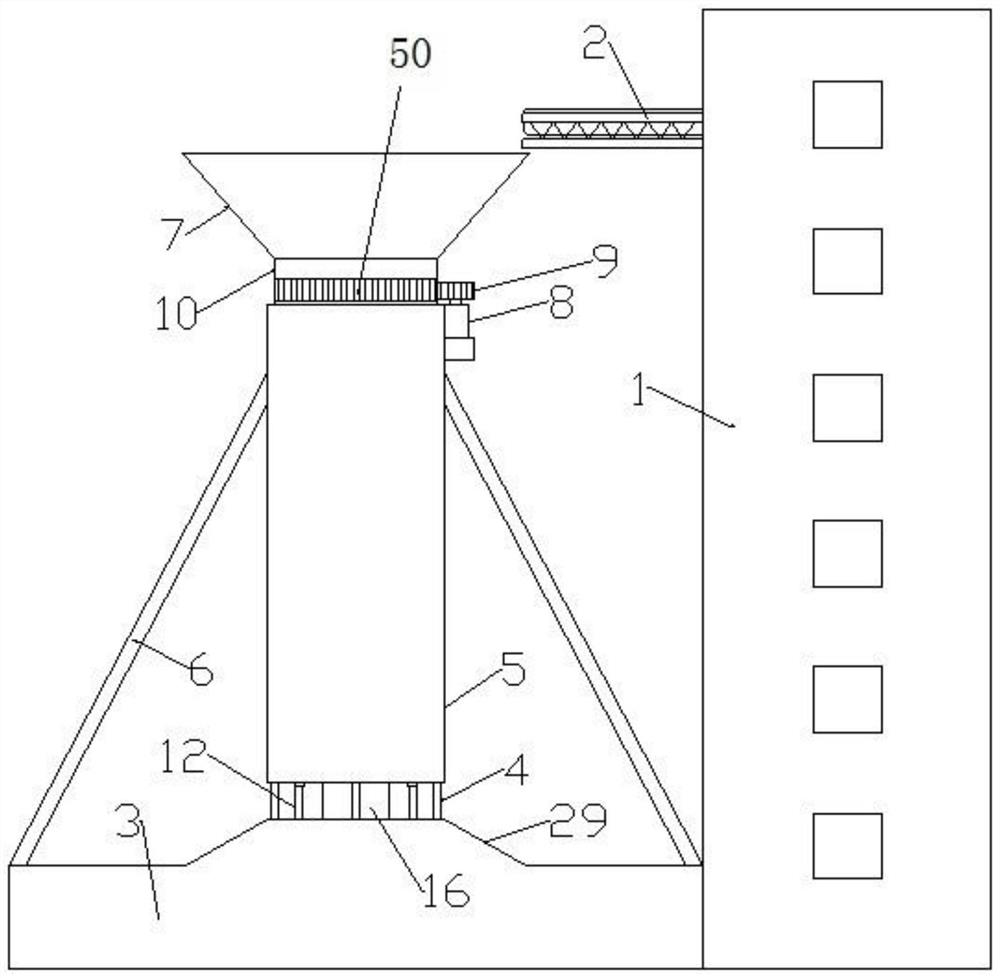

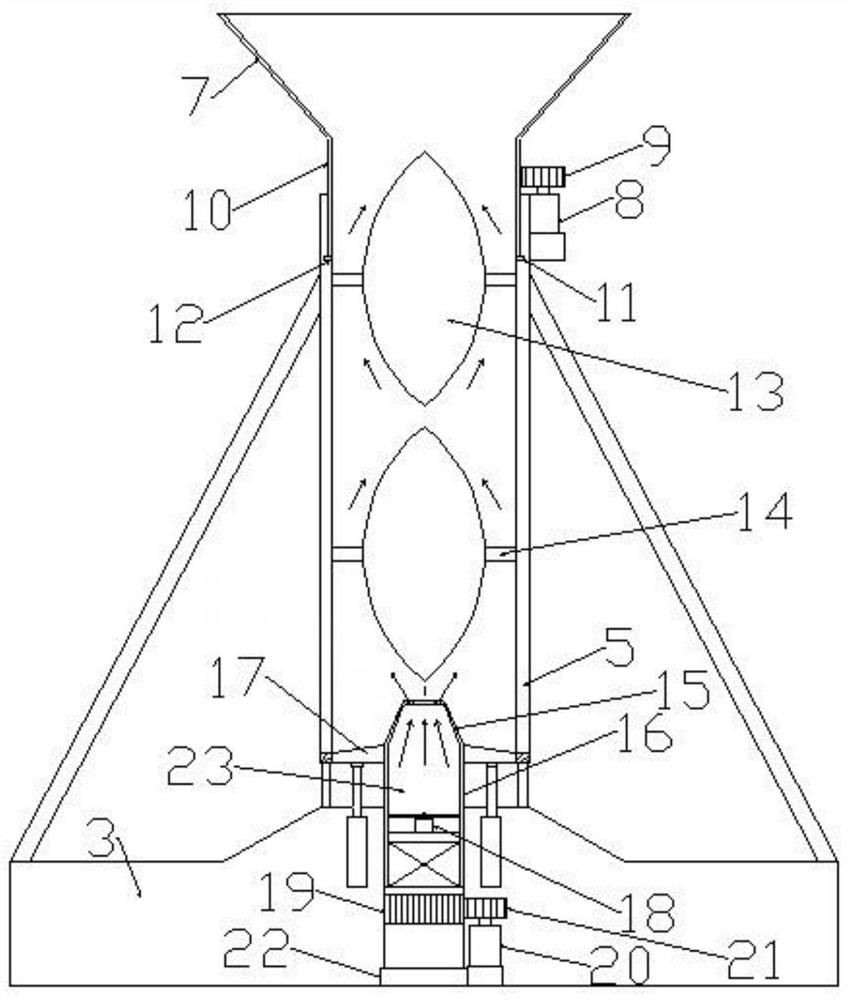

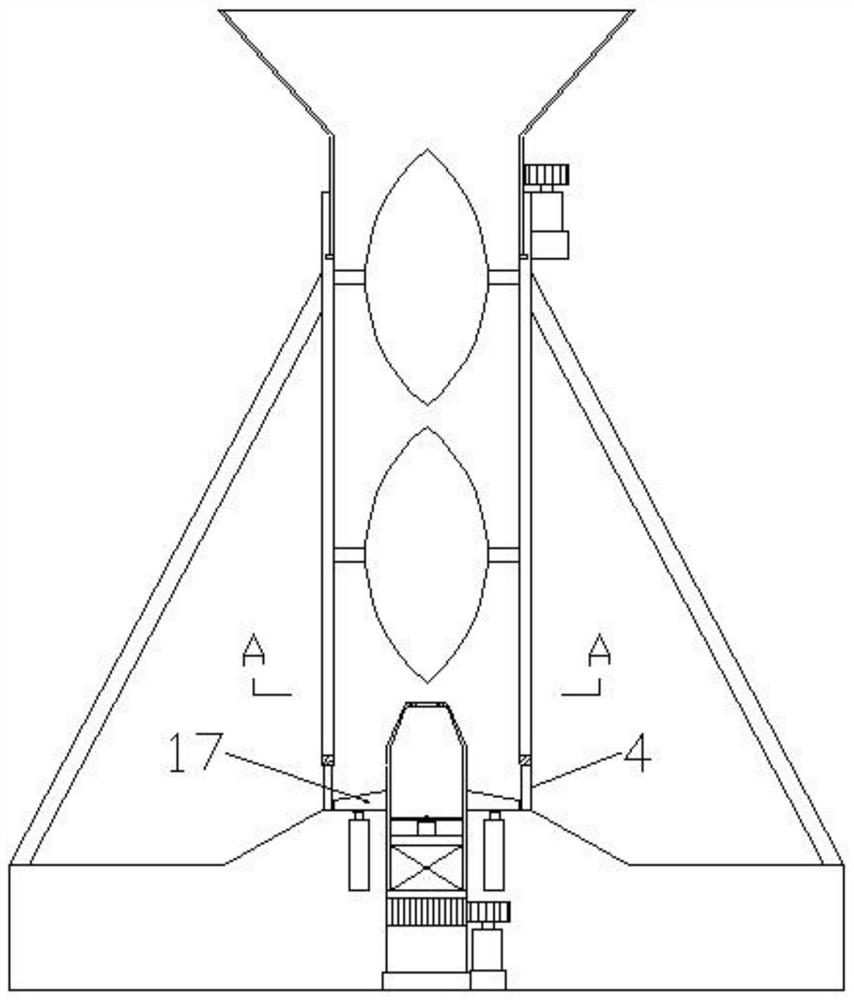

[0022] like figure 1 , 2 , 3, 4, 5, and 6, a vertical wind tunnel granulation and blanking system for microbial fertilizers, including raising the granulation preparation building 1, which is arranged on the top side of the raising granulation preparation building 1 and raised The granulation preparation building 1 is connected to the discharge conveyor belt 2, and the bottom of the discharge conveyor belt 2 is connected with a rotary rolling hopper 7, and the bottom of the rotary rolling hopper 7 is connected to the wind tunnel granulation device , The bottom of the wind tunnel granulation device is provided with a receiving platform 3 . The bottom of the rotating and rolling receiving hopper 7 is fixedly installed with a bottom supporting rotating cylinder 10, the bottom of the bottom supporting rotating cylinder 10 is fixedly equipped with a rotating bearing ring 11, and the rotating bearing ring 11 and the outer part of the bottom supporting rotating cylinder 10 are fitte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com