Catalyst support for preparing a catalyst for removal of nitrogen oxides and method for preparing thereof

A catalyst carrier and oxygen compound technology, applied in the field of catalyst carrier and its preparation, can solve the problems of difficulty in drying, unsuitability, and high cordierite price, and achieve the effects of excellent out-of-stock effect, reduced usage, and reduced cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 80 kg of the waste shown in the above [Table 3], 20 kg of zeolite (JAPAN, NAGOYANITTOREN Raw Material Co., Ltd. product name: H-3), 3 kg of lignocellulose, 10 kg of kaolin series clay, and non-combustible lubricant (JAPAN, NAGOYACOL Ltd., M -3) and water, put it into an ordinary kneader (crusher) and grind it together to obtain clay for molding.

[0039] With the help of a screw extrusion molding machine, the obtained molding clay is directly extruded to prepare a honeycomb shaped body with a length of 150mm, a width of 150mm, a height of 150mm, a thickness of 0.7mm, and a gap of 4.0mm between the walls. After drying for 1 hour, it was fired at 550° C. for 4 hours to prepare a carrier with a honeycomb structure.

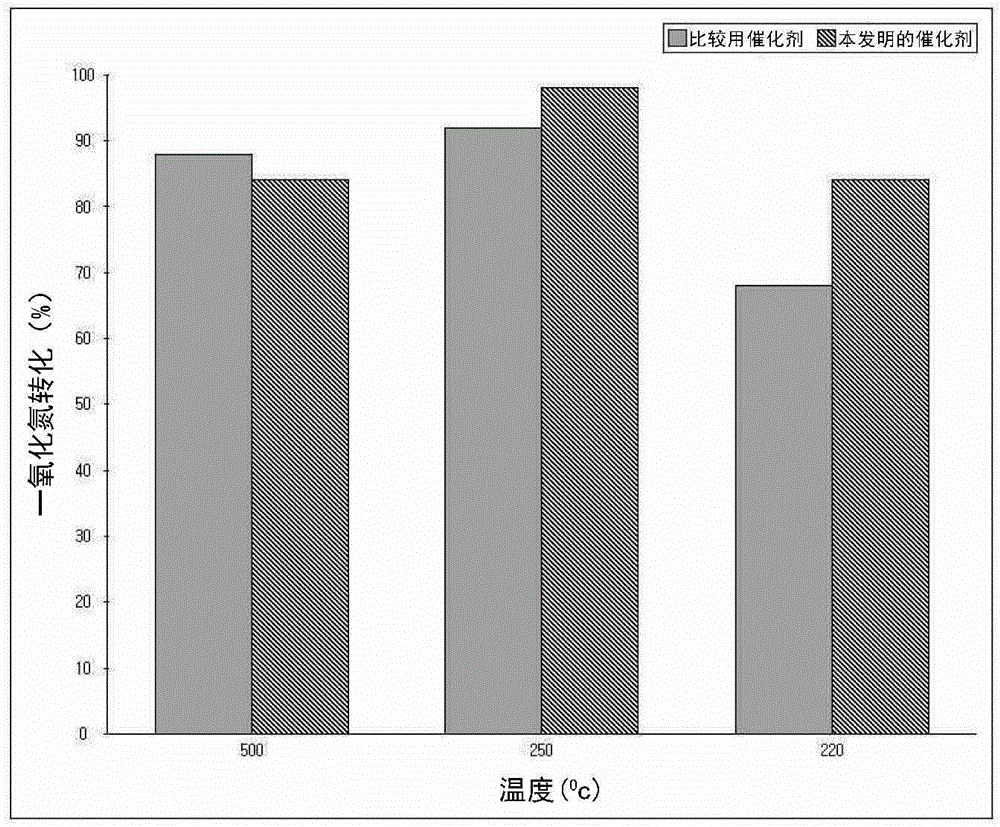

[0040] When the characteristics of the honeycomb structure carrier of the present invention prepared above were compared with a commonly used honeycomb carrier (anatase carrier), the results are shown in the following [Table 4].

[0041] Table 4

[0042] Dif...

Embodiment 2

[0047] Coordinate according to the same method as above , increase the water content, and after obtaining the muddy pottery clay, evenly cover the muddy pottery clay on a metal mesh with a mesh iron specification of 4P by a thickness of 0.3mm ( On the surface of length 15cm x width 15cm), after drying for 10 hours, it was fired at 500°C for 2 hours to prepare a flat catalyst carrier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com