Raw material storage and processing method applied to production of bioethanol

A processing method and technology of bioethanol, applied in microorganism-based methods, biochemical equipment and methods, biofuels, etc., can solve problems such as large loss of raw material dry matter, economic loss, and increased lignification degree, and reduce storage additives. The effect of reducing the use and storage costs of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

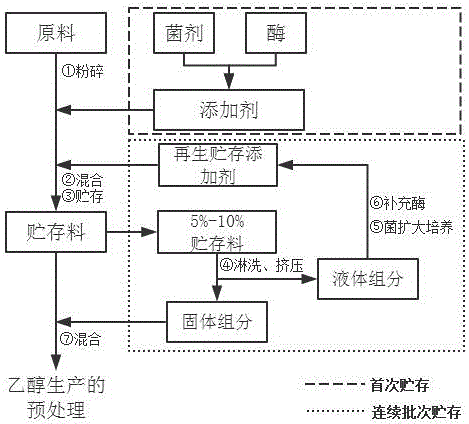

[0025] The switchgrass is the raw material for storage, and the ingredients of the used switchgrass are shown in Table 1.

[0026] Table 1 Main components of switchgrass

[0027]

[0028] The moisture content of switchgrass at harvest is 45%, and it is not crushed before storage. First, it is naturally dried to 25%-30% in a ventilated place indoors. Set 5 storage water content 30%-70%, 10% as a gradient. When the moisture content is set at 30%-50%, the crushing particle size is 2.5-5.0 cm, and when the moisture content is set at 50%-70%, the crushing particle size is 3.0-10.0 cm.

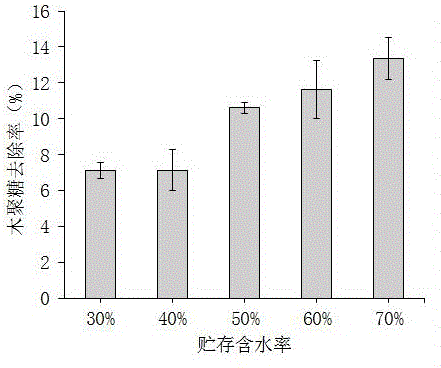

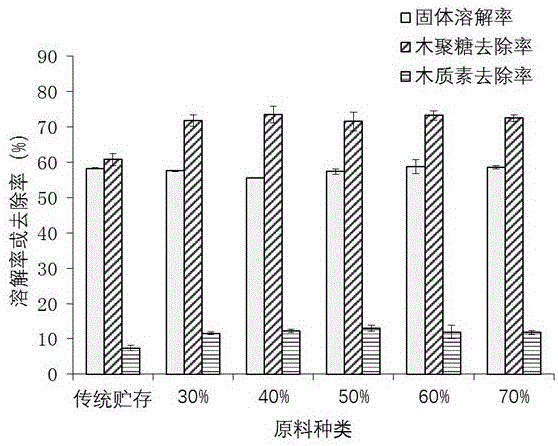

[0029] To prepare storage additives, use an appropriate amount of 30 ℃ sterile water to dilute the microbial inoculum and hemicellulase, so that the moisture content after mixing with the raw materials is about 30%, 40%, 50%, 60% and 70%. The lactic acid bacteria are Lactobacillus plantarum, Pediococcus lactis and Lactobacillus delbrueckii in a ratio of 5:1:1. Based on the dry weight of raw ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com