A kind of oregano essential oil microcapsule and preparation method thereof

A technology for microcapsules and essential oils, which is applied in the directions of microcapsules, capsule transportation, and animal feed molding or processing, can solve problems such as high price and cost constraints, and achieve the effect of optimizing process parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

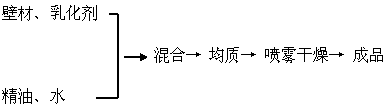

Method used

Image

Examples

Embodiment 1

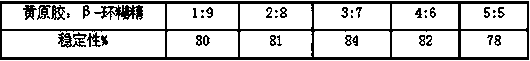

[0158] (1) In a 20L stainless steel bucket, weigh 3000g of xanthan gum and 7000g of β-cyclodextrin, pour them into the stainless steel bucket and mix them, stir them evenly with a glass rod, and get the wall material for later use;

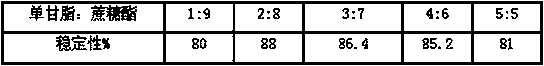

[0159] (2) In a 2L stainless steel bucket, weigh 200g of monoglyceride and 800g of sucrose ester and mix them in the stainless steel bucket. Stir evenly with a glass rod to obtain emulsifier, set aside;

[0160] (3) In a 5L stainless steel bucket, measure 100ml of oregano essential oil and add it to 300g of the wall material obtained in step (1), stir evenly with a glass rod to obtain a product mixture;

[0161] (4) Add an emulsifier and water to the mixture in step (3) to obtain a material; the amount of emulsifier added is 0.6% (W / W), and water is added to prepare a solid concentration of 18%;

[0162] (5) Homogenize the material before spray drying, the time is 1.5 min, and the homogenization speed is 16r / min;

[0163] (6) The air inlet tempe...

Embodiment 2

[0165] (1) In a 20L stainless steel bucket, weigh 1000g of xanthan gum and 9000g of β-cyclodextrin into the stainless steel bucket to mix, stir evenly with a glass rod to obtain wall material, and set aside;

[0166] (2) In a 2L stainless steel bucket, weigh 100g of monoglyceride and 900g of sucrose ester and mix them in the stainless steel bucket. Stir evenly with a glass rod to obtain emulsifier, set aside;

[0167] (3) In a 5L stainless steel bucket, measure 100ml of oregano essential oil and add it to 100g of the wall material obtained in step (1), stir evenly with a glass rod to obtain a product mixture;

[0168] (4) Add emulsifier and water to the mixture in step (3) to obtain the material; the amount of emulsifier added is 0.2% (W / W), and water is added to prepare a solid concentration of 10%;

[0169] (5) Homogenize the material before spray drying, the time is 0.5min, and the homogenization speed is 10r / min;

[0170] (6) The air inlet temperature of the spray drying...

Embodiment 3

[0172] (1) In a 20L stainless steel bucket, weigh 5000g of xanthan gum and 5000g of β-cyclodextrin, pour them into the stainless steel bucket and mix them, stir them evenly with a glass rod, and get the wall material for later use;

[0173] (2) In a 2L stainless steel bucket, weigh 500g of monoglyceride and 500g of sucrose ester and mix them in the stainless steel bucket. Stir evenly with a glass rod to obtain emulsifier, set aside;

[0174] (3) In a 5L stainless steel bucket, measure 100ml of oregano essential oil and add it to 500g of the wall material obtained in step (1), and stir evenly with a glass rod to obtain a product mixture;

[0175] (4) Add emulsifier and water to the mixture in step (3) to obtain the material; the amount of emulsifier added is 1.0% (W / W), and water is added to prepare a solid content concentration of 32%;

[0176] (5) Homogenize the material before spray drying, the time is 2.5min, and the homogenization speed is 19r / min;

[0177] (6) The inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com