Method for treating mother liquid discharged in glycine production

A treatment method, the technology of aminoacetic acid, applied in the preparation/separation of ammonia, chemical instruments and methods, and the preparation of organic compounds, etc., can solve the problems of low environmental and economic benefits, unrecoverable catalyst urotropine, difficult Survival and other issues, to achieve the effect of high price, large amount, and zero emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

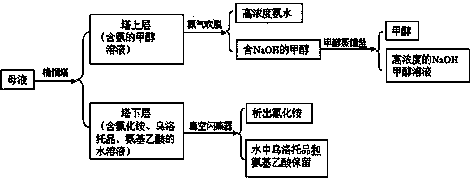

Image

Examples

specific Embodiment 1

[0020] (1) Put the mother liquor in a rectification tower, distill under reduced pressure, the pressure is -0.09Mpa, the temperature is 60°C, and the methanol and the ammonium chloride aqueous solution are separated; the methanol solution containing 8% ammonia is obtained at the top of the tower, and the methanol solution containing 8% ammonia is obtained at the bottom of the tower. Aqueous solution of ammonium chloride, urotropine, glycine;

[0021] (2) The ammonia-containing methanol separated from the top of the rectification tower in step (1) is stripped of ammonia gas, and the process is as follows:

[0022] The ammonia-containing methanol condensed from the top of the rectification tower continuously flows into the ammonium solution, and the sodium hydroxide solution is continuously added dropwise to adjust the pH value of the methanol solution to 11.8~12, so that the ammonia gas is separated from the methanol, and at the same time, air is introduced The ammonia gas is b...

specific Embodiment 2

[0026] (1) Put the mother liquor in a rectification tower, distill under reduced pressure, the pressure is -0.09Mpa, the temperature is 70°C, and the methanol and ammonium chloride aqueous solution are separated; the top of the tower obtains a methanol solution containing 12% ammonia, and the bottom of the tower contains Aqueous solution of ammonium chloride, urotropine, glycine;

[0027] (2) The ammonia-containing methanol separated from the top of the rectification tower in step (1) is stripped of ammonia gas, and the process is as follows:

[0028] The ammonia-containing methanol condensed from the top of the rectification tower continuously flows into the ammonium solution, and the sodium hydroxide solution is continuously added dropwise to adjust the pH value of the methanol solution to 11.8~12, so that the ammonia gas is separated from the methanol, and at the same time, air is introduced The ammonia gas is brought out with a resolution rate of more than 98%, and the amm...

specific Embodiment 3

[0032] (1) Put the mother liquor in a rectification tower, distill under reduced pressure, the pressure is -0.09Mpa, the temperature is 80°C, and the methanol and ammonium chloride aqueous solution are separated; the top of the tower obtains a methanol solution containing 10% ammonia, and the bottom of the tower contains Aqueous solution of ammonium chloride, urotropine, glycine;

[0033] (2) The ammonia-containing methanol separated from the top of the rectification tower in step (1) is stripped of ammonia gas, and the process is as follows:

[0034] The ammonia-containing methanol condensed from the top of the rectification tower continuously flows into the ammonium solution, and the sodium hydroxide solution is continuously added dropwise to adjust the pH value of the methanol solution to 11.8~12, so that the ammonia gas is separated from the methanol, and at the same time, air is introduced The ammonia gas is brought out with a resolution rate of more than 98%, and the amm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com