High-precision inner-cooling automatic control system

An automatic control system and high-precision technology, applied to flat products, household appliances, and other household appliances, etc., can solve the problems of not meeting the precision requirements of heavy packaging films, low product qualification rate, waste of raw materials, etc., to save raw materials and control High precision, stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

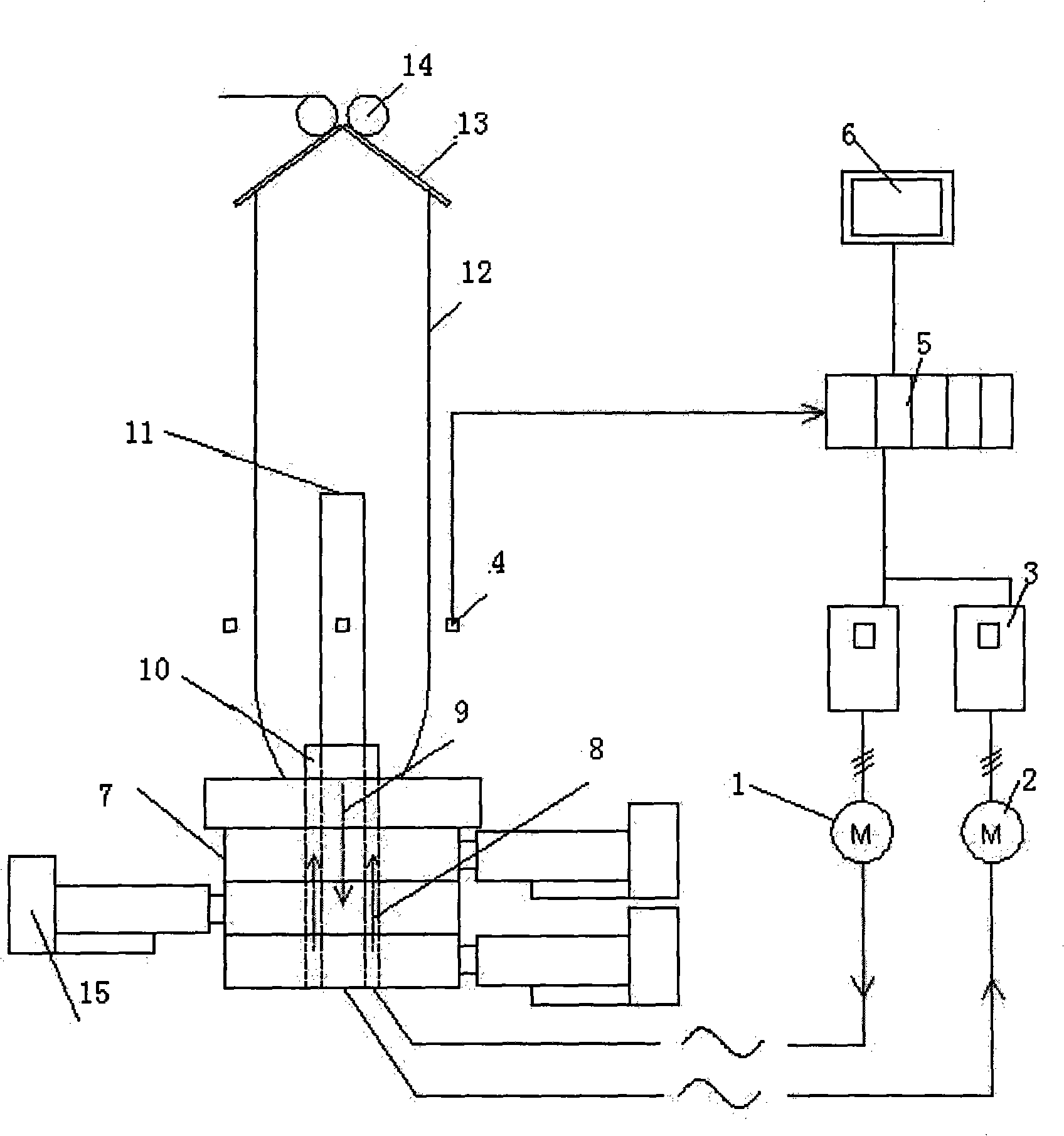

[0014] Such as figure 1 The high-precision internal cooling automatic control system shown in the hardware is composed of frequency conversion air intake fan 1, frequency conversion exhaust fan 2, frequency converter 3, ultrasonic sensor 4, controller 5 (such as PLC), and touch screen 6. The width of the product is Set value, actual value, control and operation data of air inlet and exhaust fans, P value, I value, etc. can be set and displayed on the touch screen, which is more convenient for operation.

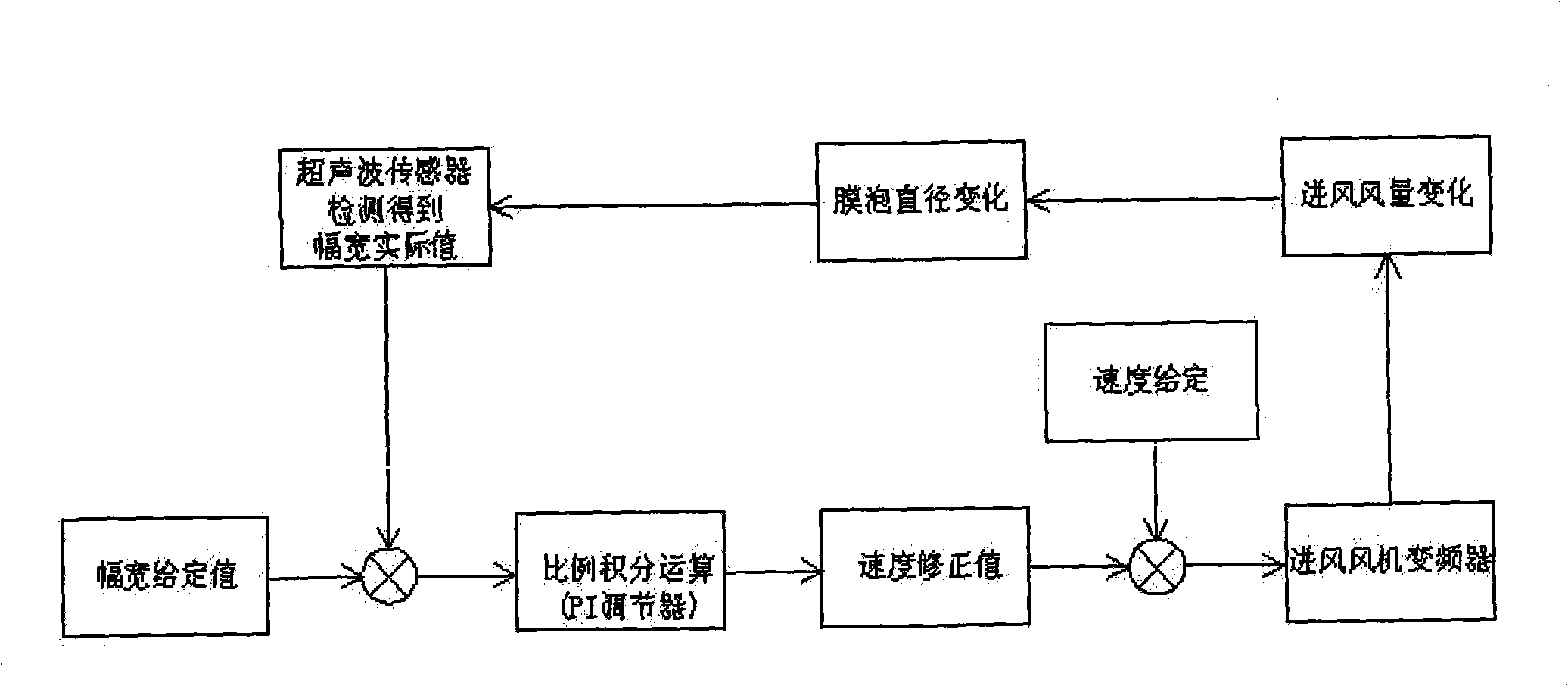

[0015] The control principle at work is as figure 2 As shown, the material is processed and extruded by the extruder 15 and the machine head 7 to form a film bubble 12, which is clamped and flattened by the herringbone plate 13, and pulled out by the upper traction roller 14. The air duct 9 has an air inlet 10 and an air outlet 11 at the film mouth. The exhaust fan speed is given a fixed value according to the production process. Three to six ultrasonic waves from Pepperl+F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com