High-efficiency corrosion resistant pre-mixed mortar

A ready-mixed mortar and corrosion-resistant technology, which is applied in the field of ready-mixed mortar materials for construction, can solve problems such as pollution, short setting time, serious problems, etc., achieve uniform microstructure, improve corrosion resistance, and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

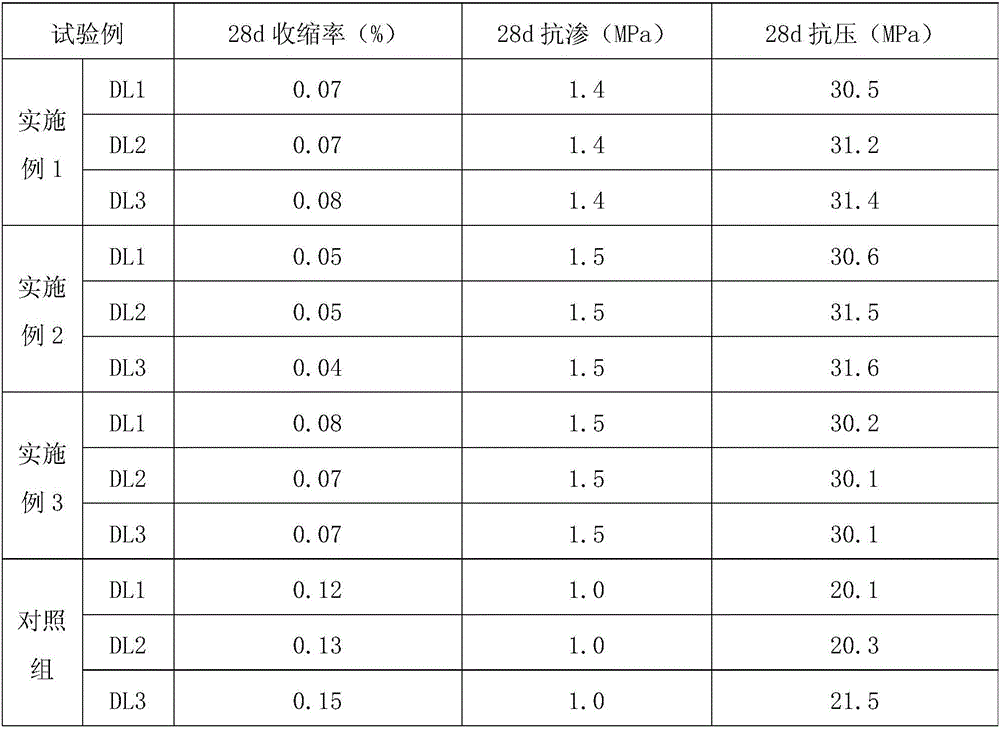

Embodiment 1

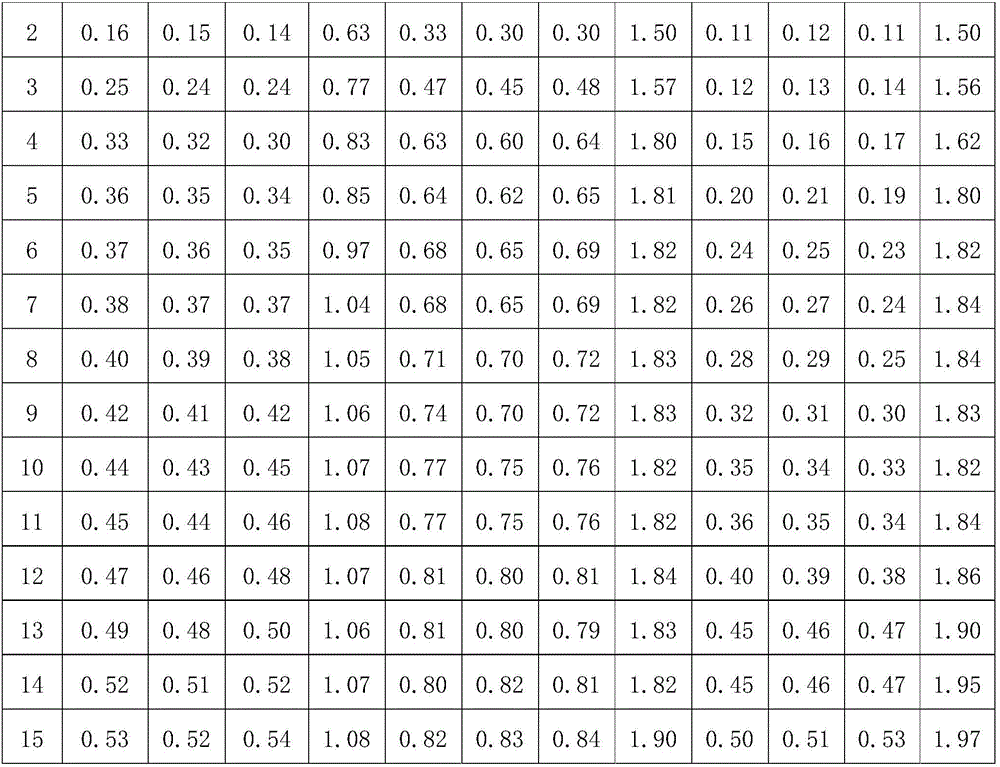

[0024] Take 20% of river sand with a particle size of 0.20mm, 30% of machine-made sand with a particle size of 1mm, 10% of fly ash with a particle size of 0.5mm-1mm, 10% of granulated blast furnace slag powder, 1 % of polycarboxylic acid, 1% of sodium gluconate, 10% of cement, 8% of redispersible latex powder, 5% of kaolin with an average particle size of 0.5-1 μm, and 5% of electrolytic manganese slag waste are stirred and mixed, Add water, after the mixing material is completely soaked and a little water overflows, put the mixed mortar concrete into a specimen mold with a size of 30cm×15cm×15cm for molding, and produce 3 specimens in total, and the 3 specimens are respectively Curing at room temperature in humidity for 1d, measuring compressive strength, impermeability strength and shrinkage rate after standard curing in water for 28d, immersing 3 specimens respectively after standard curing in water for 28d: tap water, 5% Na 2 SO 4 Solution, 5% NaOH, curing for 15 weeks, t...

Embodiment 2

[0026] Take 10% of river sand with a particle size of 0.40mm, 20% of machine-made sand with a particle size of 2.5mm, 15% of fly ash with a particle size of 0.5mm-1mm, 15% of granulated blast furnace slag powder, Stir and mix 1.5% polycarboxylic acid, 1.5% sodium gluconate, 15% cement, 5% redispersible latex powder, 7% kaolin with an average particle size of 0.5-1μm, and 10% electrolytic manganese slag waste , add water, after the mixing material is completely soaked and a little water overflows, put the mixed mortar concrete into a test piece mold with a size of 30cm×15cm×15cm to form, and produce 3 test pieces and 3 test pieces Respectively in the humidity for 1d at room temperature, after 28 days of standard water curing, measure the compressive strength, impermeability strength, shrinkage rate, after 28 days of standard water curing, immerse the three test pieces respectively: tap water, 5% Na 2 SO 4 Solution, 5% NaOH, curing for 15 weeks, test its expansion rate.

Embodiment 3

[0028] Take 5% of river sand with a particle size of 0.30mm, 15% of machine-made sand with a particle size of 1.5mm, 20% of fly ash with a particle size of 0.5mm-1mm, 20% of granulated blast furnace slag powder, Stir and mix 2% polycarboxylic acid, 2% sodium gluconate, 5% cement, 15% redispersible latex powder, 10% kaolin with an average particle size of 0.5-1μm, and 6% electrolytic manganese slag waste , add water, after the mixing material is completely soaked and a little water overflows, put the mixed mortar concrete into a test piece mold with a size of 30cm×15cm×15cm to form, and produce 3 test pieces and 3 test pieces Respectively in the humidity for 1d at room temperature, after 28 days of standard water curing, measure the compressive strength, impermeability strength, shrinkage rate, after 28 days of standard water curing, immerse the three test pieces respectively: tap water, 5% Na 2 SO 4 Solution, 5% NaOH, curing for 15 weeks, test its expansion rate.

[0029] Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com