Robot slight collision compensation and correction system

A technology of calibration system and robot, which is applied in the direction of instruments, measuring devices, optical devices, etc., can solve problems such as hidden quality problems, lack of fast and effective solutions, and long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

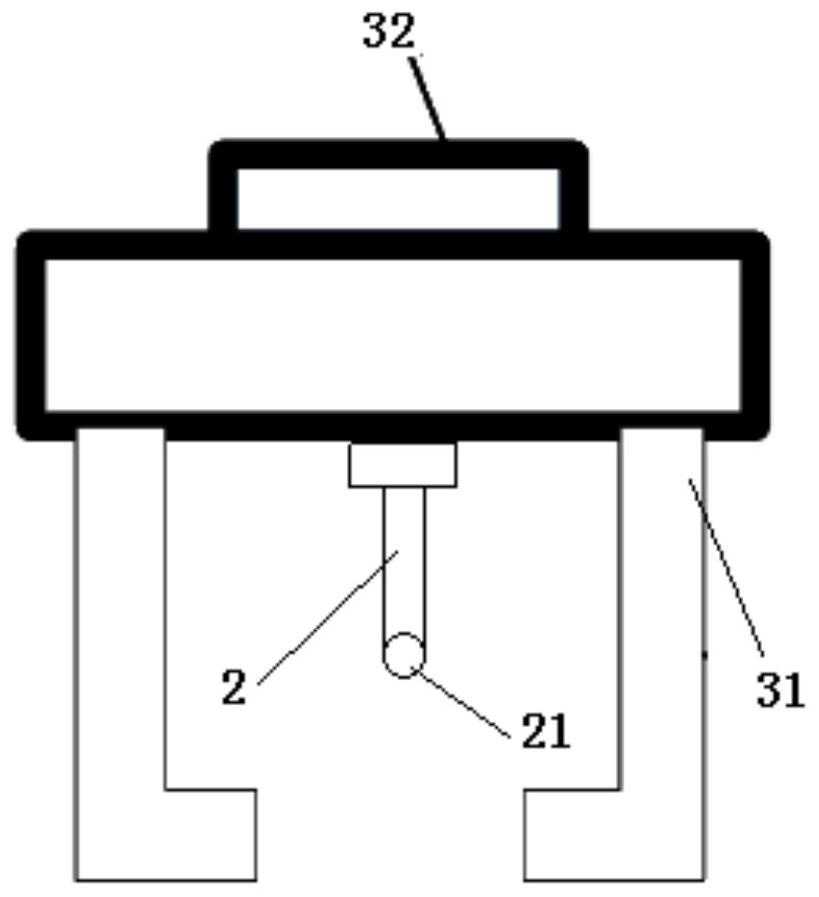

[0061] Robot slight collision compensation and correction system, which includes a standard laser detection unit 1 and a positioning pin 2;

[0062] The standard laser detection unit 1 is installed and fixed on the operation surface of the target product;

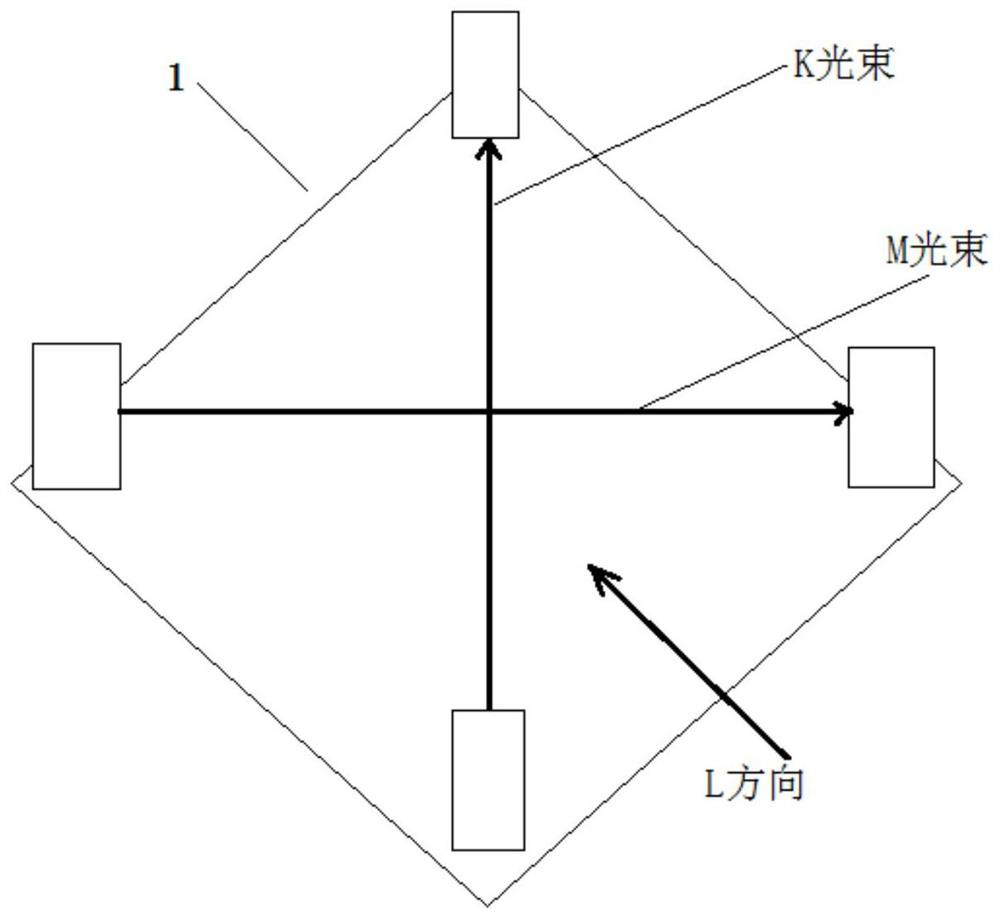

[0063] Such as figure 1 As shown, the standard laser detection unit 1 includes a K beam detection pair and an M beam detection pair;

[0064] The K-beam detection pair includes a K-beam transmitting end and a K-beam receiving end, and the K-beam emitting end emits a K-beam receiving end to the K-beam receiving end;

[0065] The M-beam detection pair includes an M-beam transmitting end and an M-beam receiving end, and the M-beam emitted from the M-beam transmitting end is directed to the M-beam receiving end;

[0066] The K beam emitting end, the K beam receiving end, the M beam emitting end, and the M beam receiving end are respectively located at the four endpoints of the rhombus;

[0067] The K beam intersects the M be...

Embodiment 2

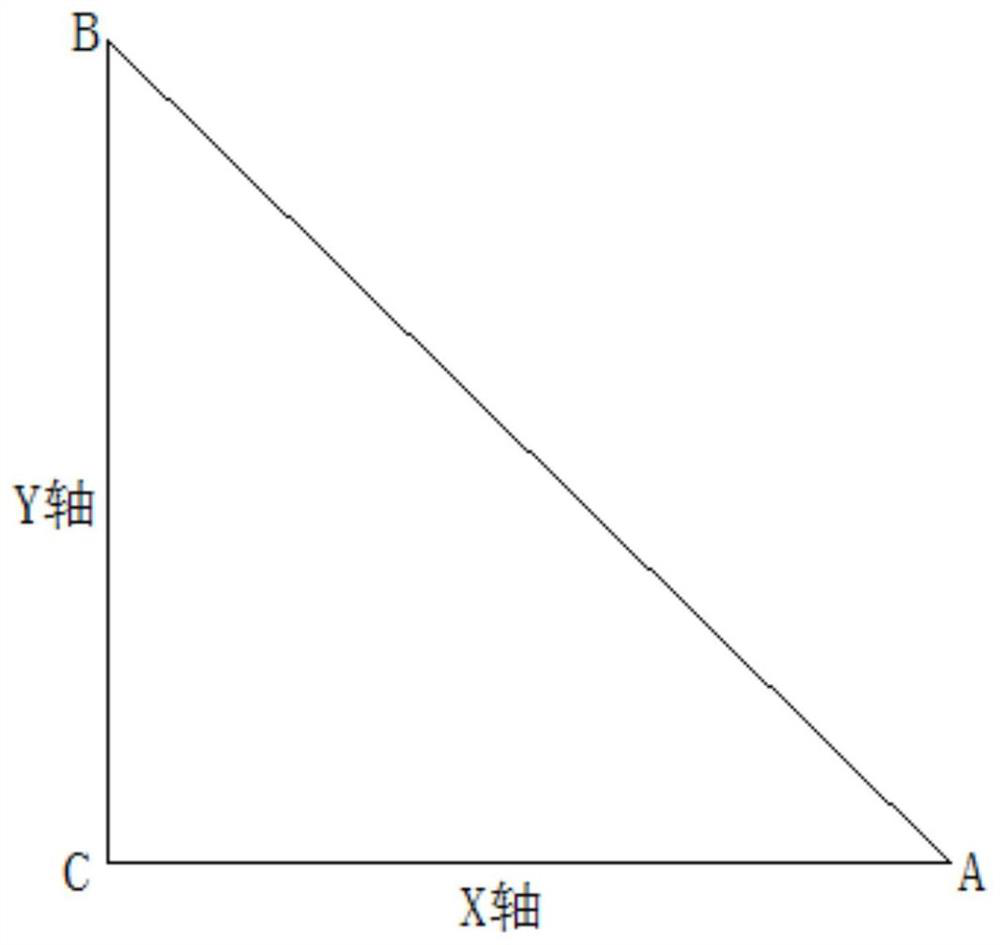

[0091] Based on the robot slight collision compensation and correction system of Embodiment 1, such as image 3 As shown, there are three standard laser detection units 1 installed and fixed on the operation surface of the target product;

[0092] The Z-axis coordinates of the geodetic coordinate system of the center points of the three standard laser detection units 1 are consistent;

[0093] The processor of the robot is calibrated with the earth coordinate system reference coordinates (a+X0, Y0, Z0) of the center point A of the first standard laser detection unit 1, and the earth coordinate system reference coordinates of the center point B of the second standard laser detection unit 1. Coordinates (X0, b+Y0, Z0), the geodetic coordinate system reference coordinates (X0, Y0, Z0) of the center point C of the third standard laser detection unit 1;

[0094] First, the robot detects the current coordinates of the geodetic coordinate system of the center point of three standard...

Embodiment 3

[0098] Based on the robot slight collision compensation and correction system of Embodiment 1, the tail end of the positioning pin 2 is fixed to the gripper side of the turntable with a buckle.

[0099] Preferably, the positioning pin 2 is coaxial with the turntable.

[0100] Preferably, the positioning pin 2 is made of steel.

[0101] Preferably, the jaws are steel cylinder jaws, which are not easily deformed mechanically.

[0102] Preferably, the standard laser detection unit is a standard laser detection unit from Captron.

[0103] In the third embodiment of the robot slight collision compensation and correction system, the installation of the positioning pin is snap-fit, avoiding the thread installation structure, because the thread installation structure itself is inclined.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com