Grabbing device and transportation system

A technology of grabbing device and driving device, which is applied in the field of transportation and palletizing machinery, can solve the problems of low clamping precision, single type of box, and easy deformation of the box, so as to improve the quality and ensure the effect of operation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

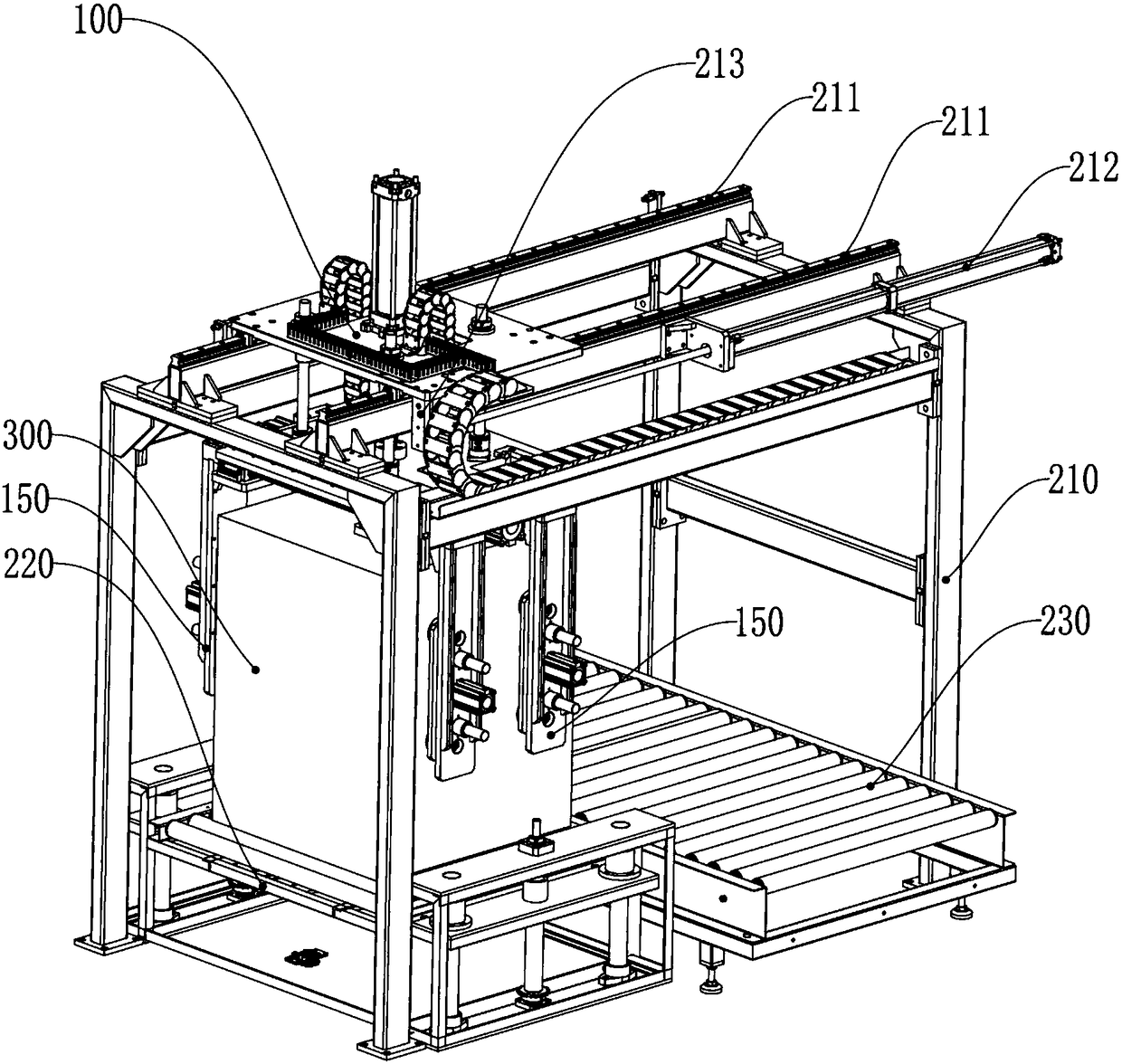

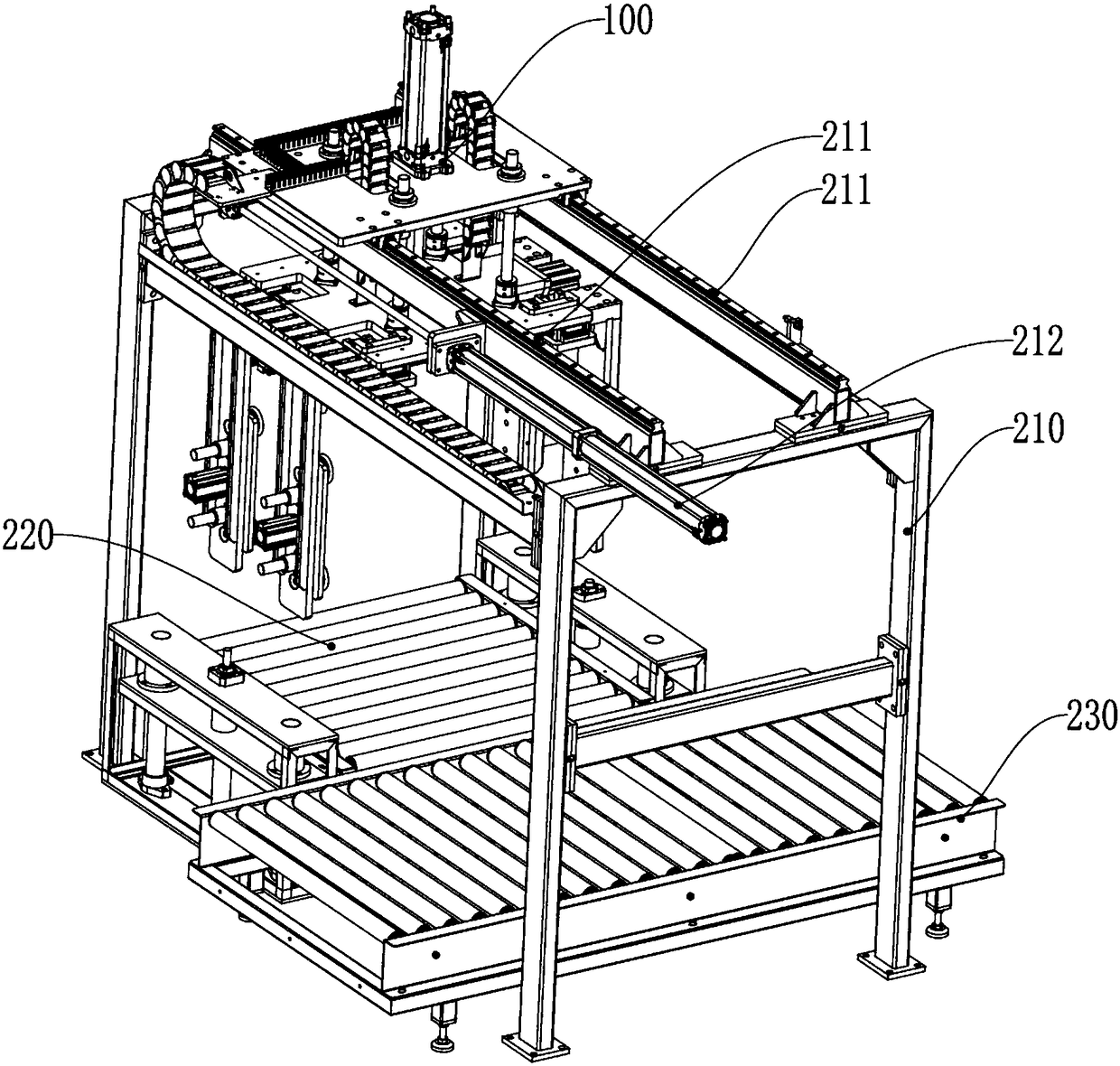

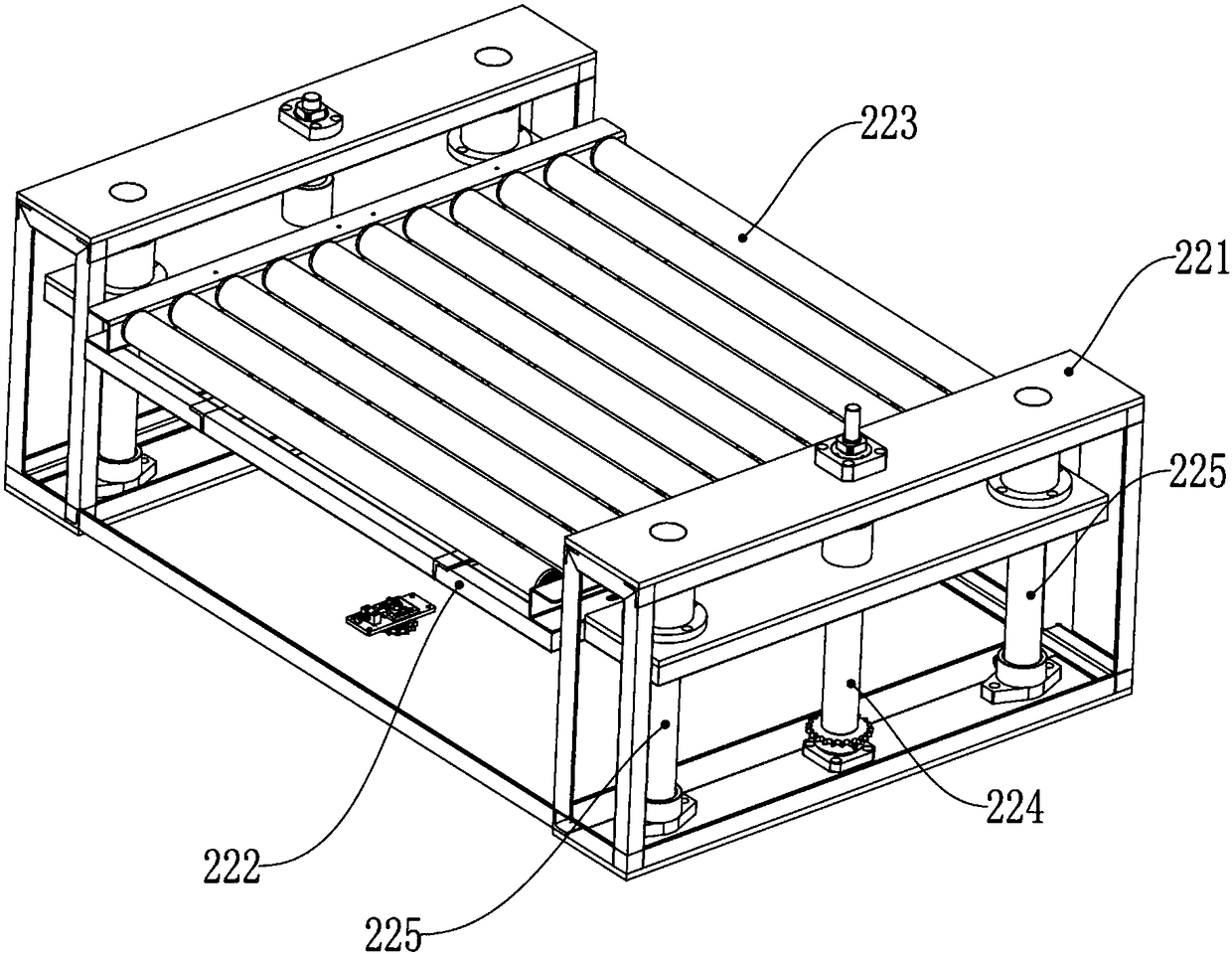

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0023] Such as Figure 4 As shown, a grabbing device 100 is used for grabbing finished packaging boxes of lighters, and it includes: an upper mounting plate 110, a lower mounting plate 120, a longitudinally telescopic driving device 130, a laterally telescopic driving device 140 and claws 150 ; The upper mounting plate 110 and the lower mounting plate 120 are arranged in parallel and facing each other; the longitudinal telescopic driving device 130 is installed on the upper mounting plate 110, and the telescopic end of the longitudinal telescopic driving device 130 is connected to the lower mounting plate The top surface of the plate 120 is vertically connected; the claws 150 are provided with an adsorption device; for example, several of the claws 150 are arranged vertically downwards perpendicular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com