A kind of food-grade bamboo leaf extract nano liposome and its preparation method and application

A technology of bamboo leaf extract and nano-liposome, which is applied in the fields of application, food science, food preservation, etc., and achieves the effects of high yield, easy large-scale production, good economic benefits and application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

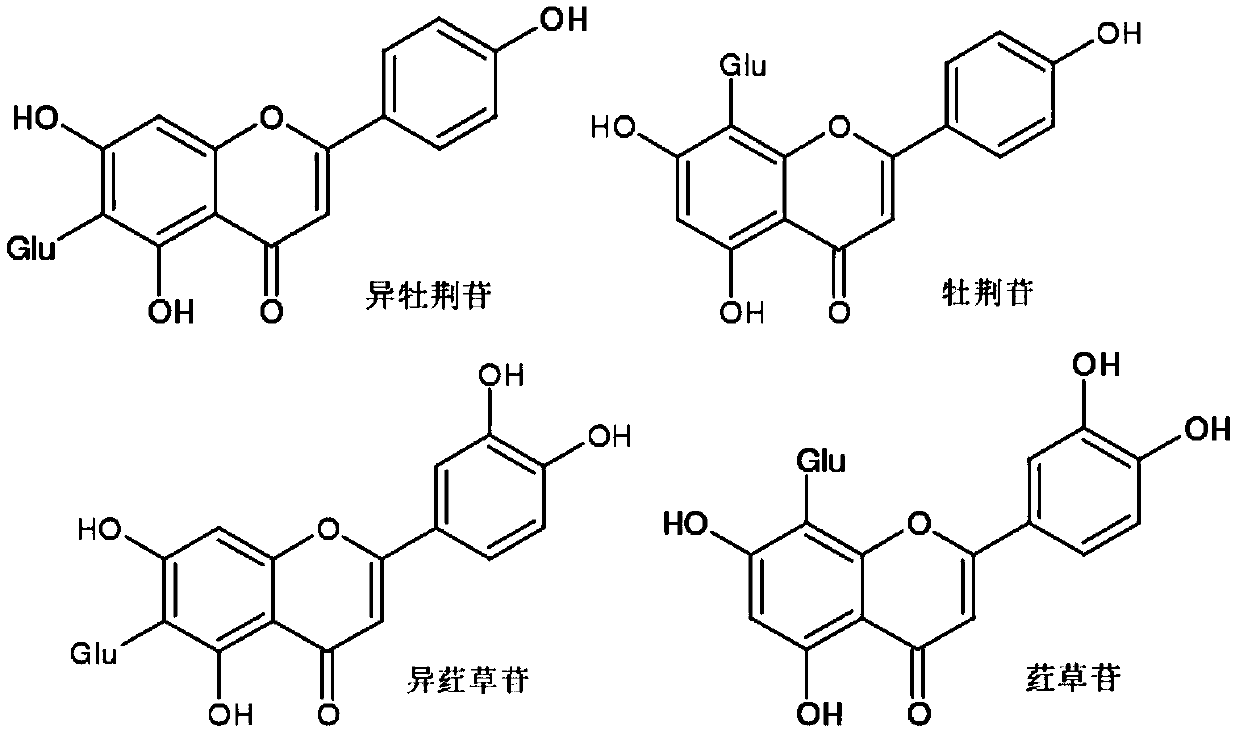

Image

Examples

Embodiment 1

[0030] 1. Take dried bamboo leaves, crush them, pass through 40 meshes, add bamboo leaves and 50-75% ethanol solution respectively at a ratio of 10Kg: 50L to 10Kg: 200L with a material-liquid ratio, and extract 20% with the aid of ultrasonic waves at a temperature of 40-70 degrees. -100 minutes to obtain the extract containing bamboo leaves.

[0031] 2. Adsorbed by macroporous adsorption resin with polystyrene skeleton, and eluted with 4 times column volume of 75% ethanol. The eluate is separated by ultrafiltration membrane and concentrated under reduced pressure to obtain 25-50 L of bamboo leaf extract concentrate.

[0032] 3. 20 parts of bamboo leaf extract concentrate, 30 parts of soybean lecithin, 40 parts of egg yolk lecithin, 5 parts of vitamin E, 2 parts of cholesterol, and 3 parts of vitamin C, mixed and fully dissolved in ethanol solution to obtain lipid solution, at temperature Under the condition of 50 degrees Celsius, the organic solvent is removed under reduced p...

Embodiment 2

[0035] 1. Select dry bamboo leaves, crush them, pass through 40 meshes, add bamboo leaves and 30-85% ethanol solution at a ratio of 1Kg: 5L to 1Kg: 20L with a material-to-liquid ratio, and extract 50% with the aid of ultrasonic waves at a temperature of 40-70 degrees. Minutes, obtain containing bamboo leaf extract.

[0036] 2. Adsorbed by macroporous adsorption resin with polystyrene skeleton, and eluted with 75% ethanol with 5 times column volume. The eluate is separated by ultrafiltration membrane and concentrated under reduced pressure to obtain 2-5L of bamboo leaf extract concentrate.

[0037] 3. 10 parts of bamboo leaf extract concentrate, 40 parts of soybean lecithin, 45 parts of egg yolk lecithin, 2 parts of vitamin E, 1 part of cholesterol, and 2 parts of vitamin C are mixed and fully dissolved in ethanol solution to obtain a lipid solution. Under the condition of 40 degrees Celsius, use a rotary evaporator to remove the organic solvent under reduced pressure, and the...

Embodiment 3

[0040]1. Select dry bamboo leaves, crush them, pass through 30 meshes, add bamboo leaves and 30-75% ethanol solution at a ratio of 5Kg: 20L to 10Kg: 50L with a material-to-liquid ratio, and use ultrasonic-assisted extraction for 60 Minutes, obtain containing bamboo leaf extract.

[0041] 2. Adsorbed by macroporous adsorption resin with polystyrene skeleton, and eluted with 75% ethanol with 5 times column volume. The eluate is separated by an ultrafiltration membrane and concentrated under reduced pressure to obtain 2-8 L of bamboo leaf extract concentrate.

[0042] 3. 15 parts of bamboo leaf extract concentrate, 50 parts of soybean lecithin, 30 parts of egg yolk lecithin, 2 parts of vitamin E, 1 part of cholesterol, and 3 parts of vitamin C, mixed and fully dissolved in ethanol solution to obtain lipid solution, at temperature Under the condition of 45 degrees Celsius, use a rotary evaporator to remove the organic solvent under reduced pressure, and the temperature is 30-50 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com