Partial layered assembling type steel-structure low-rise residential system

A prefabricated, steel structure technology, applied in the direction of residential construction, building structure, construction, etc., can solve the problem of high cost, achieve the effect of reducing material cost, shortening construction period, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

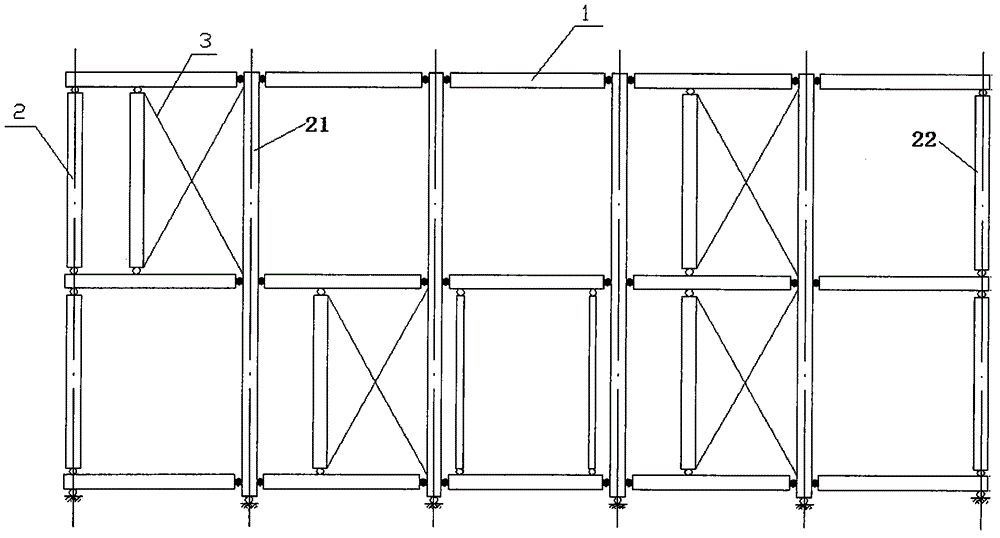

[0009] Such as figure 1 As shown, the low-rise residential system of partially layered assembled steel structure of the present invention includes a plurality of columns 2, beams 1 and supports 3, and beams 1 are arranged on each floor between the columns 2, and beams 1 on each floor Supports 3 are provided between them; the columns include through columns 21 and interlayer columns 22, interlayer columns 22 are arranged on the periphery of the structure, and through columns 21 are arranged inside the structure.

[0010] The local layered assembled steel structure low-rise residential system of the present invention:

[0011] 1) The structure is layered by beams, and beams are used internally. Through columns and interlayer columns are arranged between modules, which can be moved and arranged between beams, and serve as the skeleton of the wall structure.

[0012] 2) Flexible tensile supports are used to connect beams and columns to form a wall to resist the lateral force of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com