Metal sheet bending machine

A metal sheet and bending machine technology, applied in the field of automated production equipment, can solve the problems of easy operation accidents, difficult to guarantee manual operation accuracy, low efficiency, etc., and achieve the effects of low machine cost, improved production efficiency, and simple control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

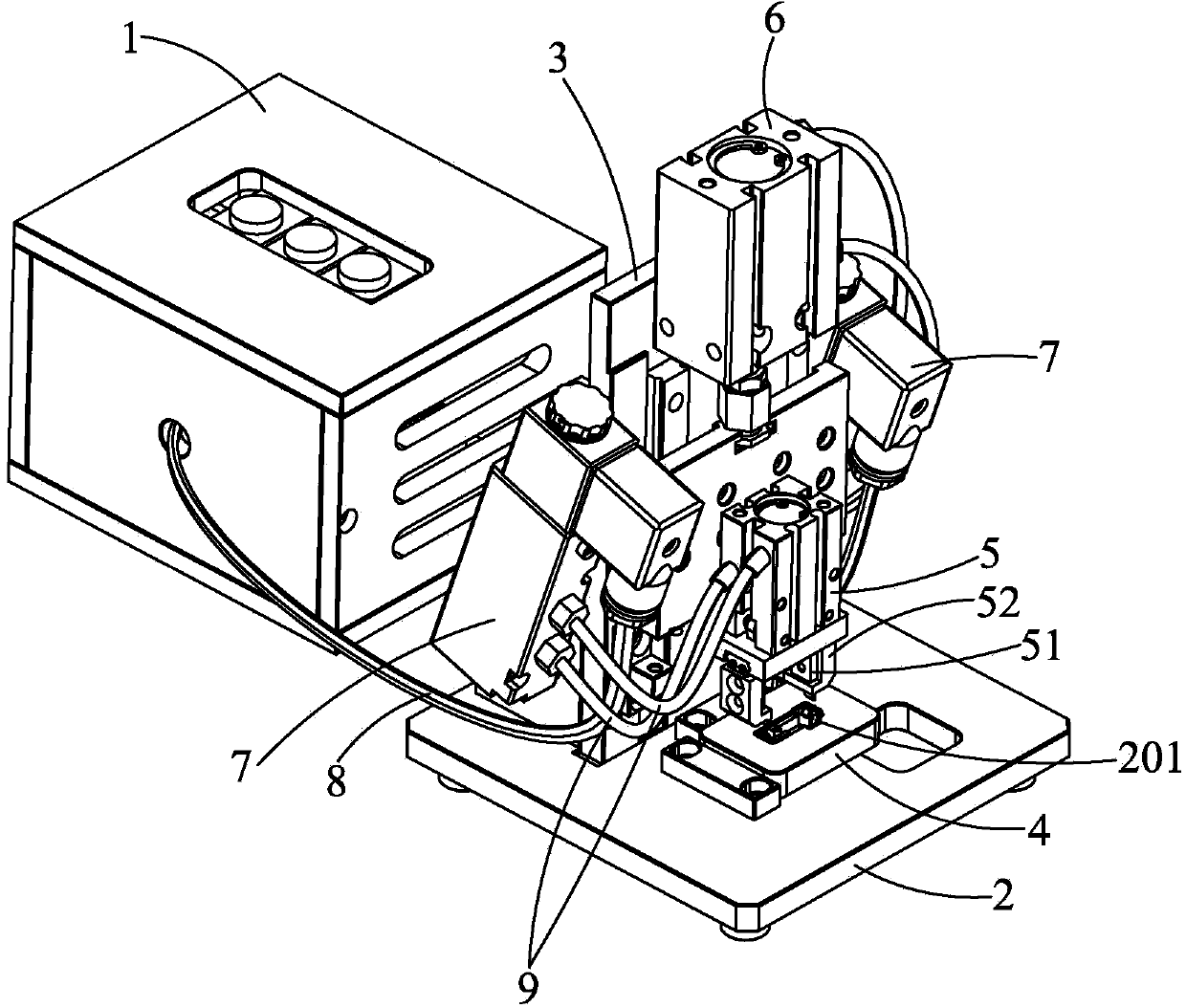

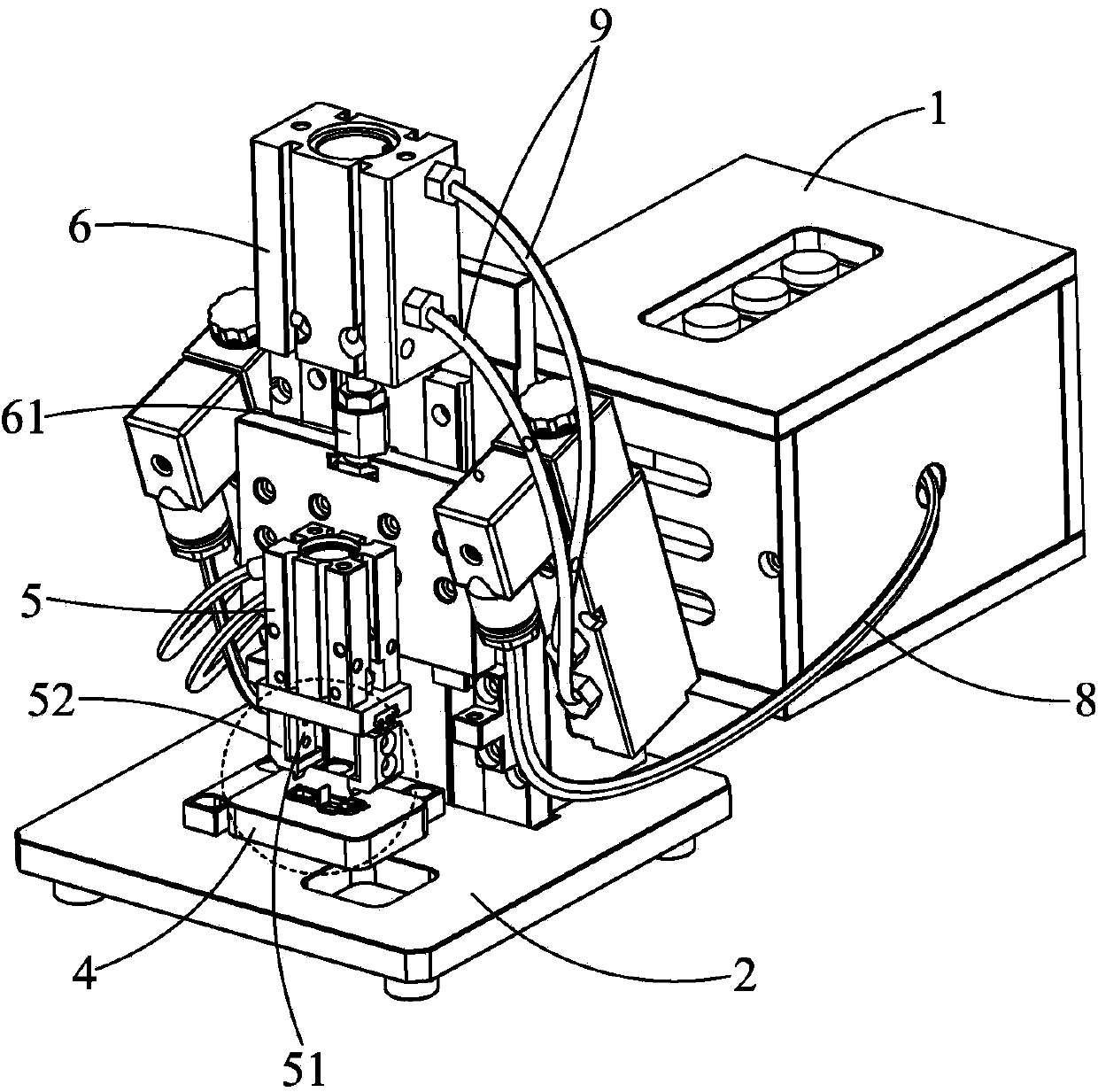

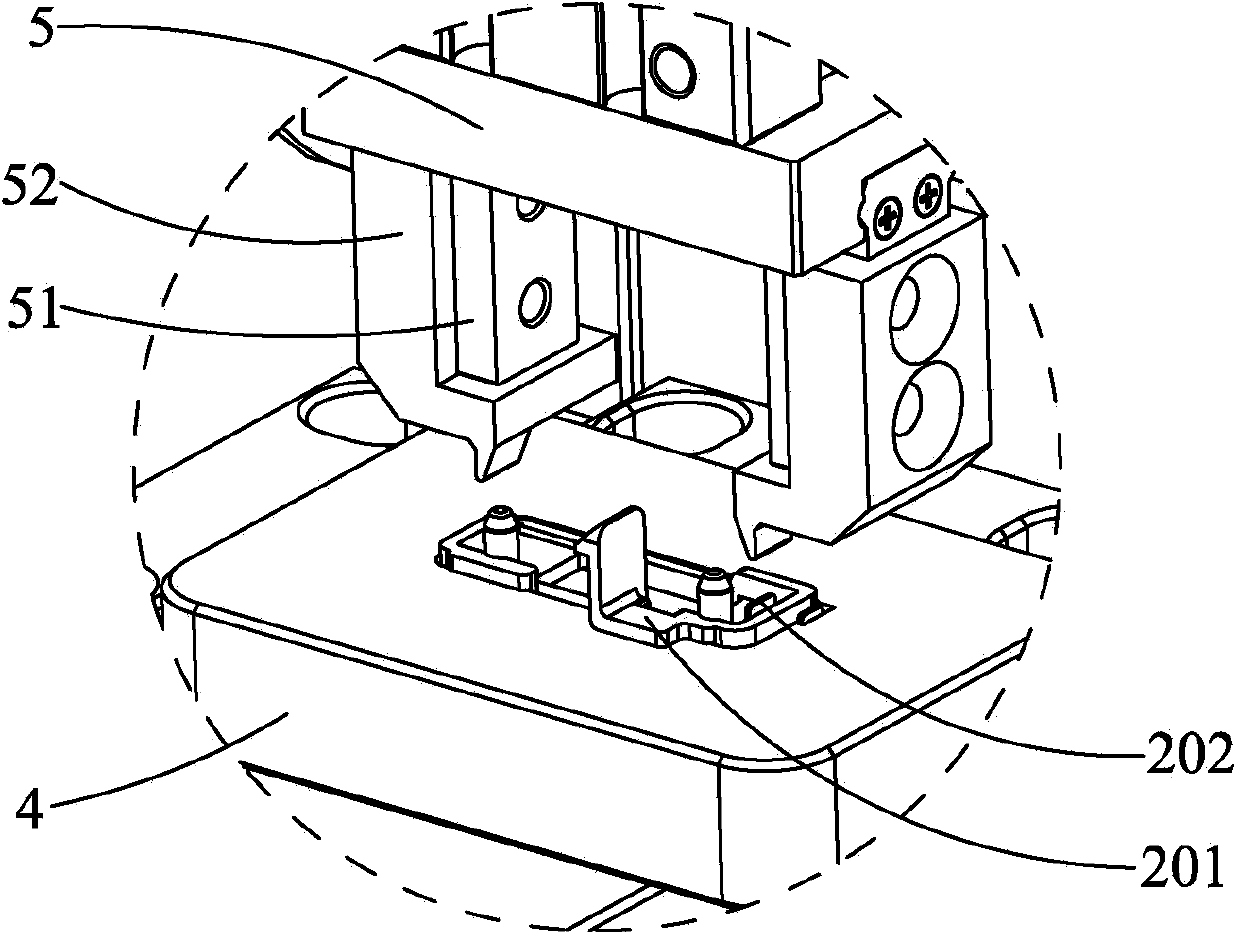

[0009] see Figure 1 to Figure 3 As shown, the metal sheet bending machine 100 of the present invention is used to bend the metal sheet 202, which includes a delay relay 1, a machine base 2, a support frame 3, a jig plate 4, an X-axis cylinder 5, a Z-axis cylinder 6, a To electromagnetic valve 7, some power lines 8, some air pipes 9 etc.

[0010] The support frame 3 and the jig plate 4 are fixed on the machine base 2 , and the jig plate 4 is located in front of the support frame 3 .

[0011] The Z-axis cylinder 6 is fixed on the support frame 3 . The X-axis cylinder 5 slides on the support frame 3, a slide rail 31 is provided between the support frame 3 and the X-axis cylinder 5, and a connecting rod 61 is provided between the Z-axis cylinder 6 and the X-axis cylinder 5, and the Z-axis cylinder 6 can pass through The connecting rod 61 drives the X-axis cylinder 5 to slide up and down along the support frame 3 .

[0012] The X-axis cylinder 5 is a jaw cylinder with a pair of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com