Patents

Literature

44results about How to "Protective ingredients" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

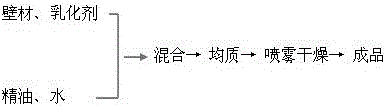

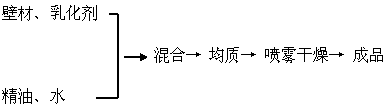

Herba origami essential oil microcapsule and preparation method thereof

ActiveCN106071074AOptimizing Process ParametersEasy to storeAnimal feeding stuffAccessory food factorsMonoglycerideSucrose

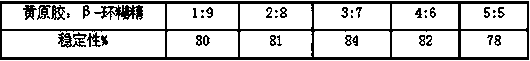

The invention provides a herba origami essential oil microcapsule which comprises a medicine core, a wall material and an emulsifying agent. Herba origami essential oil is adopted as the medicine core, a mixture of xanthan gum and beta-cyclodextrin is adopted as the wall material, and a mixture of monoglyceride and sucrose ester is adopted as the emulsifying agent. The invention further provides a preparation method of the herba origami essential oil microcapsule. According to the herba origami essential oil microcapsule and the preparation method thereof, it is determined that the herba origami essential oil serves as the medicine core, xanthan gum and beta-cyclodextrin serve as the wall material, and monoglyceride and sucrose ester serve as the emulsifying agent through tests, technological parameters of industrialized production are optimized, and the herba origami essential oil microcapsule meeting the national and international standards is obtained and can be widely applied to animal feed additives; the herba origami essential oil is processed through a spray drying method, the optimal technological formula and spray drying parameter are determined, microencapsulated products of the herba origami essential oil are developed and researched in order to better preserve the herba origami essential oil, protect functional ingredients of the herba origami essential oil, simplify the storage conditions of the herba origami essential oil and widen the application range of the herba origami essential oil, and therefore the herba origami essential oil microcapsule can replace antibiotics to achieve the bacterium resisting and growth promoting effects through feed adding.

Owner:河南华牧生物科技有限公司

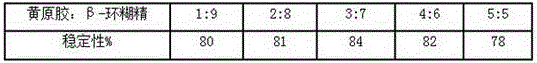

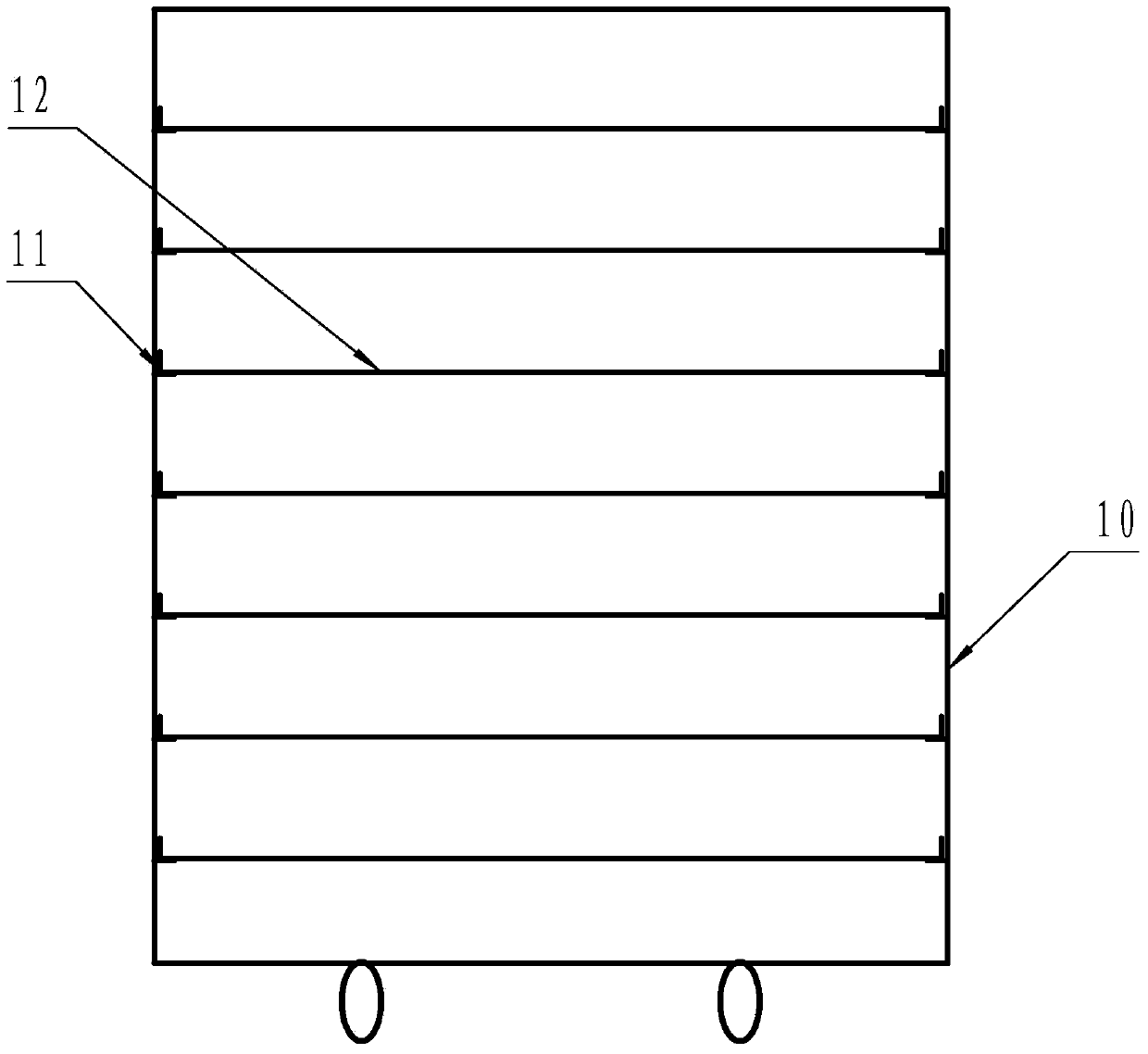

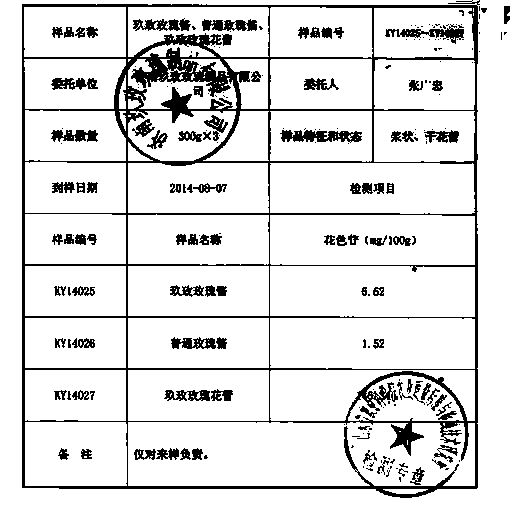

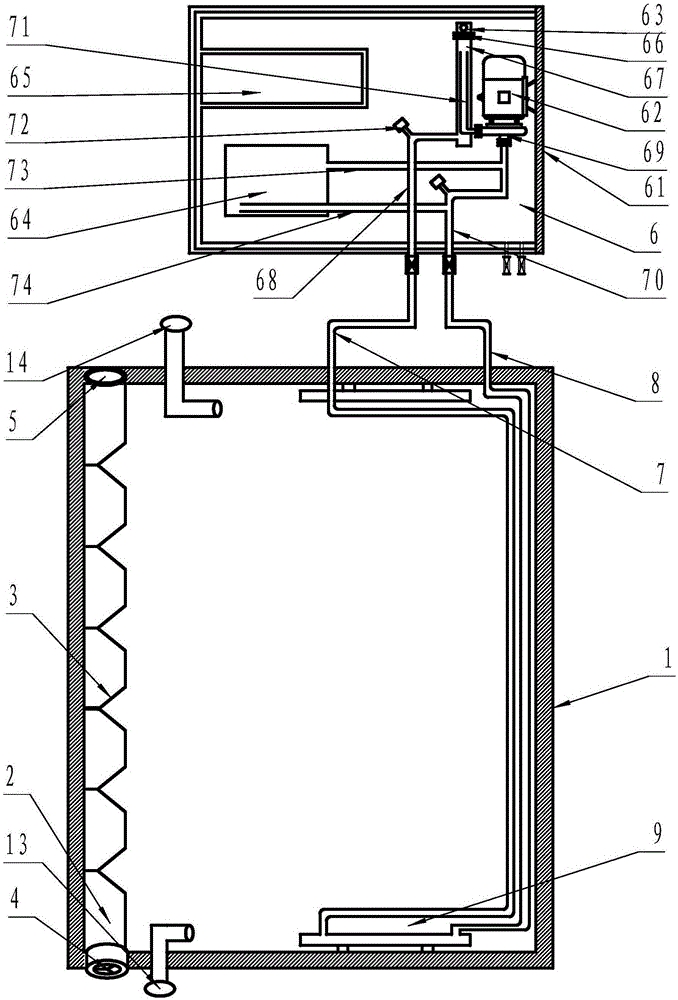

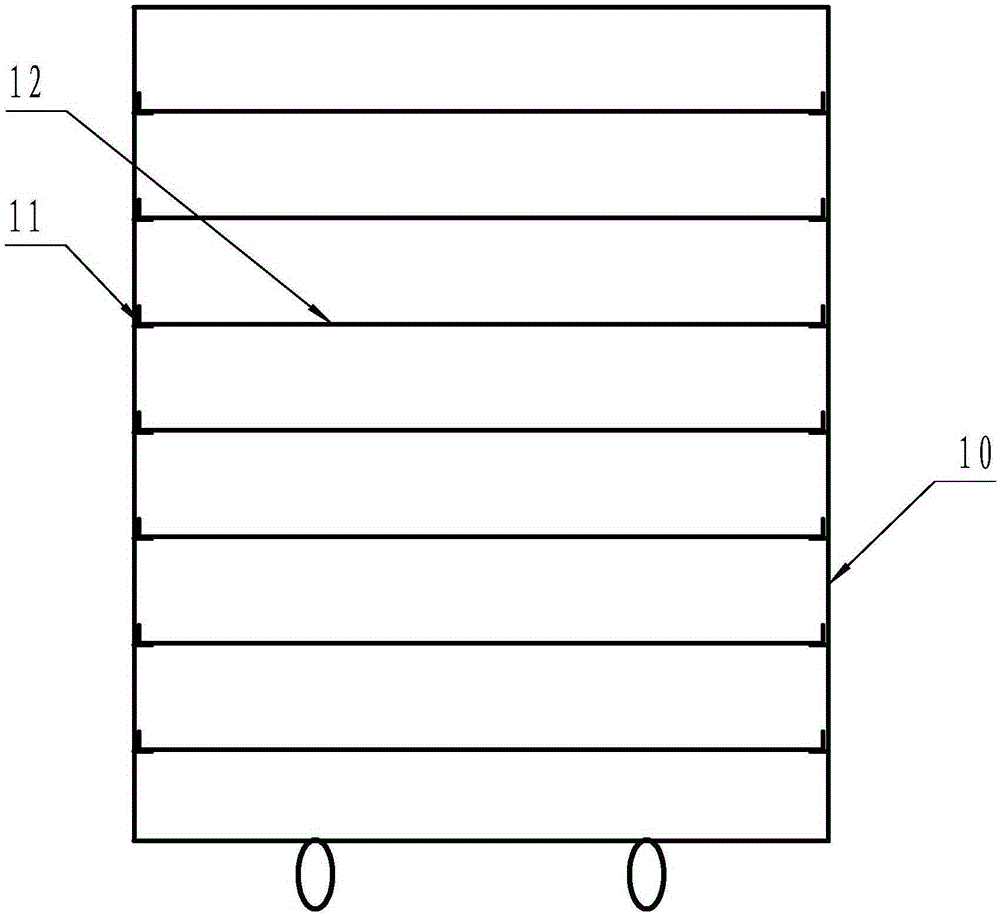

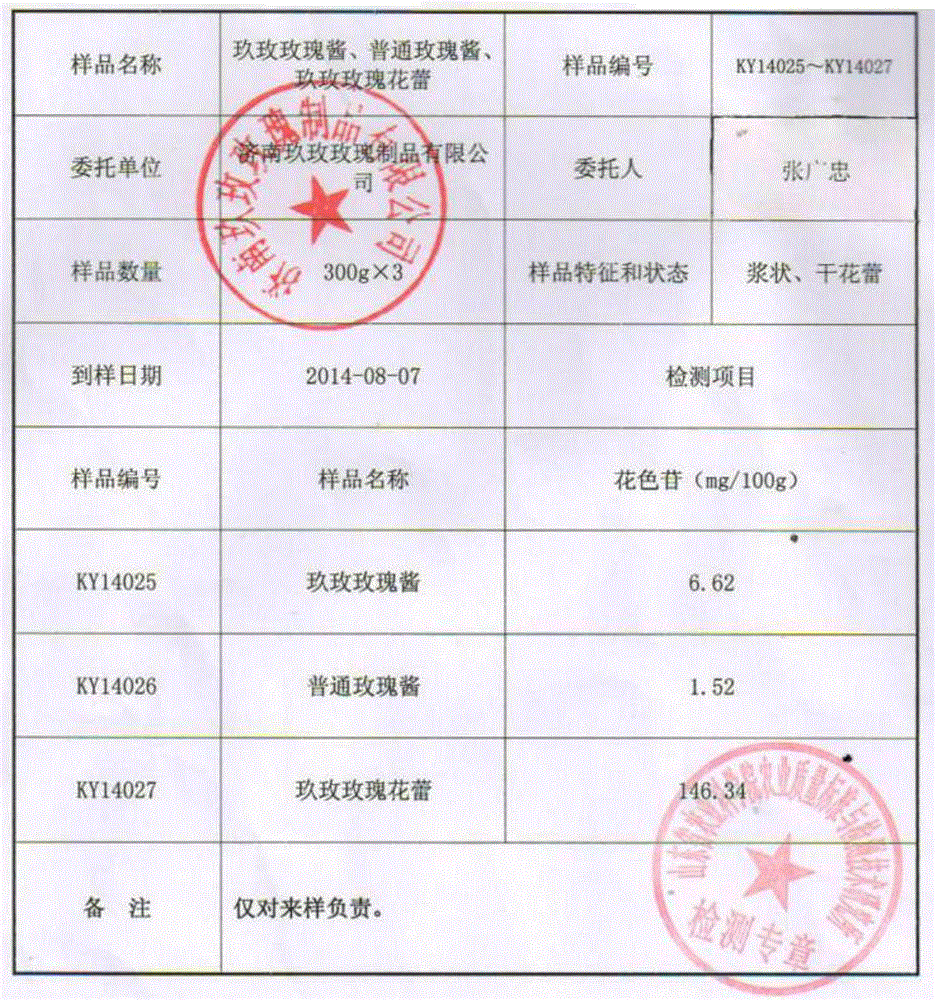

Equipment and method for low-temperature drying of roses

ActiveCN104197655AOvercoming the problem of temperature decrease and humidity increaseSolve the problem of maintaining a constant temperature in the drying box that cannot be solvedDrying machines with local agitationDrying machines with materials at restPurplish redProcess engineering

The invention discloses equipment for low-temperature drying of roses and a method using the equipment to dry the roses. The equipment comprises a drying box body, a moving trolley arranged in the drying box body, a dehumidifying and heat exchanging device arranged in the middle of the top in the drying box body, and a heat supply device for supplying heat to the drying box body. The problems of decrease of temperature and increase of humidity in the drying box body due to the fact that heat energy provided by steam at a stage of rose drying and color fixing cannot be quickly and timely supplemented for air inducing and dehumidifying are solved; the roses dried by the equipment are purplish red in color and bright in tinct, anthocyanin in the roses is protected, and nutrition and healthcare efficacy of the roses on human bodies is improved; the equipment is small in investment, low in running cost and convenient for popularization and use.

Owner:JINAN JIUMEI ROSE PROD

Compound extract for cigarette, microcapsule containing extract and preparation methods thereof

InactiveCN106666823AImprove finenessIncrease softnessTobacco smoke filtersEssential-oils/perfumesIrritationAdditive ingredient

The invention provides a compound extract for a cigarette, a microcapsule containing the extract and preparation methods thereof. The compound extract for the cigarette is prepared by mixing passion flower, rambutan, citron, clausena lansium, sea-buckthorn, pyracantha fortuneana leaves, persimmon leaves and mulberry leaves and then is prepared into the microcapsule applied to a cigarette filter stick, rich tropical fruit aroma can be endowed to the cigarette and is harmonious with cigarette aroma, sweet, aroma-absorbing fine and smooth taste is increased, and irritation is reduced. In addition, effective ingredients in the compound extract have body fluid regenerating and throat moistening effects and are brought into the oral cavity through smoke, the throat dryness problem brought by cigarette smoking can be solved, the cigarette smoking enjoyment is improved, the plant extracting rate and effective ingredient application can be greatly improved by adopting the preparation methods, involvement of unnecessary ingredients is avoided, and the effect in cigarette application is improved.

Owner:DONGGUAN BOTON FLAVORS & FRAGRANCES

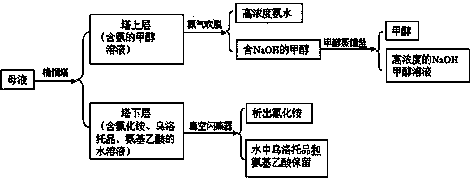

Method for treating mother liquid discharged in glycine production

InactiveCN104193751AProtective ingredientsEasy to handleOrganic compound preparationAmino-carboxyl compound preparationHigh concentrationHexamethylenetetramine

The invention belongs to methods for treating wastewater of chemical production, and in particular provides a method for treating a mother liquid discharged in glycine production. The method comprises the following steps: (1) performing reduced pressure distillation on the mother liquid so as to obtain an amino-containing methanol solution from a top tower layer and an aqueous solution containing ammonium chloride, urotropin and glycine from a bottom tower layer; (2) blowing off the ammonia gas of the amino-containing methanol solution, so as to obtain high-concentration ammonia water; (3) performing vacuum flashing on the solution obtained from the tower bottom, and concentrating the ammonium chloride solution at the tower bottom; and (4) continuously cooling the ammonium chloride solution, thereby separating ammonium chloride. An environment-friendly treatment method for recycling the mother liquid discharged in the glycine production process is adopted, effective recycling and repeated use of ammonia water, sodium hydroxide and urotropin are achieved, and thus the standard of zero sewage discharge is met.

Owner:沈美忠

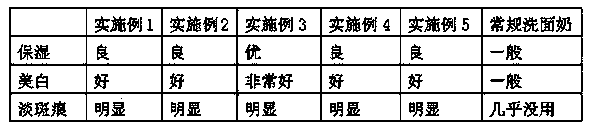

Traditional Chinese medicine facial cleanser and preparation method thereof

InactiveCN104288078AProtective ingredientsReduce manufacturing costCosmetic preparationsToilet preparationsPreservativeGlycerol

The invention discloses a traditional Chinese medicine facial cleanser and a preparation method thereof. The traditional Chinese medicine facial cleanser comprises the following raw materials in parts by weight: 12-25 parts of lemongrass extracting solution, 5-10 parts of cucumber extracting solution, 0.5-1.0 part of preservative, 5-8 parts of glycerol, 5-8 parts of pearl powder, 5-9 parts of dendrobium officinale extracting solution, 30-50 parts of deionized water and 5-10 parts of emulsifier. The preparation method comprises the following steps: step 1, preparing the lemongrass extracting solution, the cucumber extracting solution and the dendrobium officinale extracting solution, weighing the necessary parts and mixing and stirring uniformly, sterilizing to obtain a nutrient solution, and storing for later use; step 2, taking the nutrient solution, adding the pearl powder, homogenizing, adding the emulsifier, the preservative and the water, stirring, heating, preserving the temperature, and naturally cooling to obtain a semi-finished product; step 3, adding the glycerol into the semi-finished product, stirring and packaging to obtain the traditional Chinese medicine facial cleanser. The traditional Chinese medicine facial cleanser provided by the invention is good in skin cleaning effect, low in chemical content, simple in preparation method and suitable for industrialization.

Owner:JIANGSU QILIKANG SKIN PHARMA

Method for preparing coix seed beauty drink

The invention discloses a method for preparing a coix seed beauty drink. A Chinese medicine, namely coix seed, is taken as a main raw material and matched with red dates to prepare a health drink with a beautifying function. The method comprises the following steps of: cleaning and soaking the coix seed, performing enzymolysis and saccharification, separating a solution from residue, homogenizing and micro-filtering, performing ultrahigh temperature flash sterilization and the like. In the process of preparing the coix seed beauty drink, low temperature treatment is adopted, so that energy consumption is low, the damage of high temperature to nutritional and functional components is avoided, the produced health drink is red and mellow in mouthfeel, the original flavors and nutritional components of the coix seed and the red dates are protected to the greatest degree, and the drink is easy to store and suitable for industrial production.

Owner:杨军

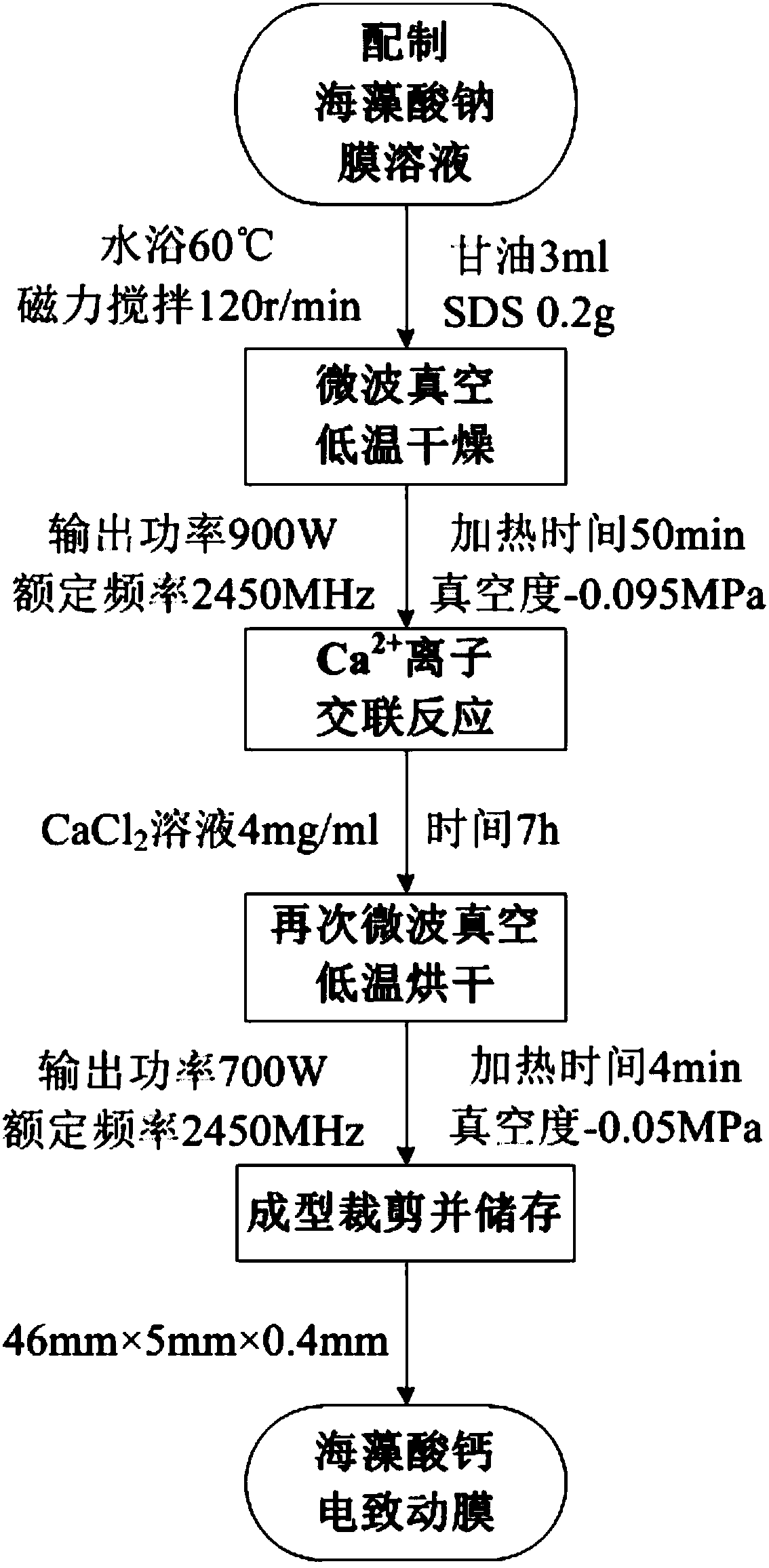

Preparation method of calcium alginate electrically-driven film adopting microwave vacuum low-temperature drying technology

InactiveCN108484955AFlat surfaceReduced diffusion rateProgramme-controlled manipulatorChemical industryCross-linkPolymer science

The invention provides a preparation method of a calcium alginate electrically-driven film adopting a microwave vacuum low-temperature drying technology. The microwave vacuum low-temperature drying technology is adopted, and through the combination with the two technologies of microwave drying and vacuum drying, the advantages of the two technologies are sufficiently and comprehensively developed.The preparation method comprises the following steps: using natural macromolecular biological materials of sodium alga acid as a film forming main material and a cross-linking agent CaCl2, and addingplasticizer glycerinum and plastic assisting agent lauryl sodium sulfate so as to prepare the calcium alginate electrically-driven film of a three-dimensional network gel structure. The raw materialsare wide in sources and low in cost, and the obtained electrically-driven film is non-toxic, tasteless and biodegradable. After microwave vacuum drying, hierarchical pore structures are connected with one another and are regular, the ionic cross-linking of Ca<2+> on the inner layer and the outer layer is comprehensive and uniform, and the electrically-driven film is excellent and controllable inelectrically-driven performance and long in service life. The microwave vacuum low-temperature drying technology of the calcium alginate electrically-driven film prepared in the invention is energy-saving, efficient and free of pollution, and is mostly beneficial for high molecular material synthesis and curing reaction with extremely high requirement for heating rate and uniformity.

Owner:HARBIN ENG UNIV

Method for fermenting ganoderma lucidum spore powder by using probiotics

ActiveCN104286827ATo break the wallPromote absorptionFood shapingFood preparationGut floraLactobacillus acidophilus

The invention discloses a method for fermenting ganoderma lucidum spore powder by using probiotics. The method comprises the following steps: carrying out liquid-state fermentation on the ganoderma lucidum spore powder with bacillus subtilis and lactobacillus acidophilus; and then, freezing, spraying and drying to obtain the product. The method has the beneficial effects that (1) the wall breaking of the ganoderma lucidum spore powder is realized and the wall breaking efficiency is more than 85%; the absorption rate is improved; (2) after probiotics fermentation, the content of nutritional components including protein, vitamins, polysaccharides and the like is increased so that the nutritional value of foods is greatly improved; (3) after the fermentation, the quantity of the probiotics in a product is great and the pH is low; the product has a certain antiseptic effect; (4) the product has a rich lactic acid flavor and is mellow and full, and smooth when being eaten; and (5) a step of freezing, spraying and drying is adopted so that functional components in the ganoderma lucidum spore powder are protected, the quantity and the activity of the probiotics in the product are maintained to the greatest extent, the balance of intestinal flora of users is benefited, and the health effect of the ganoderma lucidum spore powder is strengthened.

Owner:浙江亚林生物科技股份有限公司

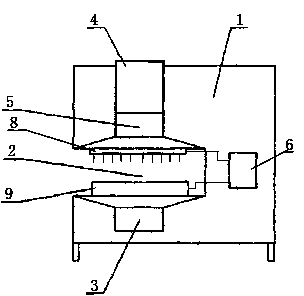

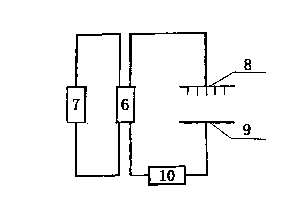

Tea leaf high-voltage electrostatic field dryer

InactiveCN103859069AProtective ingredientsReduce broken ratePre-extraction tea treatmentAgricultural engineeringTea leaf

The invention relates to tea leaf dryers, and specifically relates to a tea leaf high-voltage electrostatic field dryer. Drying technology brings direct influence for output and quality of tea leaf, present drying technology usually employs flat type, tunnel type or hot-air circulating type dryers for drying, and the flat type, tunnel type or hot-air circulating type dryers respectively have problems of influencing quality, appearance and output of tea leaf. The high-voltage electrostatic field dryer comprise a baking oven, an evaporating chamber, an air inlet, an air outlet, an air exhaust device and a high-voltage electrostatic field generating assembly; and the high-voltage electrostatic field generating assembly mainly consists of a power supply, a pressure regulating rectifier, an upper pole plate, a lower pole plate and a controller. The tea leaf drying process is performed at a normal temperature when the high-voltage electrostatic field dryer is employed, so that the compositions of tea leaf are effectively protected, and dried tea leaf is small in color and shape variation; the broken rate of tea leaf is low, the quality and the beauty of tea leaf are effectively guaranteed, the output is improved, and especially quality guarantee is provided for production of high-grade tea leaf.

Owner:高松

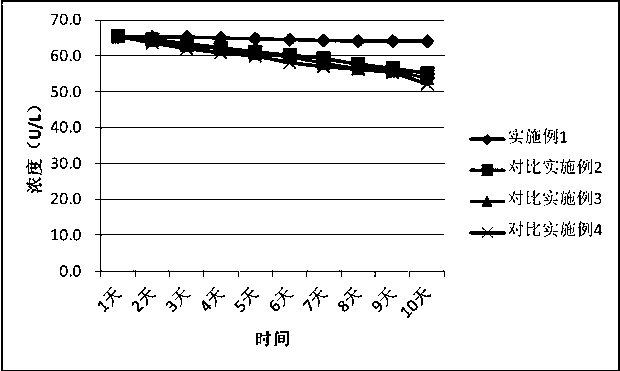

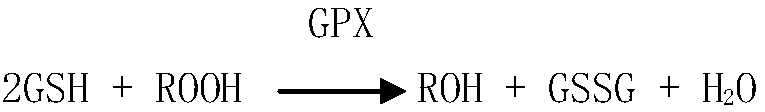

Glutathione peroxidase determination kit, preparation method of glutathione peroxidase determination kit and application of glutathione peroxidase determination kit

The invention discloses a glutathione peroxidase determination kit, the kit contains a reagent R1 and a reagent R2; the reagent R1 contains buffer solution, EDTA, glutathione reductase, reduced glutathione, potassium chloride, magnesium chloride, surfactant, stabilizer and preservative; and the reagent R2 contains the buffer solution, the EDTA, NADPH, cumene hydrogen peroxide, surfactant, stabilizer and preservative. The invention also discloses a preparation method of the glutathione peroxidase determination kit and application of the glutathione peroxidase determination kit. The kit providedby the invention is a high-sensitivity and excellently stable liquid kit.

Owner:中拓生物有限公司

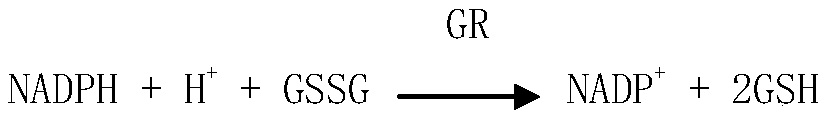

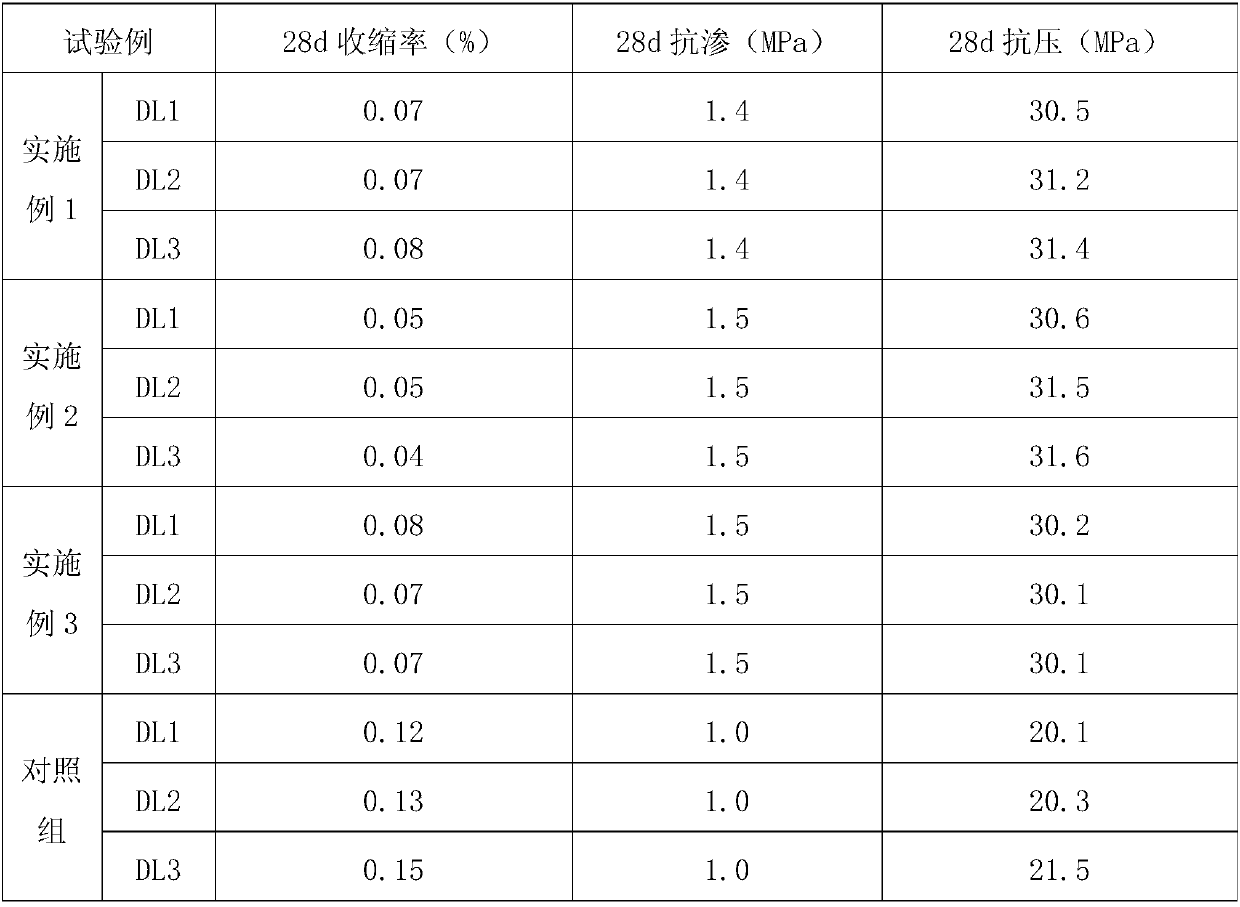

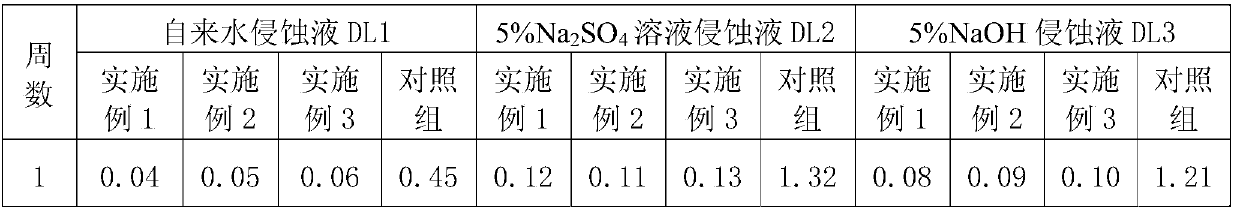

High-efficiency corrosion resistant pre-mixed mortar

The invention relates to a pre-mixed mortar material for buildings and particularly relates to high-efficiency corrosion resistant pre-mixed mortar. The mortar is prepared by mixing the following ingredients in percentages by weight: 5-20% of river sand, 10-30% of manufactured sand, 10-20% of flyash, 10-20% of granulated blast-furnace slag powder, 1-2% of polycarboxylic acid, 1-2% of sodium gluconate, 5-15% of cement, 5-15% of redispersible powder, 5-10% of kaolin and 5-10% of an electrolytic manganese slag waste. By using the pre-mixed mortar prepared at the ratio, the prepared concrete has the characteristics of being hard, corrosion-resistant and low in cost, and has wide applicability.

Owner:中山市群发建筑材料有限公司

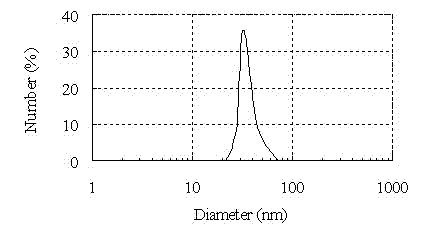

Methylphenol-containing nano-emulsion disinfectant and its preparation method

The invention relates to a disinfectant and aims to provide a methylphenol-containing nano-emulsion disinfectant having the advantages of good water solubility, small pungent smell, strong disinfection effect and long disinfection effect maintenance time, and its preparation method. The methylphenol-containing nano-emulsion disinfectant is prepared through using the following raw materials, by weight, 0.1-14.5 parts of methylphenol, 30.0-60.5 parts of a surfactant, 0-15.0 parts of a cosurfactant, 2.3-7.5 parts of oil and 22.0-53.0 parts of distilled water. The methylphenol-containing nano-emulsion disinfectant has the advantages of good stability, simple production technology, low production cost and convenience for the scale production.

Owner:HENAN INST OF SCI & TECH

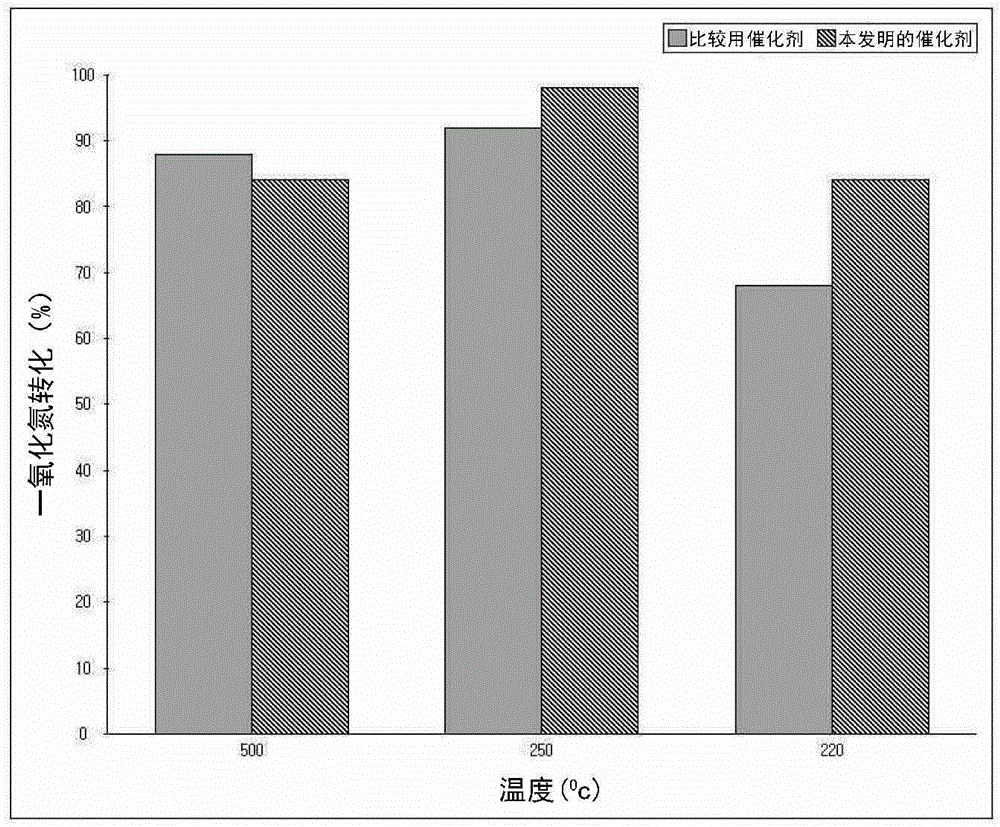

Catalyst support for preparing a catalyst for removal of nitrogen oxides and method for preparing thereof

InactiveCN105126927AExcellent out of stock effectReduce usageCatalyst carriersDispersed particle separationOil refineryAluminium oxide

The present invention relates to a method for producing an alumina-based catalyst support which is appropriate for producing a selective catalytic reduction catalyst for removing nitrogen oxide by using discarded catalyst waste after high-cost catalyst active metal components are extracted (collected) from a waste catalyst discharged from a desulfurizing step in an oil refinery or the like. A support molded product, which is molded using molding clay produced by combining 20-50 parts by weight of zeolite with respect to 100 parts by weight of the catalyst waste, is dried and plasticized.

Owner:许承柱

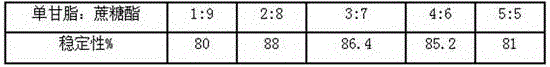

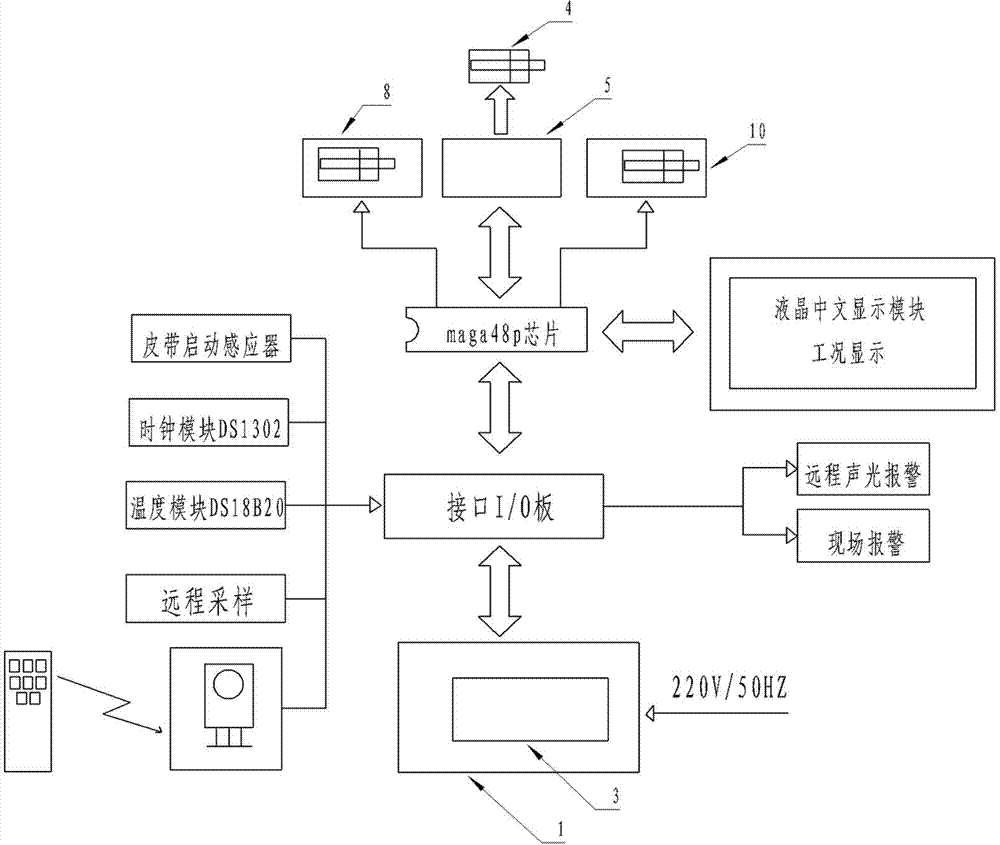

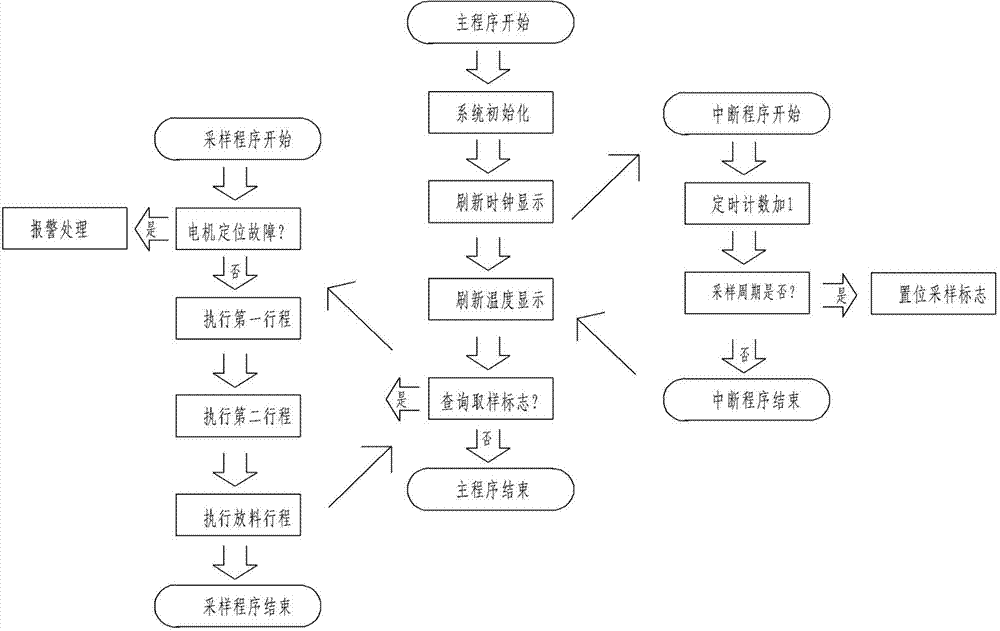

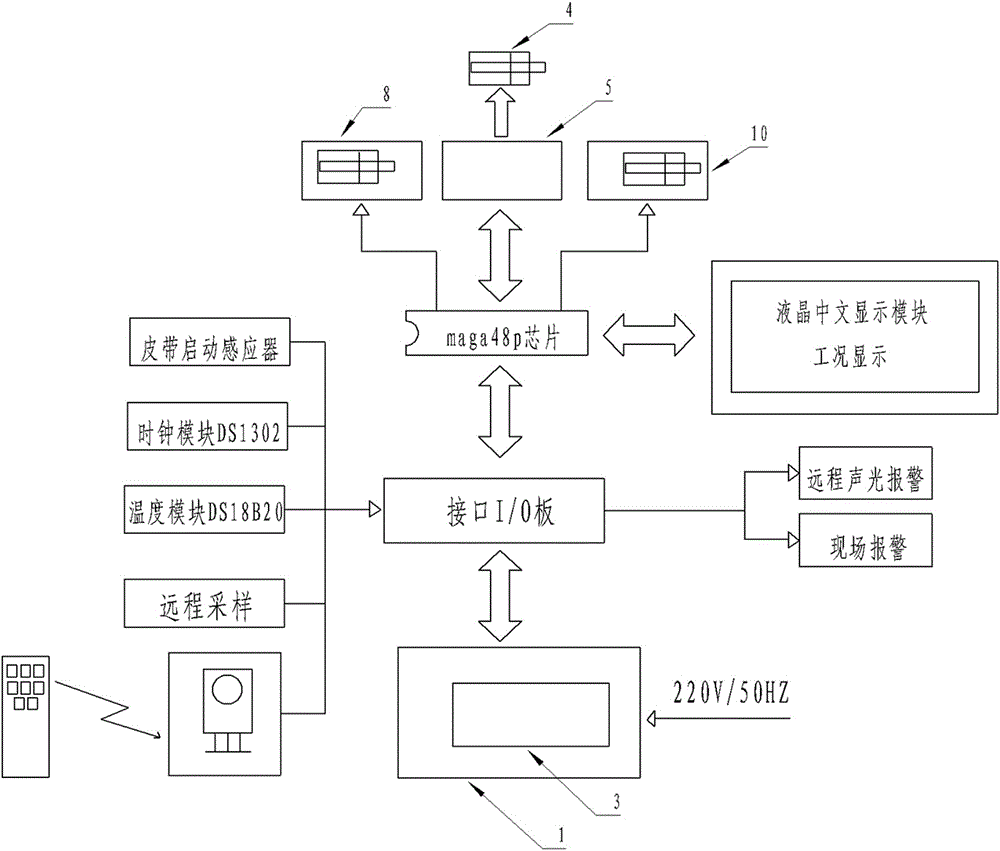

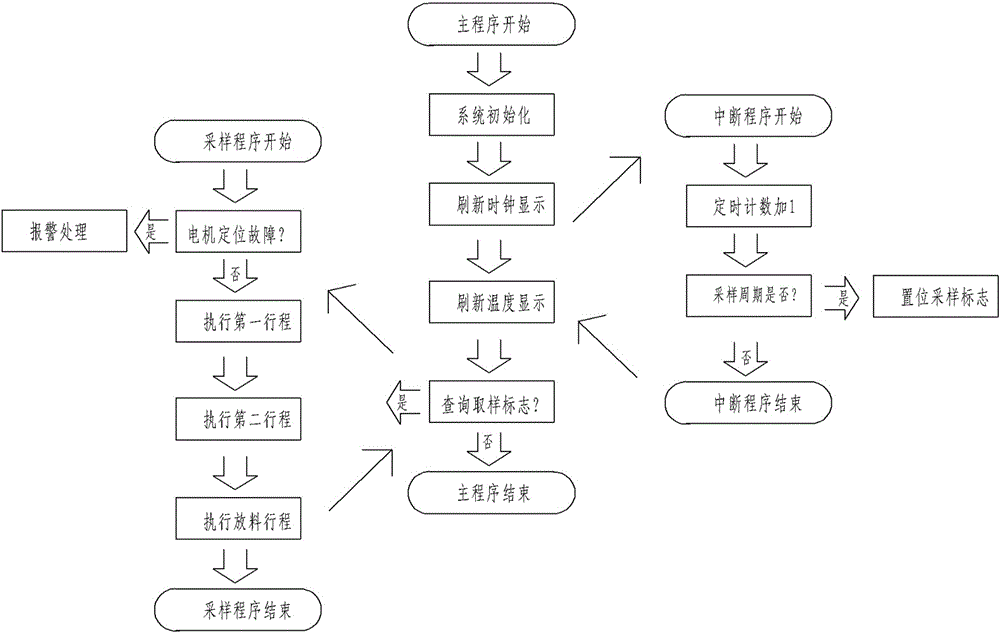

Automatic sampling system

InactiveCN103364229ASampling process automationAvoid enteringWithdrawing sample devicesEngineeringControl theory

The invention discloses an automatic sampling system which comprises a host system and an auxiliary system, wherein the host system comprises a main control module, a speed reducing stepping motor, a stepping driver and a discharging servo motor; the stepping driver is connected with the speed reducing stepping motor; the auxiliary system comprises a box and a sealed servo motor; the sealed servo motor is arranged on the box; a main shaft rotating arm is arranged on the speed reducing stepping motor; a sampling head is fixedly arranged on the end part of the main shaft rotating arm; the discharging servo motor is arranged at the end part of the main shaft rotating arm; a rotating piece is fixedly arranged on a rotating shaft of the discharging servo motor and can be used for blocking the bottom of the sampling head during the sampling; a material guide pipe is arranged in the box of the auxiliary system; an inner film bag is fixedly arranged at an upper end port of the material guide pipe; a sealing cover is fixedly arranged on a rotating shaft of the sealed servo motor and is used for covering the upper end port of the material guide pipe. The automatic sampling system is suitable for sampling matters such as powder and particles, and also suitable for sampling objects with end parts during the transport in the industries of a chemical fertilizer, grains, food and medicines.

Owner:HUBEI ZHONGFU CHEM GROUP

Ovary maintenance composition containing lotus seed exosome and preparation method thereof

InactiveCN113648347AFunction increaseAnti agingHydroxy compound active ingredientsFungi medical ingredientsBiotechnologyOvarian function

The invention relates to the field of biological medicine. The invention relates to an ovary maintenance composition containing lotus seed exosomes and a preparation method thereof. The invention provides an ovary maintenance composition containing lotus seed exosomes. The composition comprises the lotus seed exosomes, bitter gourd exosomes, spina date seed exosomes, functional raw materials and auxiliary materials. The ovary maintenance composition containing the lotus seed exosome has good effects of maintaining the ovary, improving the ovary function and improving the endocrine level.

Owner:陕西佰瑞衡健康科技有限公司

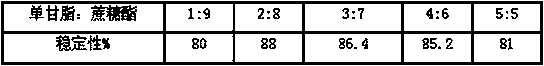

Flavone micro-emulsion and application thereof

InactiveCN107455756AReduce qualityAvoid high preservativesMeat/fish preservation using chemicalsFood ingredient functionsFood additiveFood grade

The invention provides a flavone micro-emulsion and application thereof and belongs to the technical field of food additives. The flavone micro-emulsion is prepared by the following steps: taking and mixing bamboo leaves, celery leaves and chamomile, and extracting the mixture to obtain a flavone extracting solution; separating and purifying the flavone extracting solution to obtain a flavone extract concentrated solution; and blending the flavone extract concentrated solution, and carrying out high pressure homogenization at the temperature of 30-50 DEG C so as to obtain a stable flavone micro-emulsion of which the average particle size of a disperse phase is 300-500 microns. Synchronous extraction of flavonoid components in the bamboo leaves, celery leaves and chamomile is realized, and the solubilization effect of water-insoluble flavonoids is realized by virtue of a micro-emulsification technology. Furthermore, the application of a flavonoid extract nano micro-emulsion in minced fillet products is realized, and a new method is provided for a food-grade preservation technology as well as development of a new-generation functional food for reducing hypertension, hyperlipaemia and hyperglycemia.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

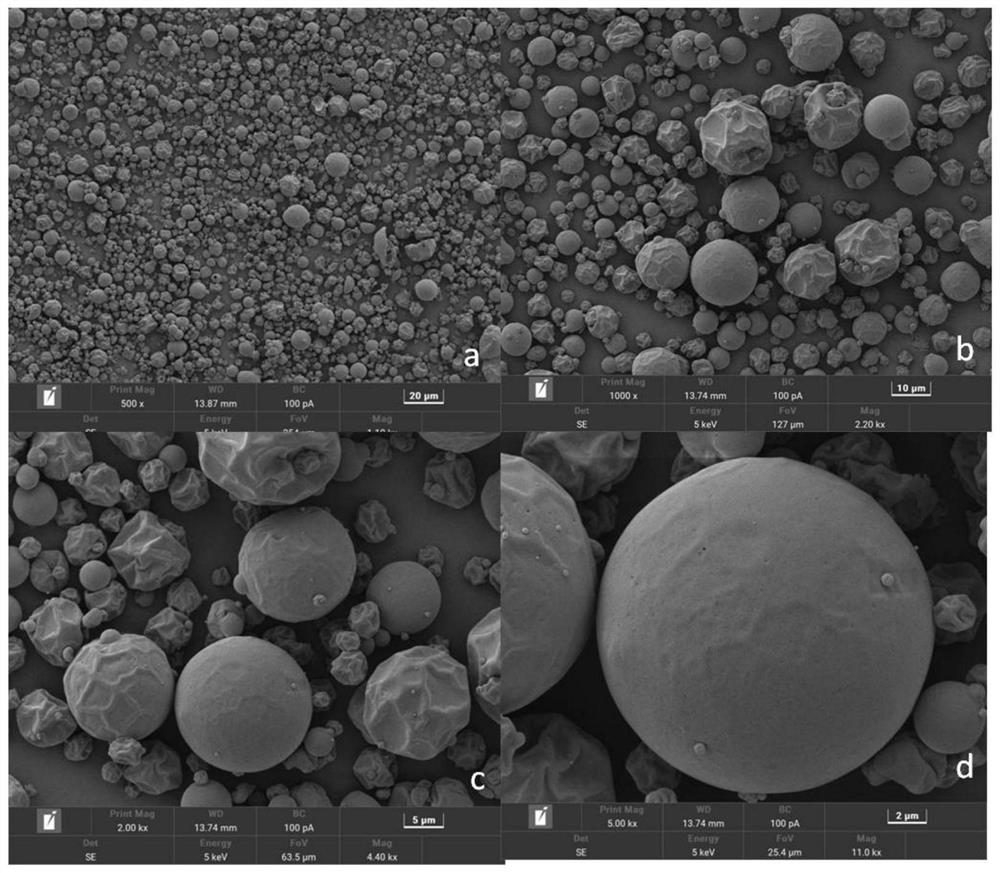

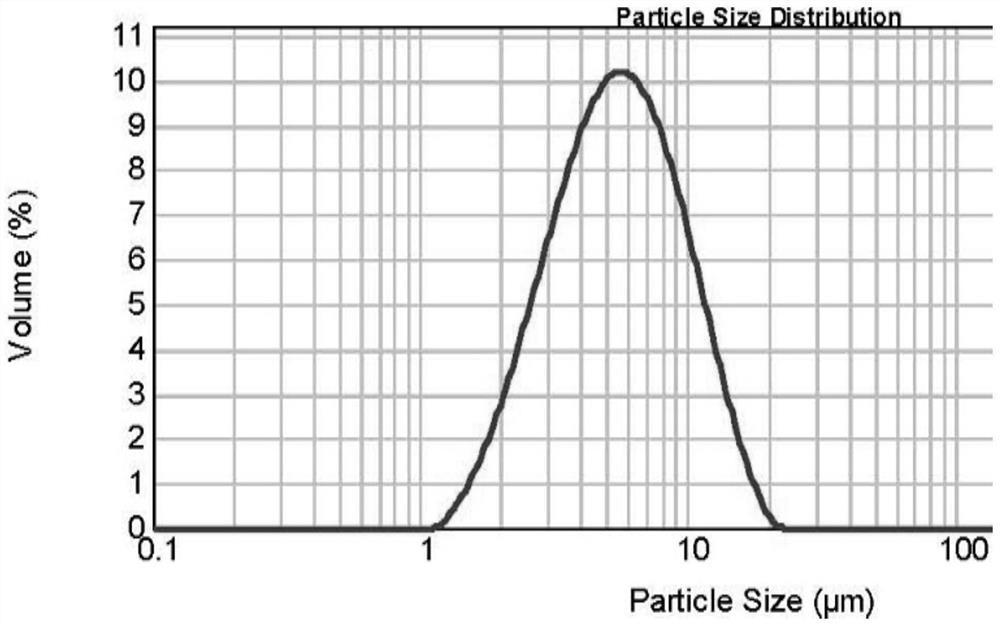

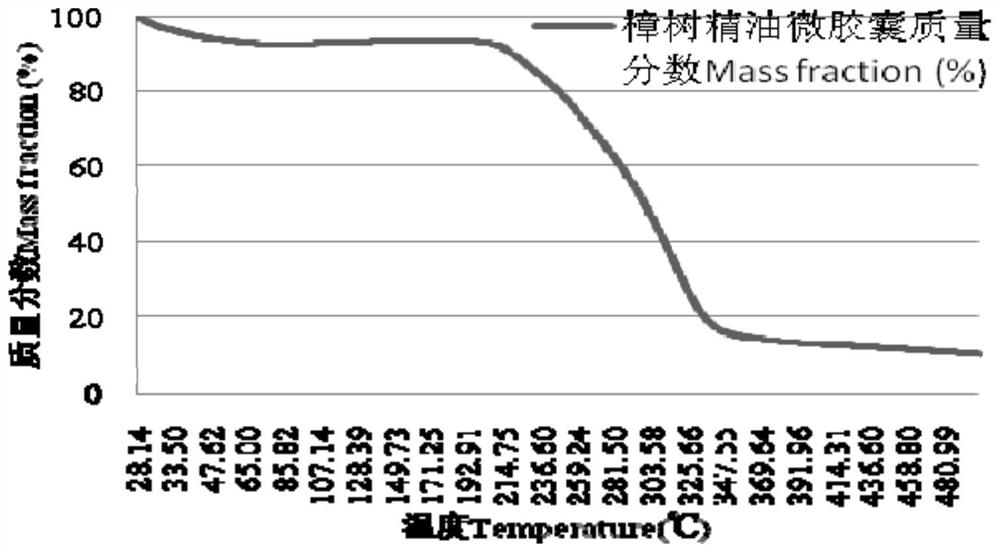

Cinnamomum camphora essential oil microcapsule and preparation method thereof

PendingCN114570301AImprove the emulsification effectHigh embedding rateMicroballoon preparationMicrocapsule preparationChemistryCinnamomum camphora

The invention discloses a camphor tree essential oil microcapsule and a preparation method thereof, the camphor tree essential oil microcapsule comprises a core material and a wall material, the core material is camphor tree essential oil, and the wall material is a mixture of modified starch and maltodextrin. Comprising the following steps: (1) taking modified starch, maltodextrin and monoglyceride, adding distilled water, stirring in a water bath of 60 DEG C until complete dissolution, cooling to room temperature, and slowly adding camphor tree essential oil; (2) mixing and emulsifying twice by using a high-speed dispersion machine to form an emulsion; and (3) carrying out spray drying on the emulsion to obtain the camphor tree essential oil microcapsule. The camphor tree essential oil microcapsule prepared by the invention is high in embedding rate, and can well protect the functional components of the camphor tree essential oil; the particle size distribution is uniform, and the solubility and dispersity of the essential oil are improved; the stability is good, the slow release performance is good, and the storage and use time of the essential oil can be effectively prolonged. The preparation method has the advantages of convenience in production, low price, more preserved functional components, good dispersity, high stability, excellent slow release performance and the like.

Owner:DONGGUAN AGRI SCI RES CENT

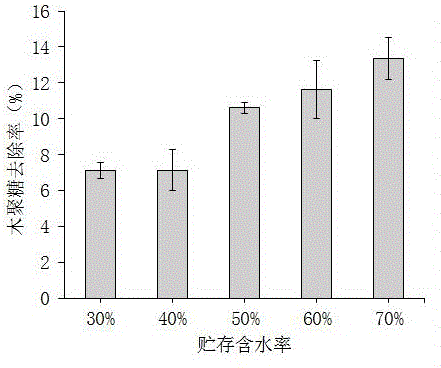

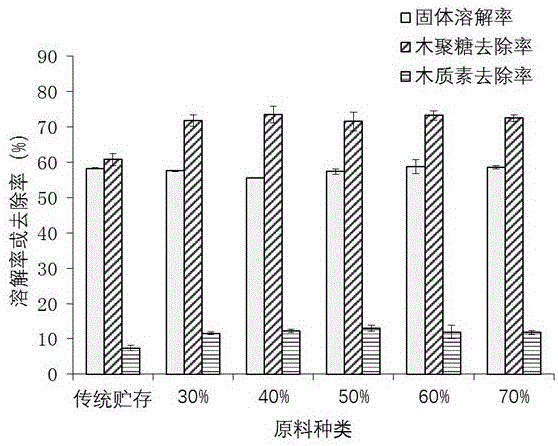

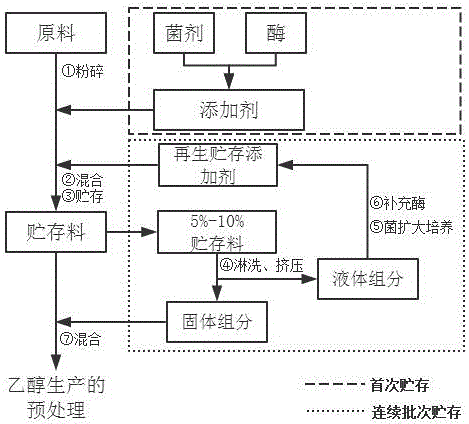

Raw material storage and processing method applied to production of bioethanol

InactiveCN106498019AProtective ingredientsGrowth inhibitionBiofuelsMicroorganism based processesDry weightCulture fluid

The invention provides a raw material storage and processing method applied to production of bioethanol, and belongs to the field of biomass recycling technological development. According to the raw material storage and processing method applied to the production of the bioethanol, the storage cost is effectively controlled, and the conversion efficiency of bioethanol products is improved. The method comprises the steps of a, adopting a raw material with 20%-70% moisture content, and conducting smashing with different particle sizes according to initial moisture content; b, preparing additive, wherein lactic acid bacteria fungicide and hemicellulase are dissolved into sterile water which accounts for 2%-3% dry weight of the raw material, and based on the dry weight of the raw material, the dosages of the lactic acid bacteria fungicide and hemicellulase are 103-105 cfu / g and 0.15-0.45 IU / g respectively; c, mixing the raw material with the additive, compacting the mixture, venting gas and storing for at least 21 days to obtain the stored material; d, conducting drip washing on 5%-10% of the stored material through the sterile water, conducting extrusion, taking the liquid component to mix with an MRS nutrient solution, and after cultivating the mixed solution for 6-12 hours at 30 DEG C, refrigerating the mixed solution for standby application; e, when storage in next batch is conducted, replenishing hemicellulase 0.5-0.75 times which is used in a previous batch into the nutrient solution, so that the regenerated storage additive is obtained so as to replace the additive needed by continuous storage; f, fully mixing the remaining storage material with the solid after drip washing to make the mixture used for pretreatment of production of ethyl alcohol.

Owner:天津市拉贝尔实验室设备有限公司 +1

Novel process for preparing gallnut tannin

ActiveCN111500655AIncrease contentProcess route Energy saving and environmental protectionBacteriaMicroorganism based processesBiotechnologyMicrobiology

The invention relates to a novel process for preparing gallnut tannin by taking gallnut as a raw material. According to the process, the endophytic lactobacillus plantarum is applied to preparation ofthe gallnut tannin, and fermentation metabolism of the lactobacillus plantarum is utilized, so that the content of the gallnut tannin in the fermentation liquor is increased by about 10%, the gallnuttannin in the gallnut is extracted more thoroughly, and the yield of the gallnut tannin is effectively increased. The supernatant obtained by centrifuging fermentation liquor is adsorbed and purifiedby AB-8 macroporous resin, 80% ethanol elution parts are collected, and gallnut tannin with the content of 90% or above can be prepared in one step.

Owner:北京北农科技有限公司 +1

Preparation method of common dayflower herb heat-clearing antivirus raw juice oral liquid

InactiveCN102552347AScientific Sterilization MethodsEasy to sterilizeAntipyreticAnalgesicsFiltrationAdditive ingredient

The invention discloses a preparation method of a common dayflower herb heat-clearing antivirus raw juice oral liquid. The method comprises the following steps of: performing surface sterilization on collected common dayflower herb; and squeezing juice and performing technologies such as vacuum degassing, enzymolysis, micro-filtration, sterile filling, high-temperature momentary sterilization and the like to protect the nutritional and active ingredients of common dayflower herb to the maximum extent. Meanwhile, industrial production and storage of a product are facilitated. The common dayflower herb is processed into the common dayflower herb heat-clearing antivirus raw juice oral liquid which is easy to store, convenient to carry, easy to take and absorb and safe and reliable, has good mouthfeel, does not contain any additive, and has medical treatment and health-care functions.

Owner:杨军

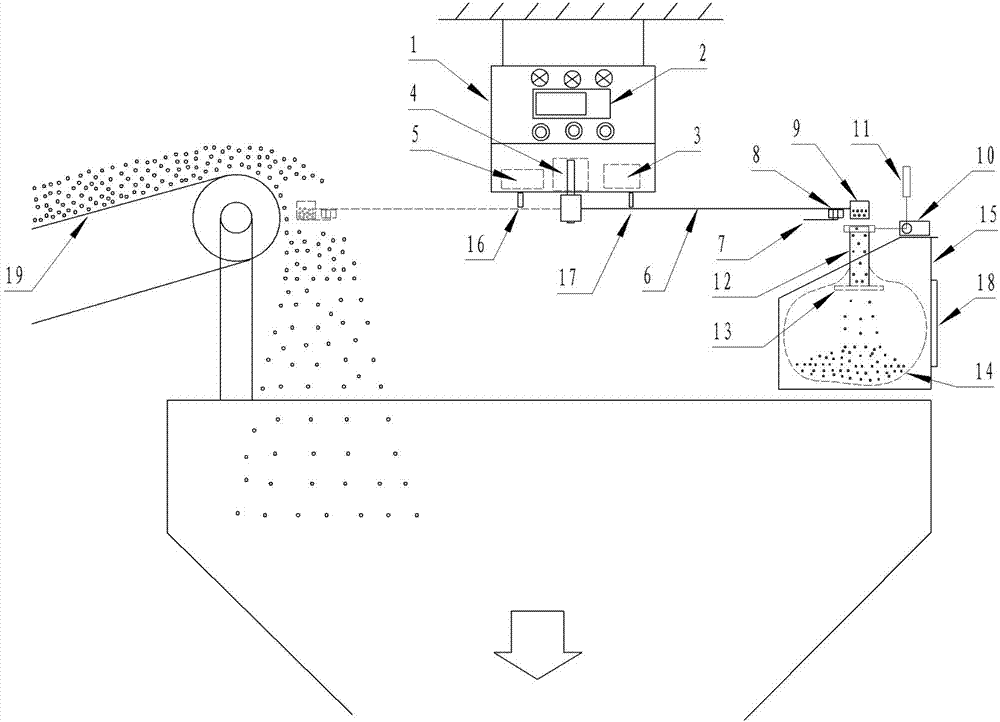

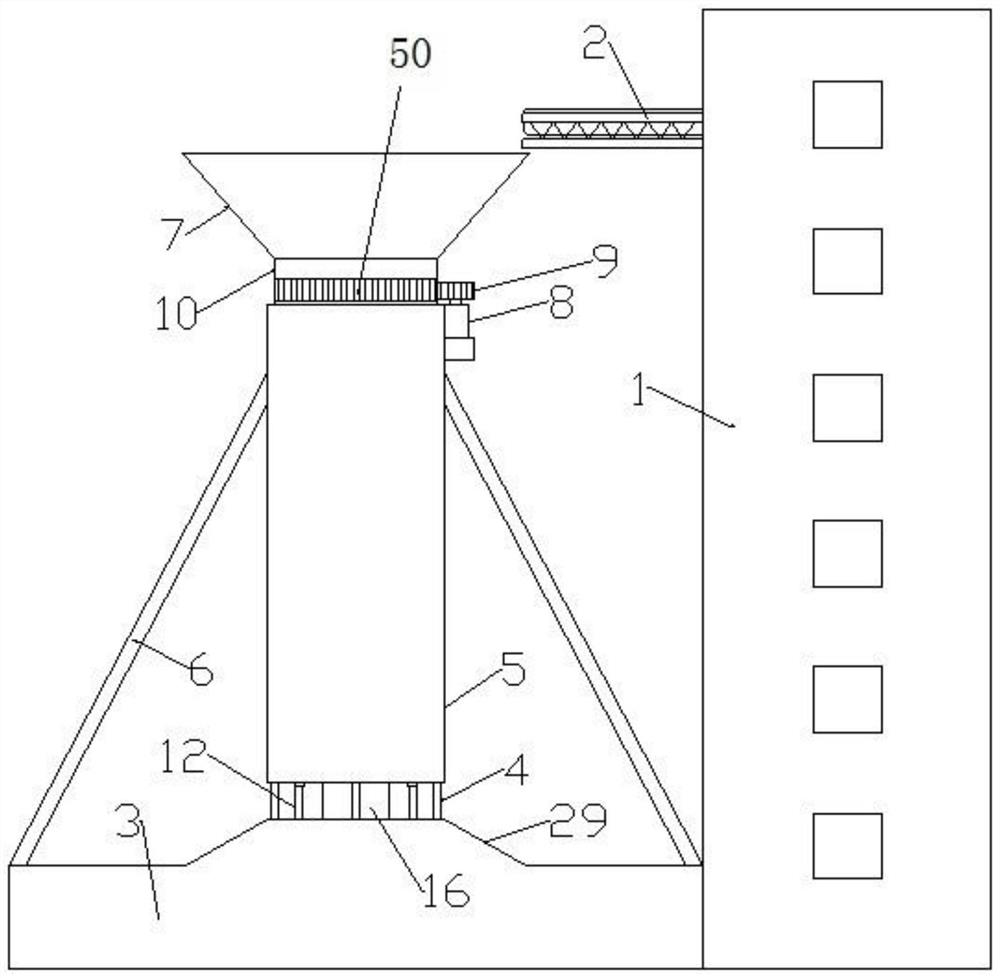

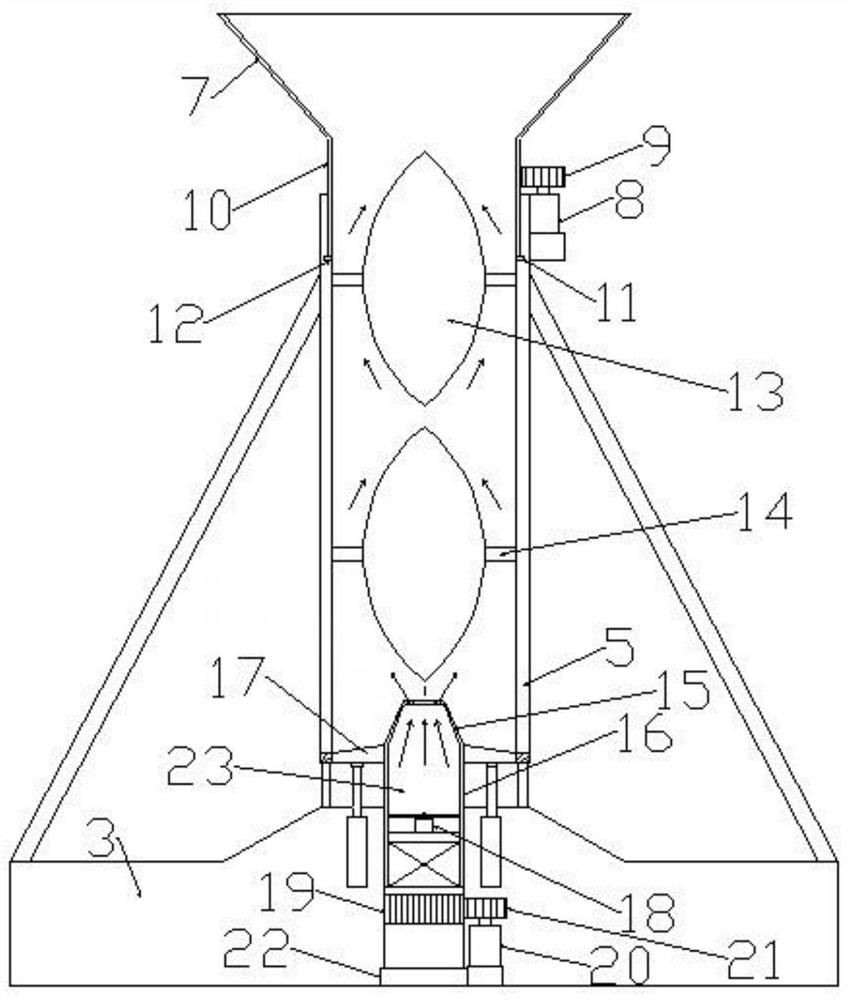

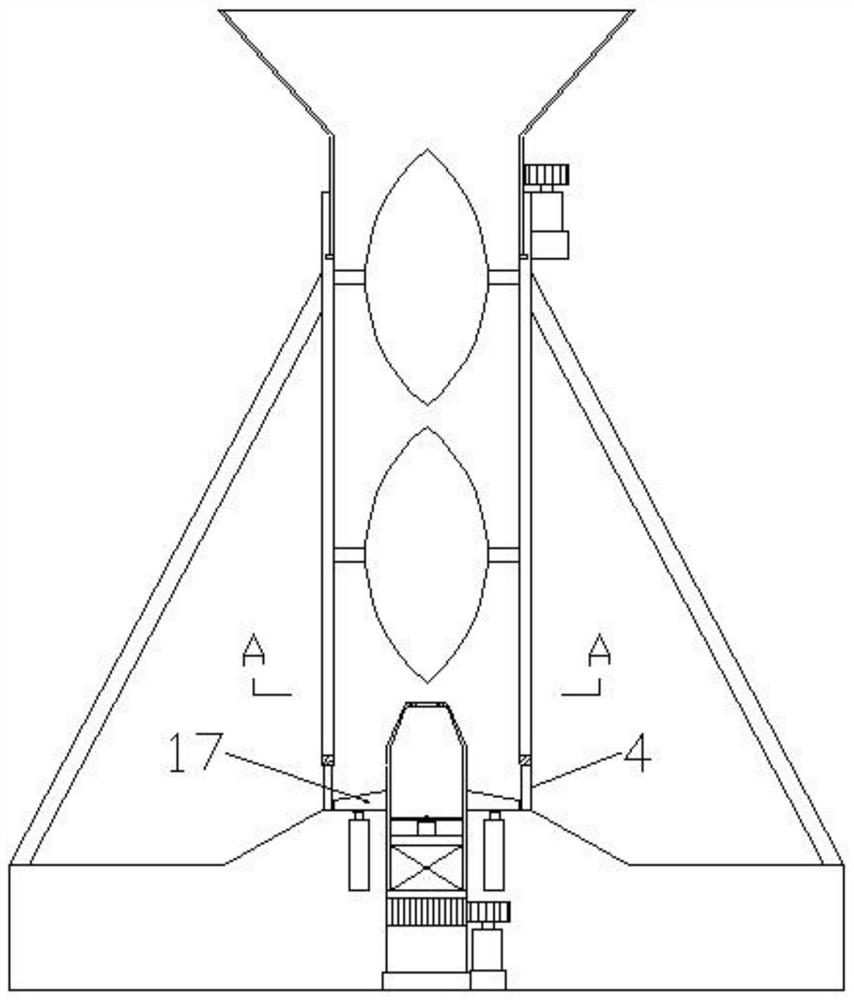

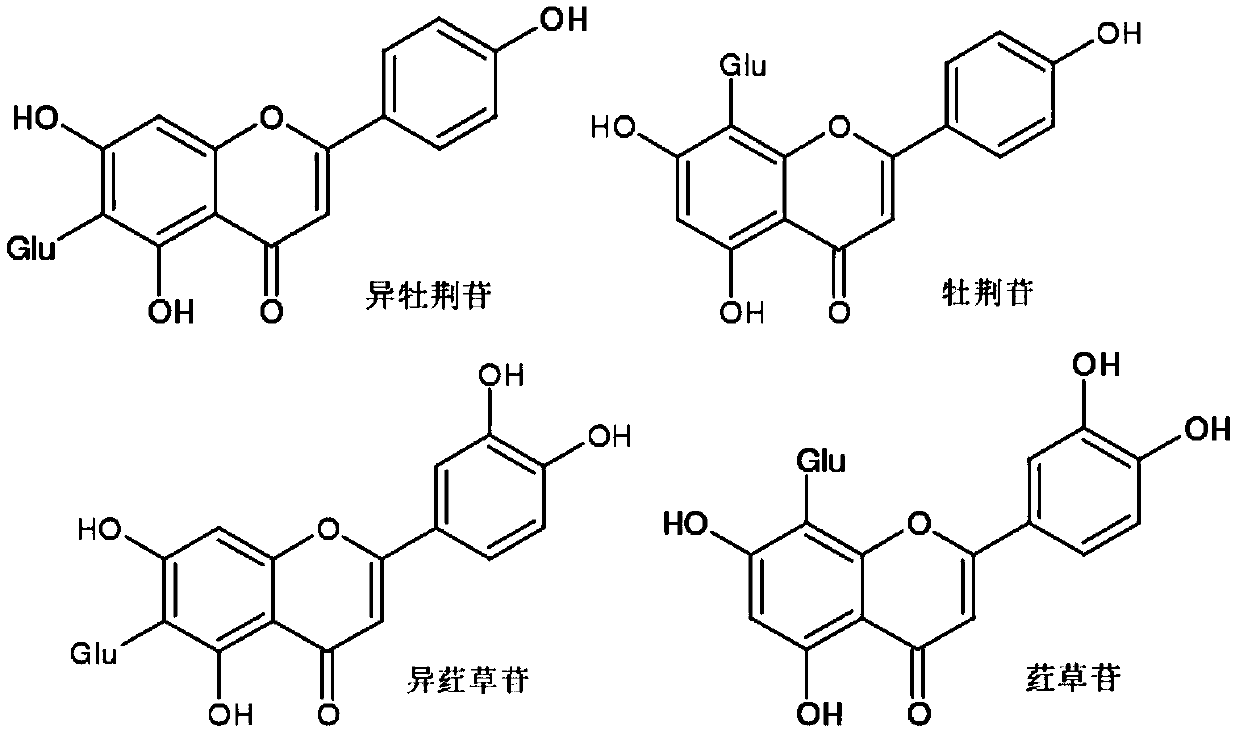

Microbial fertilizer vertical wind tunnel granulation blanking system and method

PendingCN113713712ARealize air cooling operationEvenly dispersedMaterial granulationMicroorganismEnvironmental engineering

The invention relates to a microbial fertilizer vertical wind tunnel granulation blanking system and method. The microbial fertilizer vertical wind tunnel granulation blanking system comprises a raised granulation preparation building and a discharging conveying belt arranged on one side of the top of the raised granulation preparation building and communicated with the interior of the raised granulation preparation building. A rotary rolling receiving hopper is arranged below the end of the discharging conveying belt in a bearing mode. The bottom of the rotary rolling material receiving hopper is connected with a wind tunnel granulation device, and a material receiving platform is arranged at the bottom of the wind tunnel granulation device. According to the invention, particles can be rapidly air-cooled, air is blown from bottom to top through the wind tunnel effect, the wind speed and wind power are accurately calculated according to the particle size of the particles, and wind tunnel cooling operation is effectively carried out while slow discharging is guaranteed; and the produced and prepared particles are uniformly and dispersedly discharged into a vertical cylinder at the bottom by utilizing a rotary discharging hopper type structure at the top, so that the particles at the top are prevented from being adhered, and meanwhile, top scattering and discharging operation is provided for the vertical cylinder of a wind tunnel structure.

Owner:ZHENGZHOU YONGFENG BIOLOGICAL FERTILIZER IND CO LTD

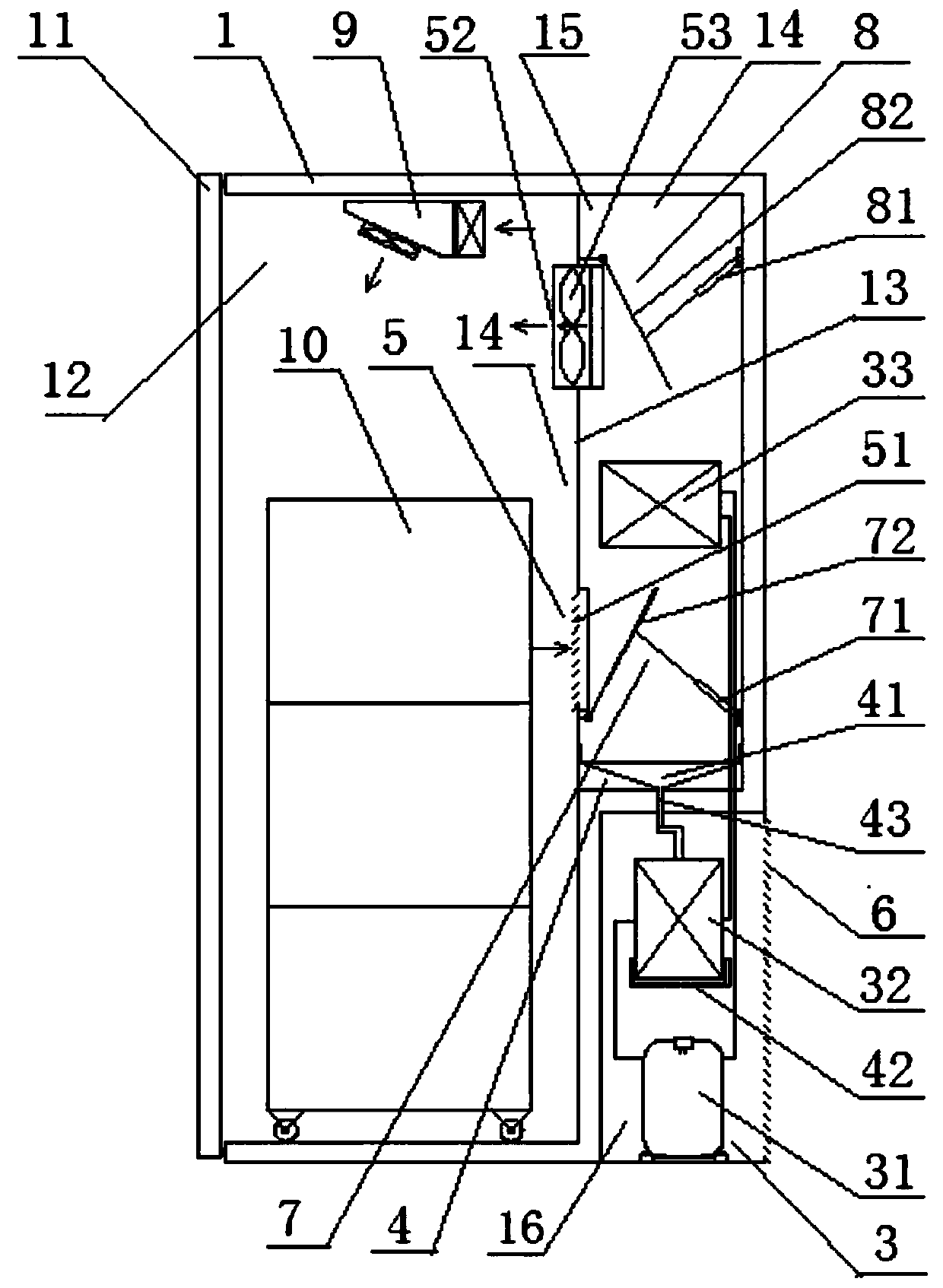

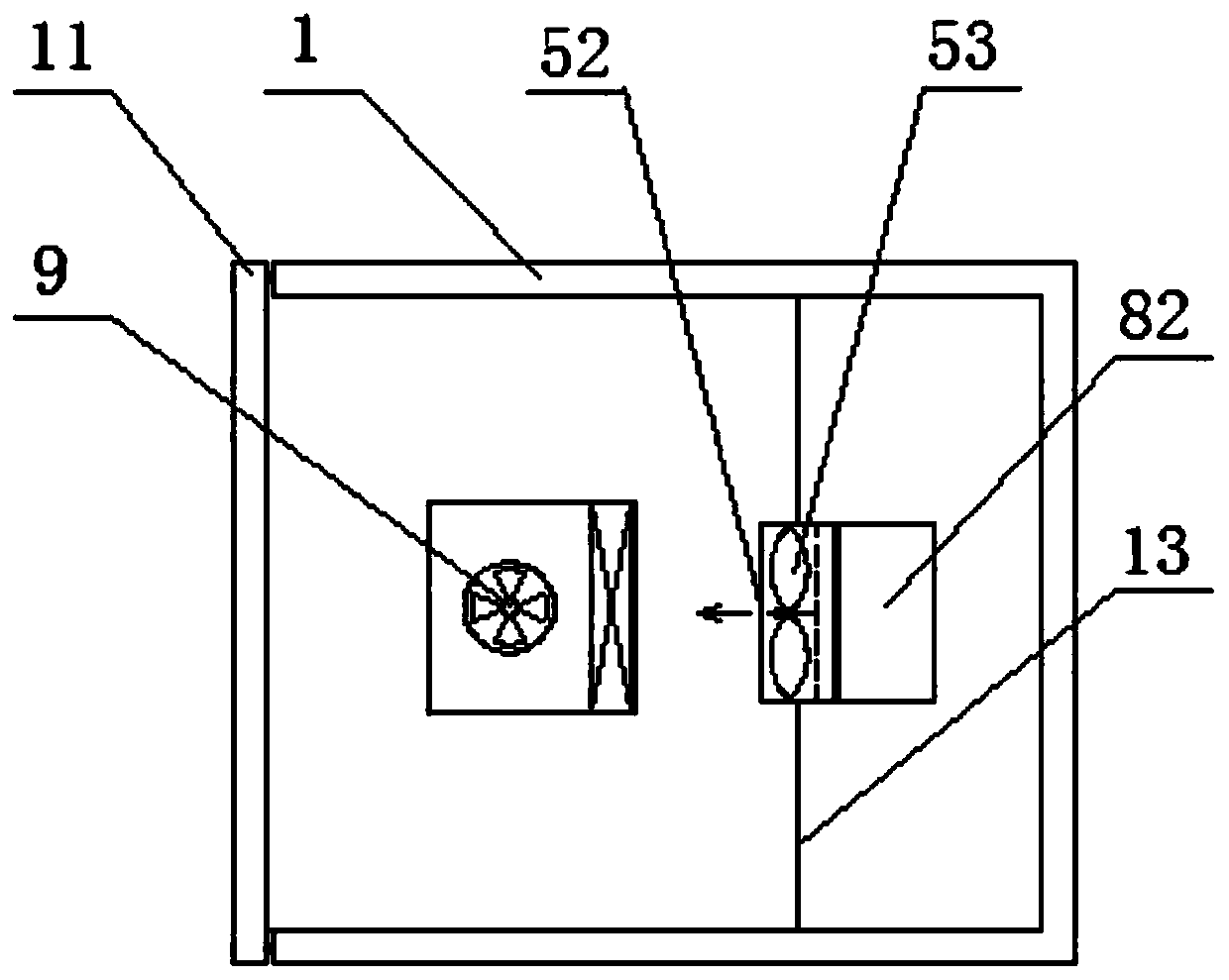

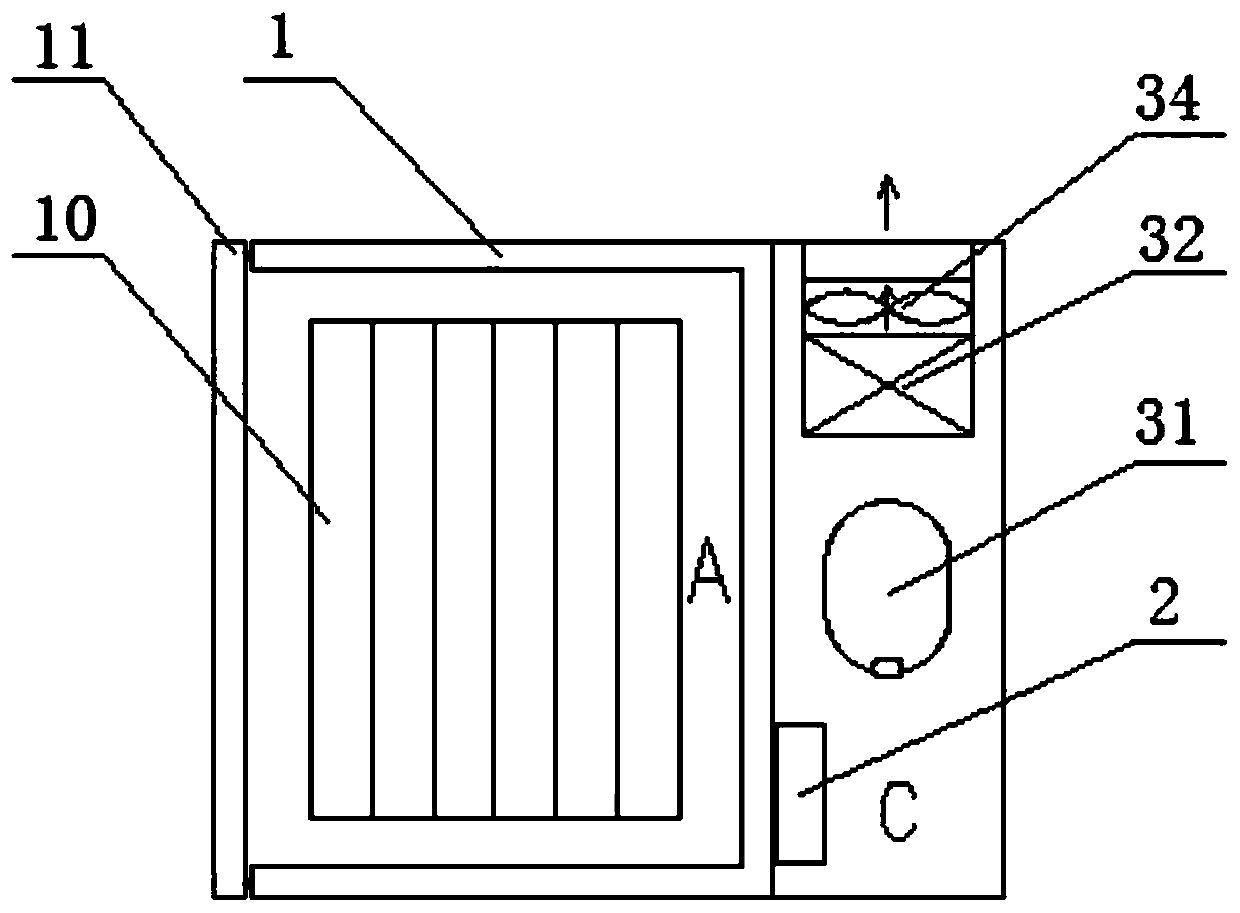

Low-temperature disinfection cabinet and disinfection method

InactiveCN109999207AImprove qualityProtective ingredientsLavatory sanitoryHeatQuality assuranceEngineering

The invention relates to the technical field of article protection, in particular to a low-temperature disinfection cabinet and a disinfection method. The low-temperature disinfection cabinet includesa cabinet body and a cabinet door hinged to the cabinet body, thee cabinet body includes a disinfection chamber used for placing a goods shelf and an equipment chamber separated from the disinfectionchamber through a baffle, and the equipment chamber is internally provided with a controller, a refrigeration dehumidification component, a dehumidification drainage component and an air circulationcomponent, wherein the refrigeration dehumidification component, the dehumidification drainage component and the air circulation component are connected with the controller; the side of the refrigeration dehumidification component is provided with a ventilation pore plate which is used for communication of the equipment chamber and the outside environment, the dehumidification drainage component is arranged on the lower portion of the refrigeration dehumidification component, and the air circulation component is arranged among the baffle, the equipment chamber and the disinfection chamber to form an air circulation loop. The cabinet effectively combines the operation functions of low-temperature sterilization, drying sterilization and low-temperature quality assurance and can kill insectsand mycete in articles, it can be ensured that the articles are not too wet or dry in the disinfection process, the quality, components, colors and effects of the articles are not changed and protected, and the cabinet has a better disinfection effect, saves energy and is environmentally friendly.

Owner:广州百立可科技有限公司

A high-efficiency corrosion-resistant ready-mixed mortar

The invention relates to a pre-mixed mortar material for buildings and particularly relates to high-efficiency corrosion resistant pre-mixed mortar. The mortar is prepared by mixing the following ingredients in percentages by weight: 5-20% of river sand, 10-30% of manufactured sand, 10-20% of flyash, 10-20% of granulated blast-furnace slag powder, 1-2% of polycarboxylic acid, 1-2% of sodium gluconate, 5-15% of cement, 5-15% of redispersible powder, 5-10% of kaolin and 5-10% of an electrolytic manganese slag waste. By using the pre-mixed mortar prepared at the ratio, the prepared concrete has the characteristics of being hard, corrosion-resistant and low in cost, and has wide applicability.

Owner:中山市群发建筑材料有限公司

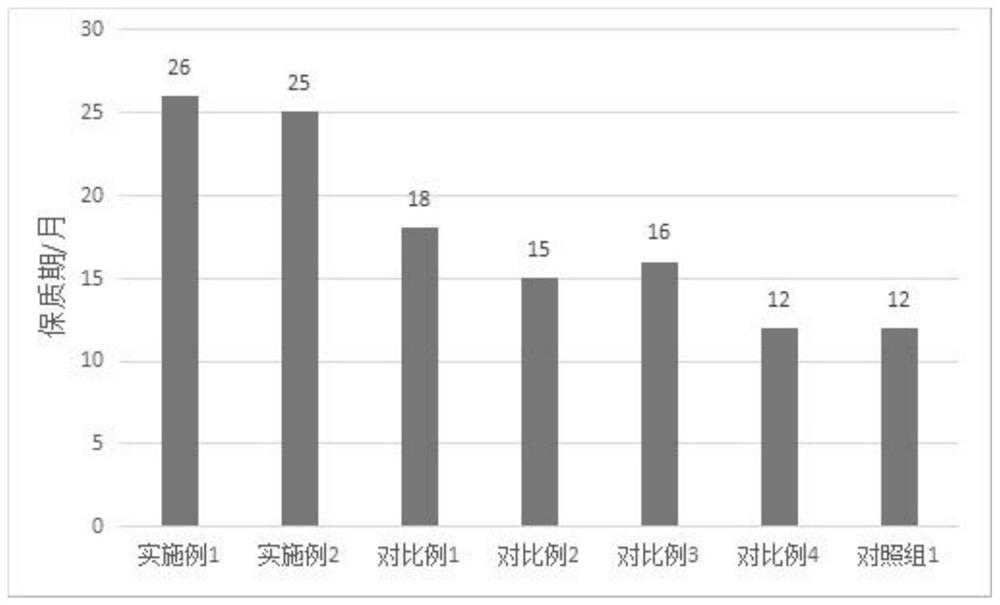

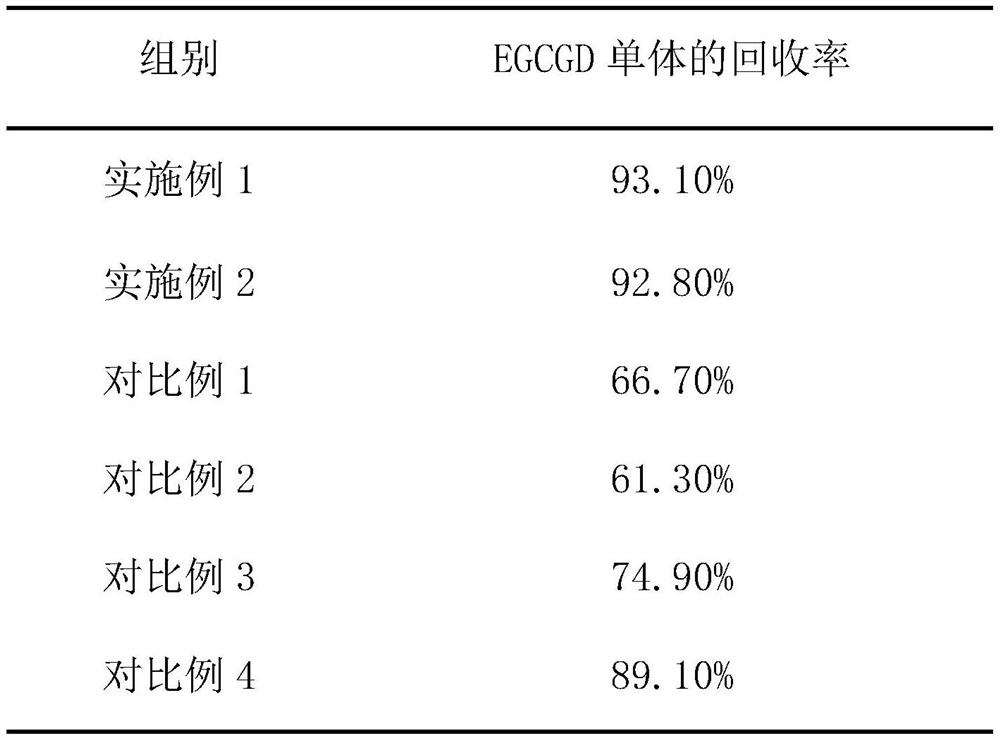

Extraction method of tea polyphenol and Persian safflower after fat dissolution and skin moistening oil thereof

PendingCN113546014AFacilitates the extraction processPrevents rapid oxidationCosmetic preparationsToilet preparationsEssence oilBiotechnology

The invention discloses an extraction method of tea polyphenol and Persian safflower after fat dissolution and skin moistening oil thereof, and belongs to the technical field of essential oils. The extraction method comprises the following steps: (1) preparing vegetable oil according to a certain proportion for later use; (2) grinding and crushing common low-EGCG-content tea polyphenol and Persian safflower, then putting into a stirrer, and then adding the standby vegetable oil; (3) starting a stirrer, carrying out low-speed stirring in a low-temperature environment, and then carrying out condensation extraction; and (4) filtering, precipitating and filtering with a molecular film to obtain a finished product. According to the extraction method of the tea polyphenol and the Persian safflower after fat dissolution, which is disclosed by the invention, the volatilization loss of tea polyphenol inclusions can be reduced, and the recovery rate and the EGCG content in the tea polyphenol are remarkably improved.

Owner:广州市百益康生物科技发展有限公司

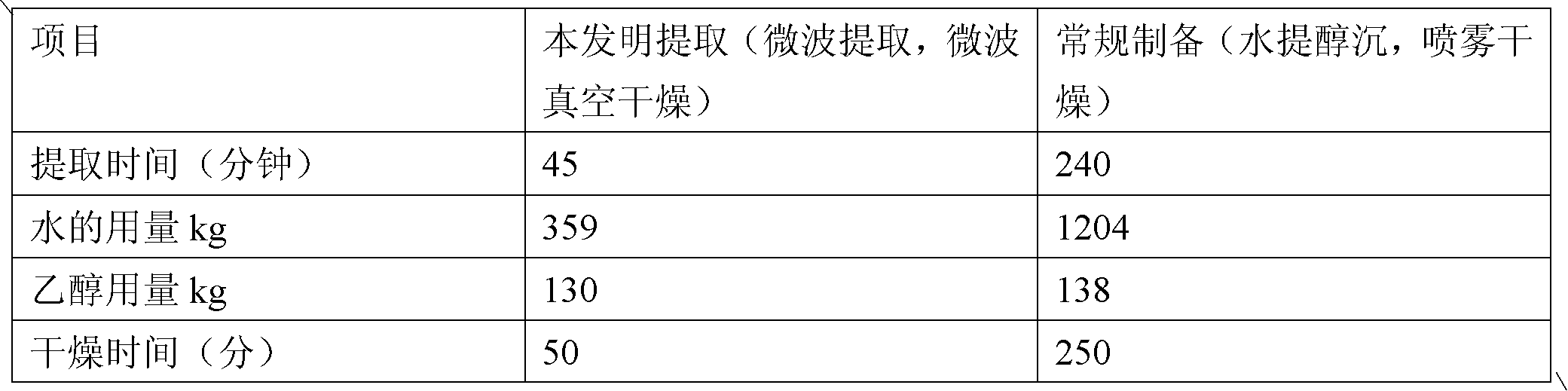

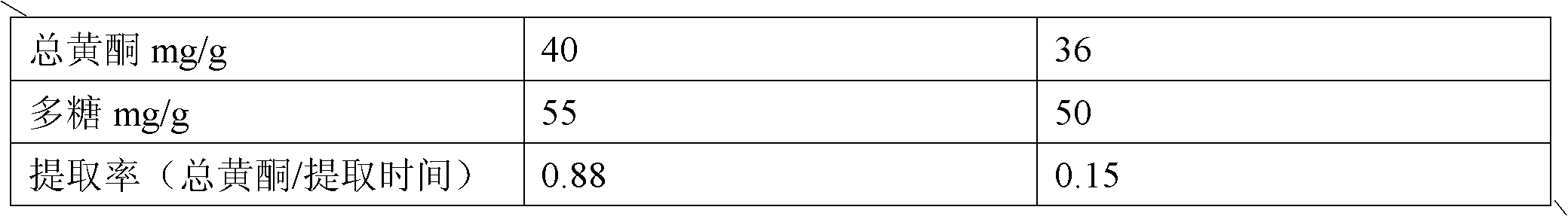

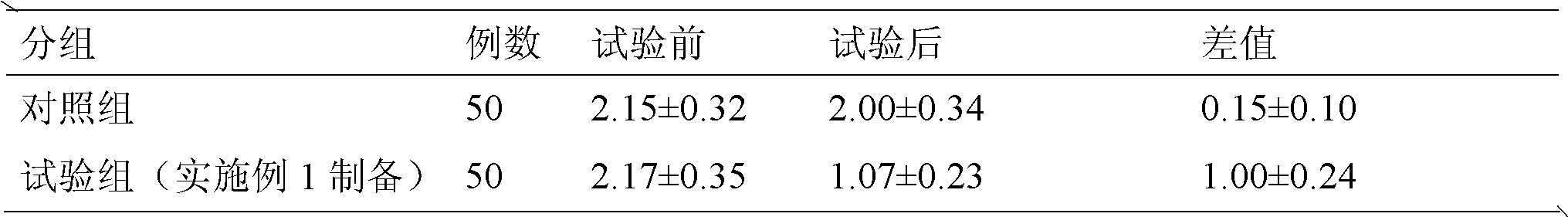

Medlar and tuckahoe composition and preparation method thereof

ActiveCN102552536BGuaranteed accuracyOvercoming restraintOrganic active ingredientsNervous disorderCurative effectAqueous solution

The invention discloses a medlar and tuckahoe composition and a preparation method thereof. The preparation method of the composition comprises the following steps of: (1) preparing medlar, tuckahoe, hawkthorn, aspartame, citric acid and melatonin; (2) drying the medlar in vacuum, crushing the medlar and the tuckahoe together, screening the medlar and tuckahoe powder, crushing the hawkthorn, and screening the hawkthorn powder; (3) adding water into the medlar and tuckahoe powder obtained in the step (2), extracting the medlar and tuckahoe powder under microwave to obtain medlar and tuckahoe extract powder, adding aqueous solution of ethanol into the hawkthorn powder obtained in the step (2), and extracting the hawkthorn powder under microwave to obtain hawkthorn extract powder; and (4) mixing the medlar and tuckahoe extract powder, the hawkthorn extract powder, the aspartame, the citric acid and the melatonin to obtain a medicinal mixture, adding auxiliary materials acceptable in foods or pharmacy into the mixture, and mixing the materials to prepare granules, tablets or capsules. The composition can relieve sleep disorder, can also overcome adverse response when the melatonin is independently taken and relapse after a medicament is not taken, and achieves the effect of treating chloasma.

Owner:TIANJIN TIANSHI BIOLOGICAL DEV

A kind of equipment and method for drying roses at low temperature

ActiveCN104197655BOvercoming the problem of temperature decrease and humidity increaseFlower color fuchsiaDrying machines with local agitationDrying machines with materials at restPurplish redProcess engineering

The invention discloses equipment for low-temperature drying of roses and a method using the equipment to dry the roses. The equipment comprises a drying box body, a moving trolley arranged in the drying box body, a dehumidifying and heat exchanging device arranged in the middle of the top in the drying box body, and a heat supply device for supplying heat to the drying box body. The problems of decrease of temperature and increase of humidity in the drying box body due to the fact that heat energy provided by steam at a stage of rose drying and color fixing cannot be quickly and timely supplemented for air inducing and dehumidifying are solved; the roses dried by the equipment are purplish red in color and bright in tinct, anthocyanin in the roses is protected, and nutrition and healthcare efficacy of the roses on human bodies is improved; the equipment is small in investment, low in running cost and convenient for popularization and use.

Owner:JINAN JIUMEI ROSE PROD

A kind of oregano essential oil microcapsule and preparation method thereof

ActiveCN106071074BOptimizing Process ParametersEasy to storeAnimal feeding stuffAccessory food factorsMonoglycerideSucrose

The invention provides a herba origami essential oil microcapsule which comprises a medicine core, a wall material and an emulsifying agent. Herba origami essential oil is adopted as the medicine core, a mixture of xanthan gum and beta-cyclodextrin is adopted as the wall material, and a mixture of monoglyceride and sucrose ester is adopted as the emulsifying agent. The invention further provides a preparation method of the herba origami essential oil microcapsule. According to the herba origami essential oil microcapsule and the preparation method thereof, it is determined that the herba origami essential oil serves as the medicine core, xanthan gum and beta-cyclodextrin serve as the wall material, and monoglyceride and sucrose ester serve as the emulsifying agent through tests, technological parameters of industrialized production are optimized, and the herba origami essential oil microcapsule meeting the national and international standards is obtained and can be widely applied to animal feed additives; the herba origami essential oil is processed through a spray drying method, the optimal technological formula and spray drying parameter are determined, microencapsulated products of the herba origami essential oil are developed and researched in order to better preserve the herba origami essential oil, protect functional ingredients of the herba origami essential oil, simplify the storage conditions of the herba origami essential oil and widen the application range of the herba origami essential oil, and therefore the herba origami essential oil microcapsule can replace antibiotics to achieve the bacterium resisting and growth promoting effects through feed adding.

Owner:河南华牧生物科技有限公司

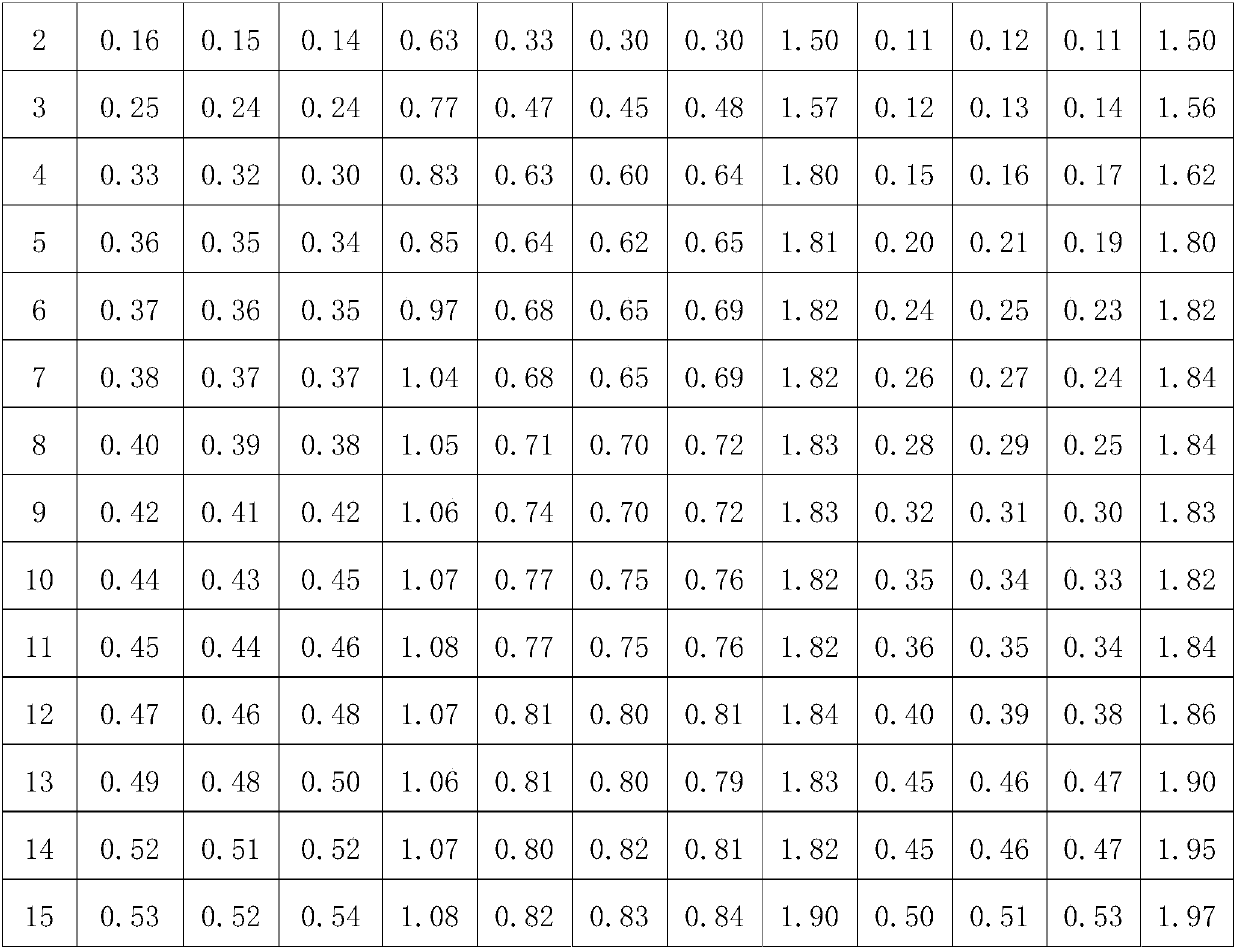

A kind of food-grade bamboo leaf extract nano liposome and its preparation method and application

The present invention relates to food-grade bamboo leaf extract nano-liposomes. The food-grade bamboo leaf extract nano-liposomes are prepared from, 5-20 parts of bamboo leaf extract concentrated bamboo liquid, 20-60 parts of soybean lecithin, 30-50 parts of egg yolk lecithin, 1-5 parts of vitamin E, 1-6 parts of cholesterol, and 1-10 parts of vitamin C by ultrasonic hydration, high pressure homogenization and reverse evaporation-thin film hydration-homogenization. The encapsulation ratio of the food-grade bamboo leaf extract nano-liposomes is 40-70%. The food-grade bamboo leaf extract nano-liposomes contain 0.01-50% of the bamboo leaf extract, have particle sizes of 300-500 [mu]m, are uniform and stable, can effectively replace preservatives to be used for food preservation, and extend shelf life.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

An automatic sampling system

InactiveCN103364229BSampling process automationAvoid enteringWithdrawing sample devicesEngineeringControl theory

The invention discloses an automatic sampling system which comprises a host system and an auxiliary system, wherein the host system comprises a main control module, a speed reducing stepping motor, a stepping driver and a discharging servo motor; the stepping driver is connected with the speed reducing stepping motor; the auxiliary system comprises a box and a sealed servo motor; the sealed servo motor is arranged on the box; a main shaft rotating arm is arranged on the speed reducing stepping motor; a sampling head is fixedly arranged on the end part of the main shaft rotating arm; the discharging servo motor is arranged at the end part of the main shaft rotating arm; a rotating piece is fixedly arranged on a rotating shaft of the discharging servo motor and can be used for blocking the bottom of the sampling head during the sampling; a material guide pipe is arranged in the box of the auxiliary system; an inner film bag is fixedly arranged at an upper end port of the material guide pipe; a sealing cover is fixedly arranged on a rotating shaft of the sealed servo motor and is used for covering the upper end port of the material guide pipe. The automatic sampling system is suitable for sampling matters such as powder and particles, and also suitable for sampling objects with end parts during the transport in the industries of a chemical fertilizer, grains, food and medicines.

Owner:HUBEI ZHONGFU CHEM GROUP

A method for subcritical water extraction of endogenous aroma substances

ActiveCN104059778BReduce pollutionTo preventTobacco treatmentEssential-oils/perfumesDecompositionNitrogen

The invention discloses a method for subcritical water extraction of endogenous aroma-inducing substances, comprising the following steps: (1) crushing tobacco raw materials to 30-120 meshes and then putting them into an extraction kettle, using high-purity nitrogen to replace the inside of the extraction kettle (2) Use high-purity nitrogen to remove the oxygen in the ionized water in the storage tank to form deionized water, and pump the deionized water into the extraction kettle after preliminary preheating; (3) The temperature gradient in the extraction kettle Raise the temperature to the extraction temperature of 120~200°C, adjust the pressure in the extraction kettle to 5~7MPa, after the extraction is completed, the extract is cooled by a cooler; (4) Repeat steps (2) and (3) for the second and third The extracts from the three extractions were combined. The method of the invention can effectively reduce the influence of by-products formed in the extraction kettle due to high-temperature oxidative decomposition, and the extraction rate is greatly improved.

Owner:SUZHOU ZEDAXINGBANG MEDICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com