Super-high-rise core tube suspended steel rib column and construction method thereof

A steel column and core tube technology, applied in the field of steel structures, can solve the problems of affecting the construction operation space of reinforced concrete columns, increasing the difficulty of construction, and occupying a large space, so as to improve the efficiency of construction machinery, reduce the cost of transportation and storage, and facilitate assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

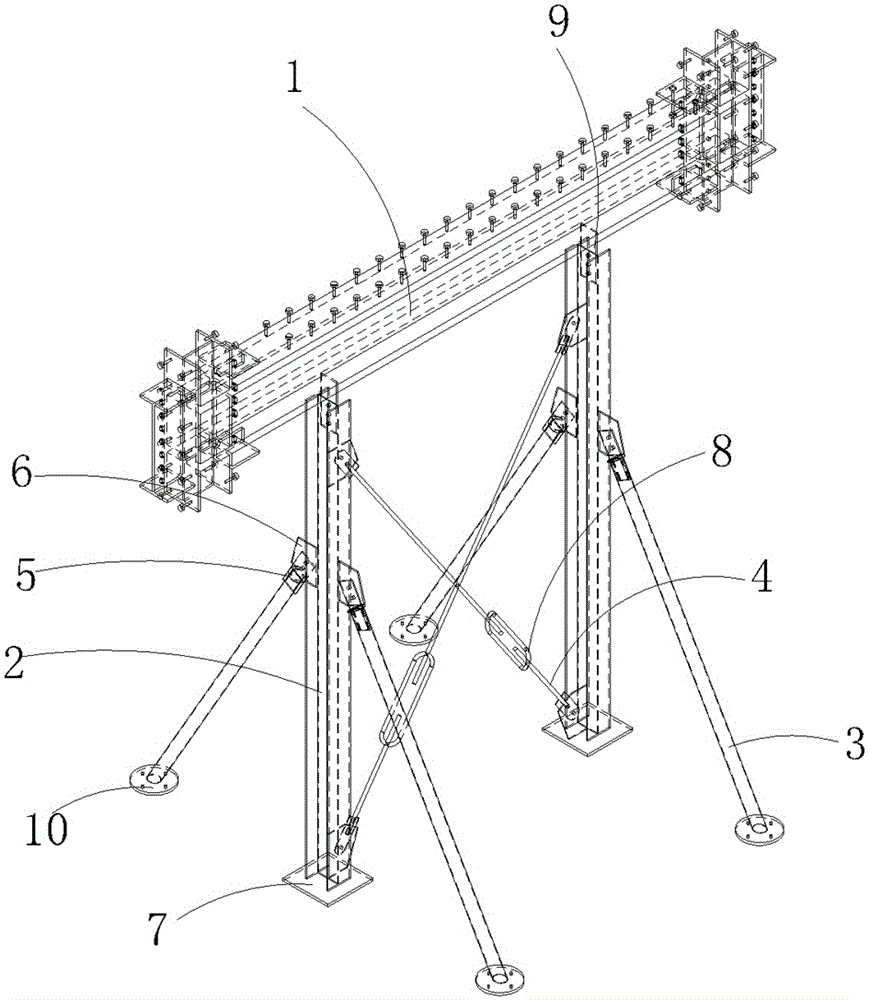

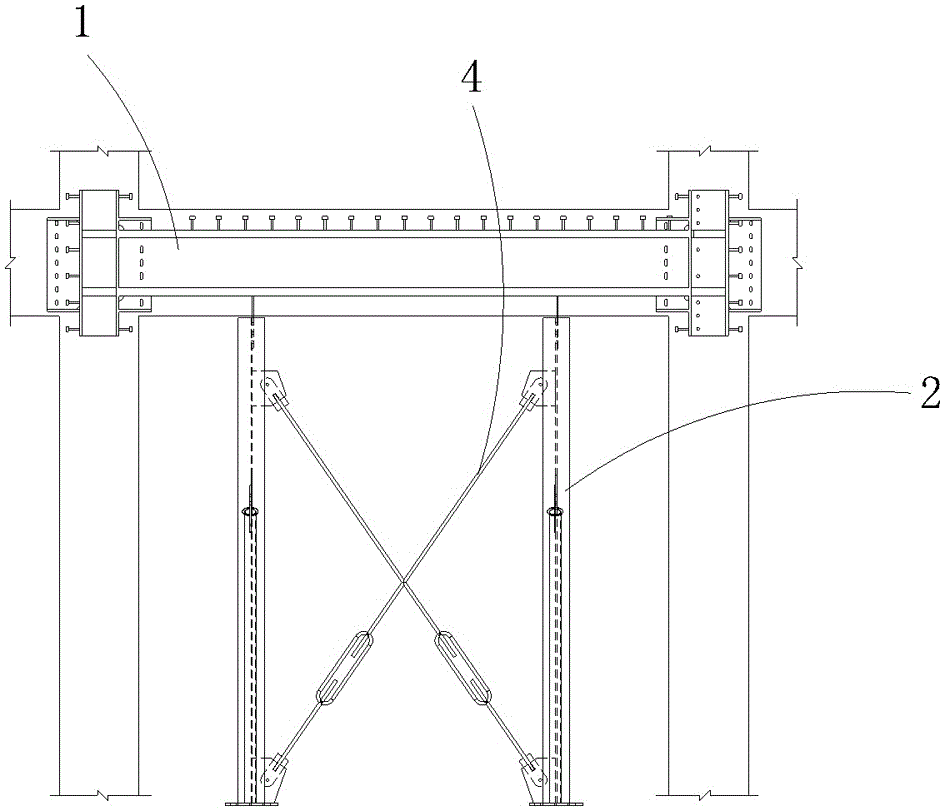

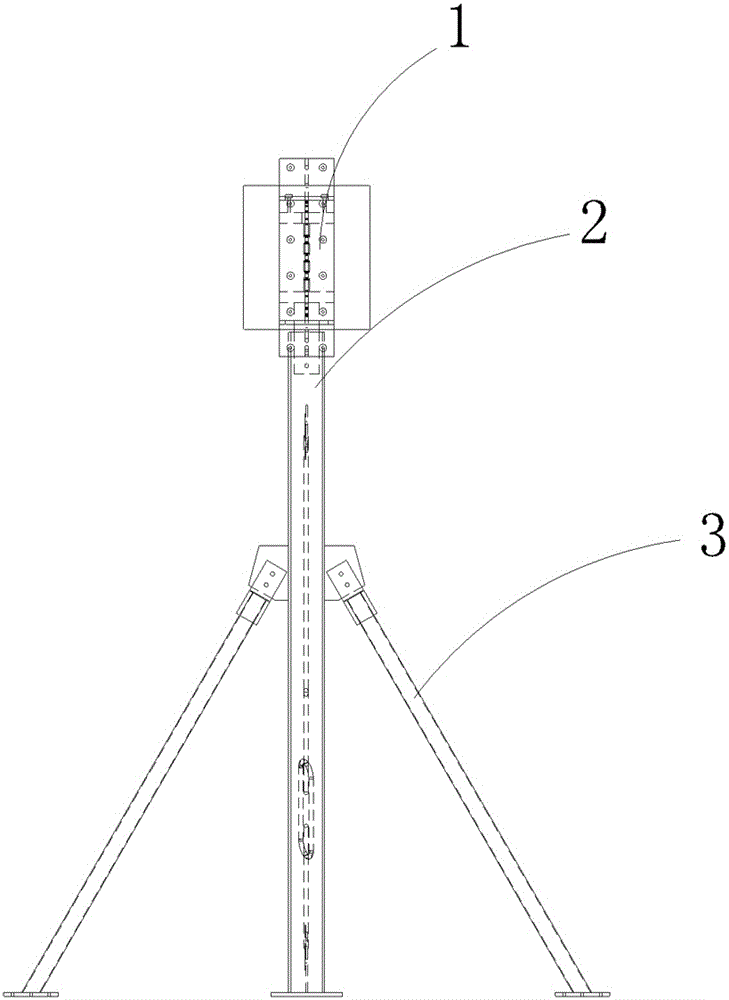

[0052] Embodiment 1: as figure 1 , figure 2 and image 3 As shown, a non-floor steel frame column in a super high-rise core tube includes a non-floor steel frame column 1, and steel column components are respectively provided at both ends of the bottom of the non-floor steel frame column 1;

[0053] The steel column assembly includes a temporary support steel column 2, and the two sides of the temporary support steel column 2 are respectively provided with out-of-plane steel pipe supports 3 extending to the ground;

[0054] The steel column components are positioned through circular pipe frames 4 distributed across.

[0055]The upper part of the out-of-plane steel pipe support 3 is provided with a plug-in plate 5, and the space between the plug-in plate 5 and the 2 temporary support steel columns, and the two sides of the round pipe frame 4 and the temporary support steel columns 2 are respectively passed through the support connecting plate 6 connections, the out-of-plane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com