An automatic sampling system

A technology of automatic sampling and host system, applied in the direction of sampling devices, etc., can solve the problems of inaccurate mechanical inertia, low degree of automation, and low reliability, and achieve the effect of reliable sampling work, strong practicability, and flexible sampling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

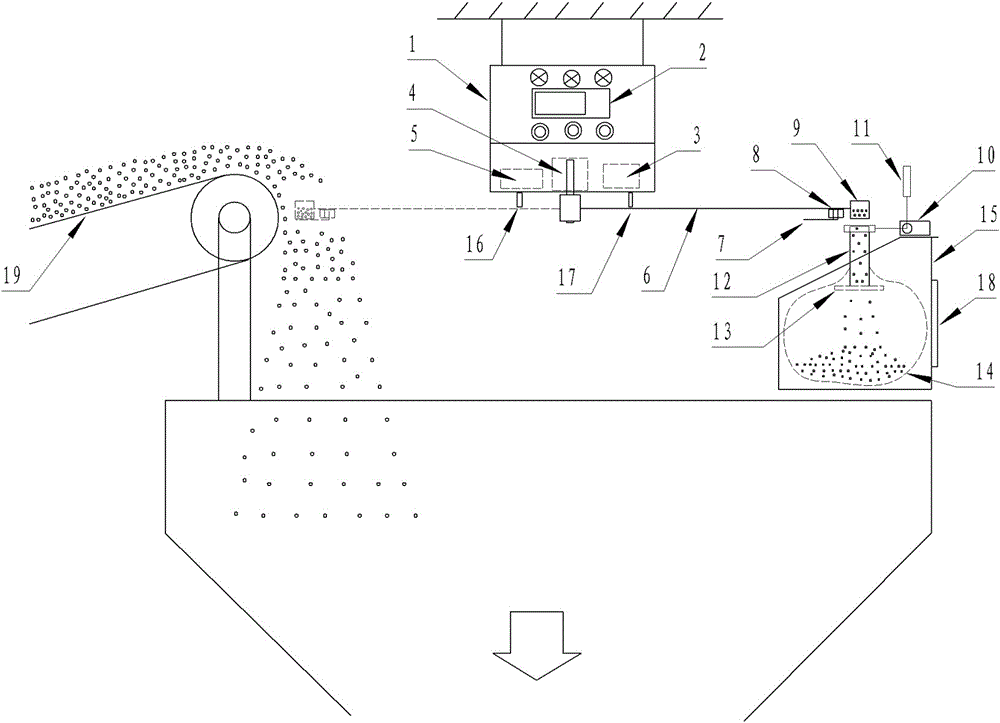

[0020] Such as figure 1 , Figure 4 As shown, an automatic sampling system includes two major systems: a host system 1 and an auxiliary system 15. The host system 1 mainly includes a host chassis, a host panel 20, a main control module 2, a spindle arm 6, and a stepping driver 5 , deceleration stepping motor 4, switching power supply 3, sampling head 9, discharging servo motor 8, rotating piece 7.

[0021] The auxiliary machine system 15 mainly includes an auxiliary machine box, a material guide pipe 12 , a material guide plate 13 , a sealed servo motor 10 , a sealed cover 11 , and a viewing window 18 .

[0022] Described host panel 20 tops are respectively power supply (red), operation (green), alarm (yellow) three indicator lamps from left to right, the middle part is rectangular main control module 2, and lower part is setting (green) respectively from left to right. ), reset (red), and manual sampling (green), the left is the hinge of the panel door, and the right is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com