Patents

Literature

113results about How to "Guaranteed operating accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

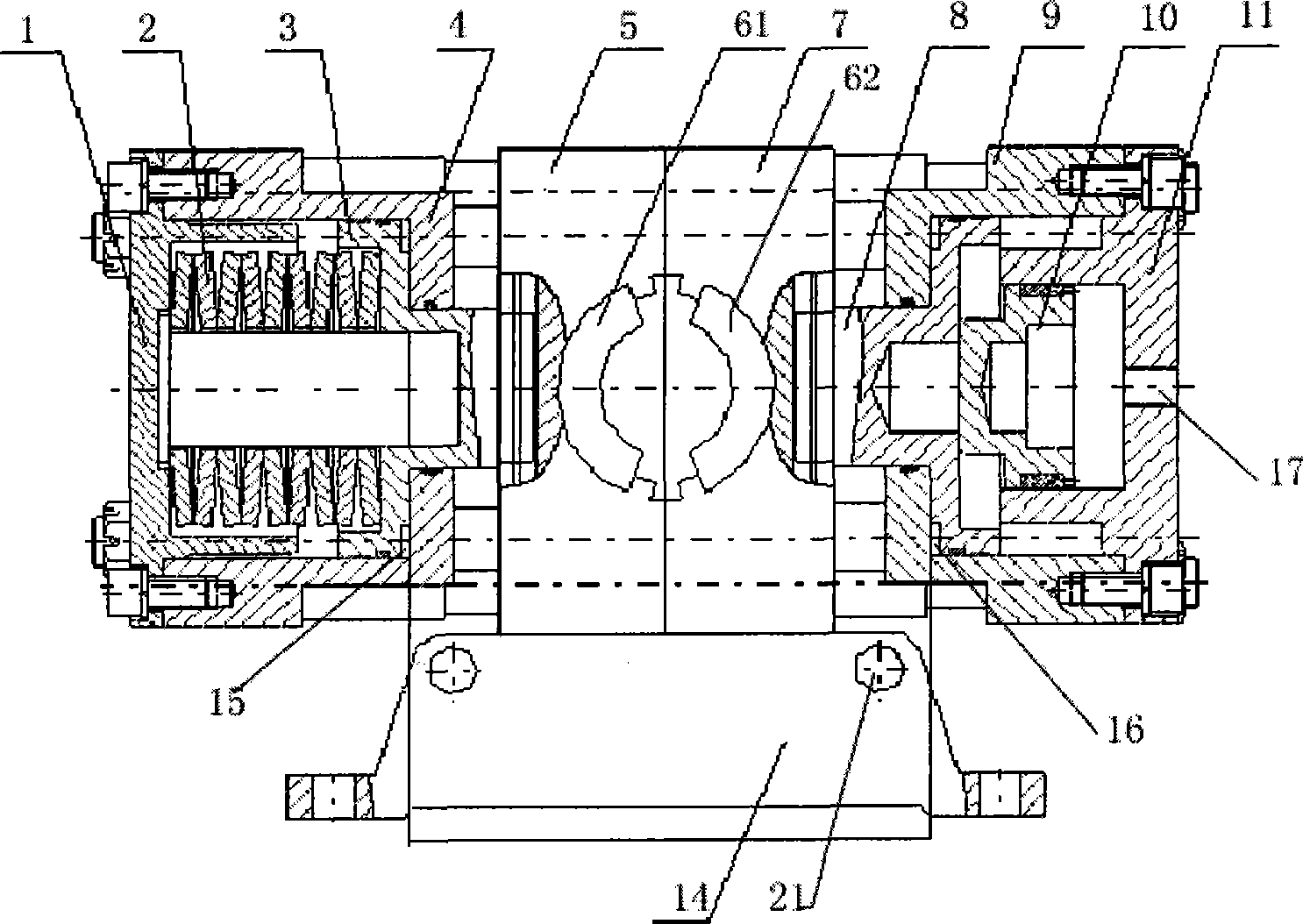

Linkage hydraulic clamper for mining fully hydraulic rig

ActiveCN101363310AGuaranteed reliabilityRealize increased force clampingDrilling rodsDrilling casingsDrive motorEngineering

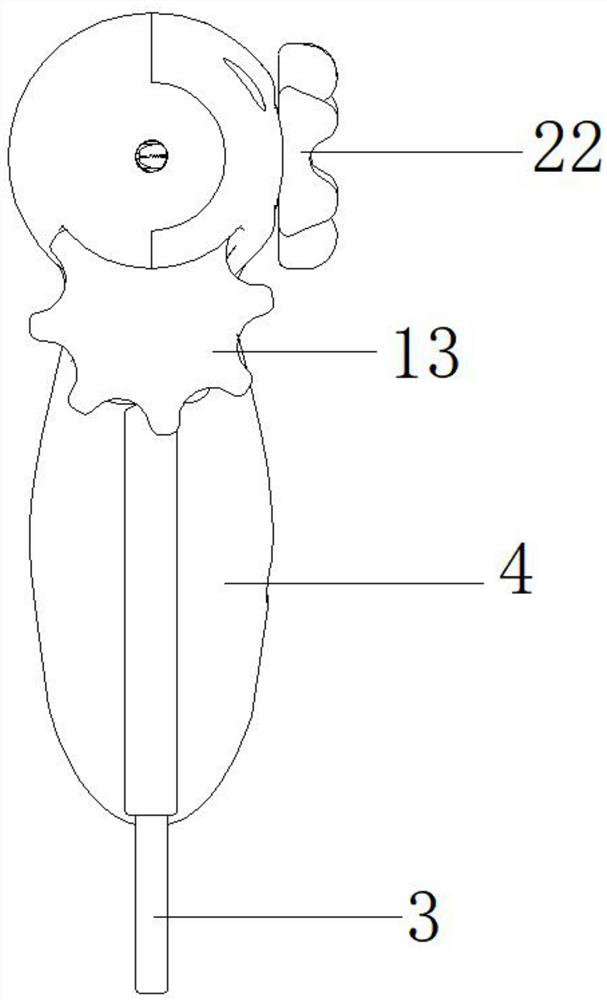

The present invention discloses a mining full hydraulic drill linkage hydraulic clamp fastener which comprises a clamp fastener body. The clamp fastener body comprises a left clamping device and right clamping device which are connected by a pull rod structure and a reinforcement oil cylinder which is arranged in the right clamping device. Compared with the traditional clamp fastener, the clamp fastener is provided with two oil cylinders which push a clamping disc spring open at the same time, and the clamp fastener can be released by less pressure, thereby being good for opening the clamp fastener by the rotation back pressure of the drill and facilitating the drill rotation-propulsion and clamp fastener linkage operation. The clamp fastener can not only use a belleville spring to clamp the a drill rod, but also couple a drill power head driving motor reverse oil passage in the reinforcement oil cylinder and utilize the reverse pressure of the drill to realize reinforcement fastening motion, thus ensuring the reliability of the fastening motion of the drill rod; the clamp fastener is also provided with an automatic float centering structure which can follow the drill rod to center the fastening motion automatically and ensure the operation precision.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

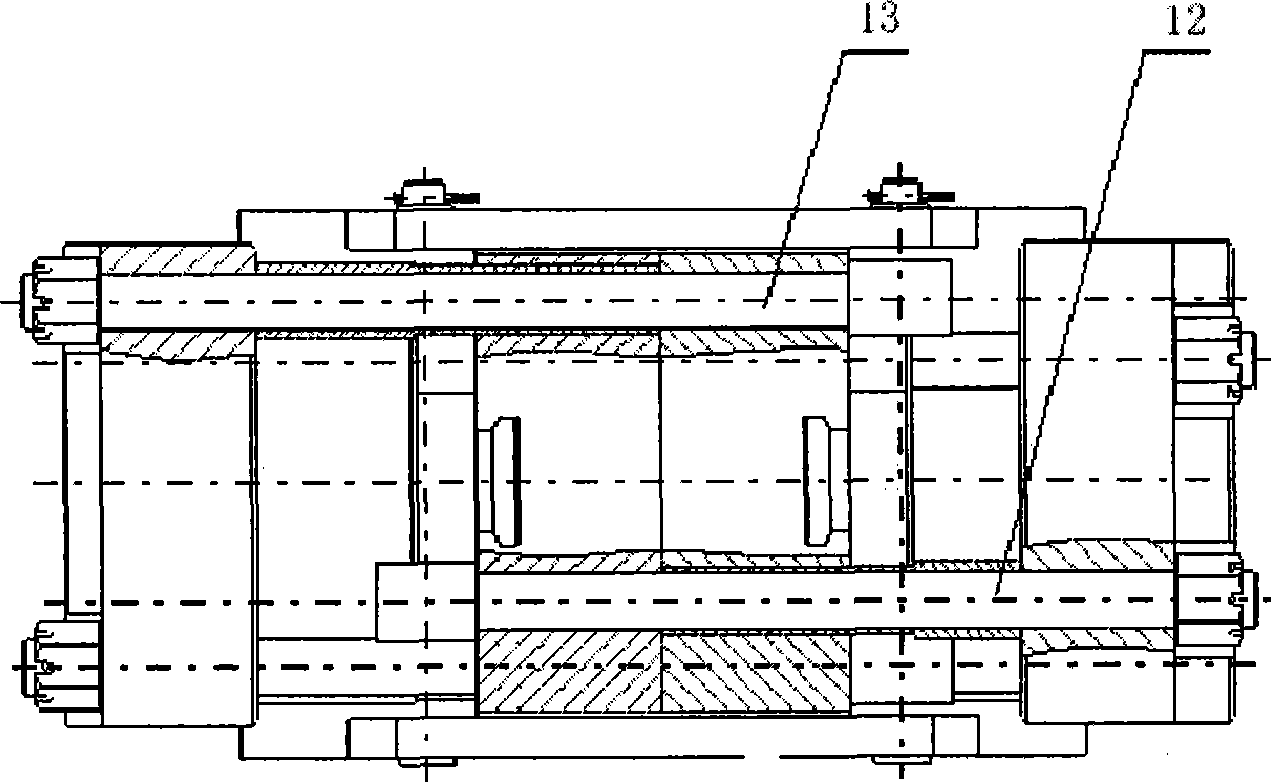

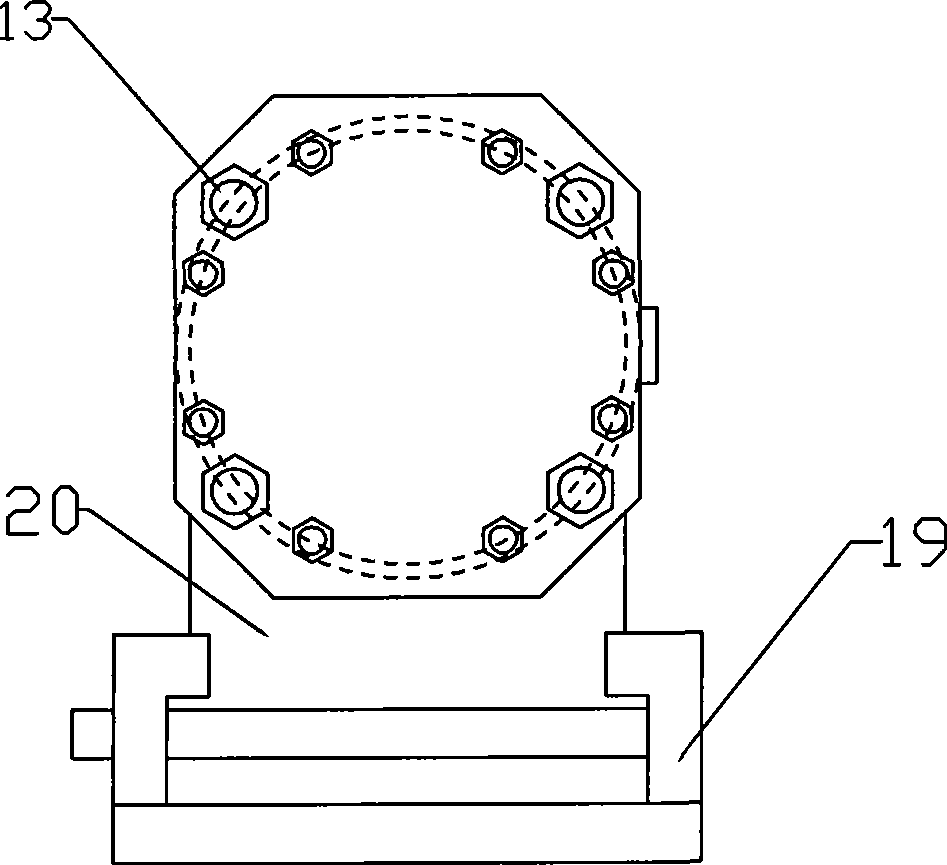

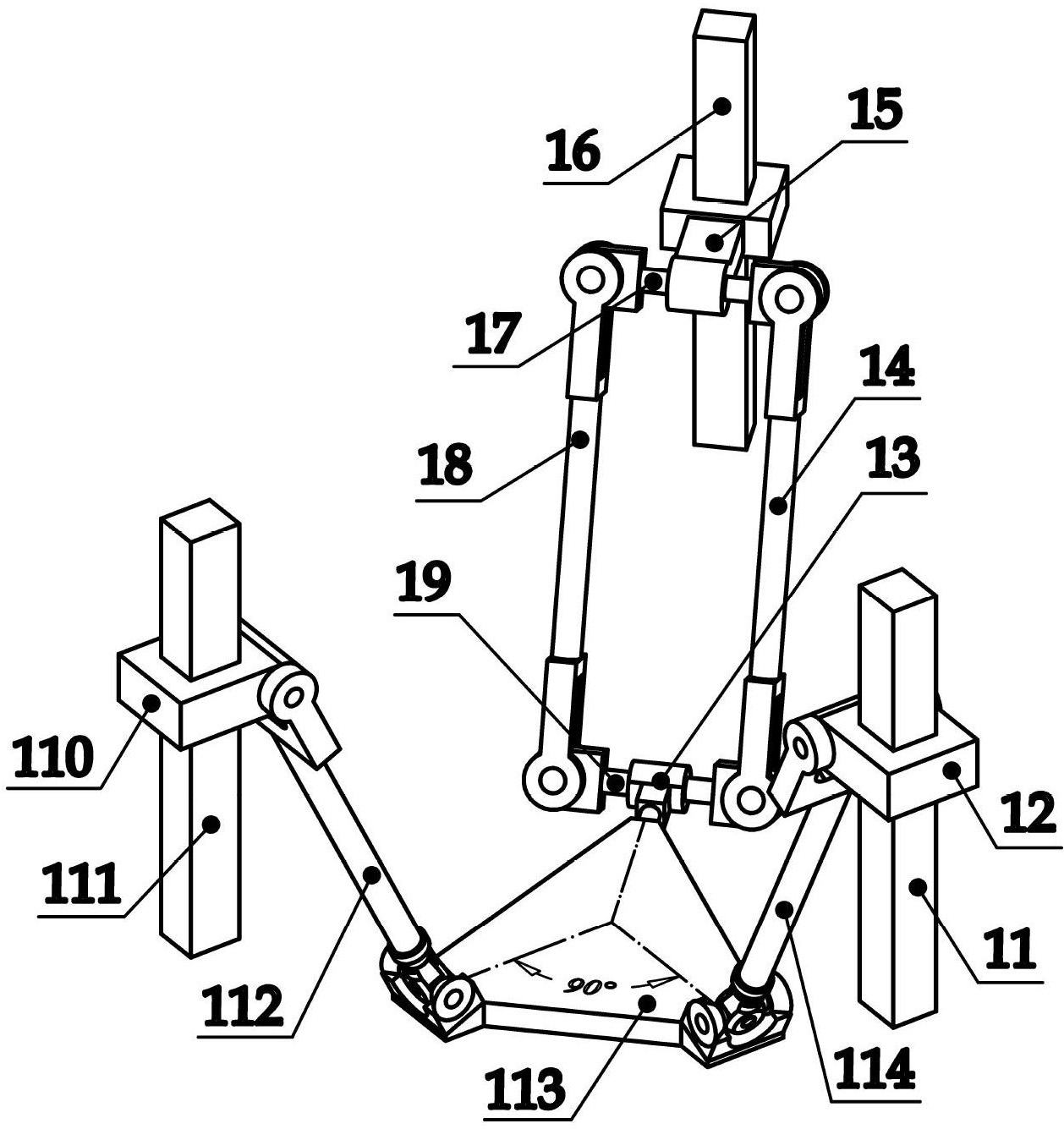

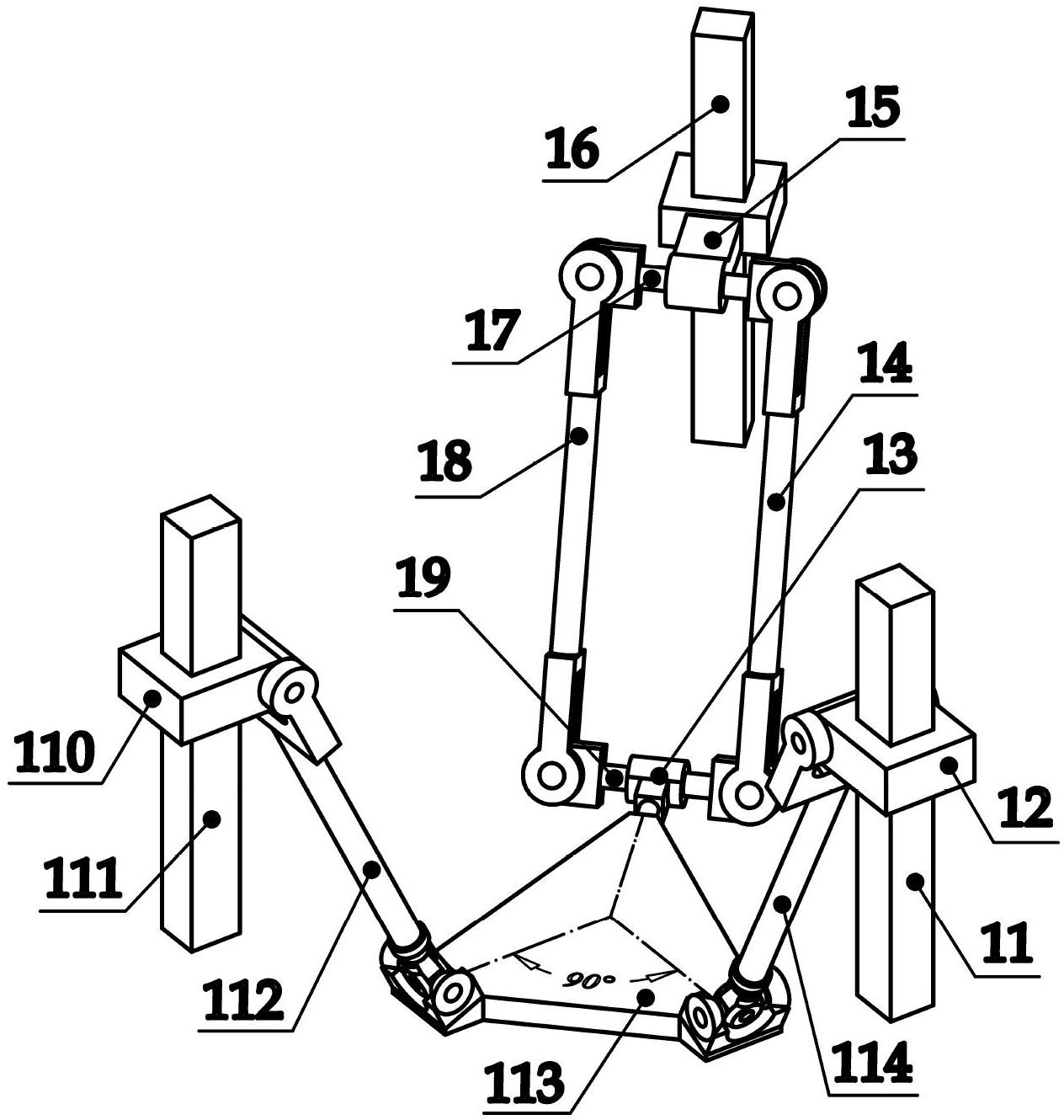

High-flexibility three-DOF (Degree of Freedom) spatial parallel mechanism

ActiveCN102626871AIncrease flexibilityImprove turning abilityLarge fixed membersRotational axisEngineering

The invention relates to a high-flexibility three-DOF (Degree of Freedom) spatial parallel mechanism, belonging to the technical field of numerical control machines, and comprising a mobile platform, a fixed platform, a first branched chain, a second branched chain and a third branched chain, wherein the mobile and fixed platforms are provided with an actuator respectively; the first and second branched chains are connected between the mobile and fixed platforms and have the same structure; and the third branched chain is connected between the mobile and fixed platforms and has a structure different from the structure of the first second branched chains. The first, second and third branched chains all contain an actively-driving kinematic pair and are respectively connected with the fixed and mobile platforms to form a spatial parallel closed-loop mechanism. The spatial parallel closed-loop mechanism drives the mobile platform to move by three input motions to realize one mobile DOF and two rotational DOFs. The spatial parallel mechanism has high flexibility, specific rotational axis, relatively simple associated movement and other characteristics, and the operation precision and quality of the mechanism can be ensured more easily.

Owner:TSINGHUA UNIV

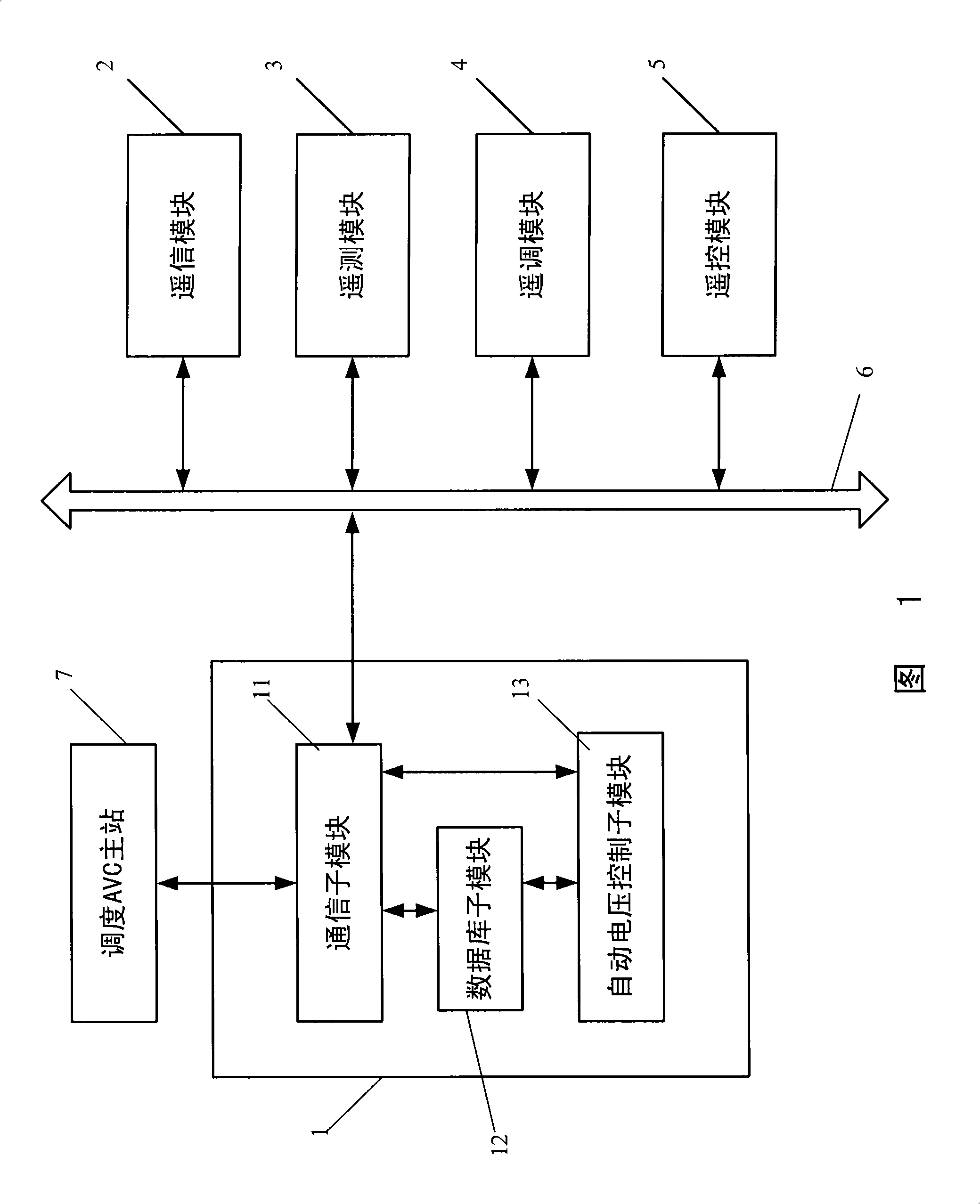

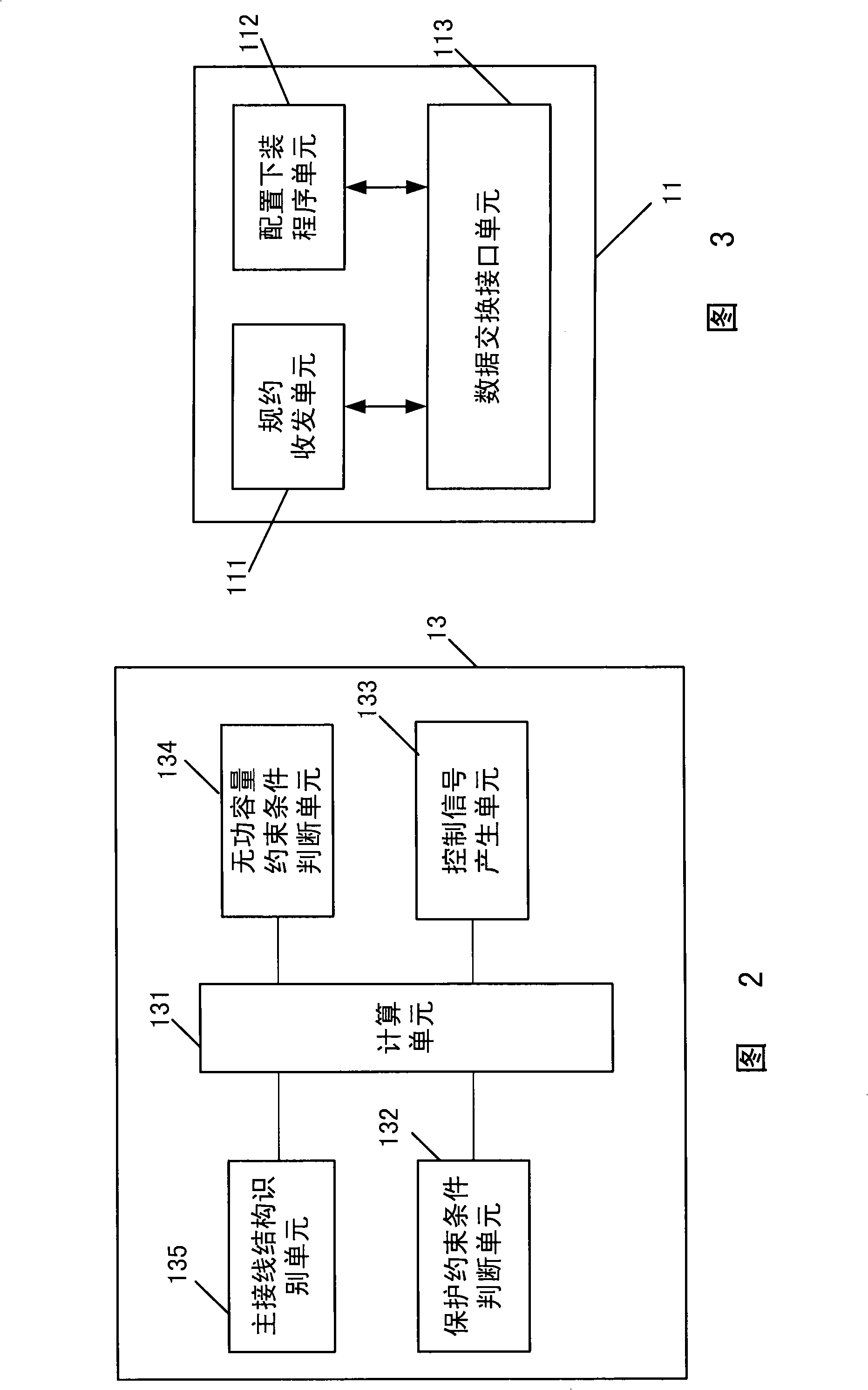

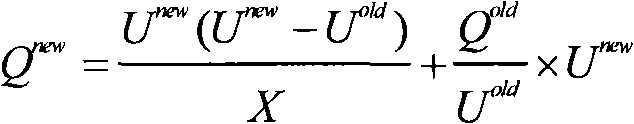

Electric power telemechanical device RTU and method for implementing automatic voltage control of generating plant

InactiveCN101299587AEnsure consistencyGuaranteed operating accuracyComputer controlSingle network parallel feeding arrangementsAutomatic controlPower station

The invention discloses an electric power telemechanical apparatus RTU and a method for realizing the automatic voltage control of the power plant. The inventive electric power telemechanical apparatus includes a central control module, a remote signalling module, a telemetering module, a remote regulating module and a remote control module, wherein the central control module includes a communication submodule, a data bank submodule and an automatic voltage control submodule, which generates the control signal for adjusting the wattless production output of the generating set, based on the data stored in the data bank submodule, and transmits the control signals to the remote regulating module or the remote control module through the communication submodule, then transmits to the generating set which participates in the voltage control through the remote regulating module or the remote control module, realizes the automatic voltage control. The invention gives full play to the function of the electric power telemechanical apparatus, reduces the amount of the situ hardware units, increases the operational precision of the data in the AVC adjusting process.

Owner:上海惠安系统控制有限公司

Mask pattern correction method

ActiveCN103376644AGuaranteed operating accuracyFast operationOriginals for photomechanical treatmentGraphicsCorrection method

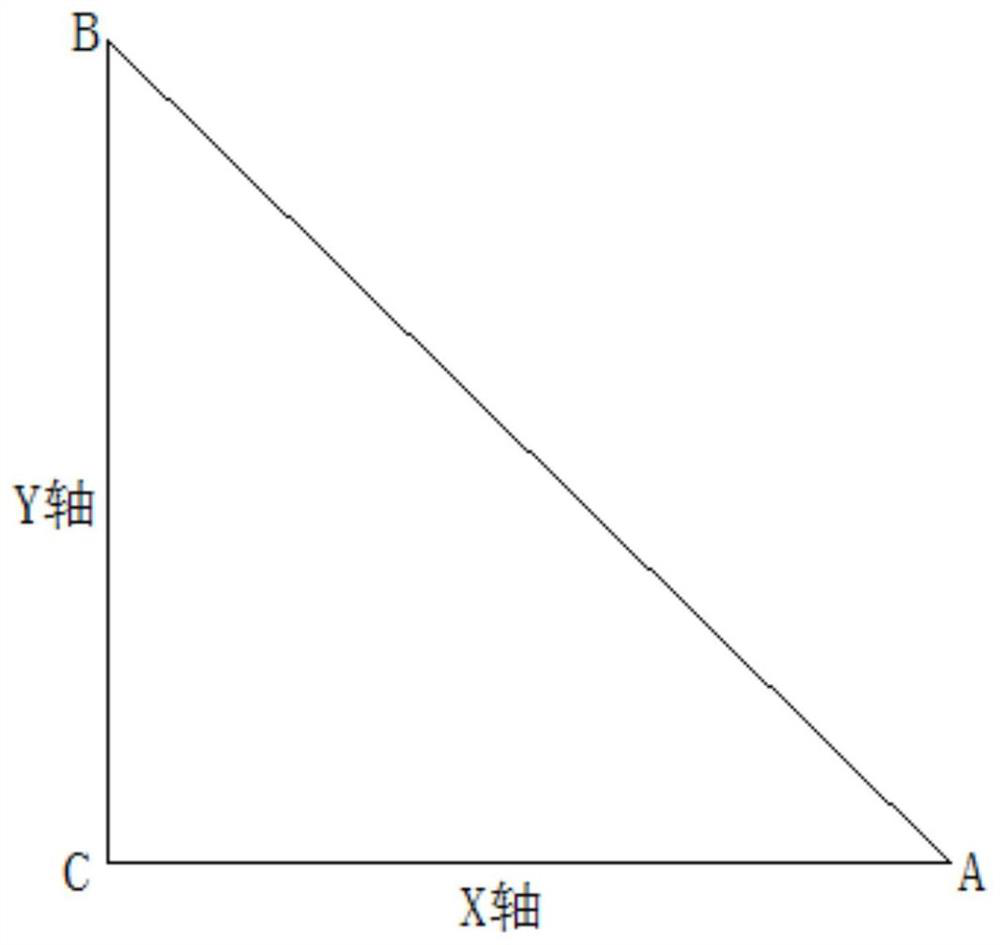

The invention discloses a mask pattern correction method which comprises the following steps of: defining an expected exposure pattern as an initial mask pattern M(), defining a standard unit pattern T() of a standard unit pattern, converting the initial mask pattern into mask pattern information expressed by the standard unit pattern, wherein () is coordinates in a two-dimensional coordinate system; calibrating an imaging effect of the standard unit pattern which passes through an optical imaging system, and establishing a light intensity mapping table; calculating to obtain actual light intensity of a light intensity investigation point of an imaging party according to the mask pattern information and the light intensity mapping table; calculating to obtain the mask pattern correction amount to be used for correcting the initial mask pattern according to the difference between the actual light intensity and the expected light intensity of the expected exposure pattern. According to the method, the operational precision is guaranteed, and the operational speed is also greatly increased.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

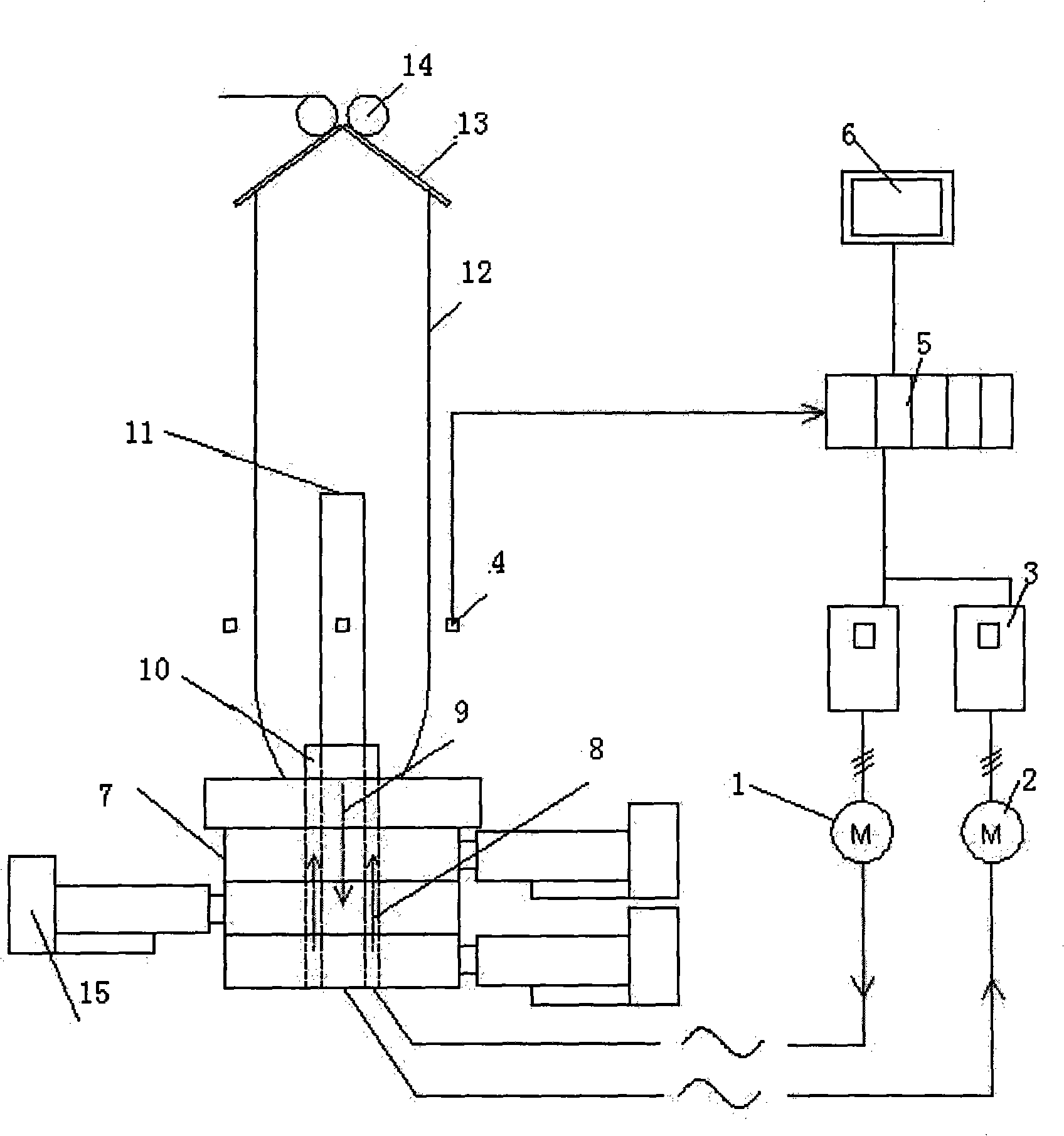

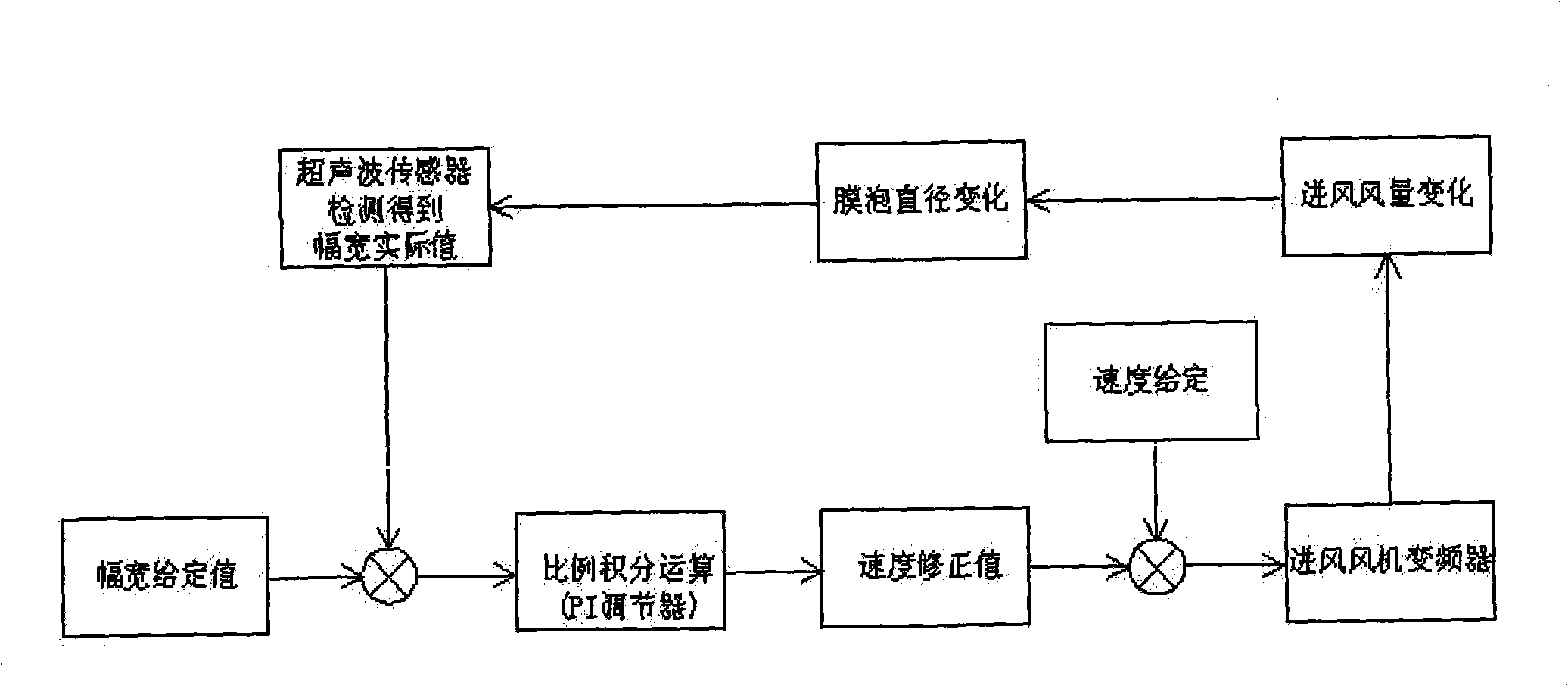

High-precision inner-cooling automatic control system

The invention relates to a high-precision automatic internal cooling control system for an internal mixer. An air inlet fan and an air exhaust fan are variable frequency type fans; a fixed specified value is provided for the rotating speed of the air exhaust fan according to the production technique; three to six ultrasonic sensors are arranged on the circumference above a bubble cooling line; after a signal of distance between the ultrasonic sensors to the bubble is measured and acquired, the signal is transmitted to a controller; the actual value of the bubble breadth is calculated through the controller; the actual value of the bubble breadth is compared with the specified value of the breadth; PID operation is performed to the differential value through an amplifier; a control signal is output to an air inlet fan frequency converter; the frequency converter controls the rotating speed of the air inlet fan, so that the air inlet amount and the air exhaust amount are maintained in balance. The control system has the advantages that the operation and the use are simple, the maintenance is convenient, the running is stable and reliable, the control precision is high, a large amount of raw materials is saved for the users, and the production cost is greatly reduced.

Owner:恒力石化股份有限公司

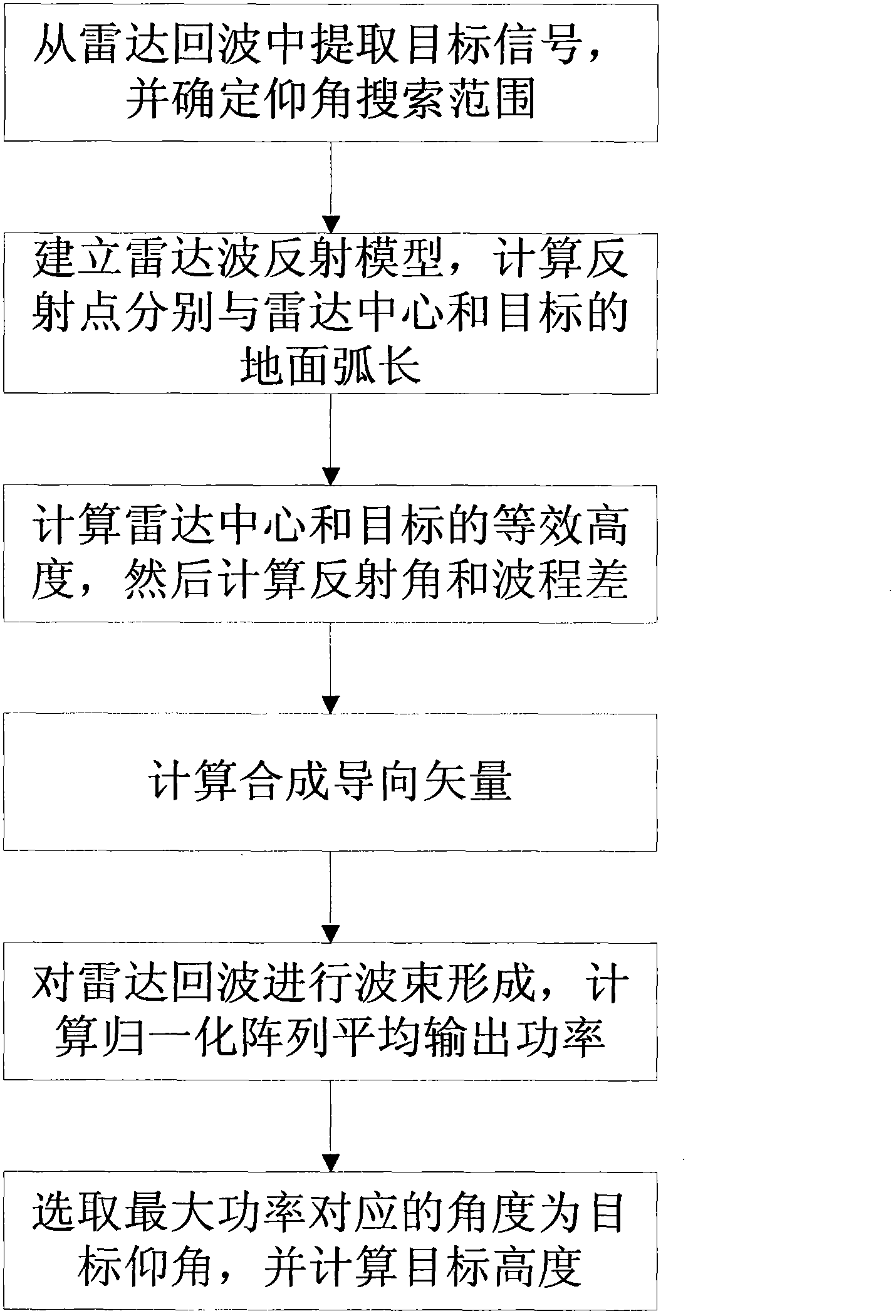

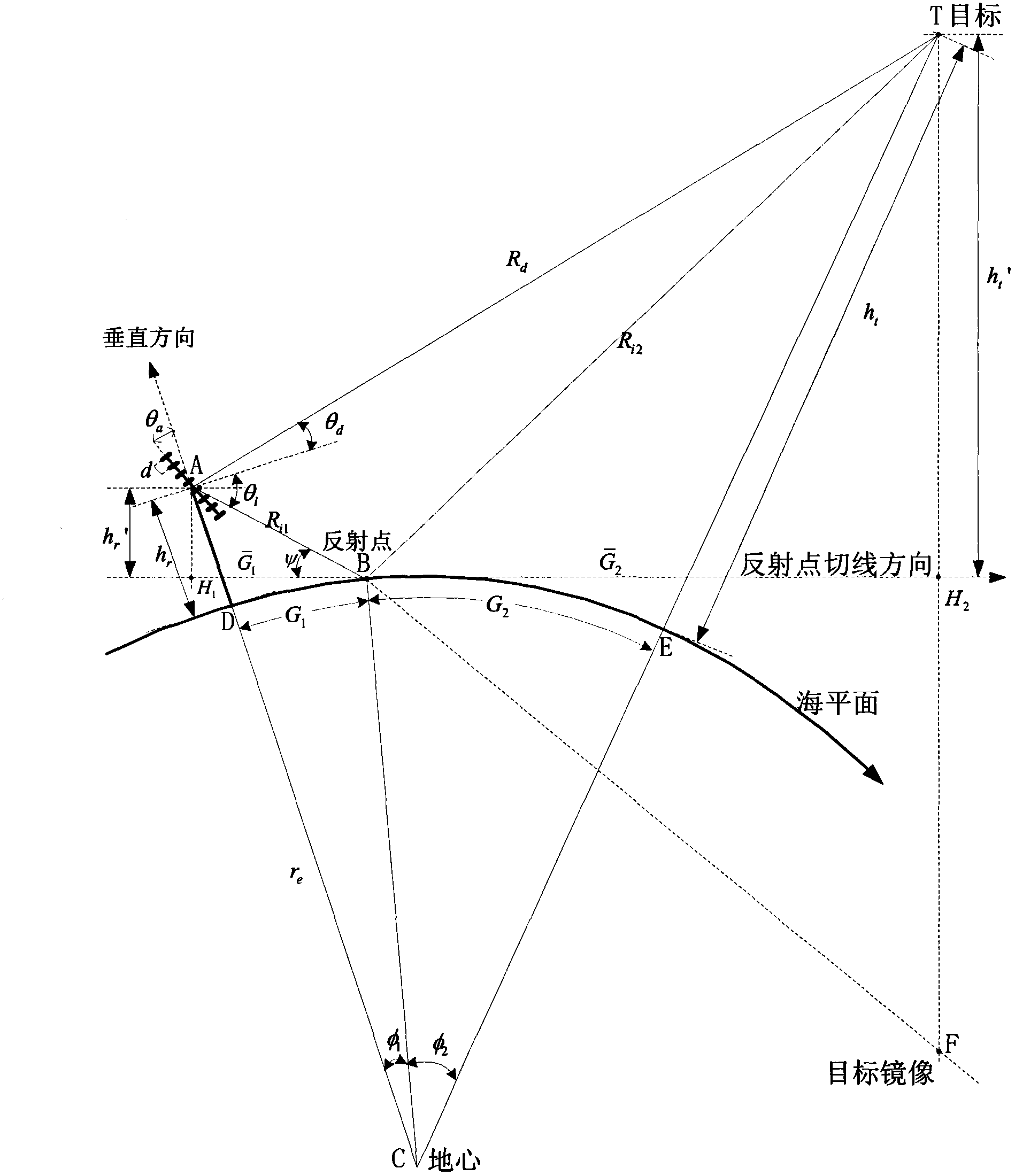

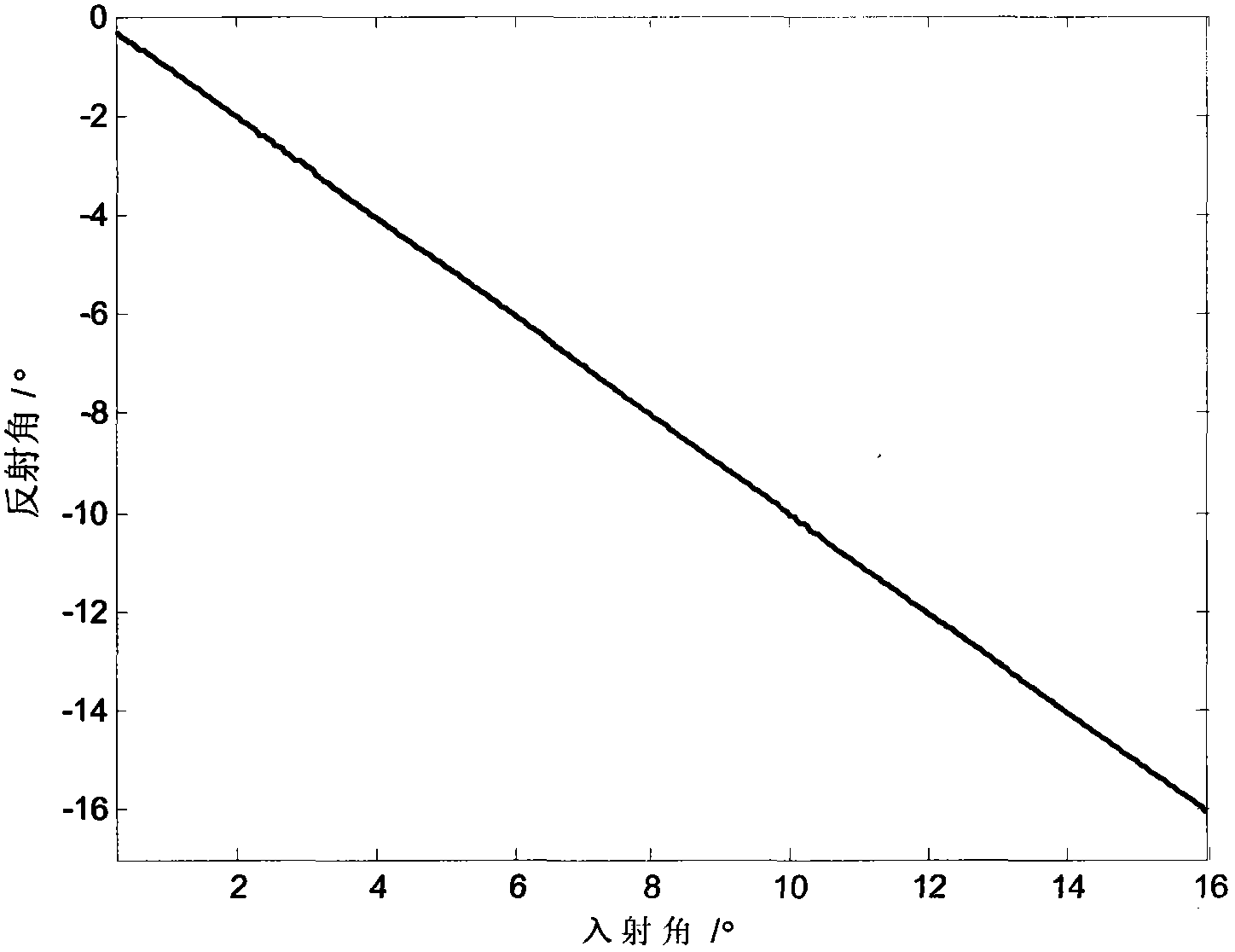

Synthetic steering vector based beam forming meter-wave radar height measurement method

InactiveCN103293526ASolve the limitation of low elevation angle altimetryImprove ability to handle goalsRadio wave reradiation/reflectionElevation angleTarget signal

The invention discloses a synthetic steering vector based beam forming meter-wave radar height measurement method, and mainly aims to solve the problems of large signal processing operation and computational complexity of the prior art during height measurement. The method includes extracting a target signal from a radar echo and determining a target elevation angle searching range; building a radar wave reflection model and computing ground arc length between a reflection point and a radar center and ground arc length between the reflection point and a target by a searched elevation angle; computing equivalent heights of the target and the radar center and then computing a reflection angle and wave-path difference between a reflection wave and a direct wave; computing a synthetic steering vector; and after data beam forming of an echo, selecting an angle corresponding to a maximum normalization power value as a target elevation angle and computing the target height. Beam forming and the synthetic steering vector are combined, the target reflection model is simplified, elevation angle estimation precision of a meter-wave radar is guaranteed, computation speed of meter-wave radar height measurement is increased, a computational process for height measurement is simplified, and real-time signal processing of the meter-wave radar is easier.

Owner:XIDIAN UNIV

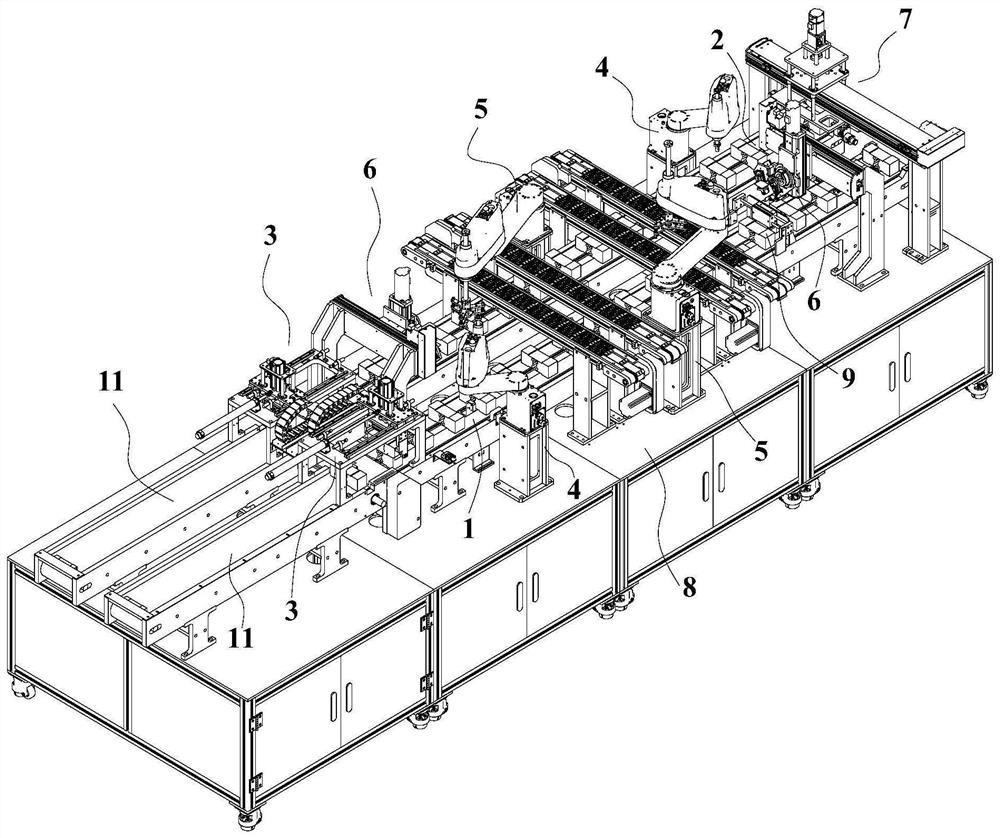

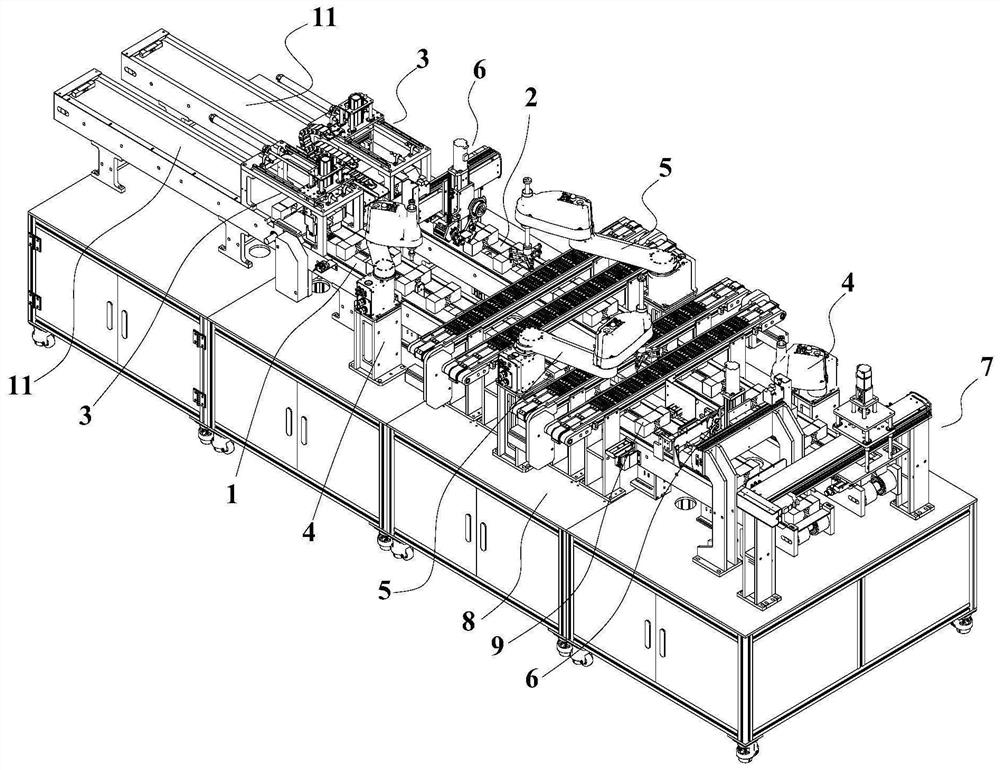

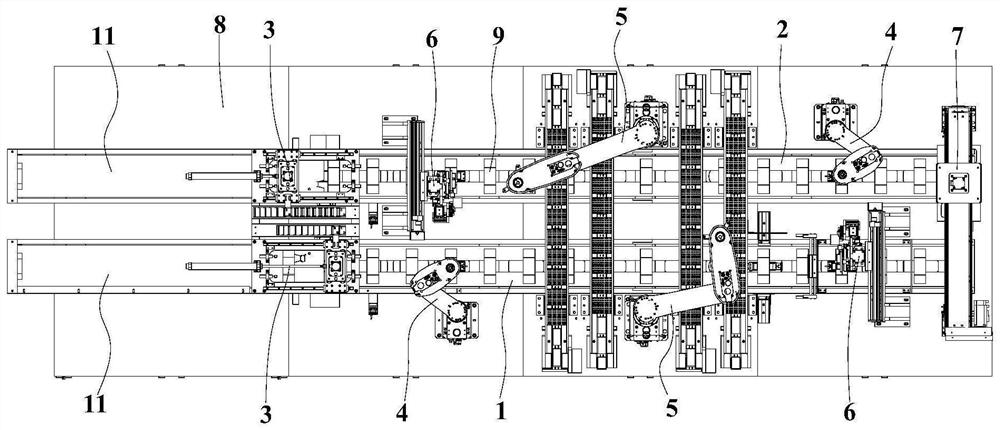

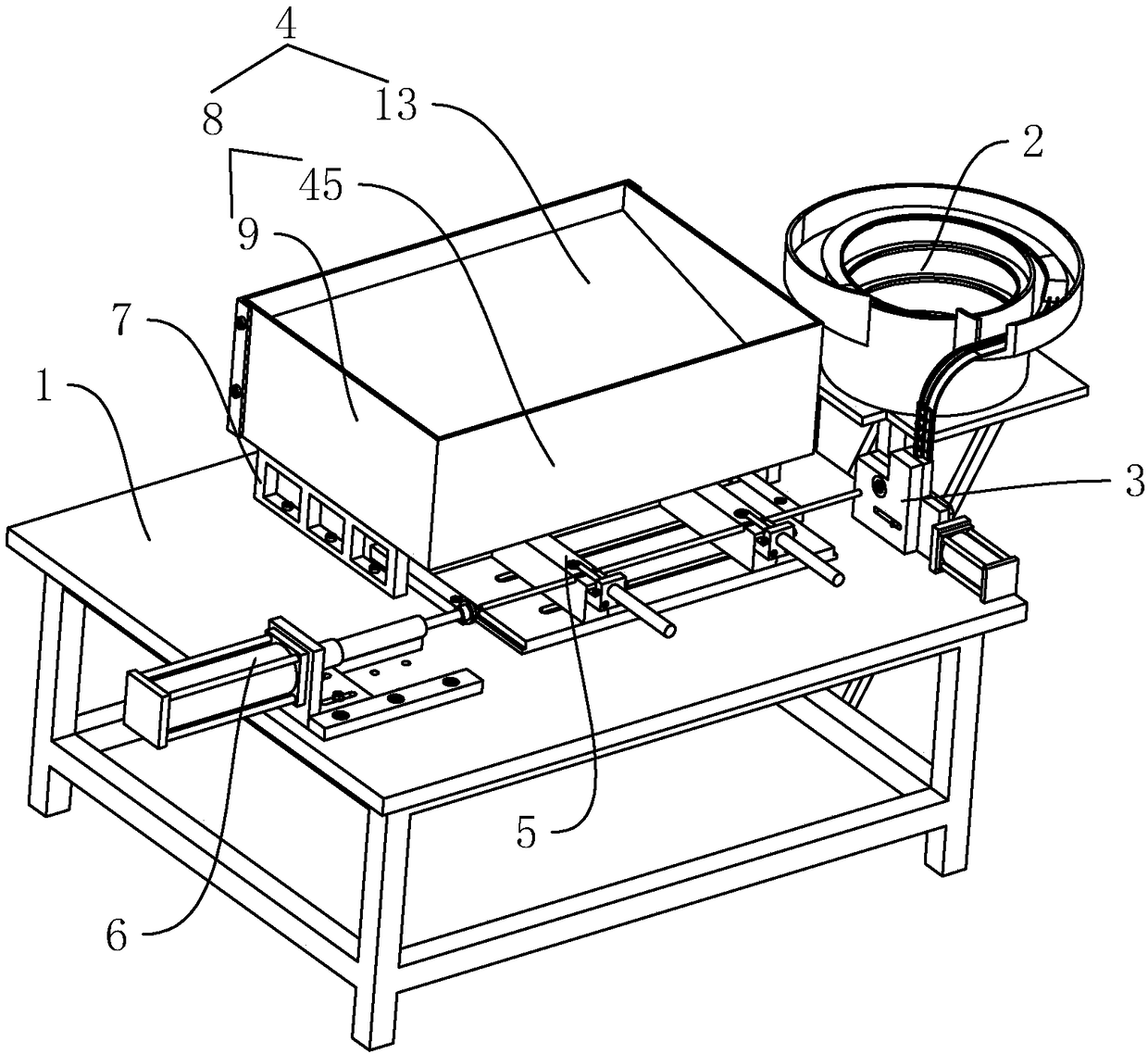

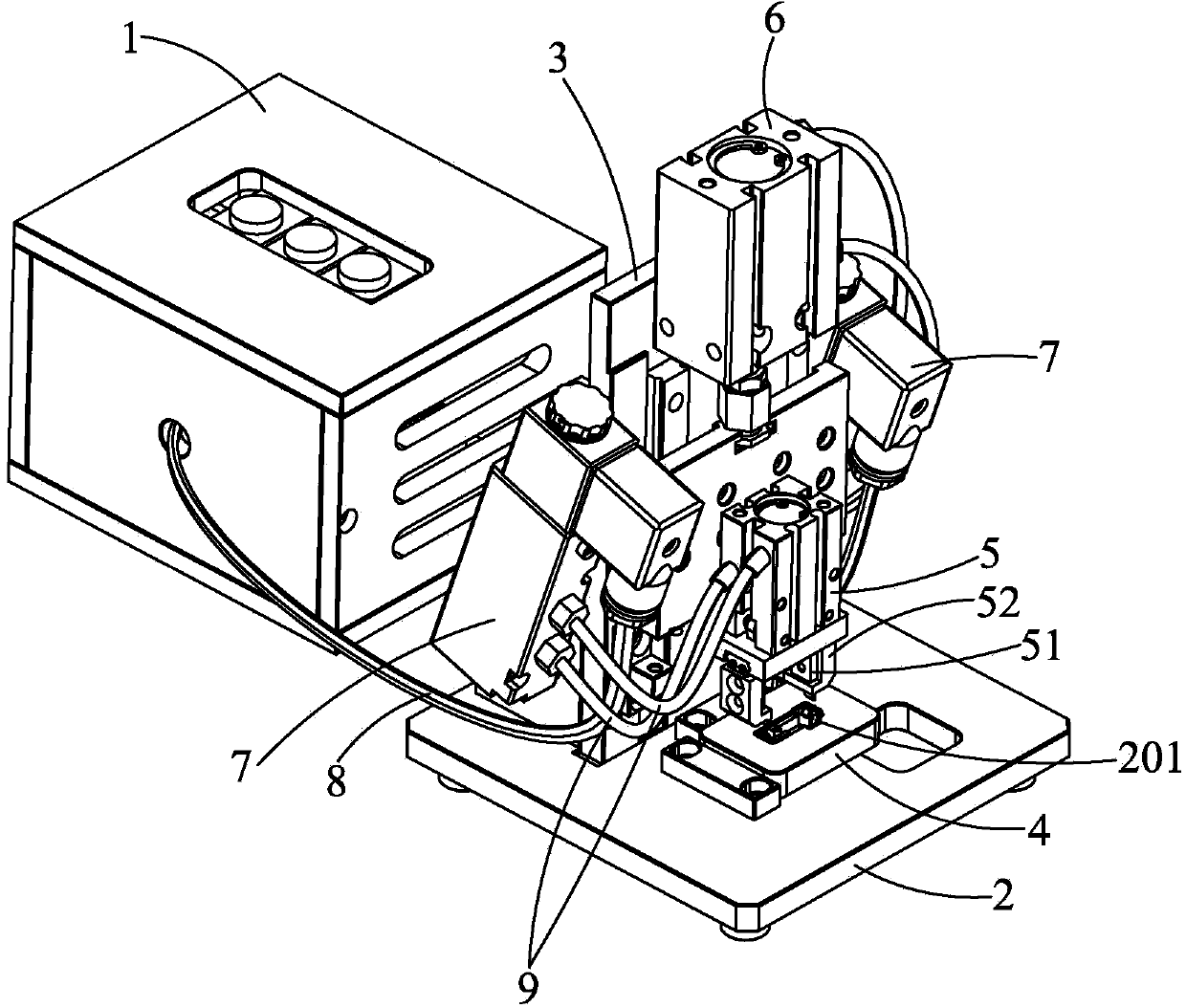

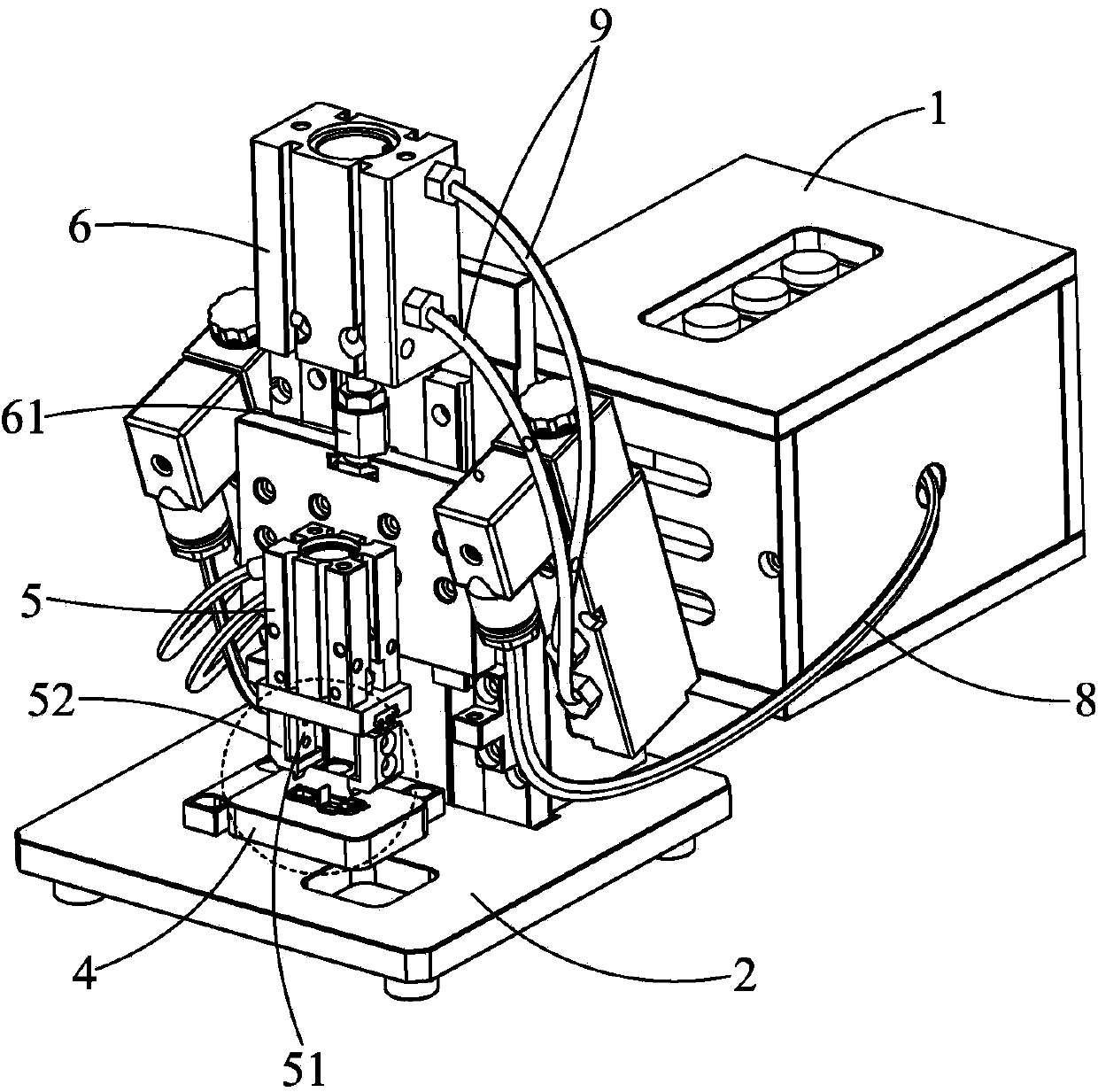

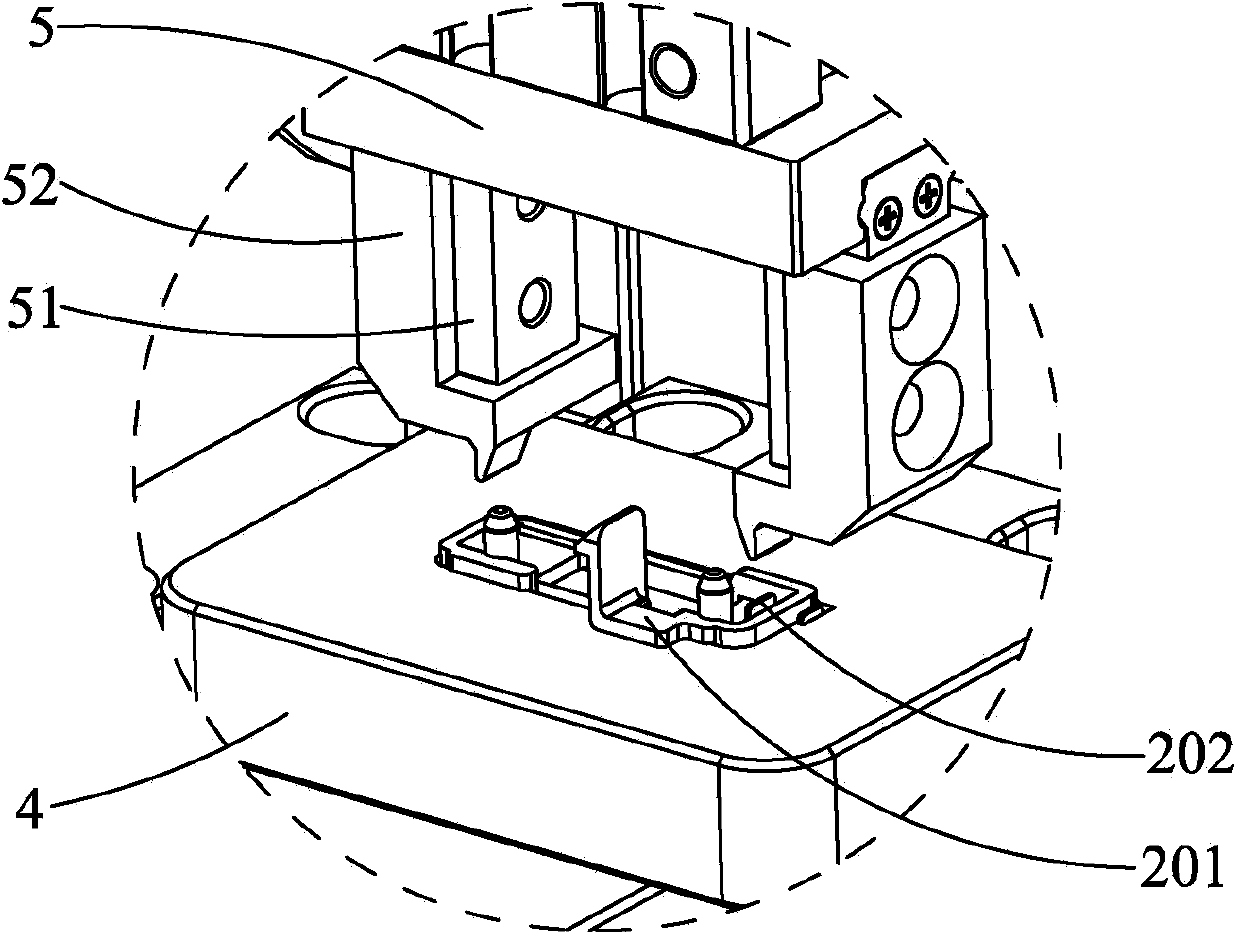

Automatic sensor component-adhering assembly line and component-adhering method

ActiveCN112390004ARealize automated productionImprove stabilityConveyor partsAdhesive beltAssembly line

The invention relates to the field of sensor production, in particular to an automatic sensor component-adhering assembly line and a component-adhering method. The automatic sensor component-adheringassembly line comprises a machine frame, and a first conveying mechanism and a second conveying mechanism are arranged on the machine frame; the first conveying mechanism is sequentially provided witha material transferring mechanism, a gluing mechanism, a component-adhering mechanism and an adhesive tape pasting mechanism from the feeding end to the discharging end; a carrying turnover mechanismis arranged between the discharging end of the first conveying mechanism and the feeding end of the second conveying mechanism; and the second conveying mechanism is sequentially provided with a gluing mechanism, a chip mounting mechanism and an adhesive tape pasting mechanism from the feeding end to the discharging end. The component-adhering method comprises the following steps of feeding, conveying at equal intervals, gluing, component adhering, adhesive tape pasting, carrying and overturning and secondary component adhering. The automatic sensor component-adhering assembly line and the component-adhering method have the advantages that the sensor component adhering efficiency is high, the product consistency is good, and the operation process is simple and convenient.

Owner:HRG INT INST FOR RES & INNOVATION

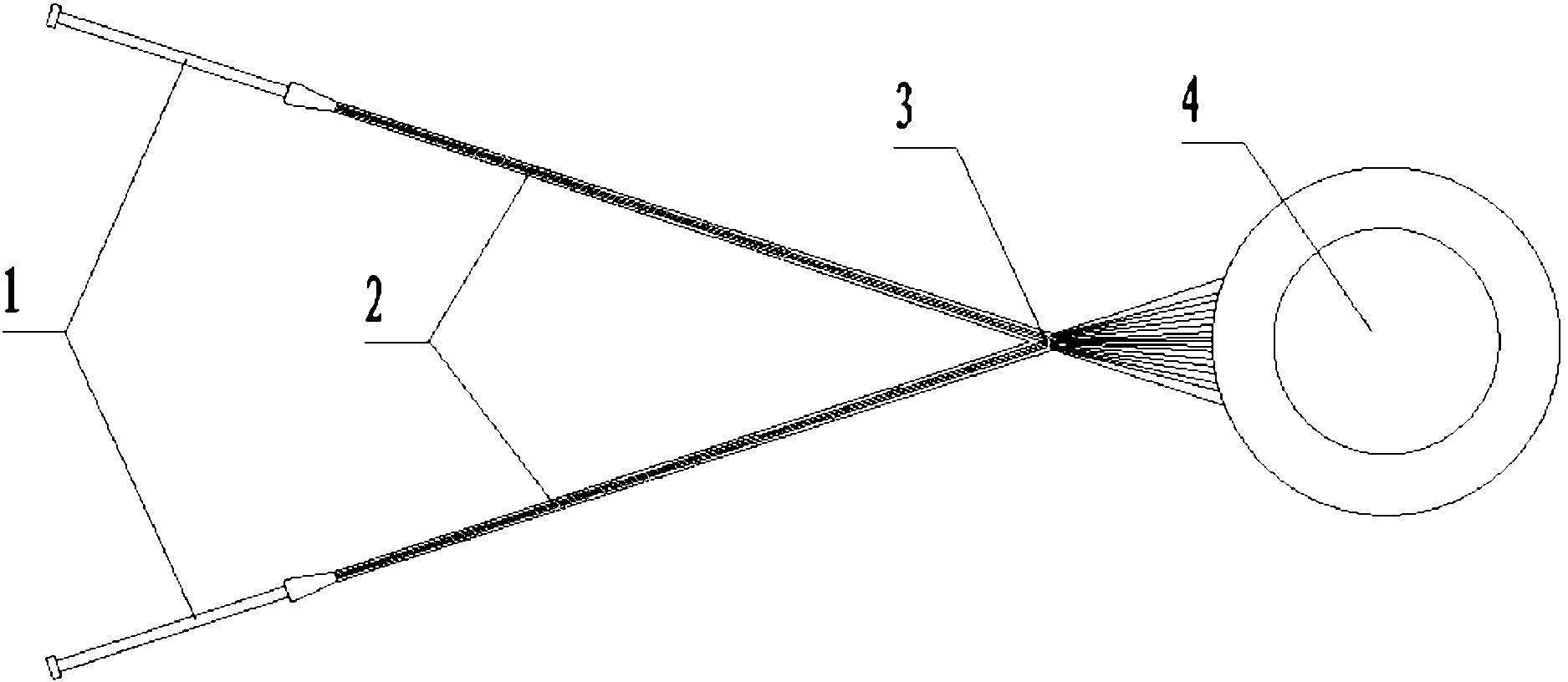

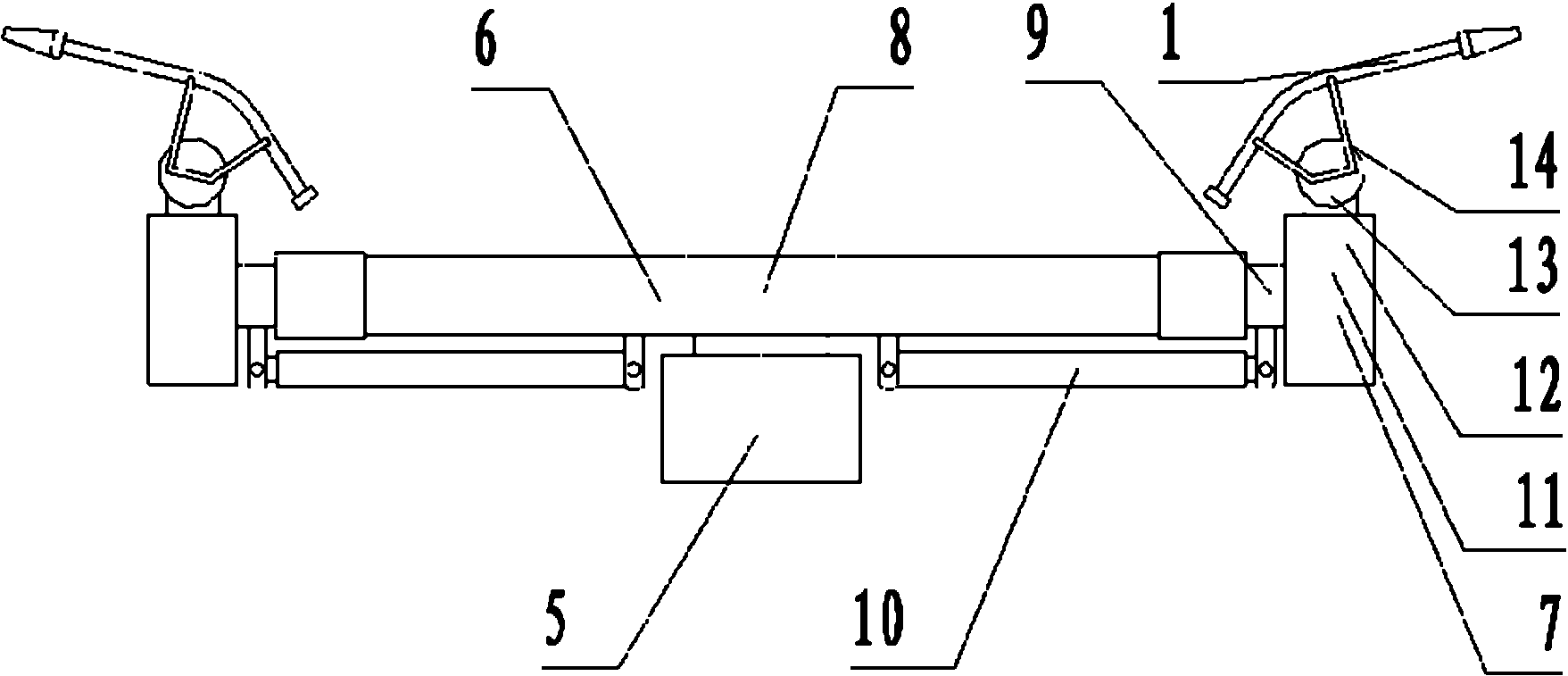

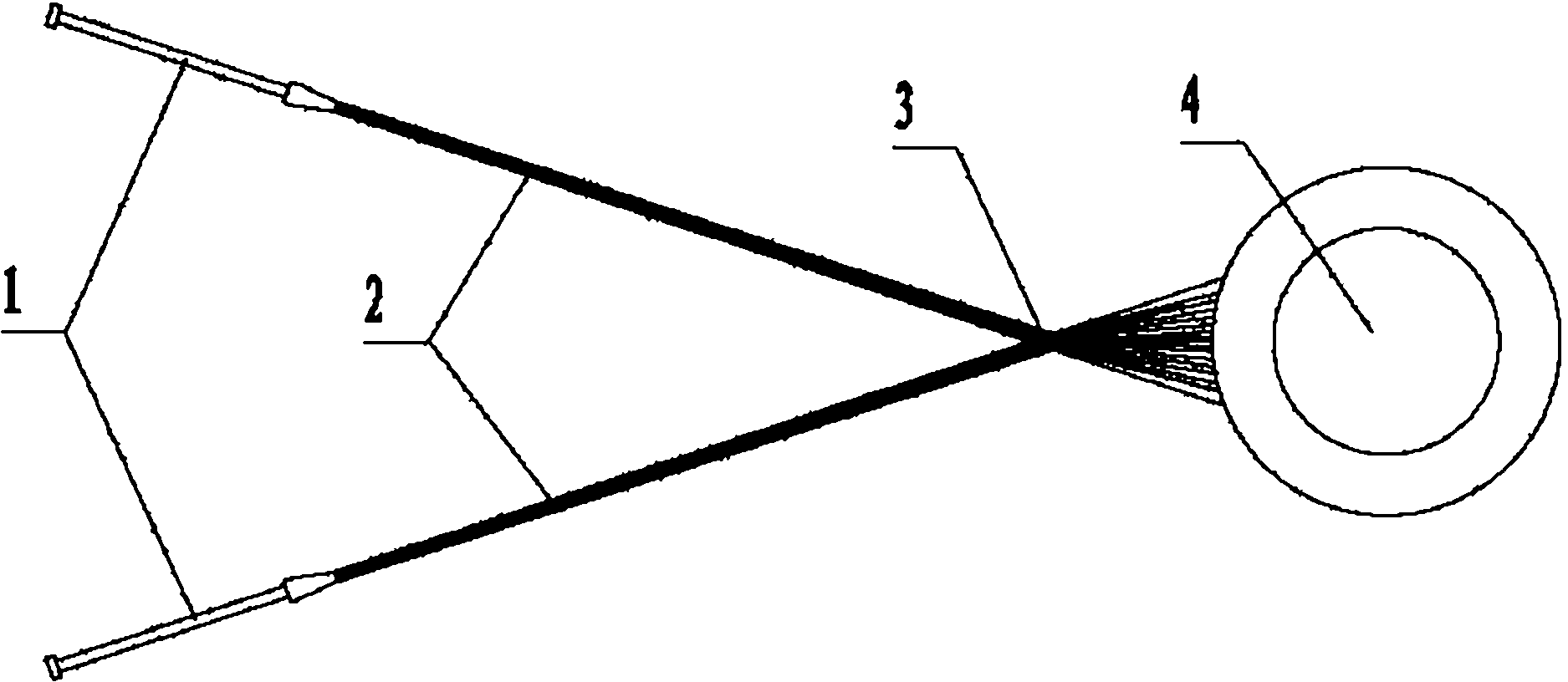

Charged water washing dual-water column masing washing method and device

InactiveCN102125915AFulfil requirementsAvoid damageCleaning using liquidsSputteringAutomatic control

The invention relates to a charged water washing dual-water column masing washing method and device, and the method comprises the following steps: (1) using two water guns for jetting out high-speed water flow beams respectively; (2) intersecting the two high-speed water flow beams by the included angle which is more than 0 degree and less than 180 degrees; and (3) transforming the beam-like water columns to radial water flow through mutual extrusion after the intersection point, and cleaning a charged device to be cleaned by using the radial water flow. The optimized scheme increases the step (4): changing the distance from the intersection point to the charged device according to the need of regulating the pressure of the water flow for cleaning the charged device. As for the used charged water washing dual-water column masing washing device, auxiliary arms, water gun supports at the tail ends of the auxiliary arms and water guns are arranged into two sets respectively. By adopting the method and the device, dead angles and dead zones can be prevented from generating, impact force can be controlled, harm to the charged device can be prevented, and the sputtering length and the region can be reduced; and the automatic control can be realized by using electrical power and hydraulic power driving elements, the operation precision can be ensured, and the operation safety can be improved.

Owner:江苏诚意智腾建材科技发展有限公司

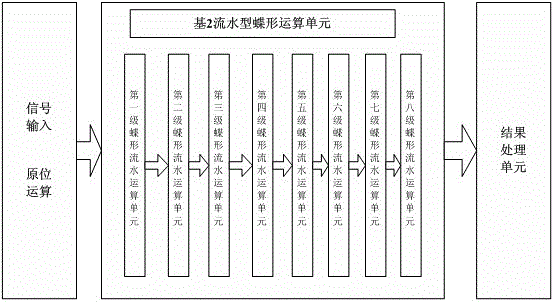

Universal floating point full-pipeline FFT (Fast Fourier Transform) operation IP (Internet Protocol) core

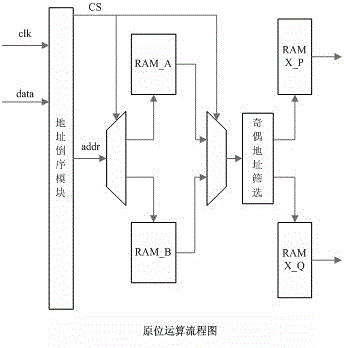

InactiveCN103559019AClear structureSimple configurationDigital data processing detailsConcurrent instruction executionFast Fourier transformSimulation

The invention discloses a universal floating point full-pipeline FFT (Fast Fourier Transform) operation IP (Internet Protocol) core, which comprises an in-situ operation unit, a base-2 pipeline type butterfly operation unit and a result processing unit, wherein the in-situ operation unit is used for segmenting and sorting input digital signals, completing in-situ operation by means of address order reversal, sequentially caching the input digital signals in a way of keeping 256 points in each group by using a ping-pang cache method, and generating data which are convenient for butterfly operation input via screening of odd and even sequences; the base-2 pipeline type butterfly operation unit comprises multiple stages of butterfly pipeline operation units; a first-stage butterfly pipeline operation unit is used for receiving data generated by the in-situ operation unit, and then each stage of butterfly pipeline operation unit is connected with a previous stage butterfly pipeline operation unit respectively to calculate FFT operation output corresponding to the input of each point; the result processing unit is connected with the base-2 pipeline type butterfly operation unit, and is used for sorting the FFT operation output calculated by using the base-2 pipeline type butterfly operation unit.

Owner:SHANGHAI SPACEFLIGHT INST OF TT&C & TELECOMM

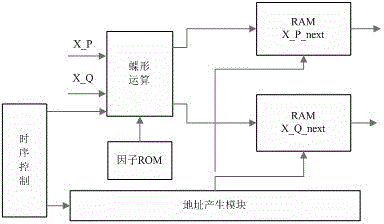

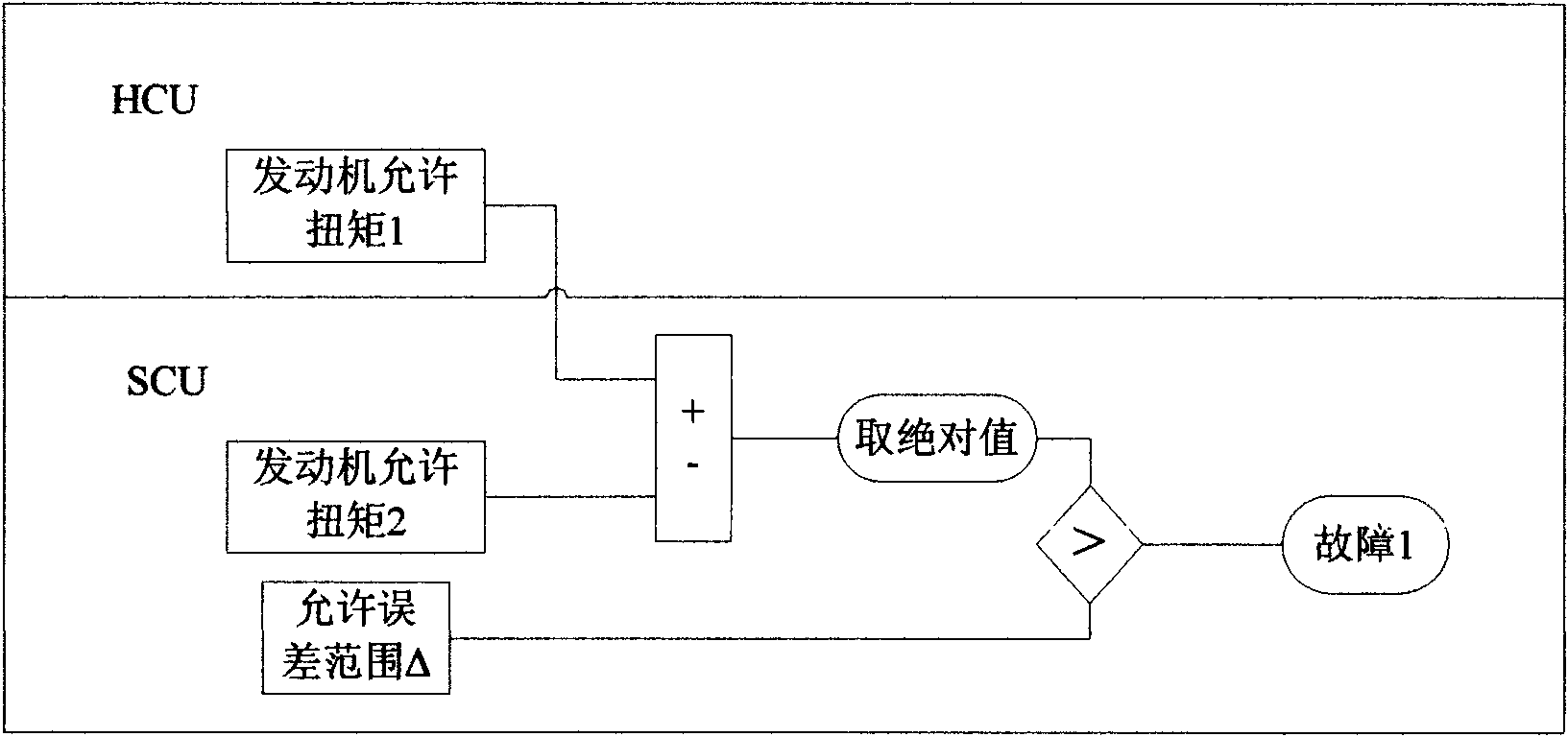

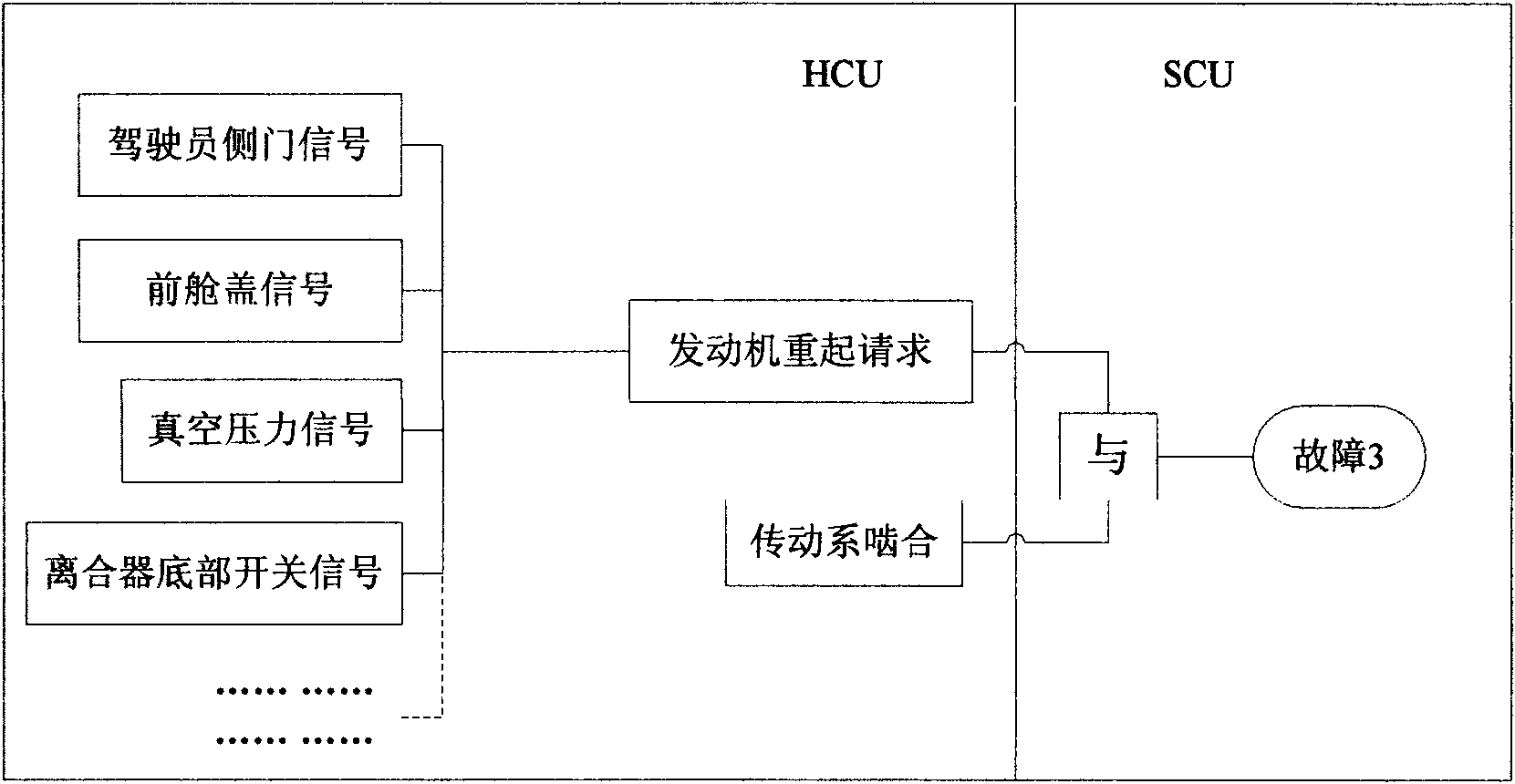

Safety protection control method of hybrid vehicle

ActiveCN101648564AGuaranteed operation accuracyRealize monitoringProgramme controlHybrid vehiclesHybrid systemSafety control

The invention discloses a safety protection control method of a hybrid vehicle. The method is characterized in that a hybrid control unit (HCU) and a safety control unit (SCU) calculate the allowable torque of an engine by the same algorithm; the HCU sends a calculation result to the SCU which carries out comparison; and if a difference between the results calculated by the HCU and the SCU exceeds a range of allowable error, the SCU reports a first failure signal, closes an inverter, switches off communication between the HCU and a CAN receiver and sends a signal for lighting a failure light to the CAN receiver. The method ensures the calculation accuracy of various control units, monitors special parts, ensures the operation of a hybrid system in the normal working states of the special parts and avoids influencing the running safety due to part failures.

Owner:CHERY AUTOMOBILE CO LTD

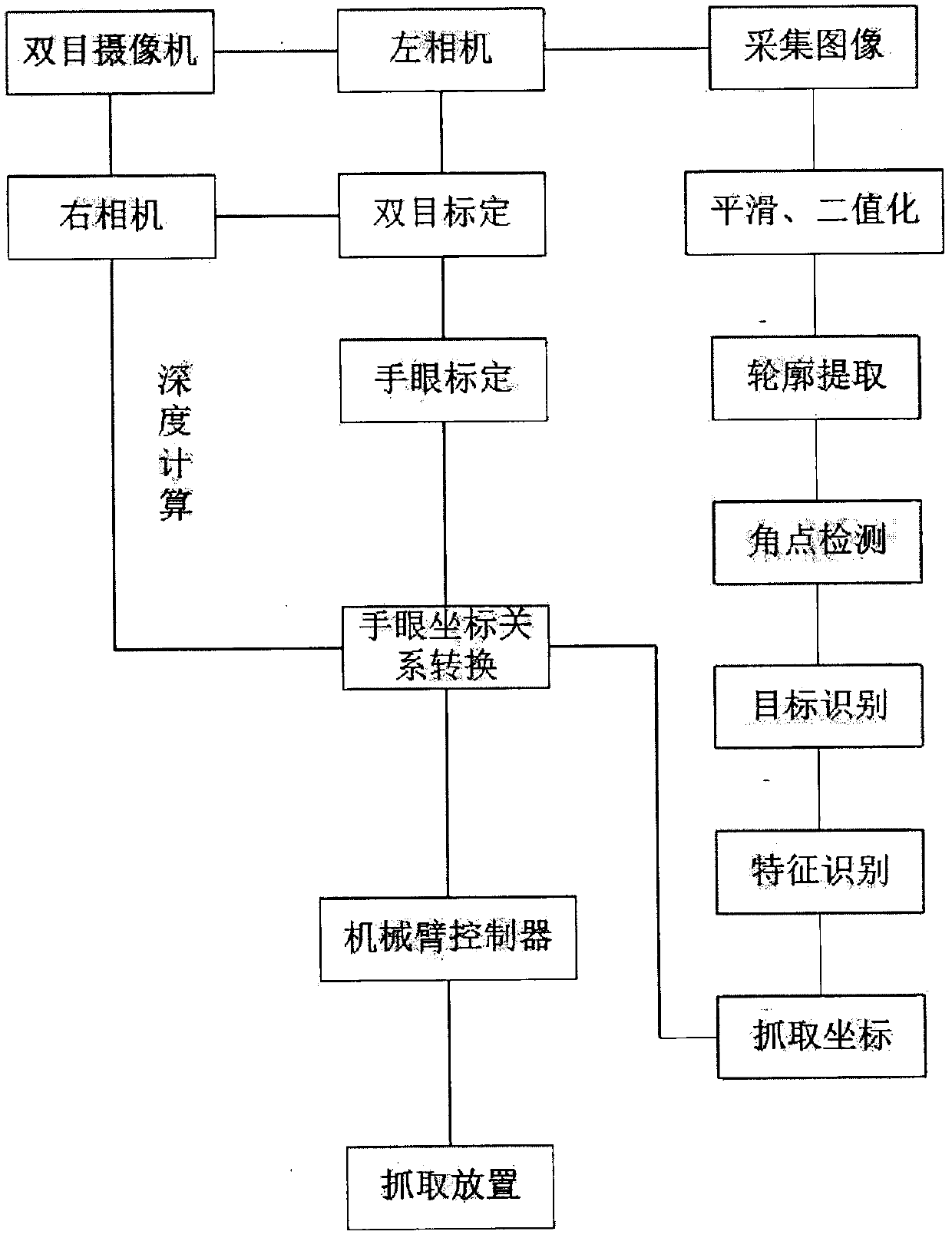

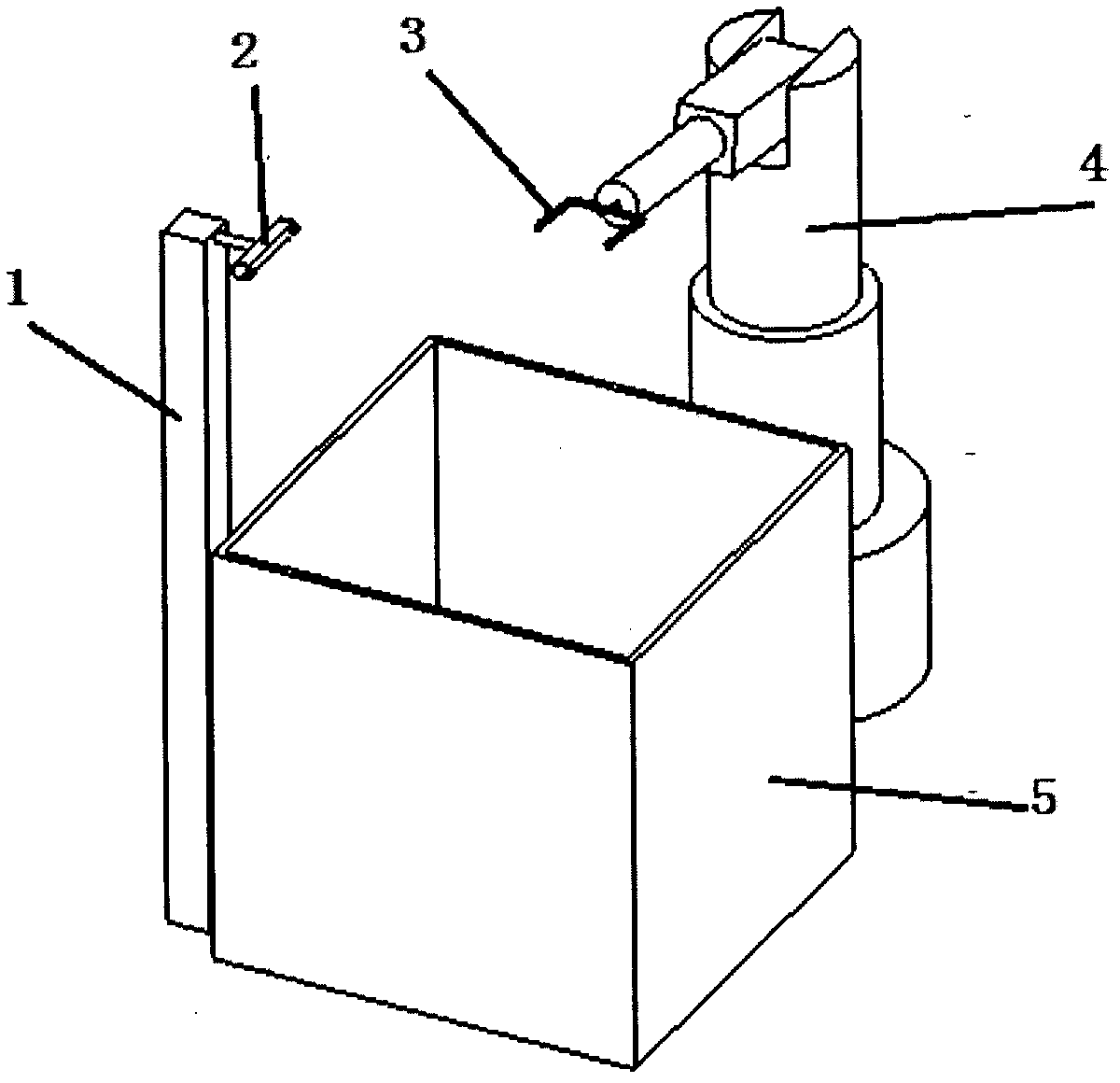

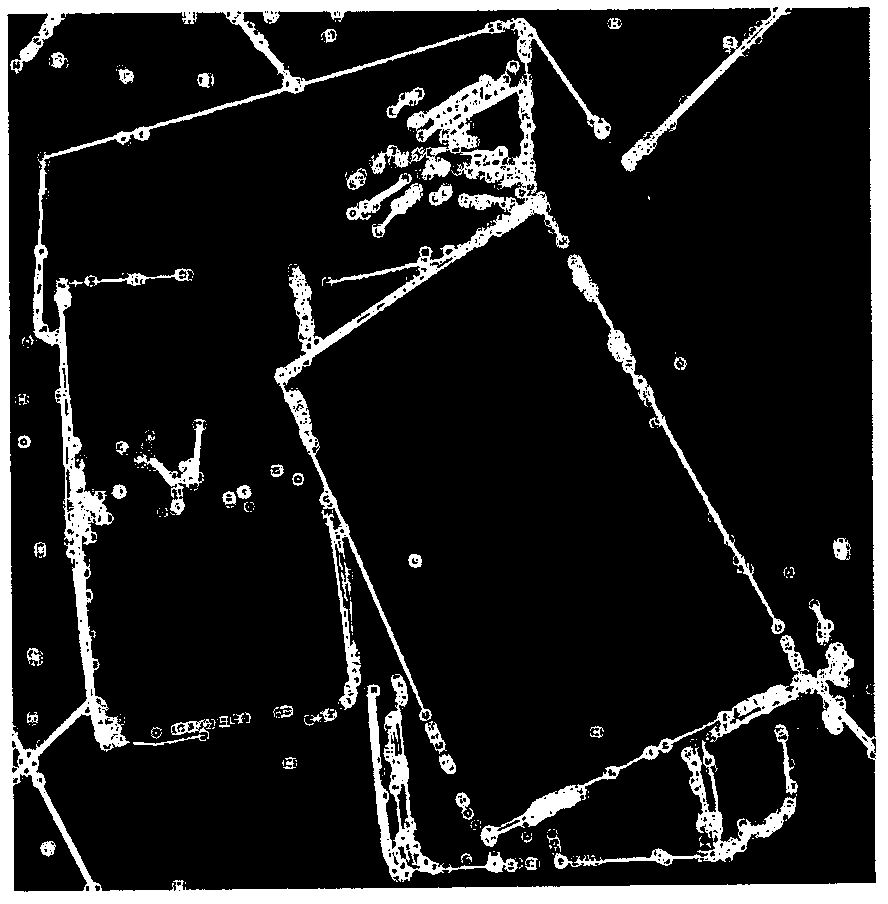

Binocular vision-based express parcel grabbing device and grabbing method

PendingCN109540105ASave work spaceGuaranteed operating accuracyPicture taking arrangementsPicture interpretationAngular pointWorkspace

The invention discloses a binocular vision-based express parcel grabbing method and device. The method includes the steps of coordinate system establishing, image preprocessing, angular point detection, contour extraction and determination of a robot grabbing position and posture. According to the express parcel grabbing device, a binocular camera is arranged at the top end of a device bracket, acage car is arranged below the binocular camera, and a six-axis mechanical arm is arranged on one side of the cage car; the six-axis mechanical arm is equipped with a mechanical gripper. The method and device have the beneficial technical effects that operation objects are express parcels, and the shapes are basically similar to cuboid; the device has the main functions of recognition of key points in images, recognition of parcel contours, calculation of grabbing position and posture of the tail end of the grasping robot, control of grasping trajectory and the like, the integration of the functions is realized, the workspace is saved, the operation accuracy is ensured, the intelligent level of work is improved, and the method and device can be integrated with wider-range express sorting systems subsequently.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

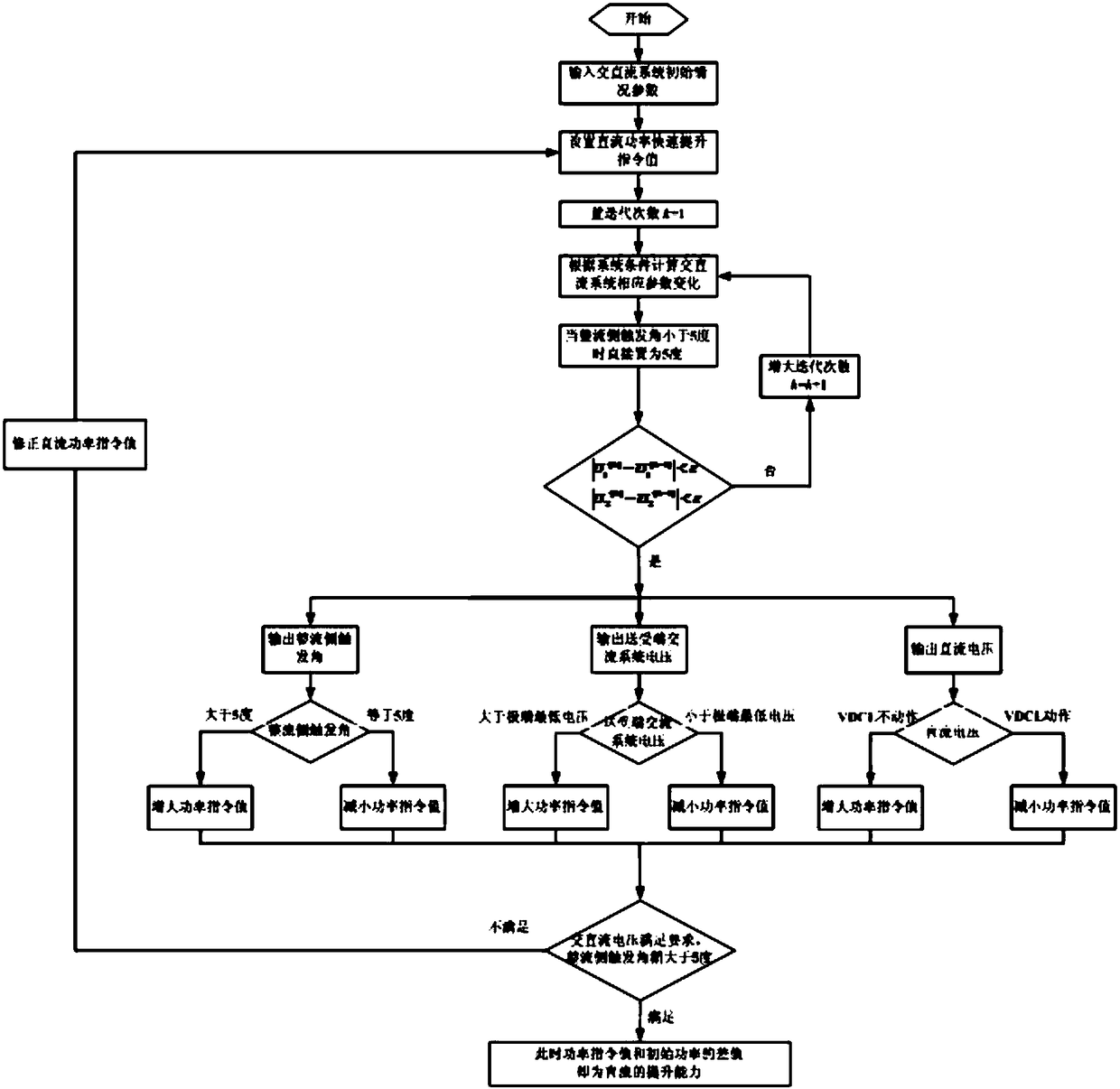

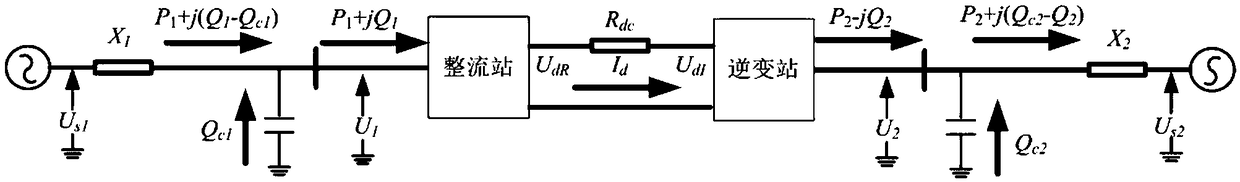

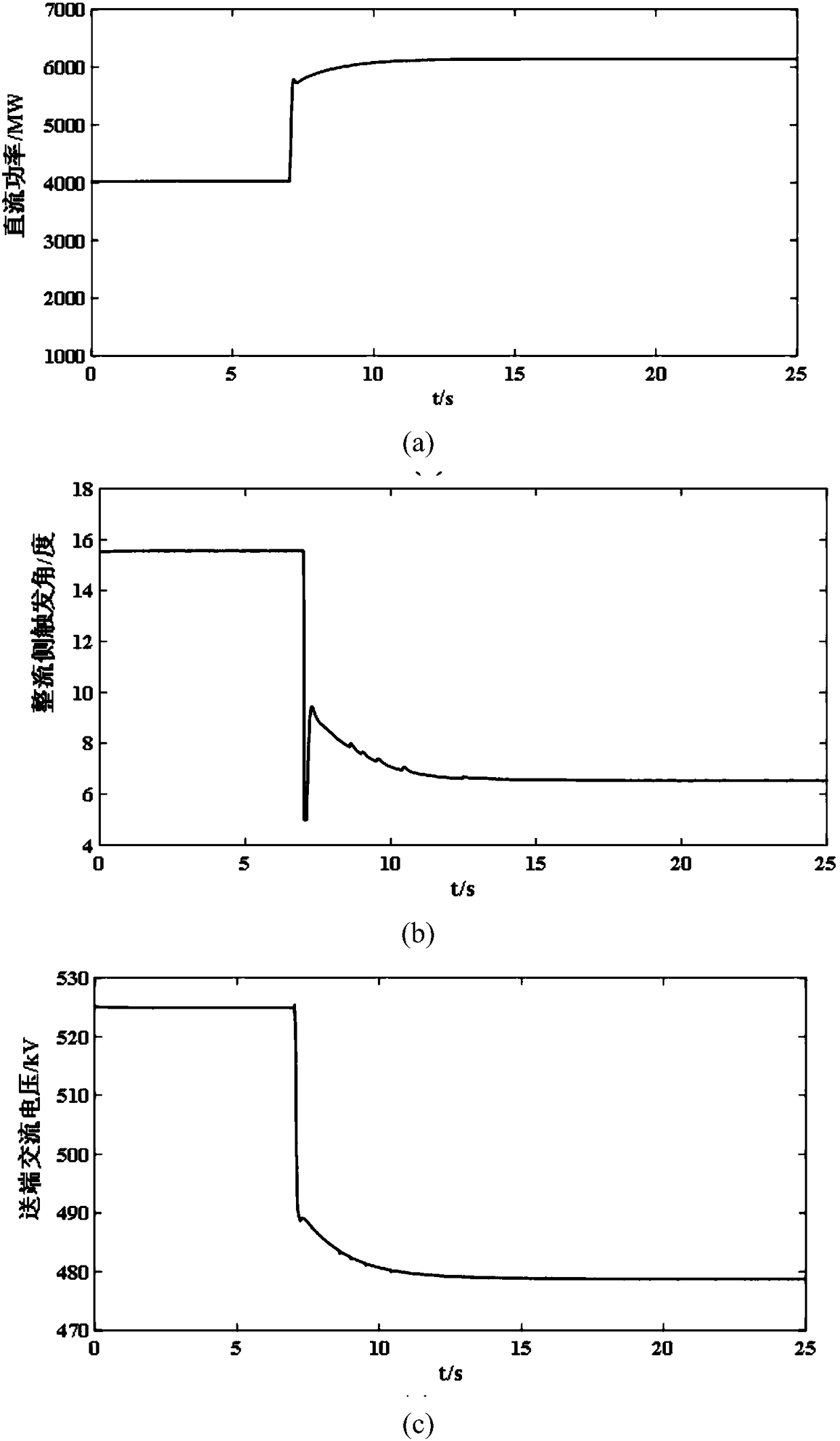

Calculation method and system for high-voltage direct-current transmission system rapid power-up capability

ActiveCN109038641AAvoid Simulation CalculationsGuaranteed operating accuracyElectric power transfer ac networkPower capabilityState parameter

The invention relates to a calculation method and a system for rapidly increasing power capability of a HVDC transmission system, comprising the following steps: 1) according to the initial conditionof an AC / DC system in the HVDC transmission system, obtaining an initial state parameter of the AC / DC system, wherein the initial state parameter comprises an initial active power; 2) set a power boost command value and calculate that steady-state parameters of the AC / DC system; 3) correcting the power boost command value based on the trigger angle of the rectify side and the AC / DC system voltageof the transmitting and receiving terminal, and entering step 2) for iteratively calculating the change of the steady-state parameters of the AC / DC system; Until the AC system voltage and trigger angle of rectifier meet the preset requirements, the DC system fast power-up capability is obtained, wherein, the DC system fast power-up capability refers to the difference between the final DC power-upcommand value and the initial active power of the AC / DC system.

Owner:STATE GRID ECONOMIC TECH RES INST CO +4

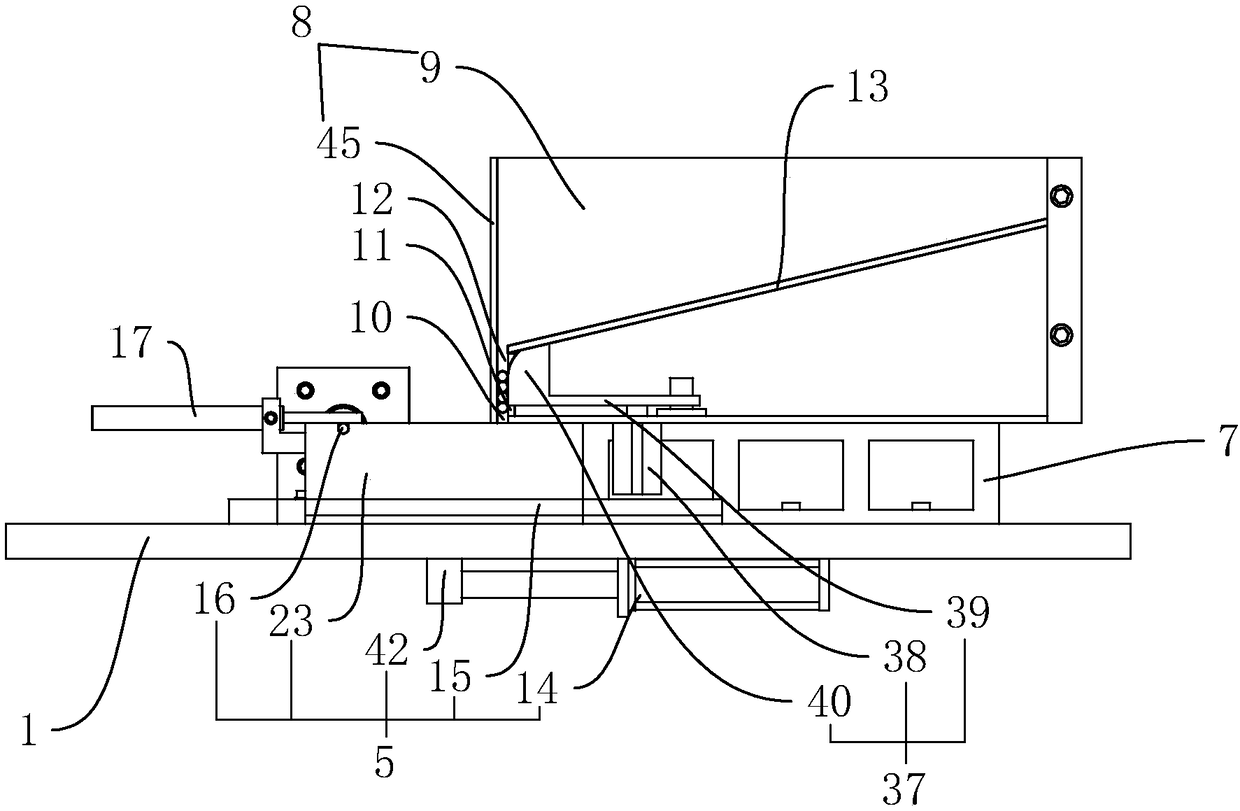

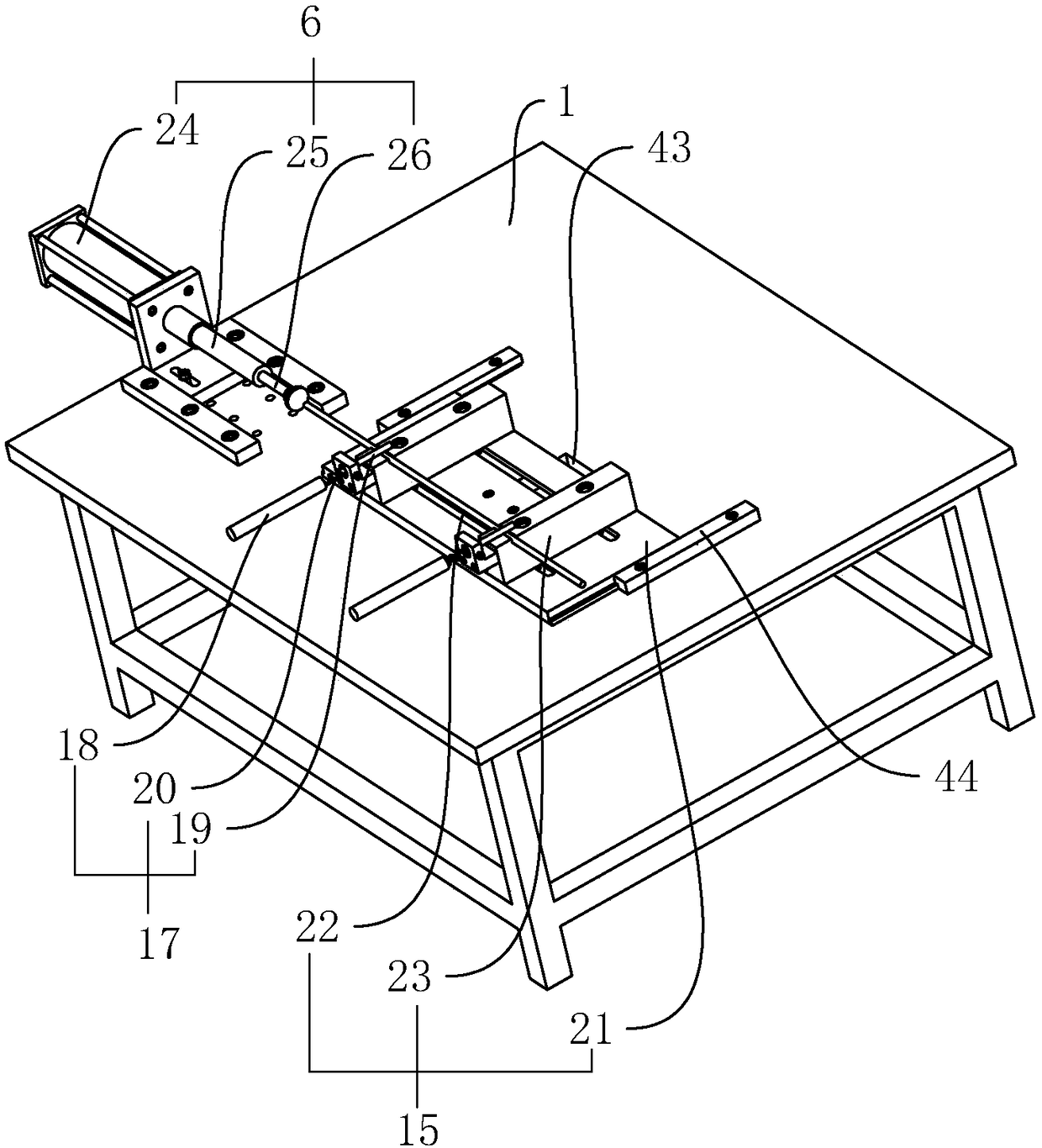

Automatic steel strip end cap sleeving machine

ActiveCN108213906ARealize feedingAchieve continuous feedingMetal working apparatusEngineeringMechanical engineering

The invention discloses an automatic steel strip end cap sleeving machine, and aims at solving the problems that during traditional manual steel strip and end cap installation, efficiency is low, andmanpower is wasted. According to the technical scheme, the automatic steel strip end cap sleeving machine is characterized by comprising a rack, a vibration material disc arranged on one side of the rack, a clamping assembly connected to the discharging end of the vibration material disc and used for clamping an end cap, a feeding mechanism arranged on the rack and used for arranging steel strips,a conveying assembly arranged below the feeding mechanism and used for pushing one steel strip out, and a drive mechanism which is arranged on the rack and is collinear to the discharging position ofthe conveying assembly. According to the automatic steel strip end cap sleeving machine, through automatic steel strip and end cap installation, manpower is greatly liberated, labor force consumptionis reduced, and the installing efficiency is improved.

Owner:徐锋

Metal sheet bending machine

The invention relates to a metal sheet bending machine, which is used for bending metal sheets. The metal sheet bending machine comprises a time-delay relay, a machine seat, a support frame, a fixture plate, an X-axis air cylinder, a Z-axis air cylinder, a pair of electromagnetic valves, a plurality of power lines and a plurality of air pipes, wherein the support frame and the fixture plate are fixed on the machine seat; the fixture plate is used for fixing the metal sheets; the power lines are connected between the time-delay relay and each of the electromagnetic valves; the X-axis air cylinder is connected with the corresponding electromagnetic valve through the corresponding air pipe; the Z-axis air cylinder is connected with the corresponding electromagnetic valve through the corresponding air pipe; the Z-axis air cylinder is fixed on the support frame and can drive the X-axis air cylinder to slide back and forth; the X-axis air cylinder is a clamping jaw air cylinder, and is provided with a pair of clamping jaws which extend downwards; the clamping jaws can be closed and opened from left to right; a cutter head, which is used for bending the metal sheets, is fixed on each of the clamping jaws; the cutter heads can perform closing and opening actions along with the clamping jaws. The metal sheet bending machine, disclosed by the invention, has the advantages of simple manipulation and capabilities of beneficially guaranteeing the operation precision and improving the production efficiency.

Owner:KUNSHAN XUNTAO PRECISION MACHINERY

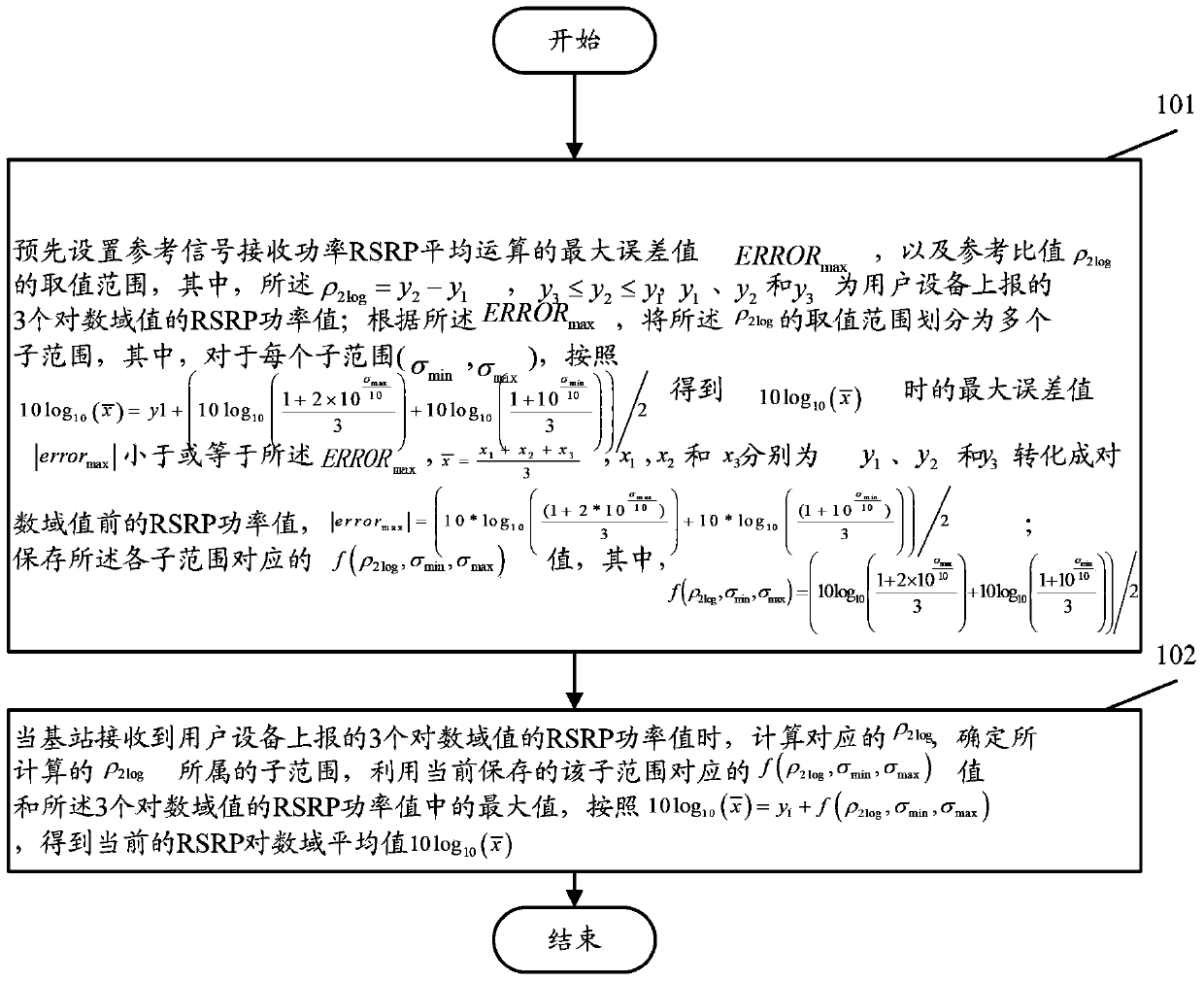

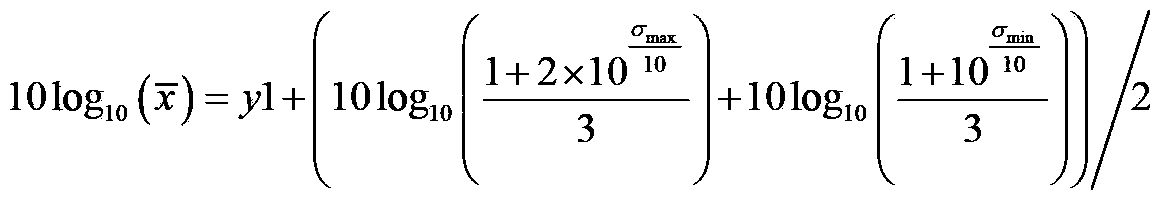

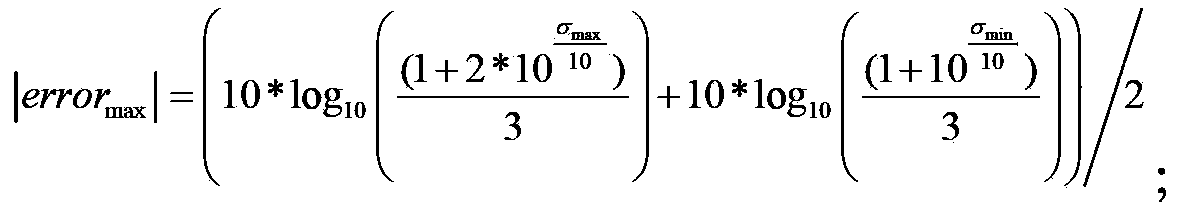

Method of determining reference signal receiving power

InactiveCN104185202AReduce operational complexityGuaranteed operating accuracyWireless communicationMaximum errorAlgorithm

The invention discloses a method of determining reference signal receiving power. According to the method, a reference ratio rho2log=y2-y1 and an intermediate calculation parameter f(rho2log, sigmamin, sigmamax) are introduced, wherein y3, y2, y1 are reported RSRP power values of three log domain values, and y3< / =y2< / =y1; according to the value range of the rho2log and the allowed maximum error value of the system, the value of the intermediate calculation parameter corresponding to each sub range when the maximum error value in the value range of the rho2log is met is determined in advance; and according to the belonging sub ranges of the rho2log corresponding to the RSRP power values of three log domain values reported currently by user equipment, the intermediate calculation parameter value corresponding to the sub region is determined, and the current RSRP log domain average value as described in the specification is obtained by using the intermediate calculation parameter value. By adopting the method of the invention, the RSRP log domain average value can be accurately determined, and calculation complexity can be greatly reduced.

Owner:POTEVIO INFORMATION TECH

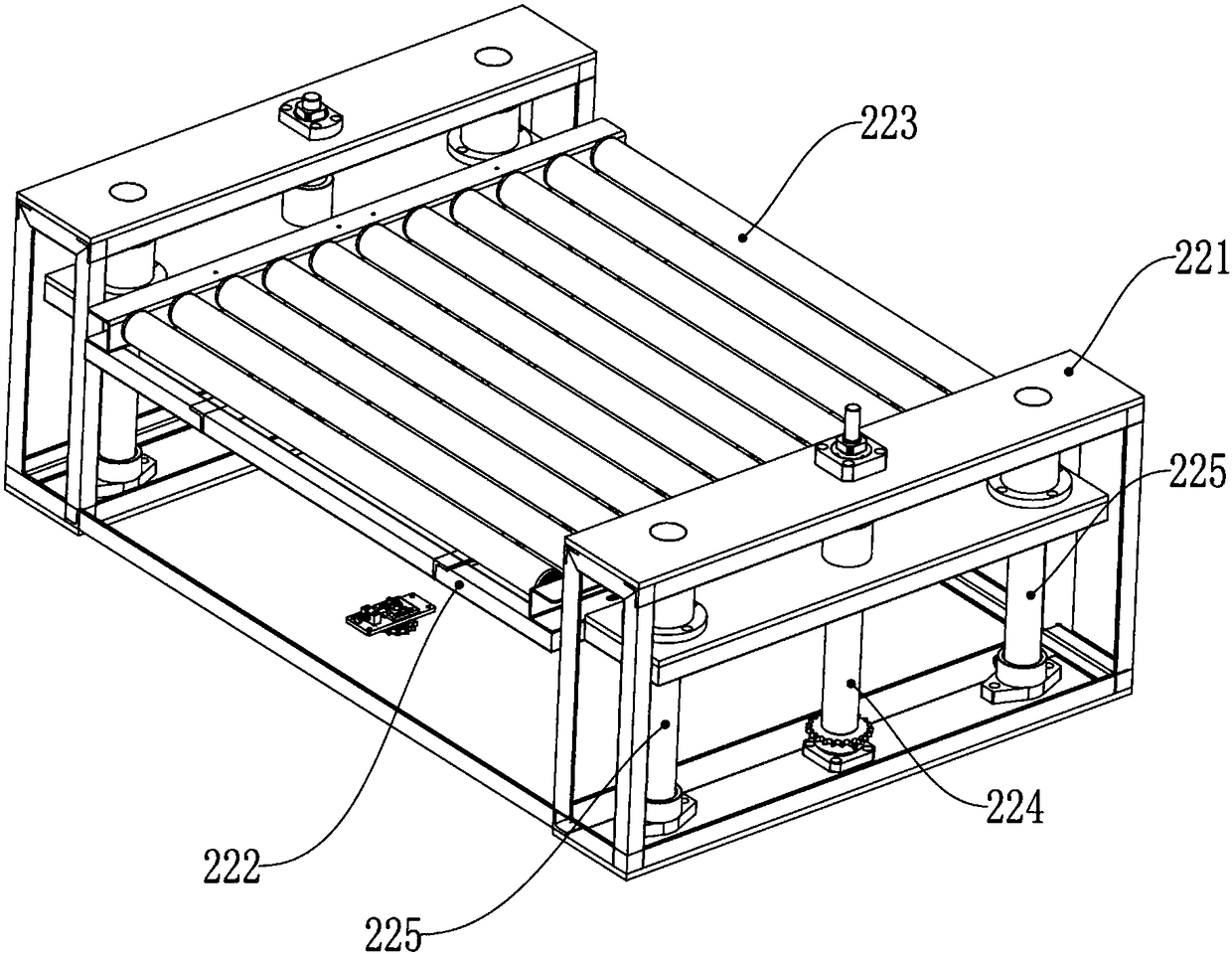

RGV body

PendingCN114162539AAccurate Floating GrabQuick resetCharging stationsVehicular energy storageVehicle frameIn vehicle

The invention relates to an RGV body, and belongs to the technical field of tracking conveying vehicles. The RGV body runs on the foundation track and comprises a vehicle frame and a multi-stage platform installed in the vehicle frame in a floating mode. The floating installation mode is achieved through a flexible chain connected between the vehicle frame and the multi-stage platform. The multi-stage platform is suspended by a flexible chain, so that floating fit between the multi-stage platform and the vehicle frame is realized; the vehicle body further comprises an aligning mechanism, and the aligning mechanism is located between the multi-stage platform and the vehicle frame to achieve aligning or resetting of the multi-stage platform relative to the vehicle frame. After the multi-stage platform grabs and unlocks a vehicle chassis and a battery locking mechanism on the chassis in a matched mode, the flexible chain enables the multi-stage platform to swing laterally through lateral swing to adapt to matching of the positioning cone and the conical groove, and accurate floating grabbing of a vehicle-mounted battery is facilitated. After the vehicle-mounted battery is grabbed, an aligning mechanism is installed between the multi-stage platform and the upper connecting frame, and the multi-stage platform is assisted in rapidly and accurately aligning or resetting.

Owner:泽清新能源科技有限公司

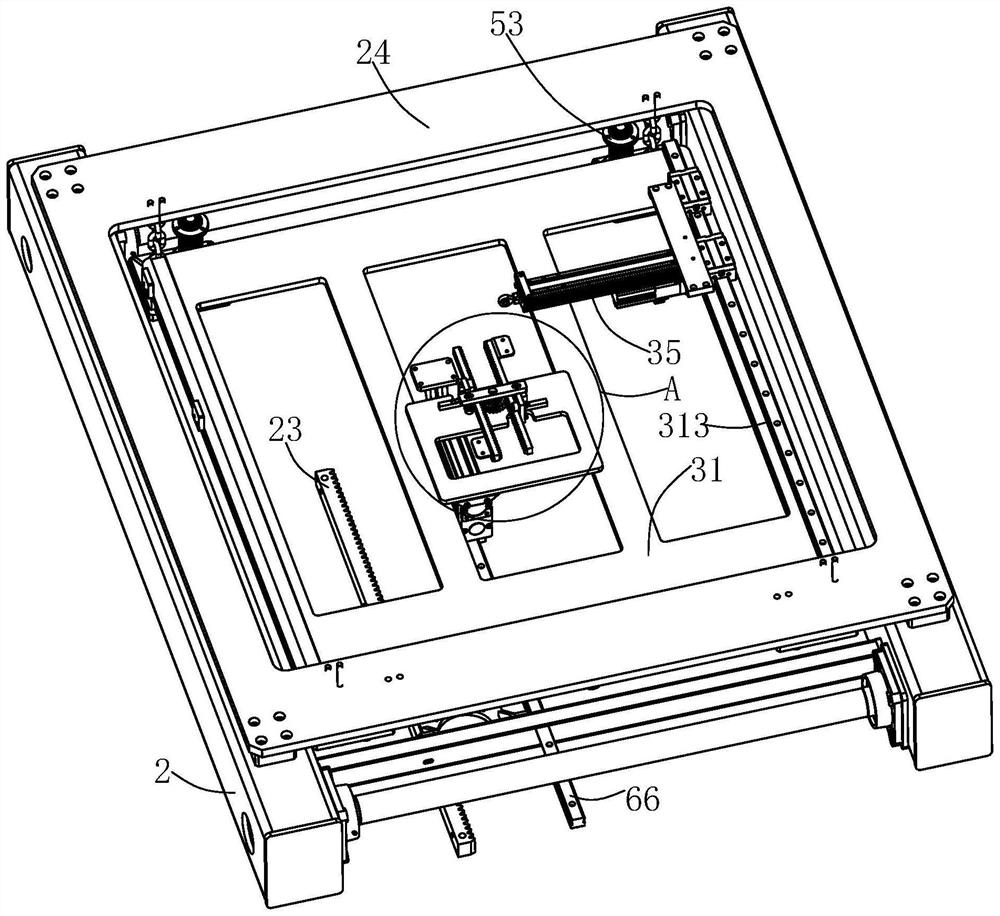

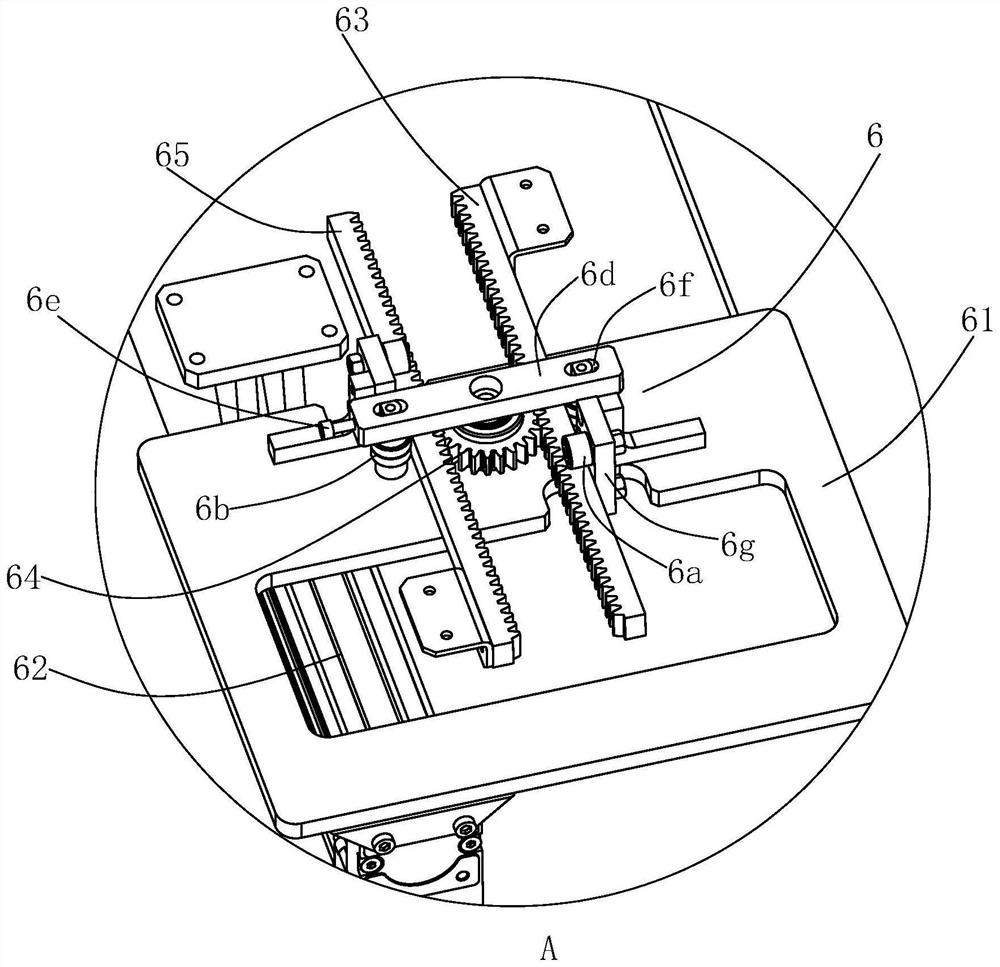

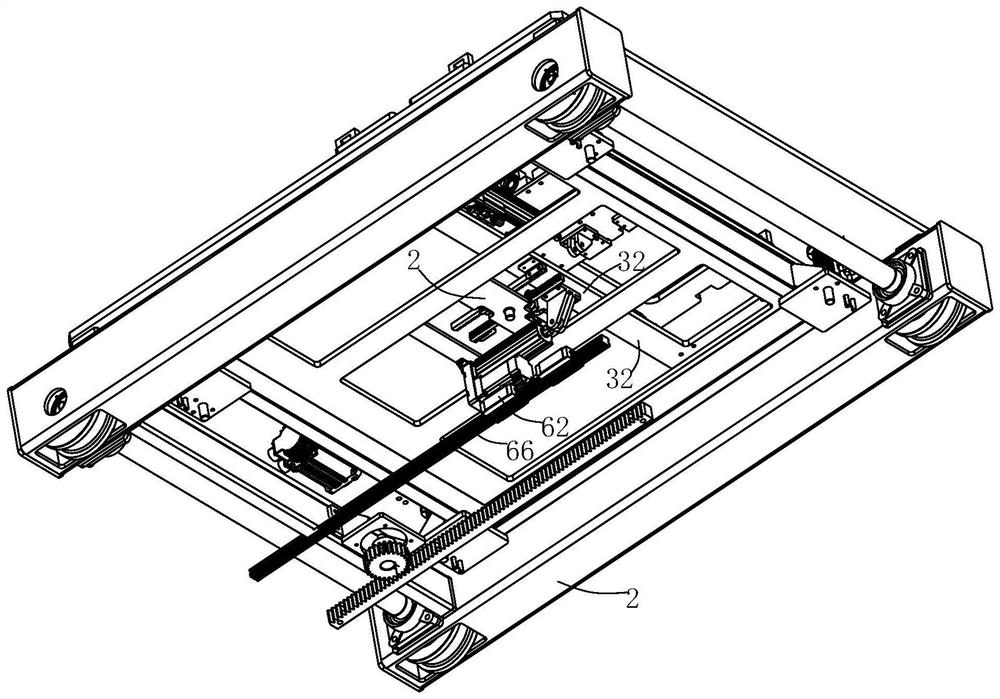

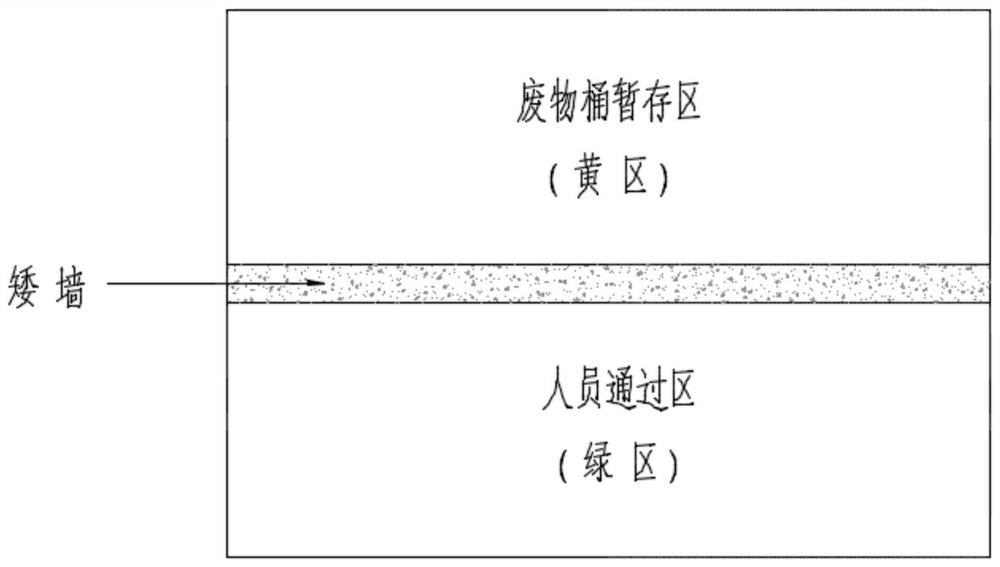

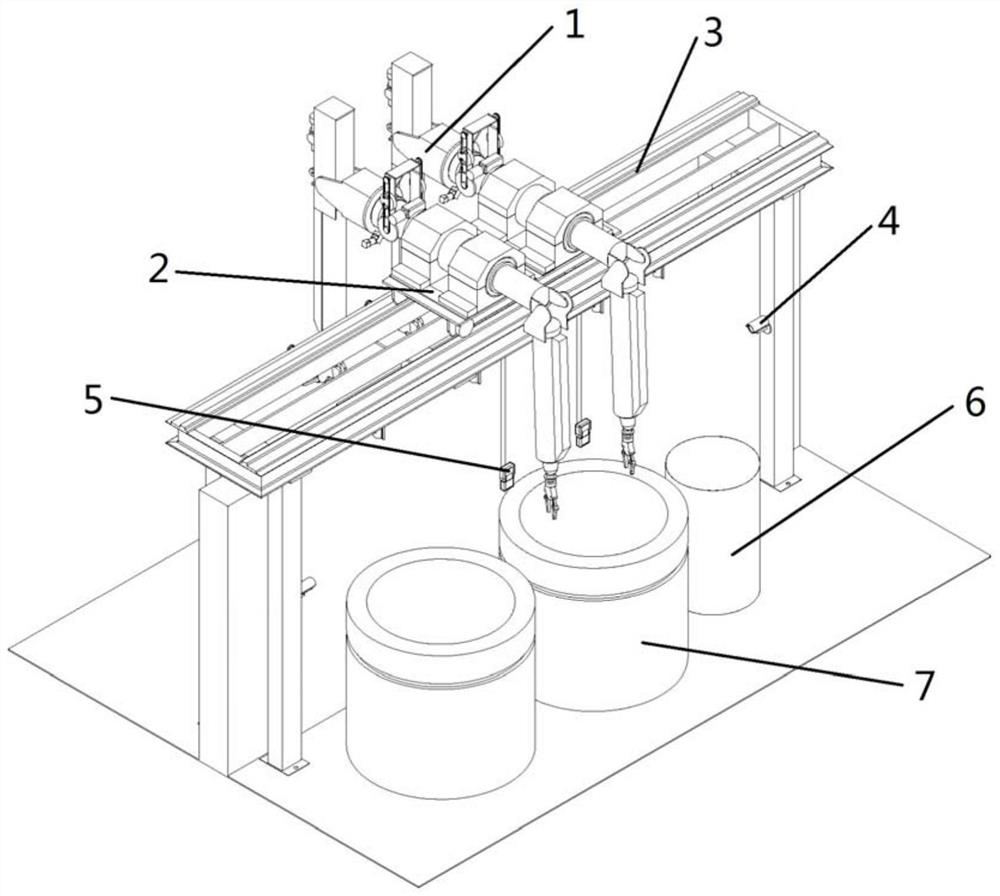

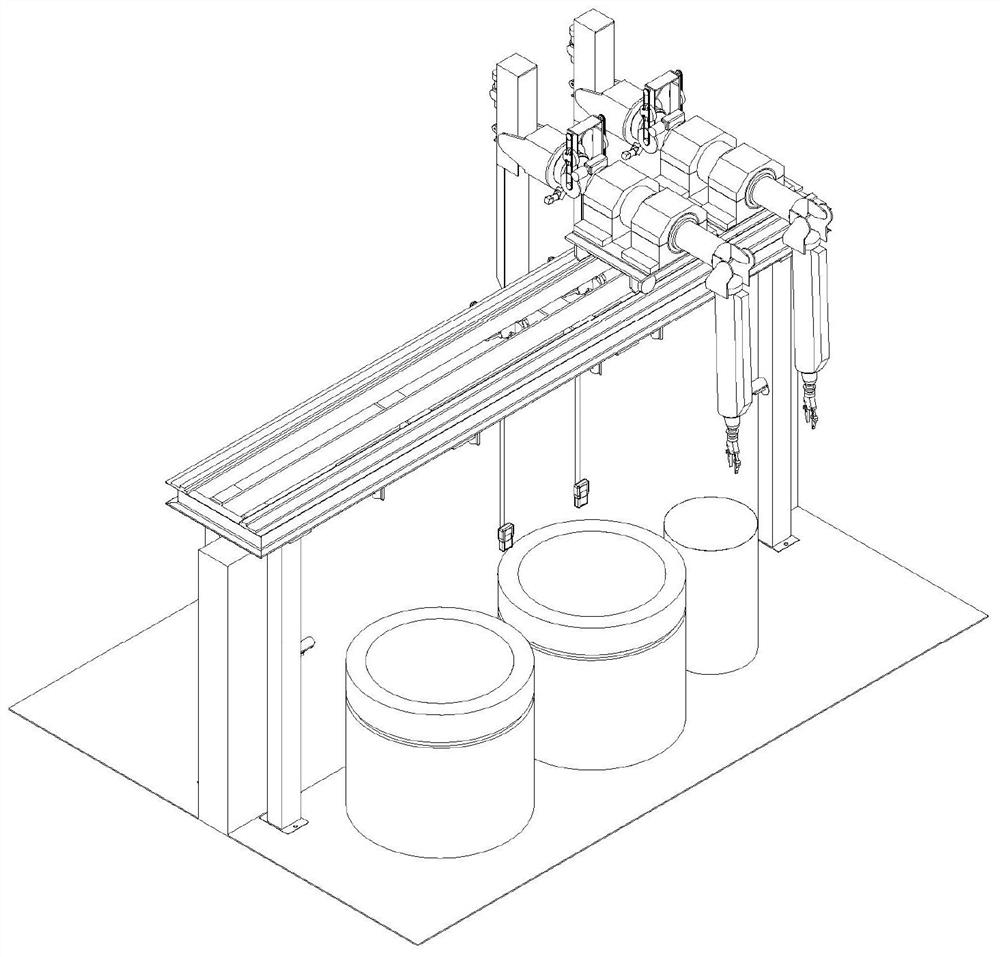

Movable radioactive waste sorting device and using method thereof

PendingCN111617974AIncrease flexibilityWide applicabilitySolid waste disposalSortingProcess engineeringRadioactive waste

The invention discloses a movable radioactive waste sorting device and a using method thereof. The device comprises a mounting platform mounted at the top of a low shielding wall; railways are arranged on the mounting platform in the length direction; a trolley which can slide along the railways is arranged on the railways; two manipulators are mounted on the trolley side by side; clamp forceps ofthe manipulators are located in a radioactive waste storage area located inside the low shielding wall; and a dosage measurement instrument and a video system are further mounted on an inside wall surface of the low shielding wall. According to the sorting device disclosed by the invention, the mounting platform is connected to supporting vertical posts by bolts; when other radioactive waste storage areas need sorting, the platform can be detached quickly; the overall sorting device is moved to the low shielding wall of the radioactive waste storage area for performing sorting work; and a detachable structure is high in flexibility, wide in applicability, and convenient to mount and detach, and facilitates transportation and adjustment.

Owner:QINGDAO DONGKA ENVIRONMENTAL PROTECTION ENG TECH +1

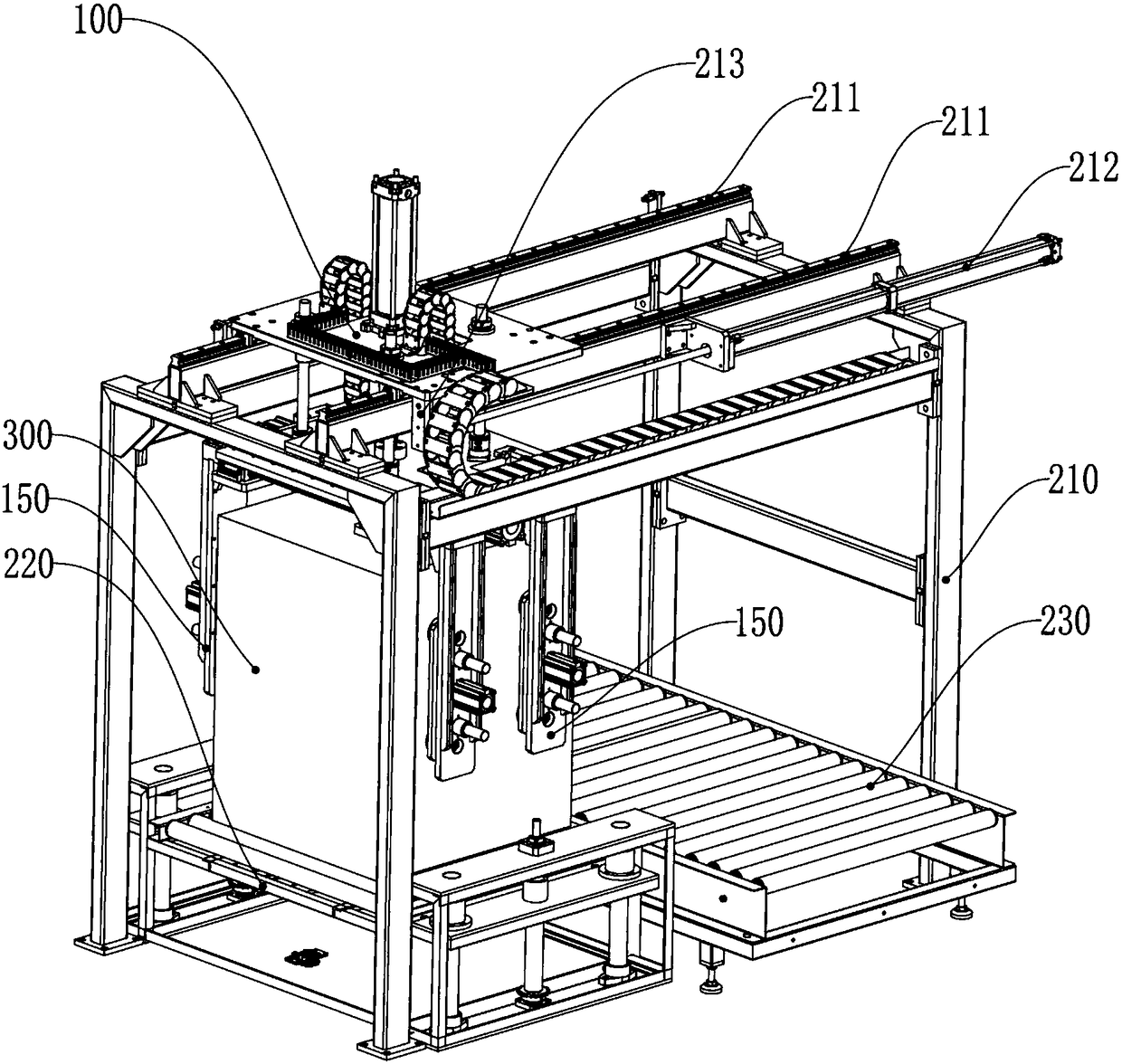

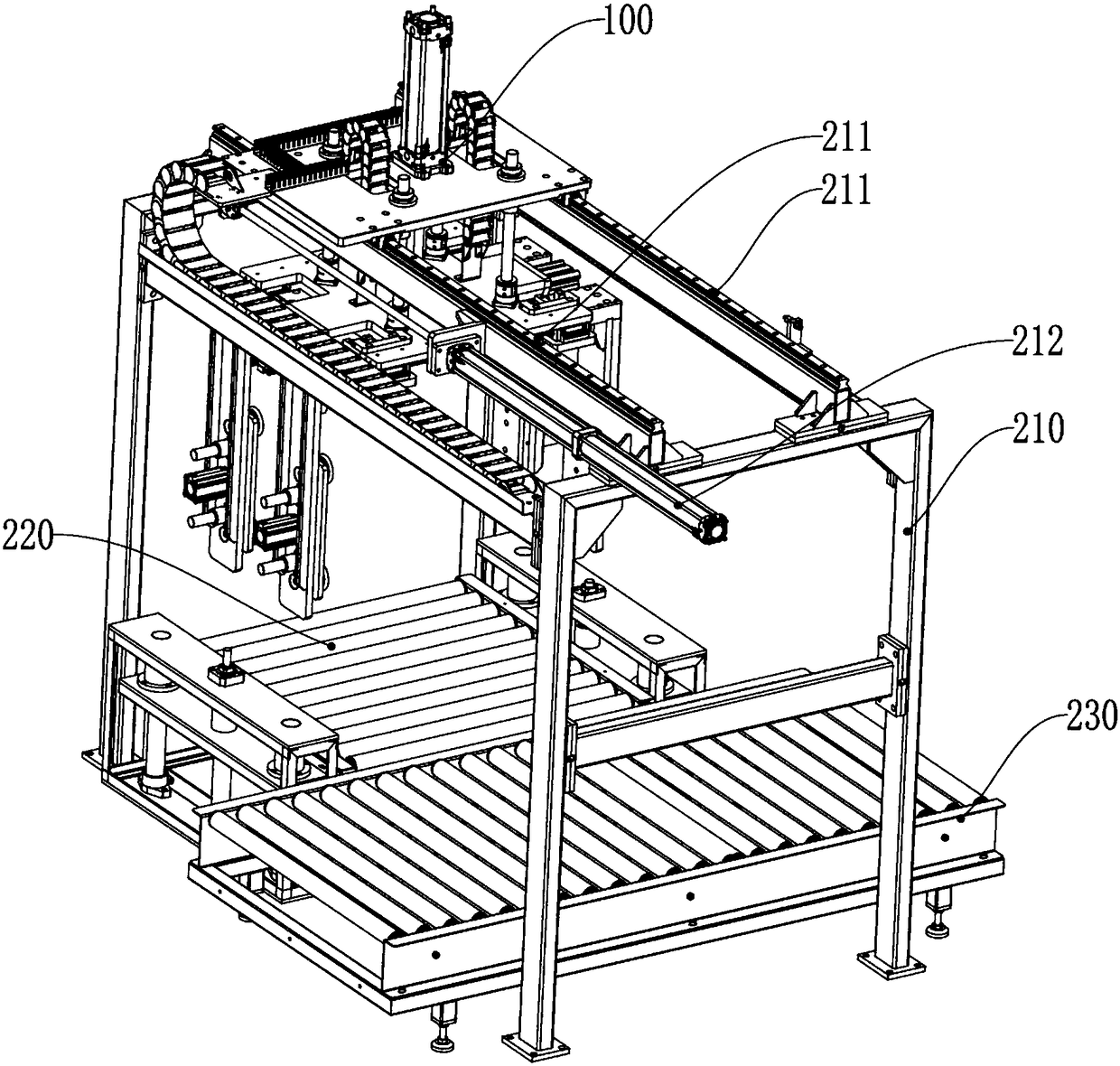

Grabbing device and transportation system

PendingCN108584430AGuaranteed operating accuracyQuality improvementConveyorsConveyor partsManufacturing lineEngineering

The invention relates to the field of transport stacking machines, in particular to a grabbing device and a transportation system. The grabbing device comprises an upper mounting plate, a lower mounting plate, a longitudinal telescopic driving device, a transverse telescopic driving device and clamping jaws; the transportation system comprises a grabbing device, a machine frame, an X-axis transportation device and a Y-axis transportation device; the grabbing device is mainly used for adsorbing by adopting an adsorption device, the lateral clamping effect is only guaranteed that the adsorptiondevice is always tightly attached to a box body for adsorption all the time, and deformation caused by the fact that too large force is applied to the side face of the box body is avoided; and the clamping claws can grab the box body and transversely or longitudinally move the box body on the production line under the driving of the longitudinal driving device and the transverse driving device sothat the box body can stably and accurately achieve translation or lifting operation. According to the transportation system, the grabbing device is ingeniously utilized so that the box body can quickly complete operations such as grabbing and turning transition transportation in the transportation system, then the operation precision is guaranteed, the box body is kept intact, and the product quality is improved.

Owner:SHAODONG INTELLIGENT MFG INNOVATIVE INST

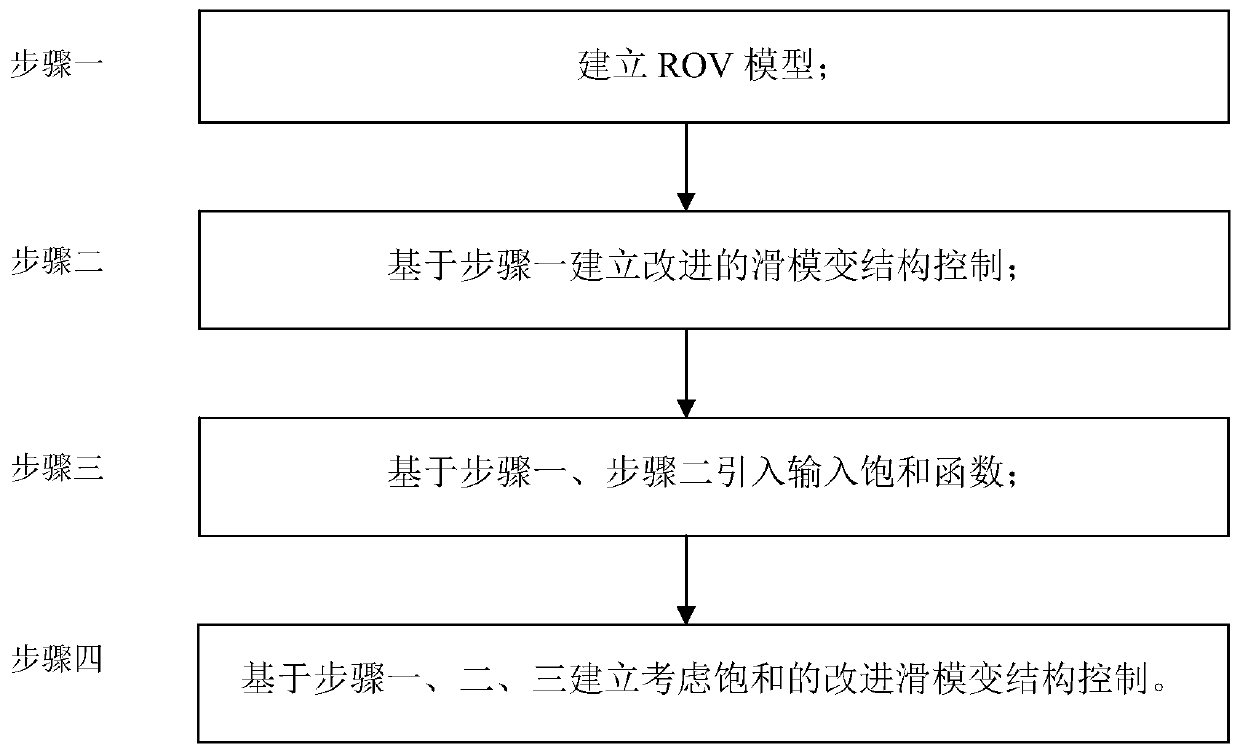

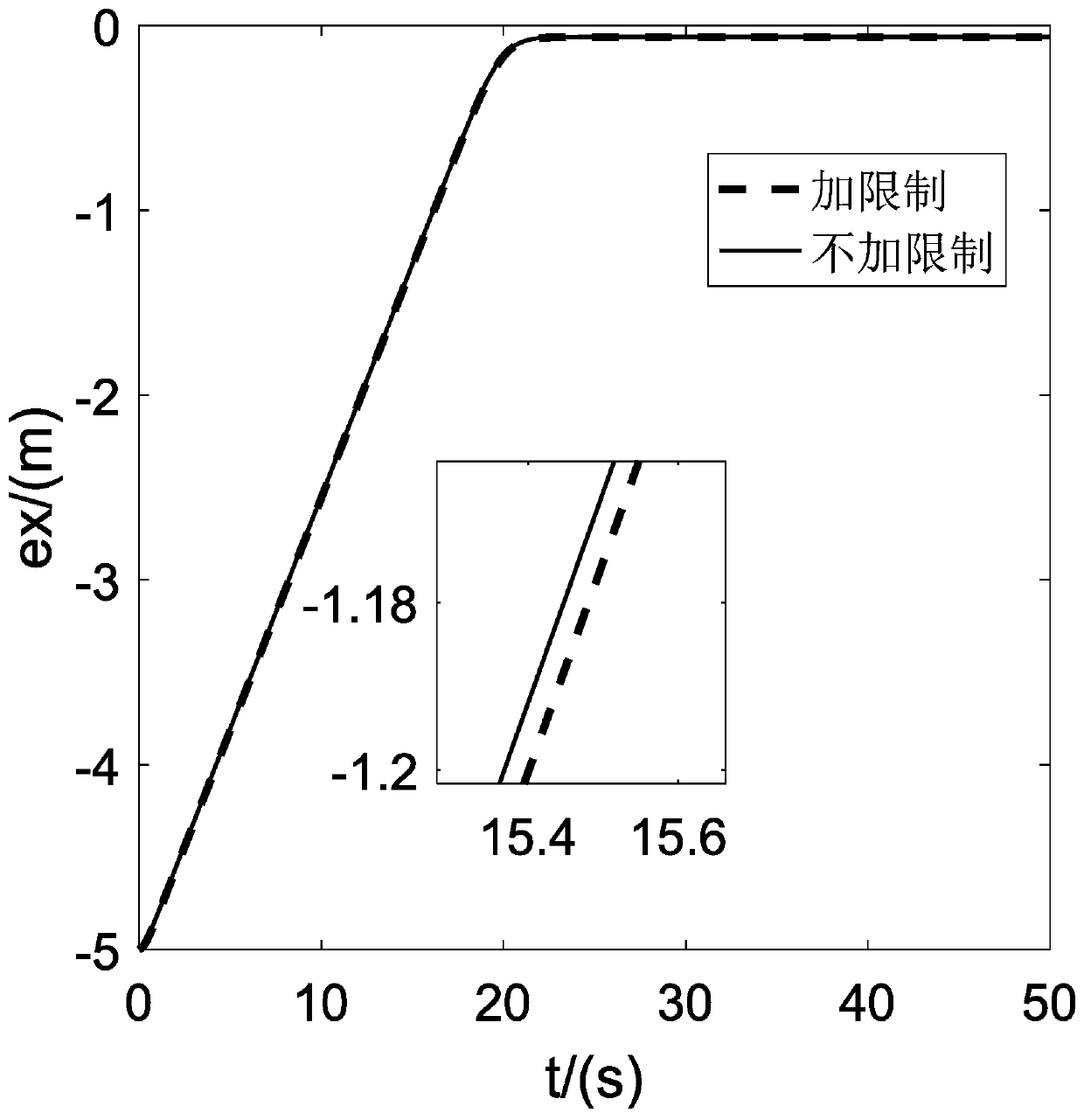

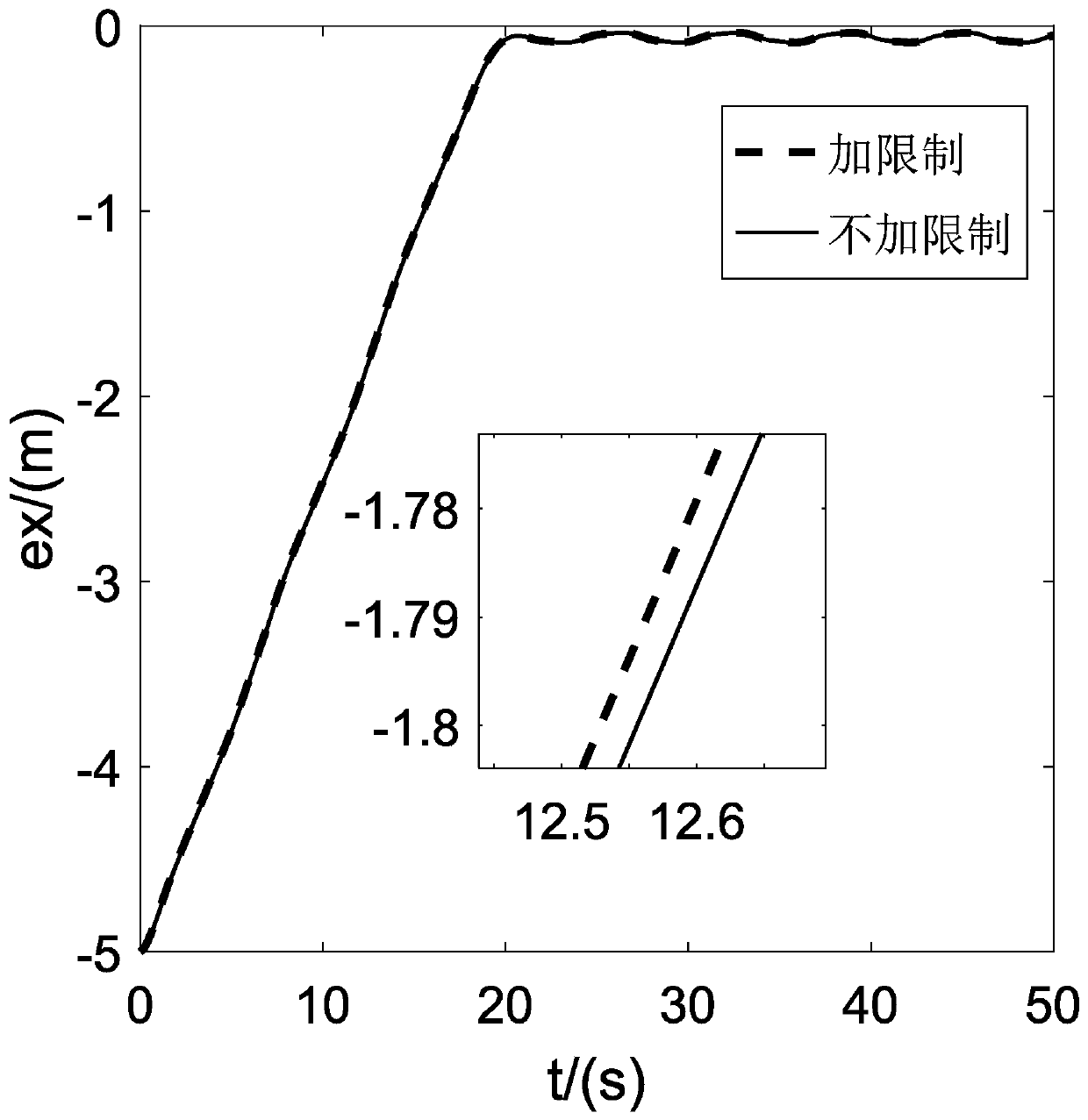

Saturation control method of seafloor accuracy landing of tethered cabled underwater robot based on sliding mode technology

ActiveCN110007604AHigh precisionImprove fixed-point landing accuracyAdaptive controlVariable structure controlUnderwater robot

The invention relates to a saturation control method of seafloor accuracy landing of a tethered cabled underwater robot based on a sliding mode technology. The problems that time and energy are wasted, precision of accuracy landing is poor, it is prone to collision and even accident with underwater structures, and serious economic losses are caused due to the fact that most landing is manual whenan existing ROV lands on the seafloor are solved. The saturation control method has the specific processes that 1, a ROV model is established; 2, improved sliding mode variable structure control is established based on the step 1; 3, an input saturation function is introduced based on the step 1 and the step 2; and 4, improved sliding mode variable structure control considering saturation is established based on the step 1, the step 2 and the step 3. The saturation control method is used in the field of saturation control of seafloor accuracy landing of the tethered cabled underwater robot.

Owner:HARBIN ENG UNIV

Robot slight collision compensation and correction system

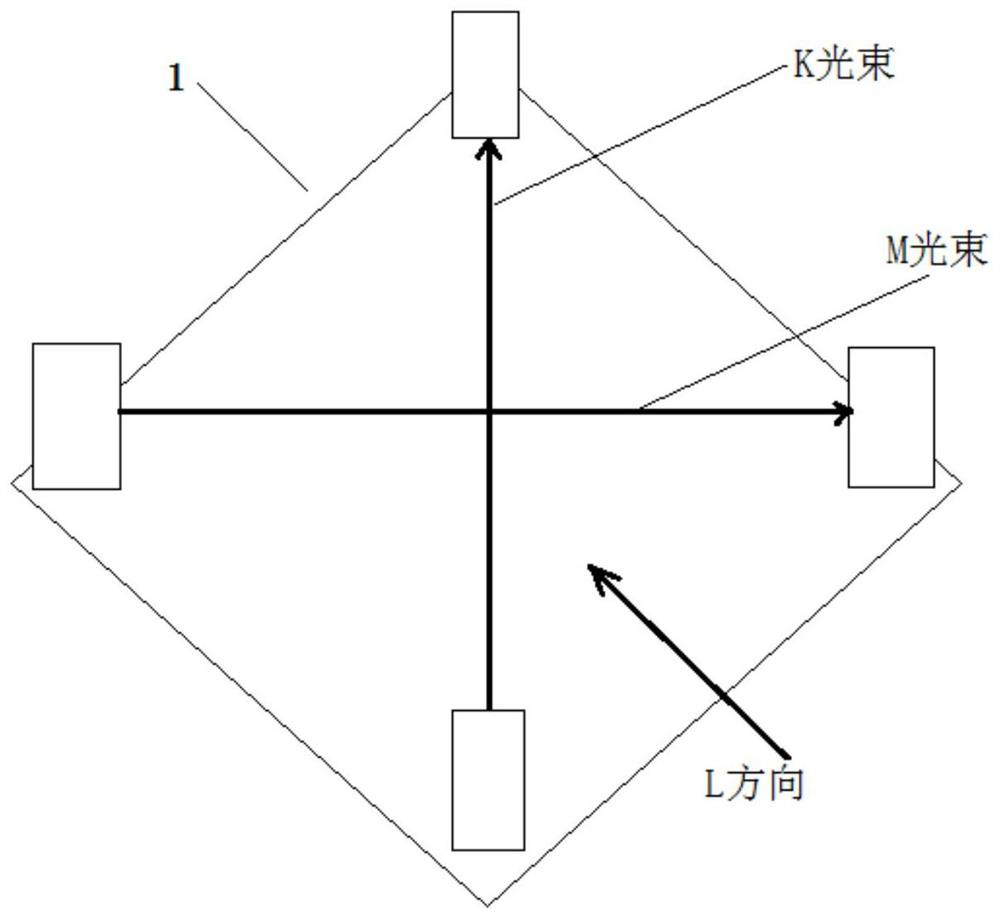

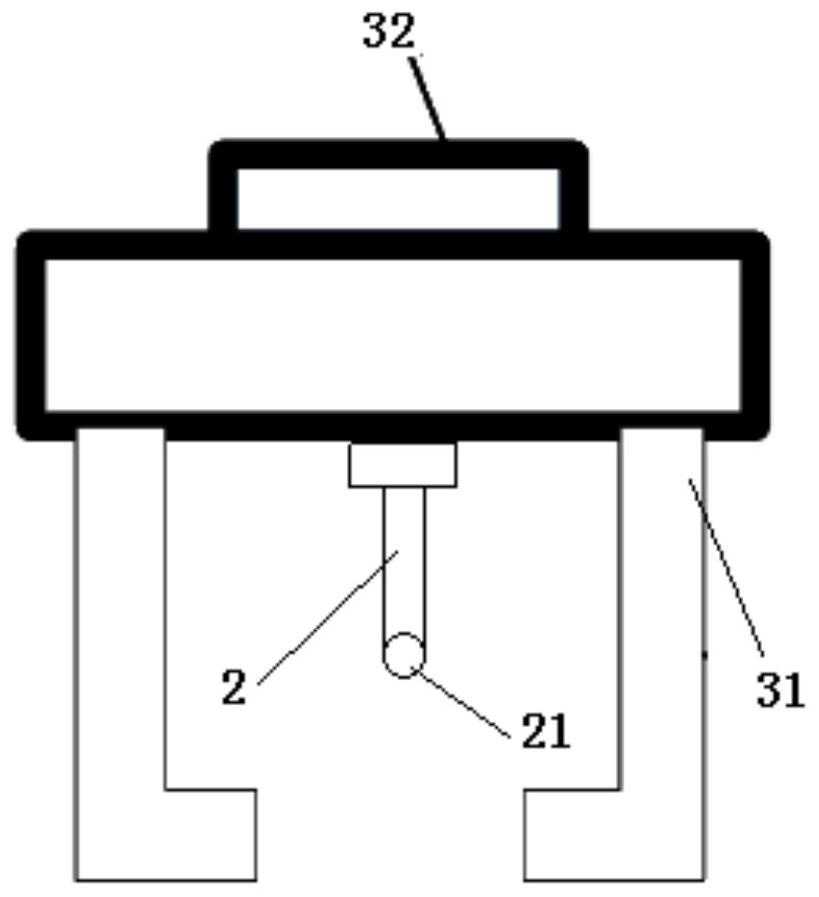

ActiveCN112729110AImprove work efficiencyGuaranteed operating accuracyUsing optical meansClassical mechanicsLight beam

The invention discloses a robot slight collision compensation and correction system which comprises a standard laser detection unit and a positioning needle. The standard laser detection unit is installed and fixed on an operation surface of a target product. The standard laser detection unit comprises a K light beam transmitting end, a K light beam receiving end, an M light beam transmitting end and an M light beam receiving end; a robot clamping jaw is installed on a robot arm through a rotary disc; the tail end of the positioning needle is fixed on the clamping jaw side of the rotary disc; a probe ball is arranged at the head end of the positioning needle; a geodetic coordinate system reference coordinate (X0, Y0, Z0) of the central point of the standard laser detection unit is calibrated in a processor; the processor controls the clamping jaw to move, the current geodetic coordinate system coordinate value (x1, y1, z1) of the center point of the standard laser detection unit is obtained, and offset of the movement point position of the robot is corrected. According to the invention, offset of the motion point position of the robot caused by slight collision of the robot can be automatically, quickly and effectively corrected, and the working efficiency and the operation accuracy of the robot are improved.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

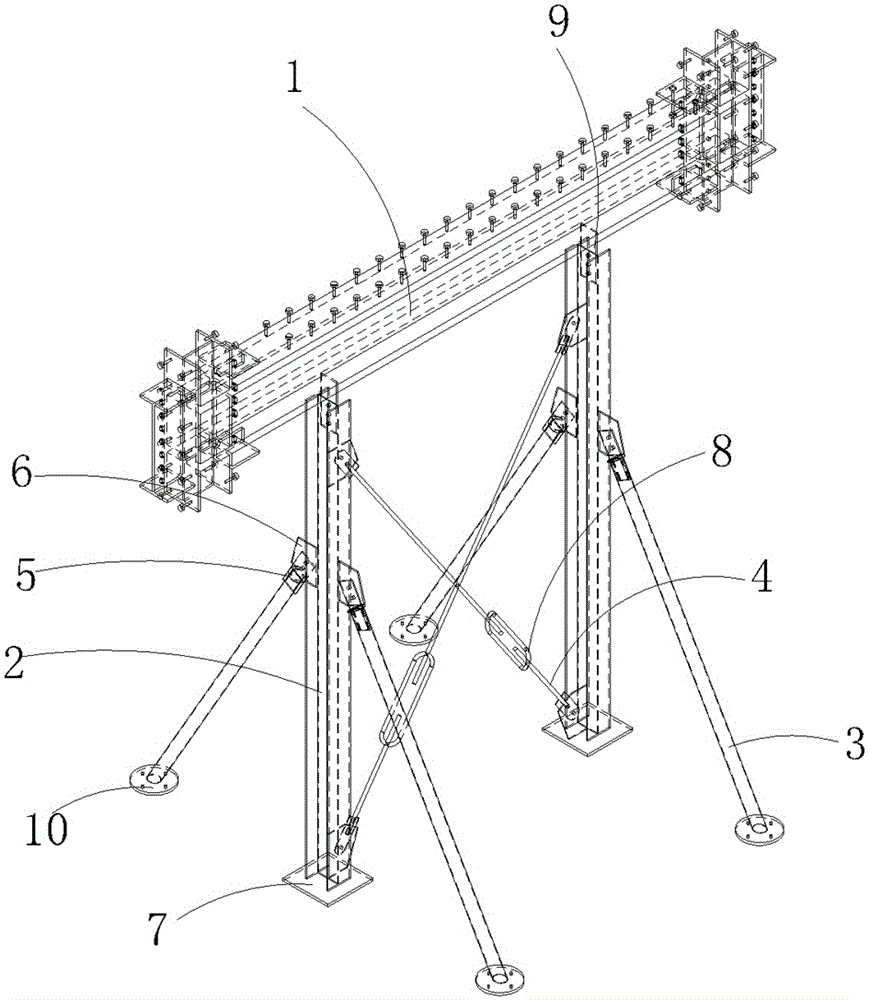

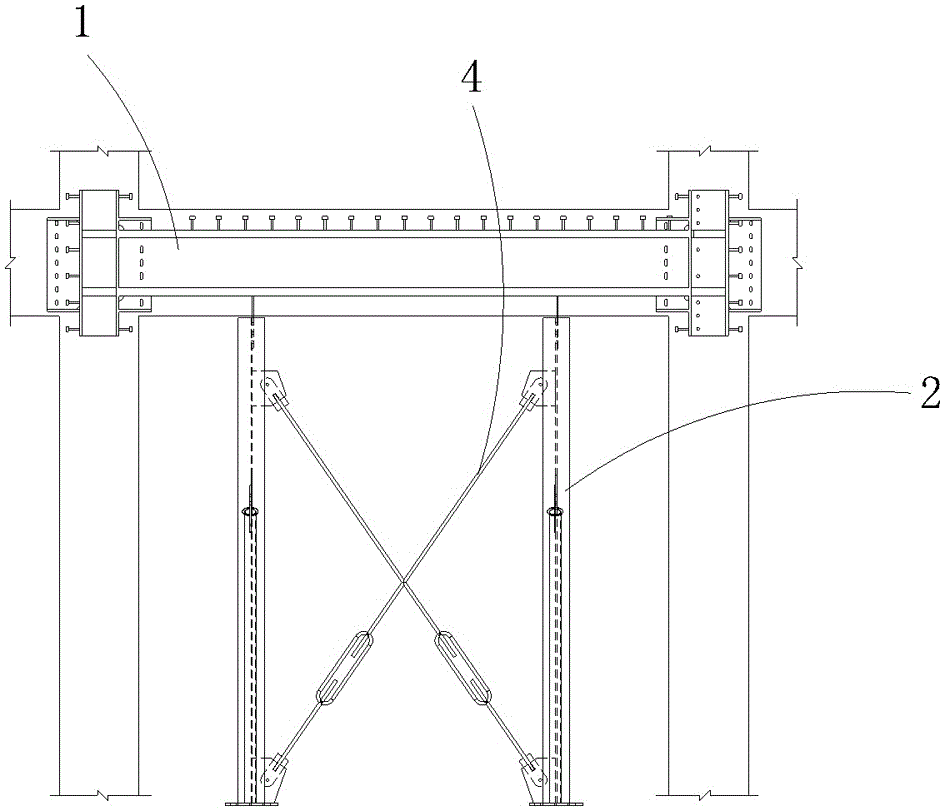

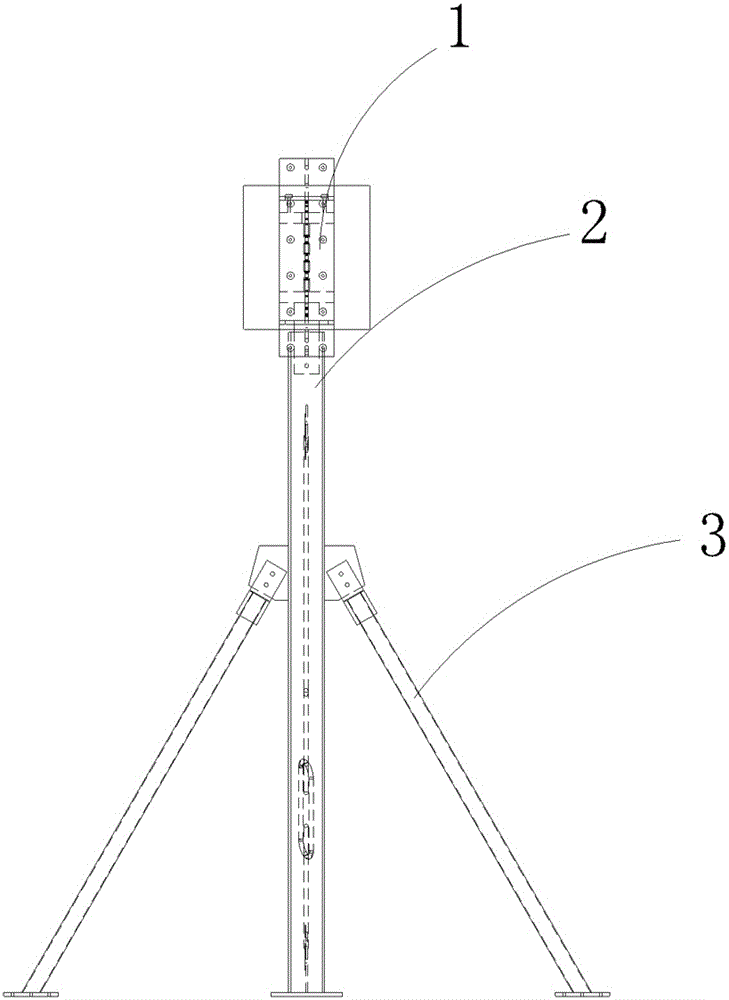

Super-high-rise core tube suspended steel rib column and construction method thereof

ActiveCN105926855AReduce steel consumptionReduce waste of resourcesStrutsBuilding material handlingSteel columnsHigh rise

The invention relates to a suspended steel rib column, and in particular relates to a super high-rise core tube suspended steel rib column and a construction method thereof, belonging to the field of steel structures. The super-high-rise core tube suspended steel rib column comprises a suspended steel rib column, wherein steel column components are respectively arranged at two ends of the bottom of the suspended steel rib column. According to the super-high-rise core tube suspended steel rib column and the construction method thereof, the structure is compact, the operation precision can be ensured, and the construction cost can be reduced.

Owner:浙江东南网架股份有限公司

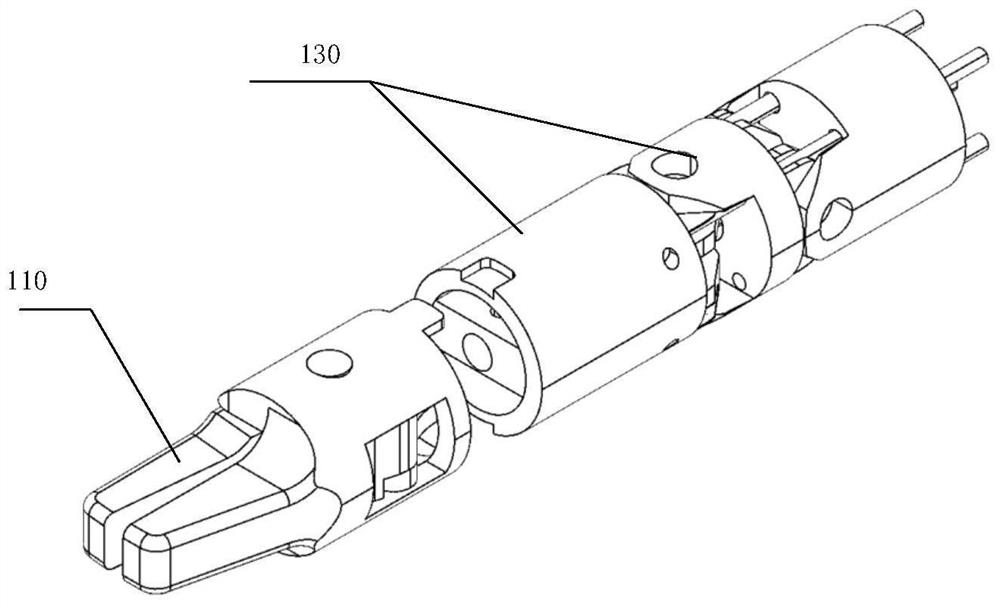

Front end structure of electrocoagulation forceps

PendingCN113786237AEasy to useConducive to manual operationInstrument handpiecesSurgical instruments for heatingElectrocoagulationForceps

The invention discloses a front end structure of electrocoagulation forceps. The front end structure comprises a forceps head, a forceps rod which is connected with the forceps head and drives the forceps head to be opened and closed through axial movement, a forceps handle which is connected with the forceps rod and drives the forceps rod to move axially, and a handle; the front end of the handle is connected with a handle tube; the handle tube comprises a hard tube section of which the rear end is fixed to the handle, a bendable section coaxially fixed to the front end of the hard tube section, and a hard fixed shaft section coaxially fixed to the front end of the bendable section; the forceps head is rotatably and coaxially connected to the front end of the fixed shaft section; and a rotation driving mechanism for driving the forceps head to rotate around the fixed shaft section and a bending driving mechanism for driving the bendable section to bend are arranged in the handle. By means of bidirectional bending of the bendable section of the front section of the handle tube and rotation of the forceps head, the pair of electrocoagulation forceps has various operation angles, handle tube turning, head rotating and clamping functions can be achieved at the same time, the pair of electrocoagulation forceps is convenient to use under the condition of complex cavities, and relatively large tissue damage cannot be caused.

Owner:YOUCARE TECH CO LTD

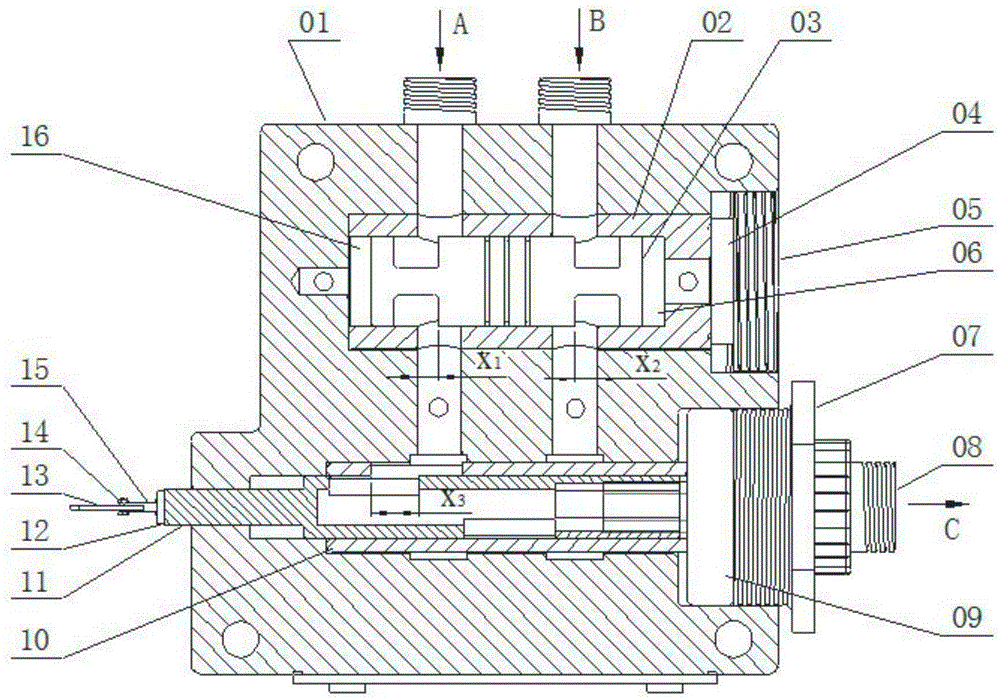

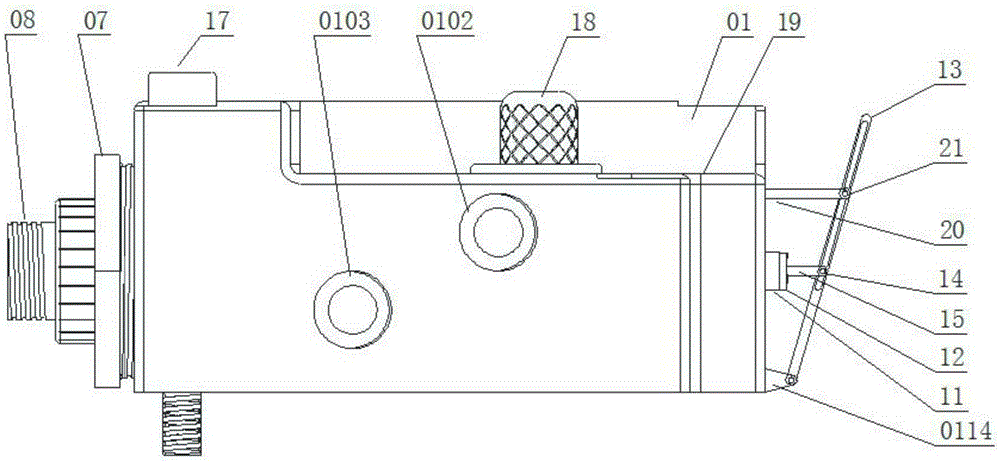

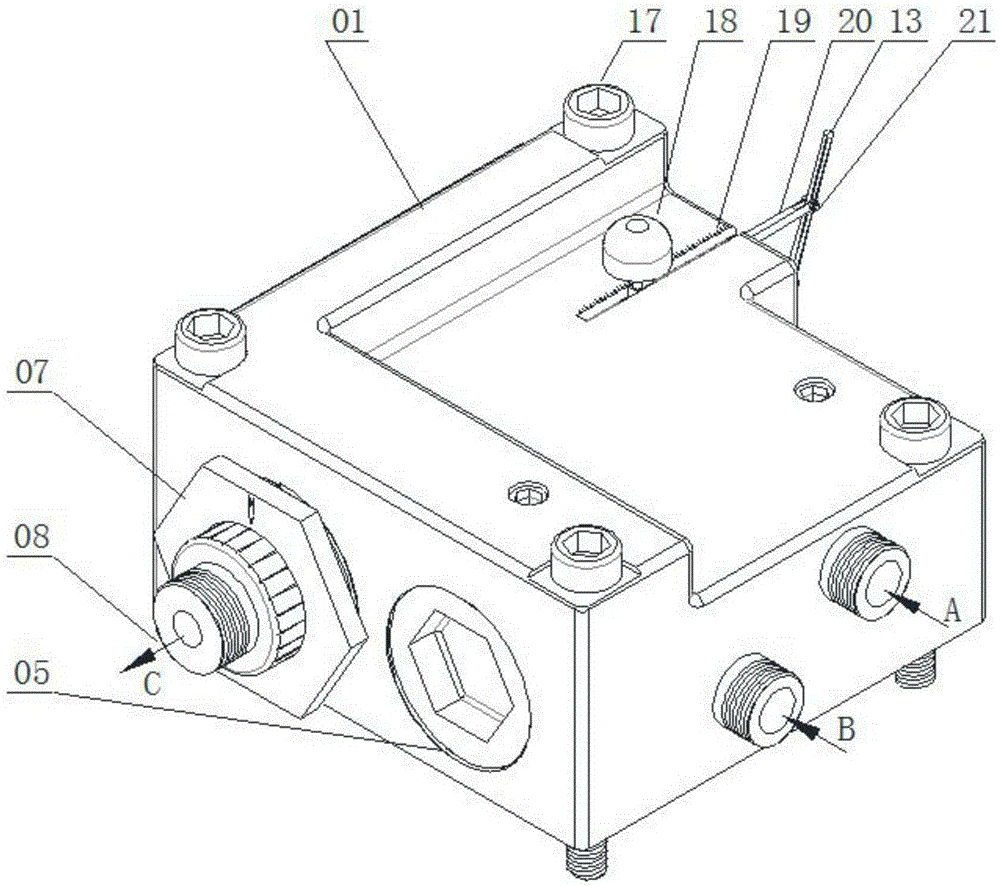

Fluid proportioning valve with pressure balancing device and application thereof

ActiveCN105221795ASet the volume ratio arbitrarilyImprove timelinessMultiple way valvesEngineeringPressure balance

The invention relates to a fluid proportioning valve with a pressure balancing device and an application thereof. The fluid proportioning valve comprises a shell, wherein a first valve cavity and a second valve cavity which are connected are formed in the shell; a pressure balancing unit is arranged in the first valve cavity; a center valve body and a center valve core are arranged in the second valve cavity; a valve body inlet A and a valve body inlet B are formed in the center valve body; a valve core inlet A and a valve core inlet B which are respectively matched with the valve body inlet A and the valve body inlet B are formed in the center valve core; and the flow areas of fluid A and fluid B are adjusted by rotating the angle of the center valve core in the center valve body, further the proportioning of the two fluids is adjusted, and the outflow of mixed fluid is adjusted by linear displacement of the center valve core. The fluid proportioning valve can set the volume ratio of the fluids after mixing at random, meanwhile can adjust the outflow of the mixed fluid and is relatively high in efficiency and good in timeliness.

Owner:SHANDONG UNIV OF SCI & TECH

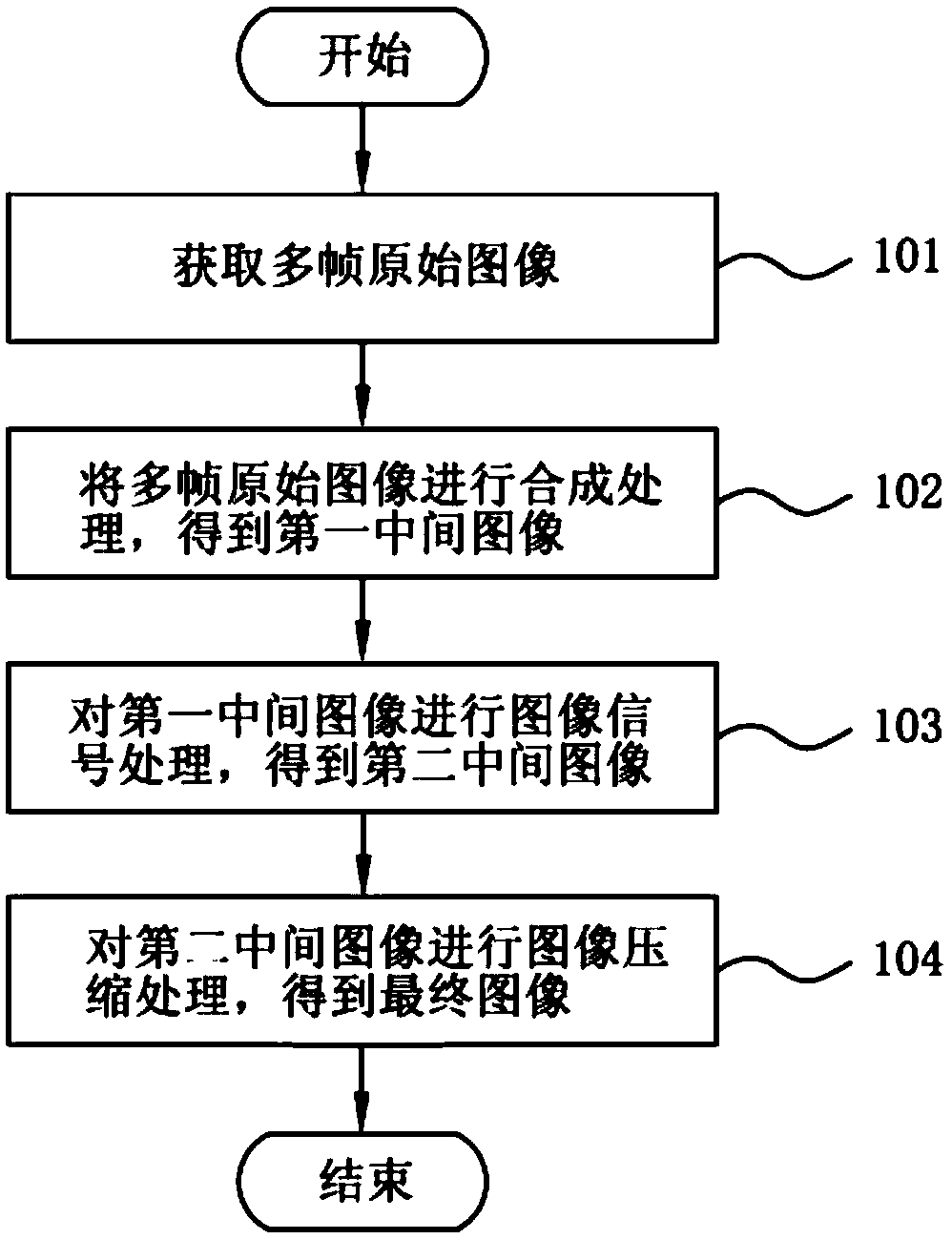

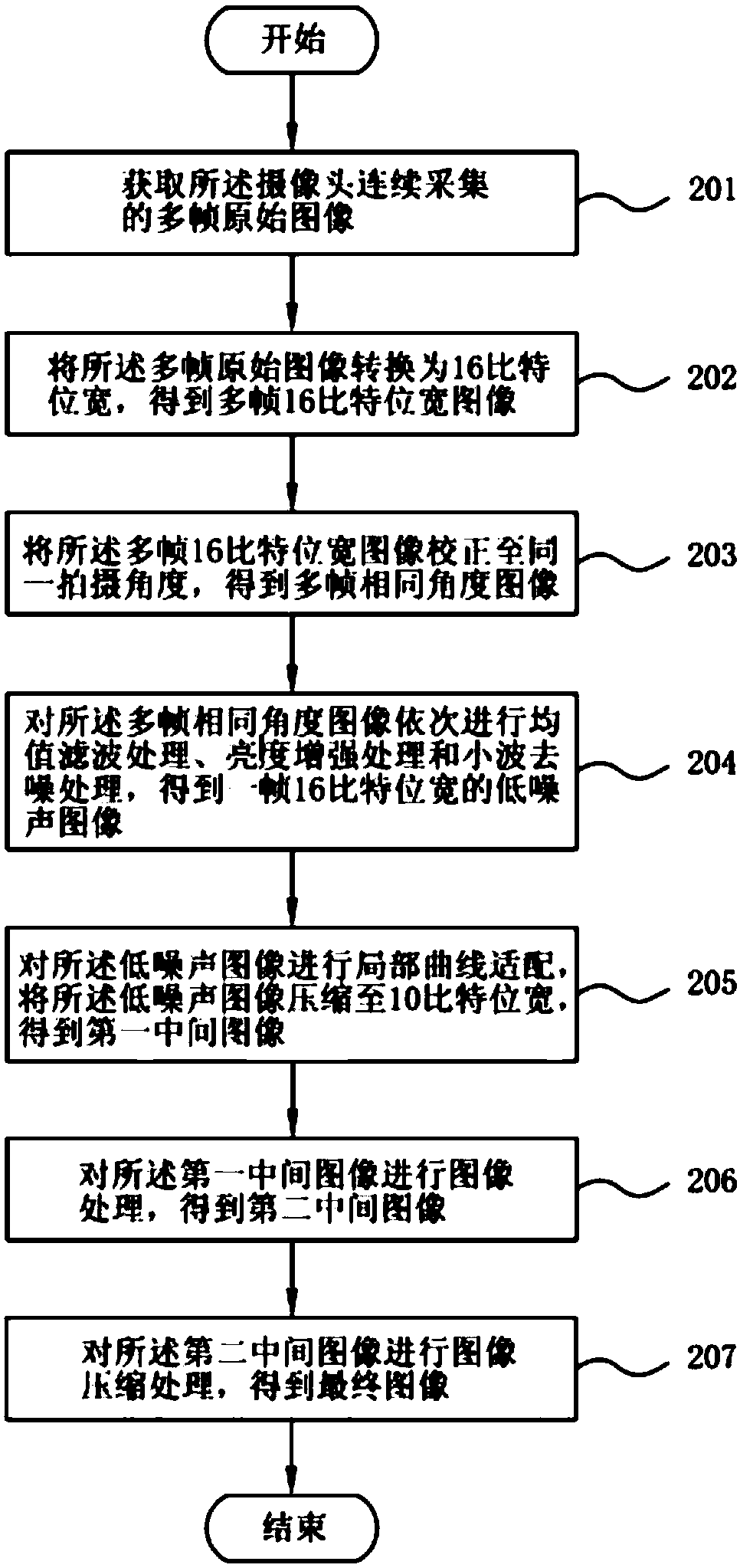

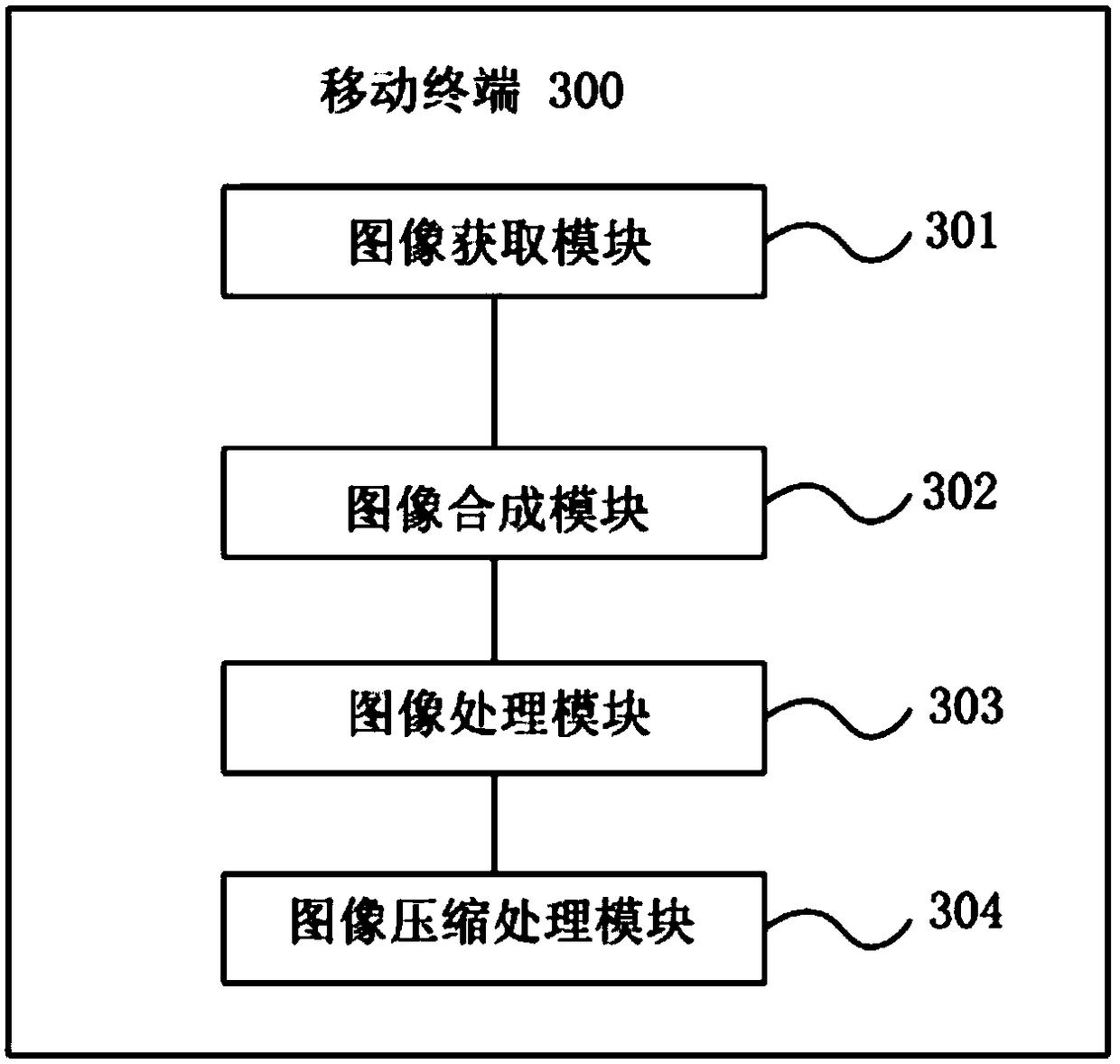

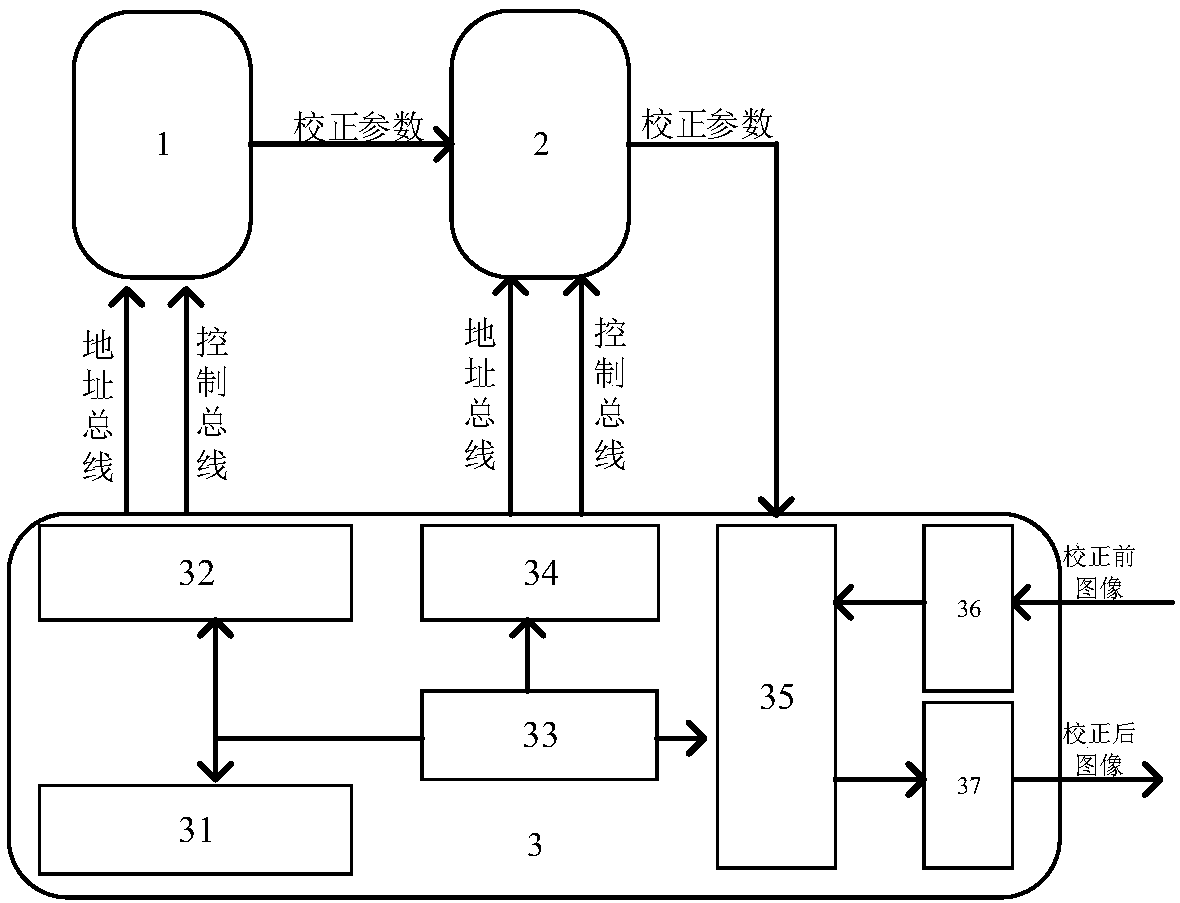

Image processing method and mobile terminal

ActiveCN105827971BGood detailsImprove acceleration performanceImage enhancementTelevision system detailsIntermediate imageImaging processing

Examples of the present invention provide an image processing method and mobile terminal.This image processing method includes: to obtain the multi -frame original image collected continuously in the camera; synthesize the first intermediate image by the preset algorithm;Get the second intermediate image; perform the image compression processing of the second intermediate image to obtain the final image. Among them, the multi -frame primitive image and the first intermediate image are all RAW format images with 10 than the special.The middle image is an 8 -than -wide YUV format image, and the final image is a JPEG format image with a wide range of eights.The image processing method provided by the embodiment of the present invention can obtain a wider dynamic range, less image noise, and more image details when using a mobile terminal to synthesize and enhance the processing.

Owner:VIVO MOBILE COMM CO LTD

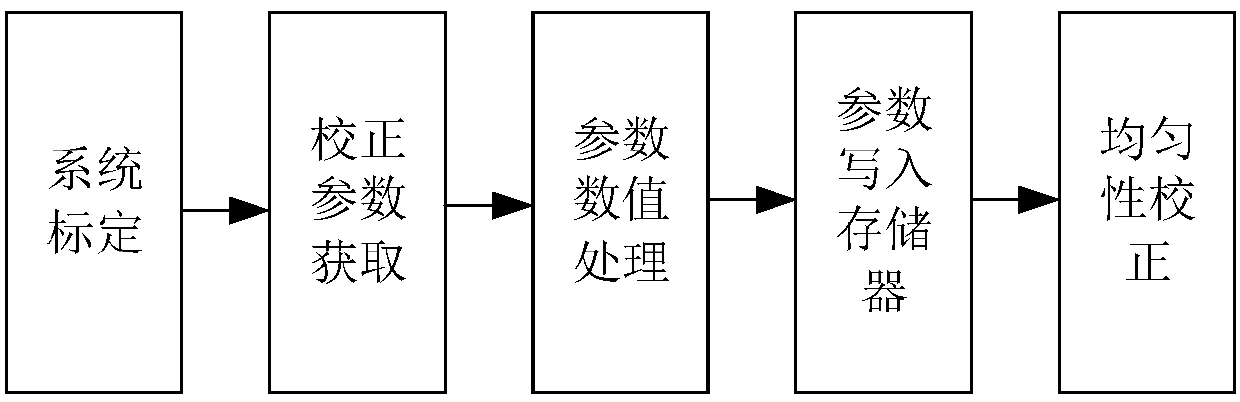

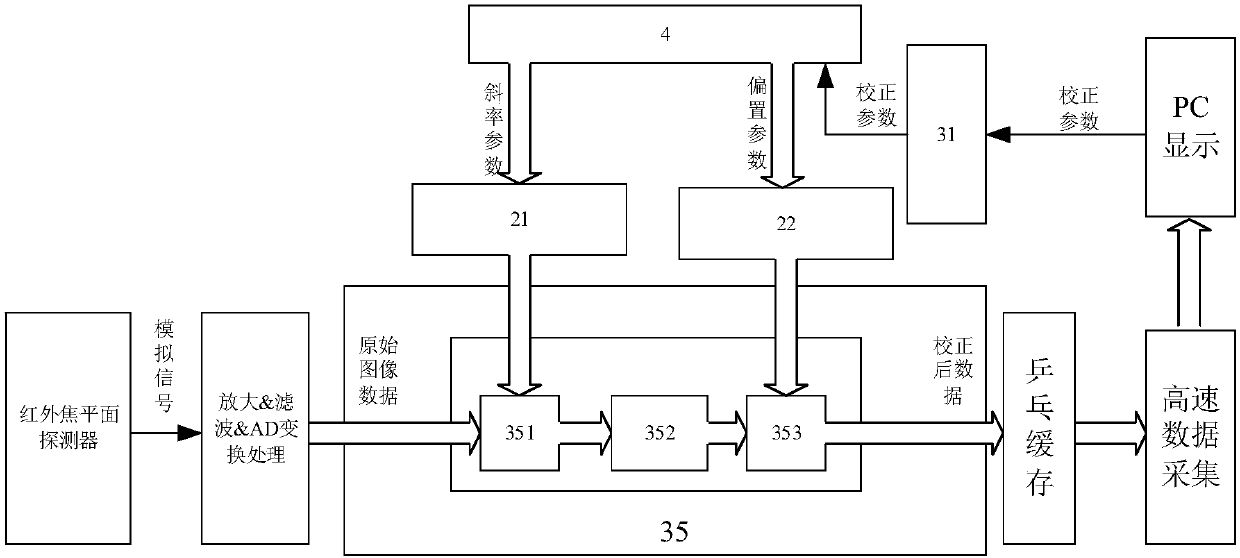

Real-time non-uniformity correction system and method for large-scale infrared focal plane

InactiveCN109974857AReal-time processingLarge parameter storage capacityRadiation pyrometryComputer moduleControl circuit

The invention relates to a real-time non-uniformity correction system and method for a large-scale infrared focal plane. The correction system comprises a large-capacity non-volatile memory, a parameter memory SRAM and a logic time sequence control circuit; the logic time sequence control circuit comprises a main control module as well as a non-volatile memory read / write control module, an SRAM read / write control module, a parameter up-pouring module and a correction operation module which are connected with the main control module; the correction system further comprises an image data input interface and an image data output interface which are connected with the correction operation module; the large-capacity non-volatile memory is connected with the parameter memory SRAM and the non-volatile memory read / write control module; and the parameter memory SRAM is also connected with the SRAM read / write control module and the correction operation module. Compared with the prior art, the system and method of the invention can effectively ensure correction speed while ensuring operation precision and have the advantages of large parameter storage capacity, high operation real-time performance and the like, and can be applied to the real-time correction of large-scale area array detectors.

Owner:上海德运光电技术有限公司

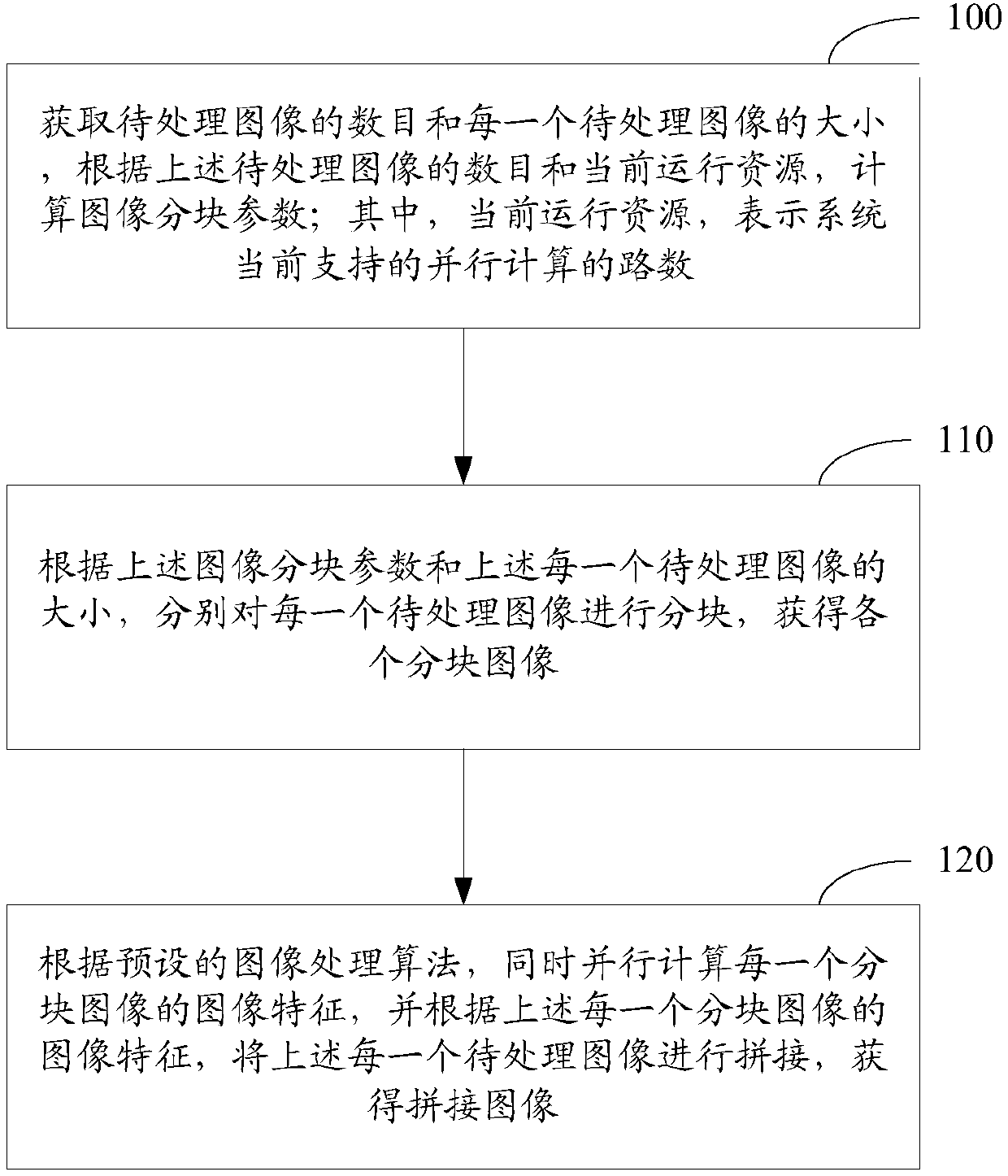

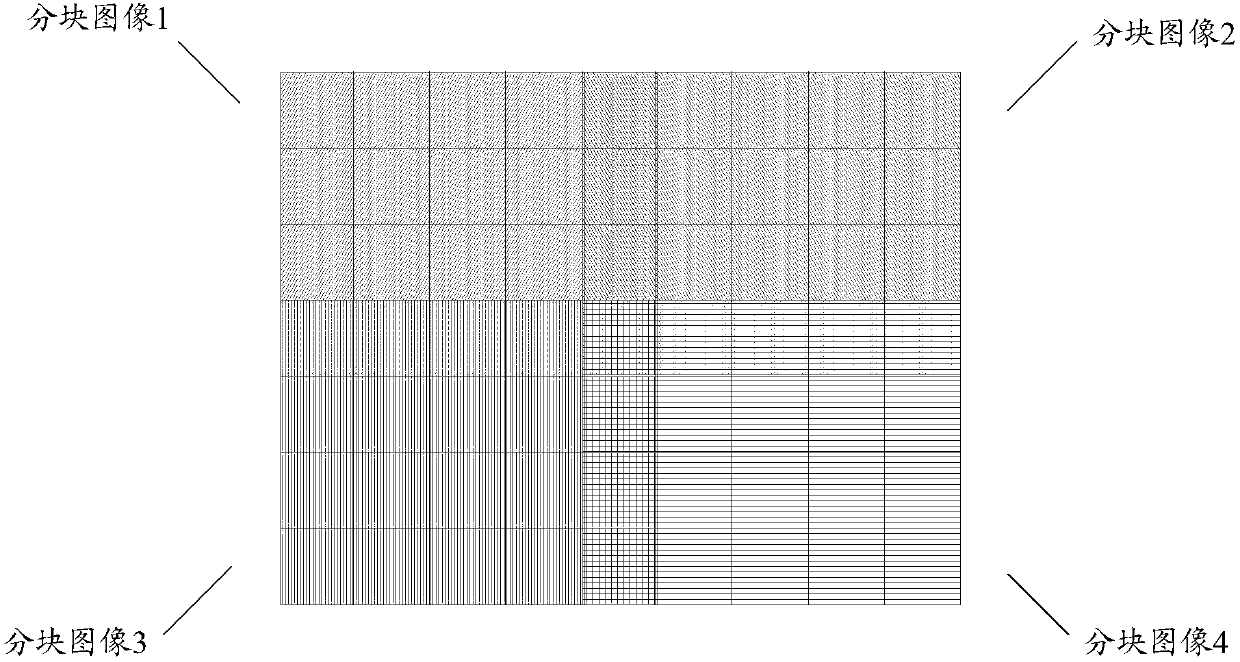

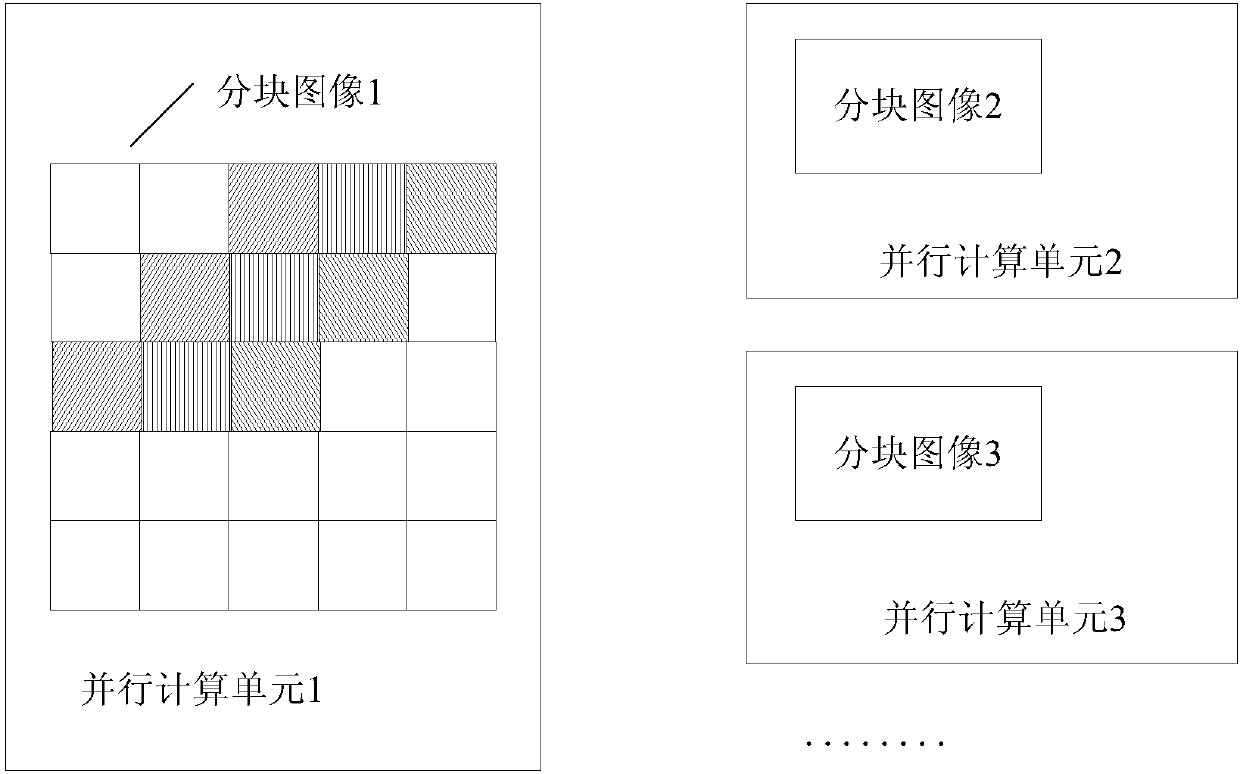

Image processing method and device

InactiveCN107767336AProcessing speedReal-timeGeometric image transformationDetails involving image processing hardwareImage segmentationImaging Feature

The invention relates to the field of digital image processing, and especially relates to an image processing method and device. The image processing method comprises obtaining the number of images tobe processed and the size of each image to be processed, and computing an image segmentation parameter according to the number of the images to be processed and the current operation resource; wherein the current operation resource represents ways of parallel computation supported by the system at present; segmenting each image to be processed according to the image segmentation parameter and thesize of each image to be processed, and obtaining each segmented image; computing image features of all the segmented images in parallel at the same time according to a preset image processing algorithm, and splicing each image to be processed according to the image features of all the segmented image to obtain a spliced image. In this way, the image to be processed is segmented, furthermore allthe segmented images are processed in parallel at the same time, image splicing is achieved, the processing performance of a parallel device can be achieved furthest, and the processing speed and efficiency are increased.

Owner:CHINA MOBILE COMM LTD RES INST +1

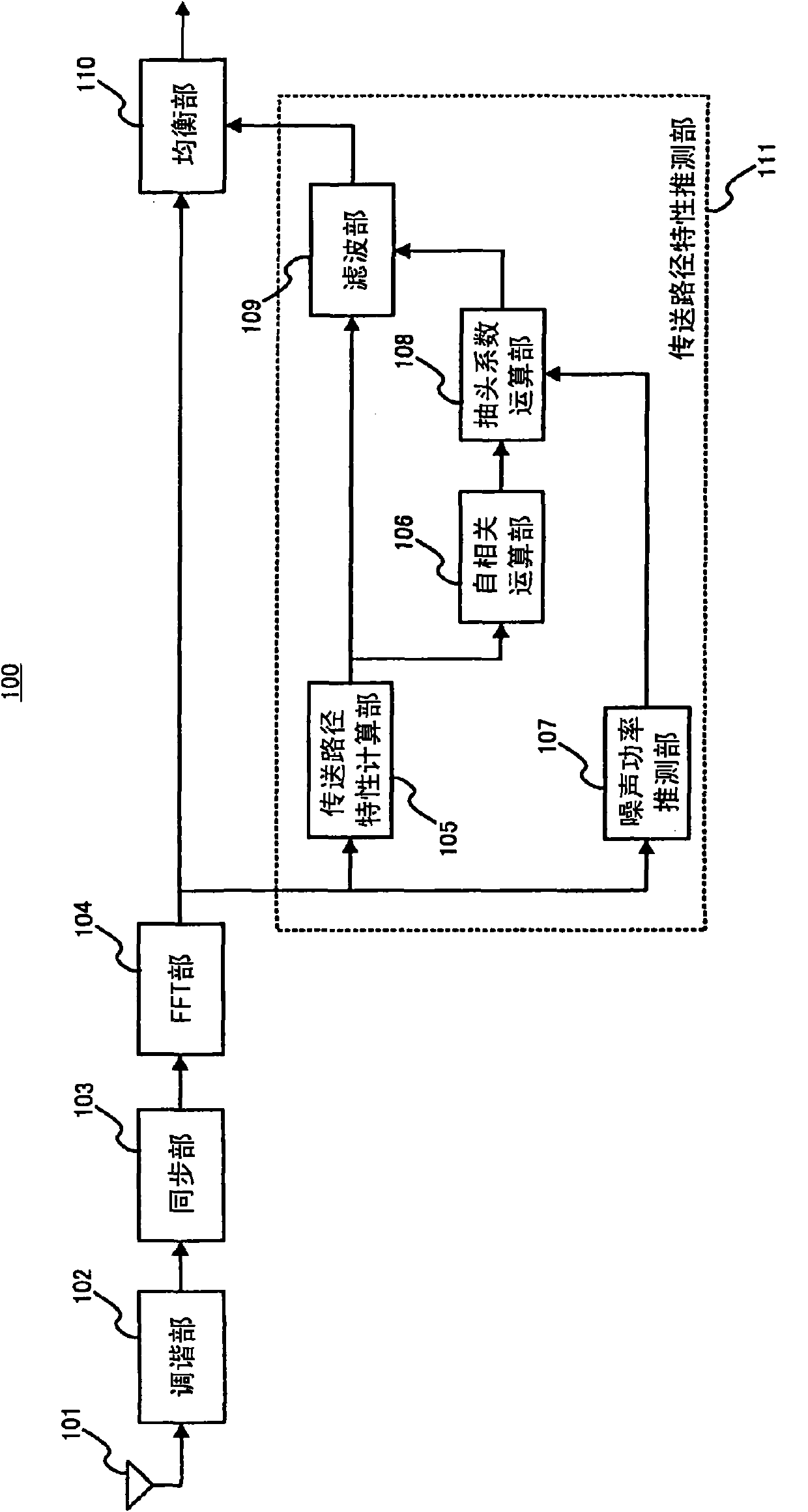

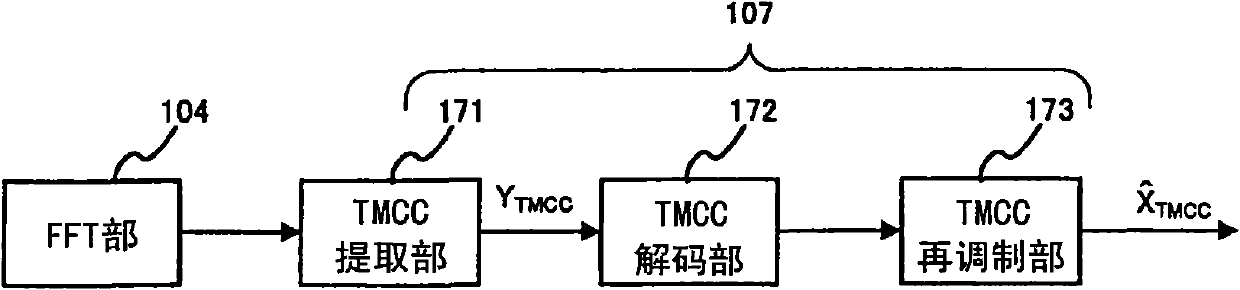

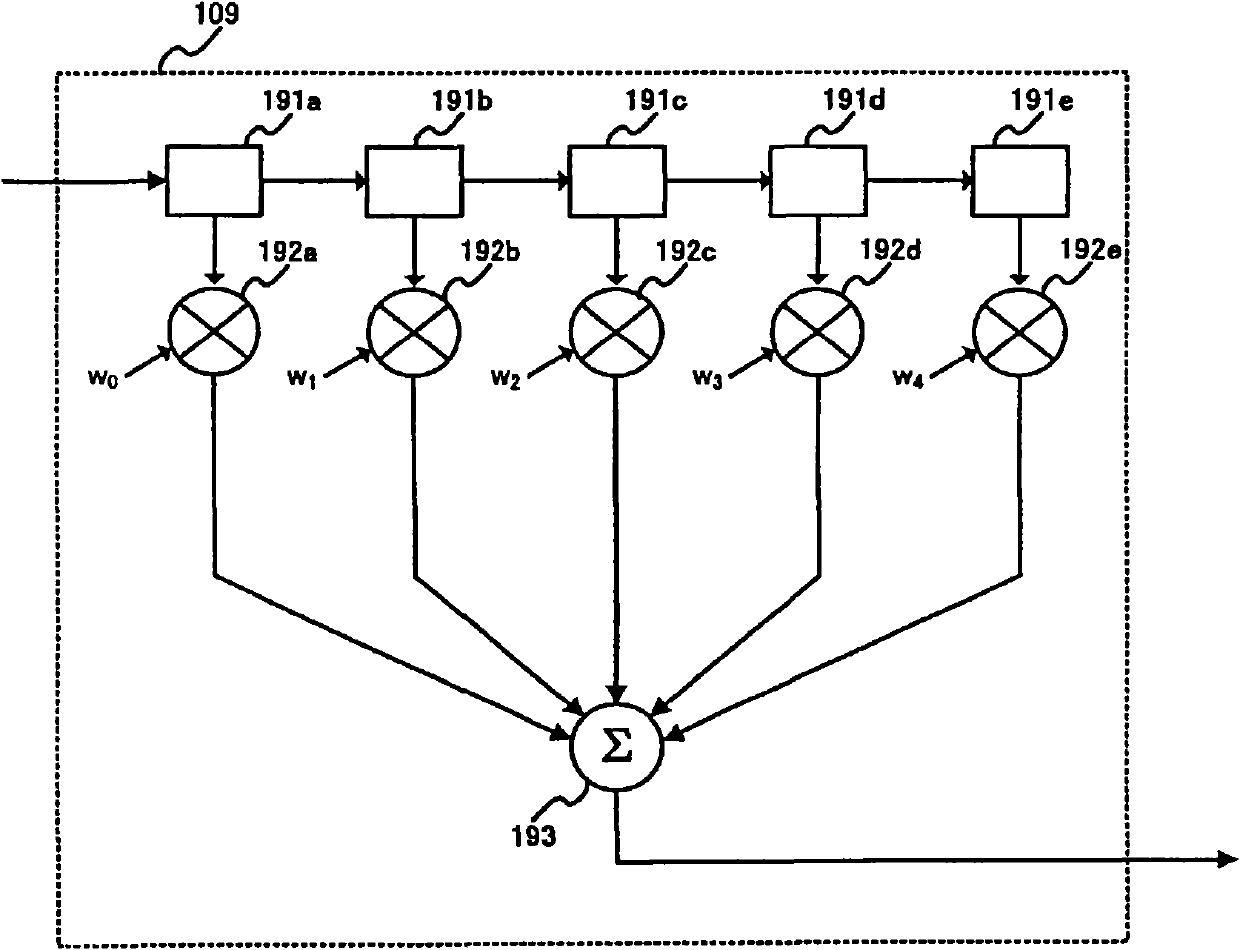

Receiving apparatus, receiving method, integrated circuit, digital television receiver, and program

ActiveCN101682457AEffective adaptive processingGuaranteed operating accuracyModulated-carrier systemsChannel estimationPath propertyDigital television

A receiving apparatus (100) wherein a noise power estimation section (107) estimates noise power contained in a received signal in a frequency area from the received signal. A transmission path property estimation part (111) estimates a transmission path property on the basis of a reference signal contained in the received signal. A tap coefficient calculation section (108) calculates the tap coefficient of a filtering section (109) on the basis of the noise power contained in the received signal and the autocorrelation value of the transmission path property. The filtering section (109) calculates the estimated value of the transmission path property by filtering the transmission path property according to the tap coefficient.

Owner:PANASONIC CORP

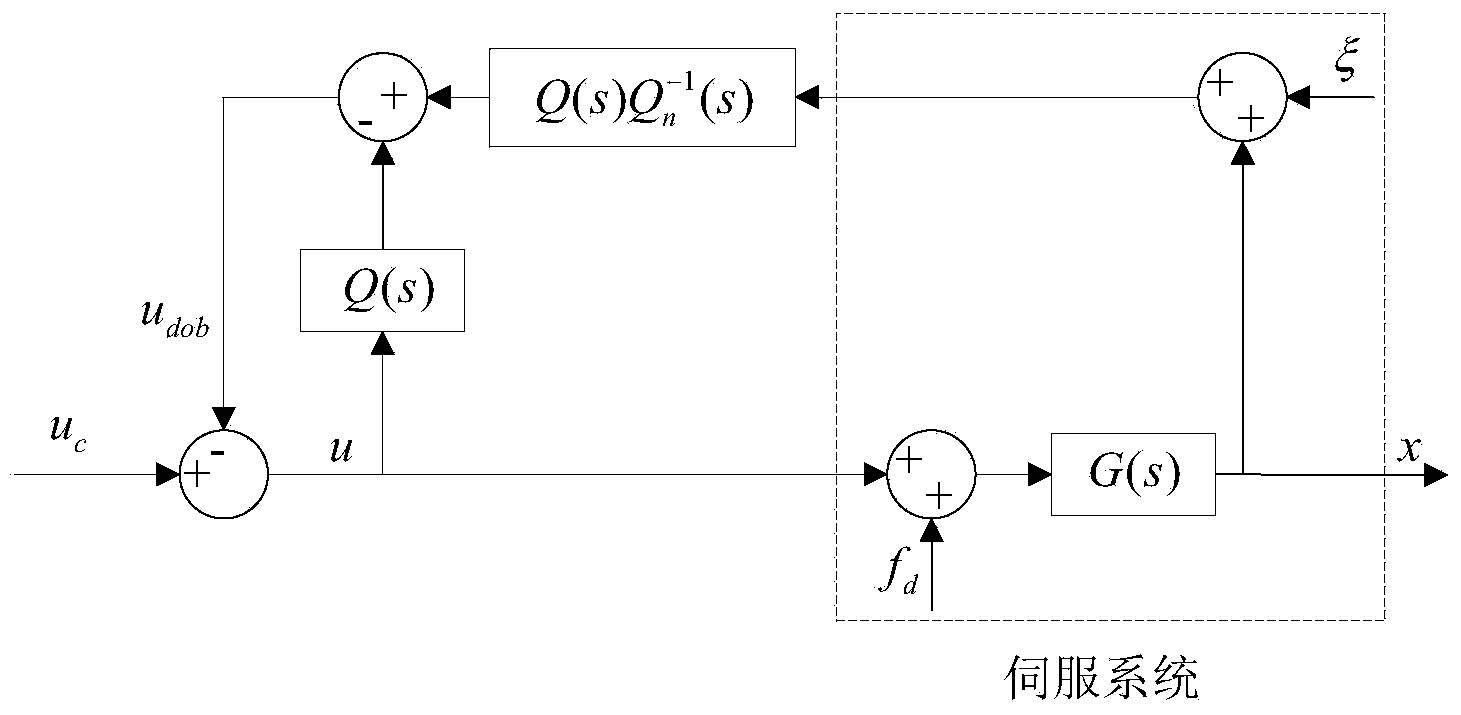

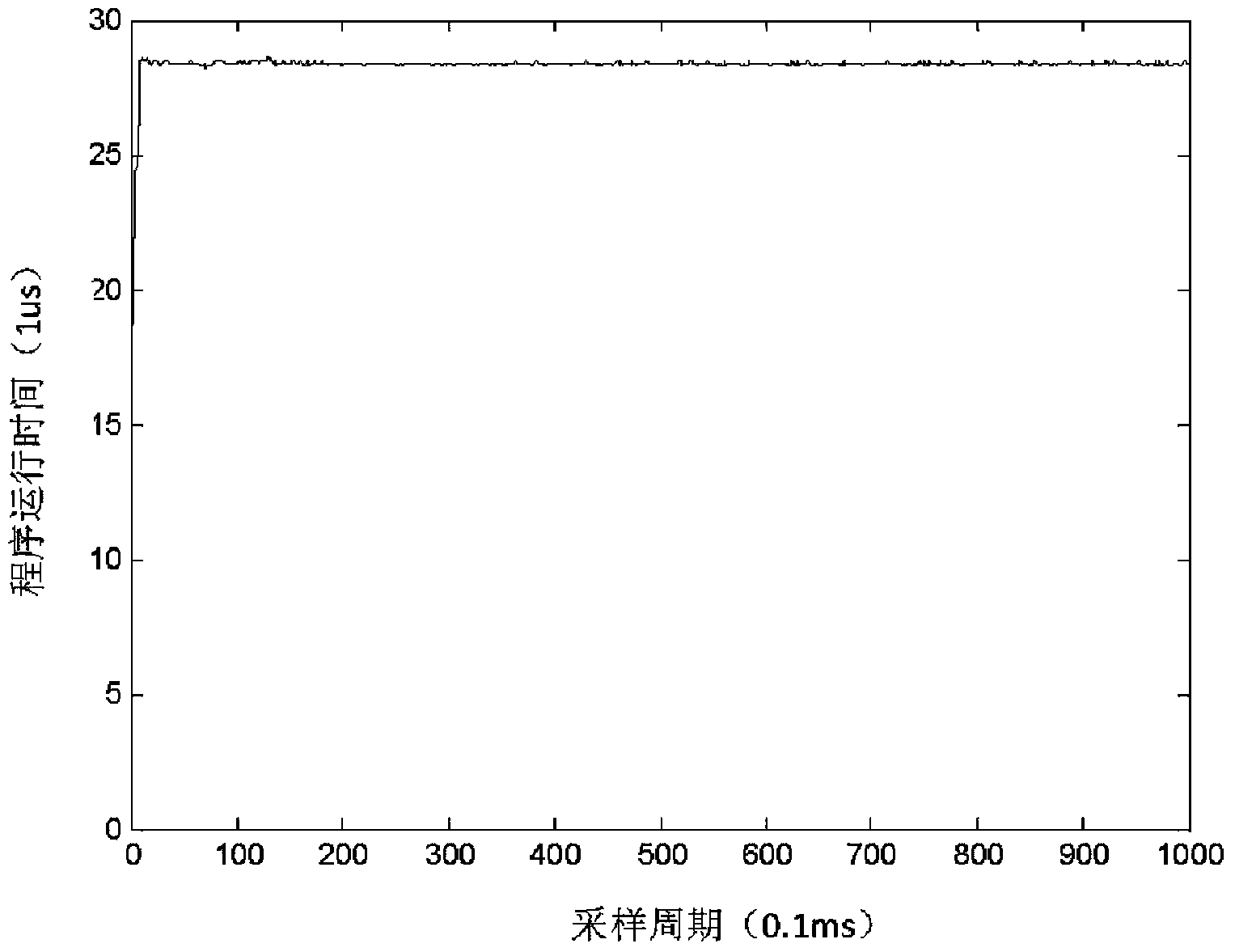

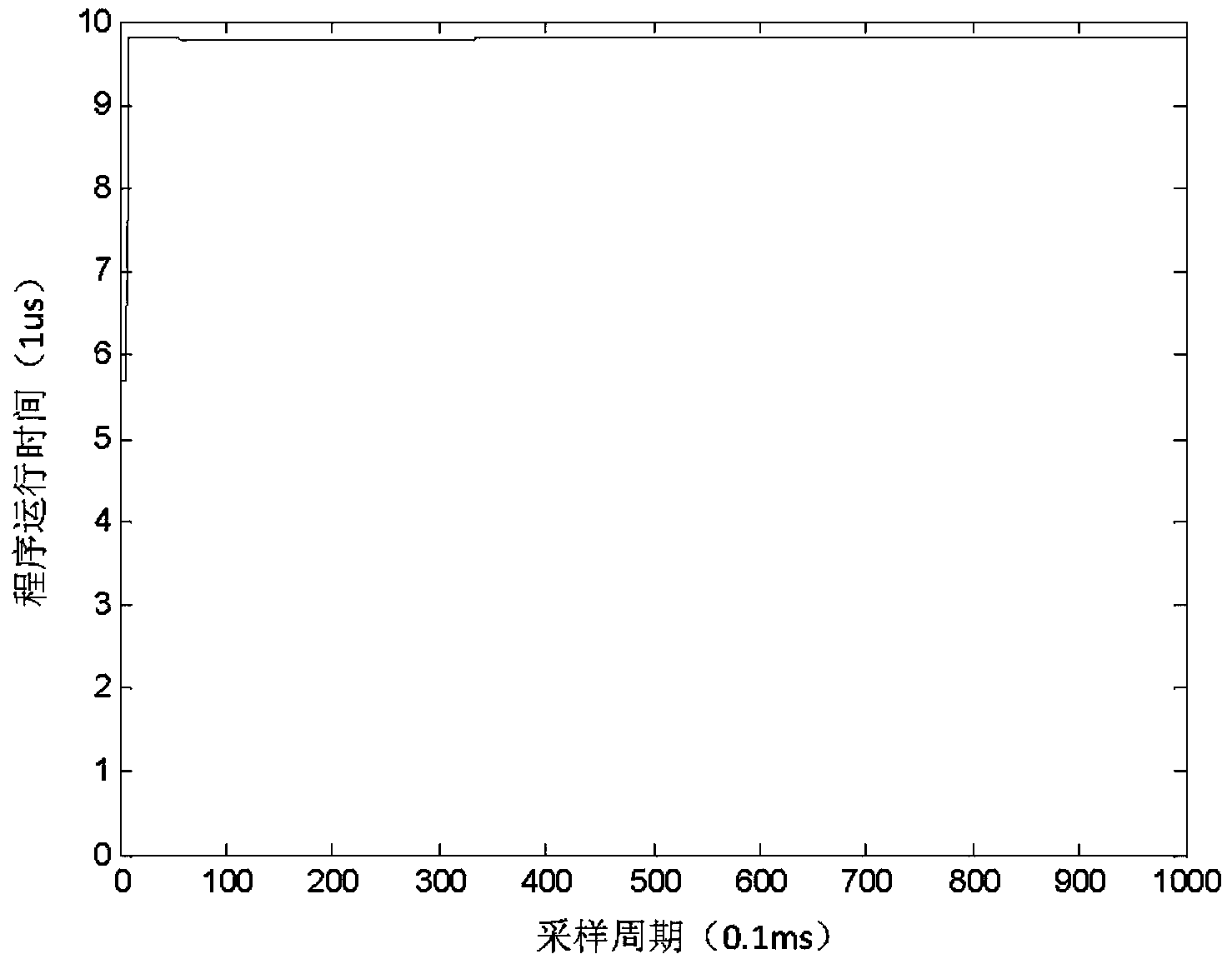

A method for implementing a high-order disturbance observer in embedded motion control

Provided is a method for implementing a high-order disturbance observer in a fixed-point DSP. The method comprises implementing the high-order disturbance observer with a cascade connection manner so as to effectively prevent influences caused by quantization errors and truncation errors in a calculating process and guarantee the operational precision of the high-order disturbance observer in the fixed-point DSP; and implementing the high-order disturbance observer in the fixed-point DSP with a manner integrating a integer-type format, a floating point formant, and an IQ format so as not to influence the operational precision of digital control quantity and to shorten the running time of a program in order to decrease the time delay of the disturbance observer and increase response speed.

Owner:SHANGHAI JIAO TONG UNIV

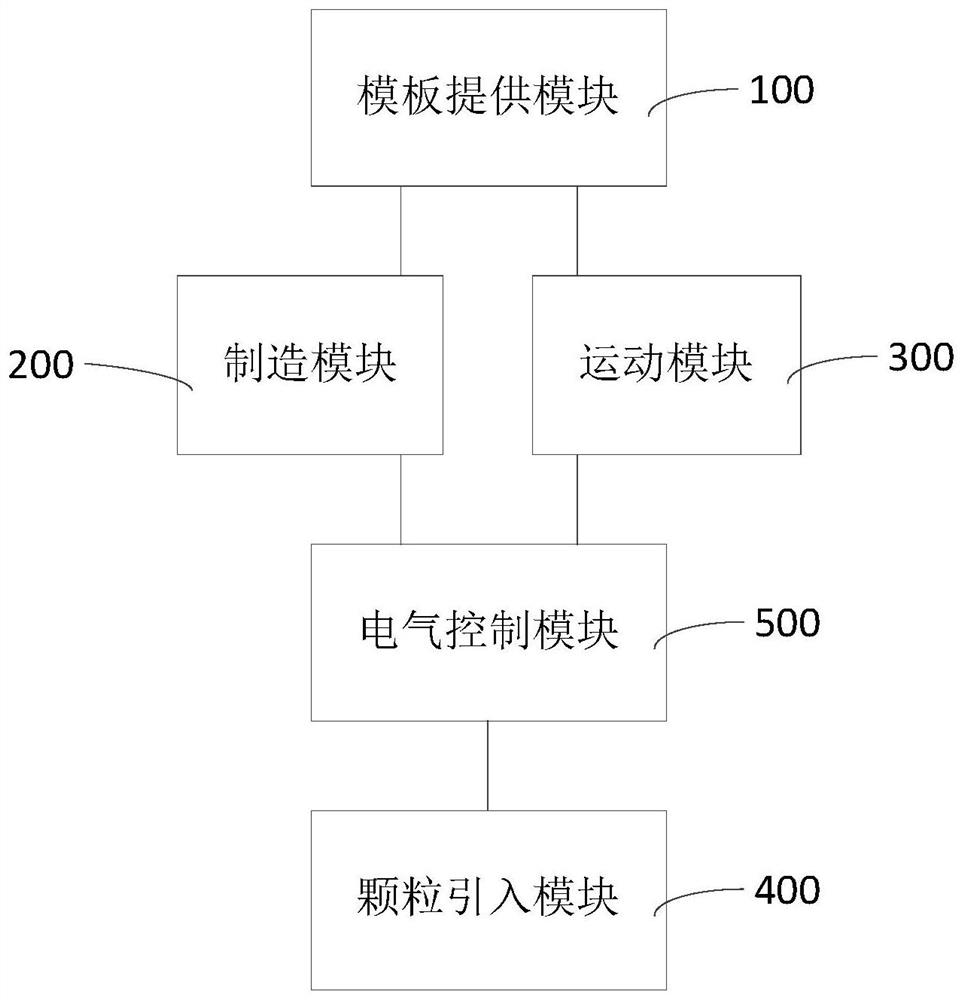

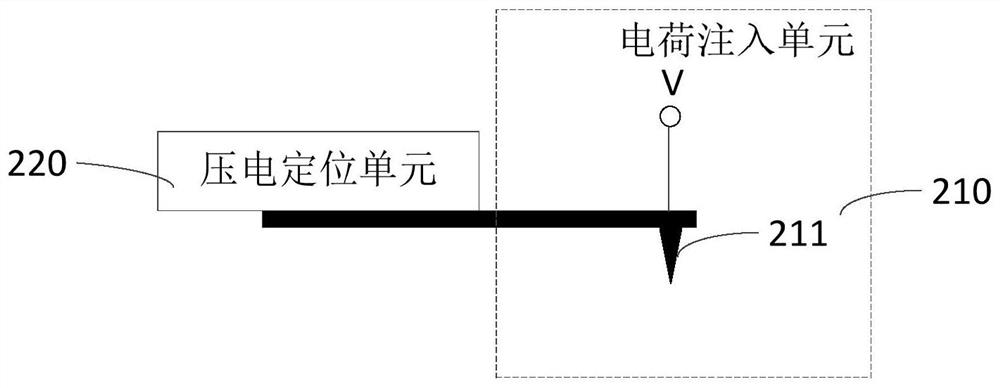

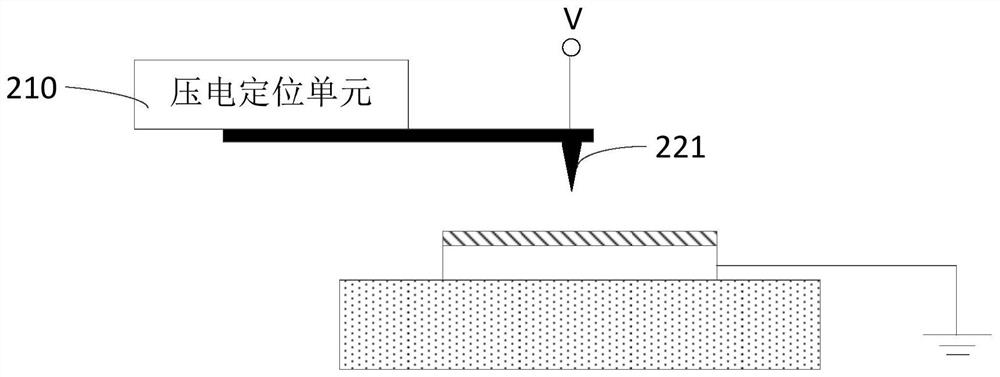

Micro-nano manufacturing device

PendingCN112279215AGuaranteed accuracyGuaranteed operating accuracySpecific nanostructure formationDecorative surface effectsNano structuringNano manufacturing

The invention relates to the technical field of nanometer, and discloses a micro-nano manufacturing device. The method comprises the following steps of providing pattern information of a to-be-formedpattern by using a template providing module; fixing a substrate on a motion table unit of a motion module, and driving the substrate to move according to the pattern information through the motion module; positioning the manufacturing module on the substrate to a position where the to-be-formed pattern needs to be formed, and charges are written in to form the to-be-formed pattern. The particle introduction module introduces nanoparticles into the area where the to-be-formed pattern is located to form a to-be-formed structure. The micro-nano manufacturing device provided by the invention cancomplete electrostatic nano-printing manufacturing of micro-nano structures from nanoscale to centimeter level and above, solves the problem that large-scale and cross-scale structures cannot be manufactured by a scanning probe technology, and can realize structure writing in a centimeter or larger range. Precision of local details is ensured to be in a nanoscale.

Owner:NANJING UNIV

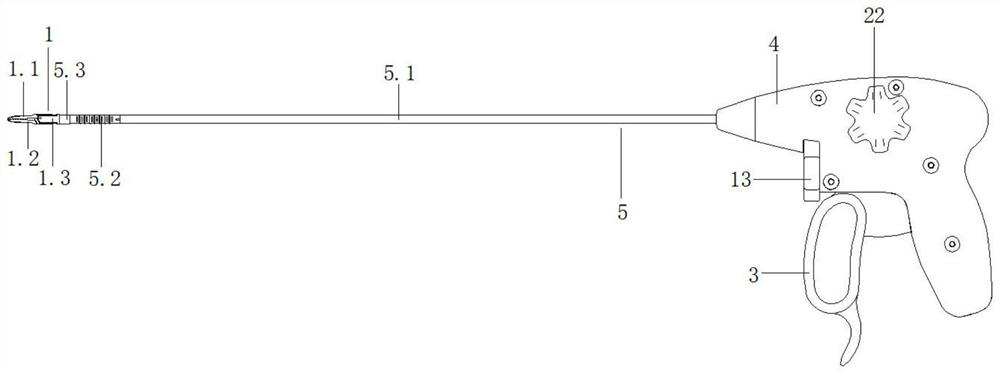

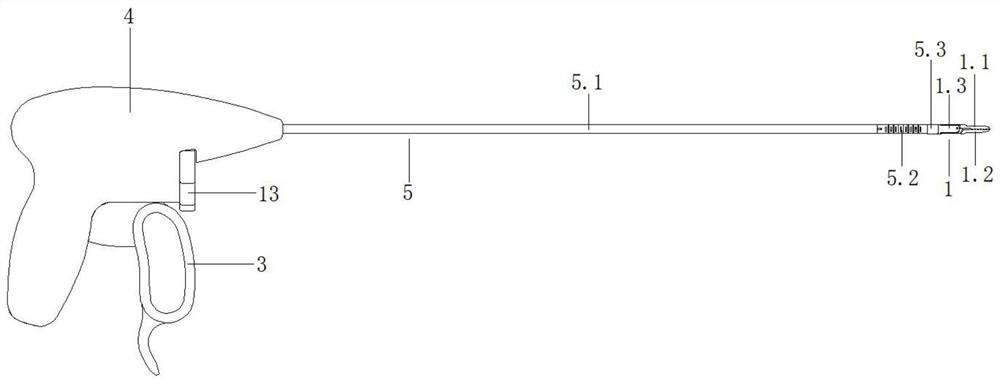

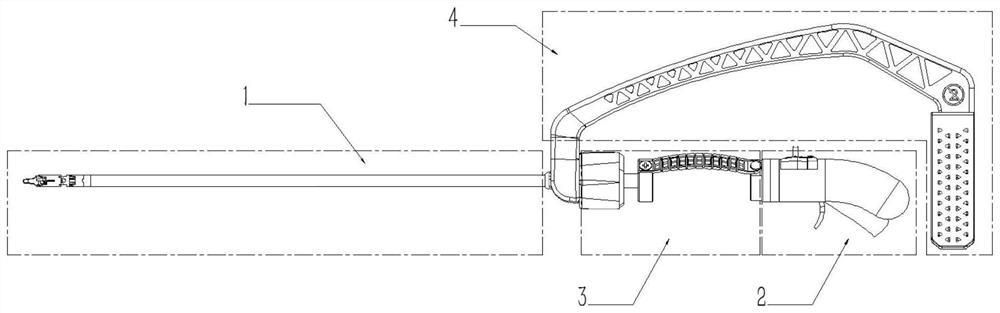

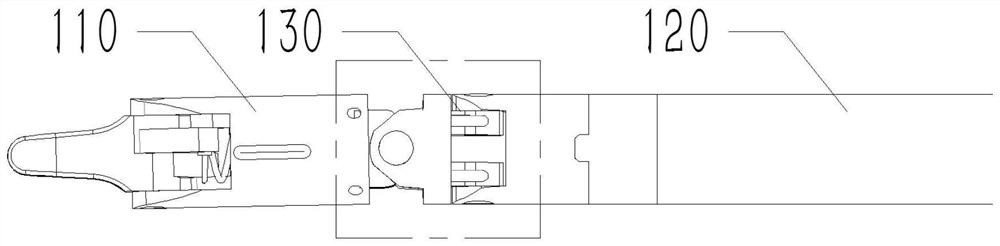

Five-axis minimally invasive instrument integrated system

ActiveCN113243950AEasy to adjustControl the opening and closing actionDiagnosticsSurgical forcepsSurgical riskAbdominal cavity

The invention discloses a five-axis minimally invasive instrument integration system. The system comprises a surgical instrument, and a surgical unit, a deflection unit and a supporting unit which match the surgical instrument; the surgical instrument is configured to comprises a surgical head and an instrument rod; an universal adjusting assembly is arranged on the instrument rod; and at least one matching visual tracking point is arranged on the universal adjusting assembly. Compared with the prior art, the five-axis minimally invasive instrument integration system is used for solving the problems that in the prior art, a surgical head is fixedly connected with an instrument rod, and one instrument rod matches one surgical head, so that the cost of equipment is increased, and meanwhile the congenital defect that the existing surgical head cannot be replaced is overcome; and in addition, the matching visual tracking point is arranged at the adjusting assembly at the front end of the instrument, so that a camera in an endoscope can be guided to focus in real time, the position of the surgical head can be determined in real time, the surgical head is prevented from being in unnecessary contact with organs in an abdominal cavity, and the surgical risk is reduced.

Owner:MIANYANG MEIKE ELECTRONICS EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com