Charged water washing dual-water column masing washing method and device

A rinsing device and technology of charged water, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc. Small sputtering length and area, preventing dead angle and dead zone, and ensuring the effect of working accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

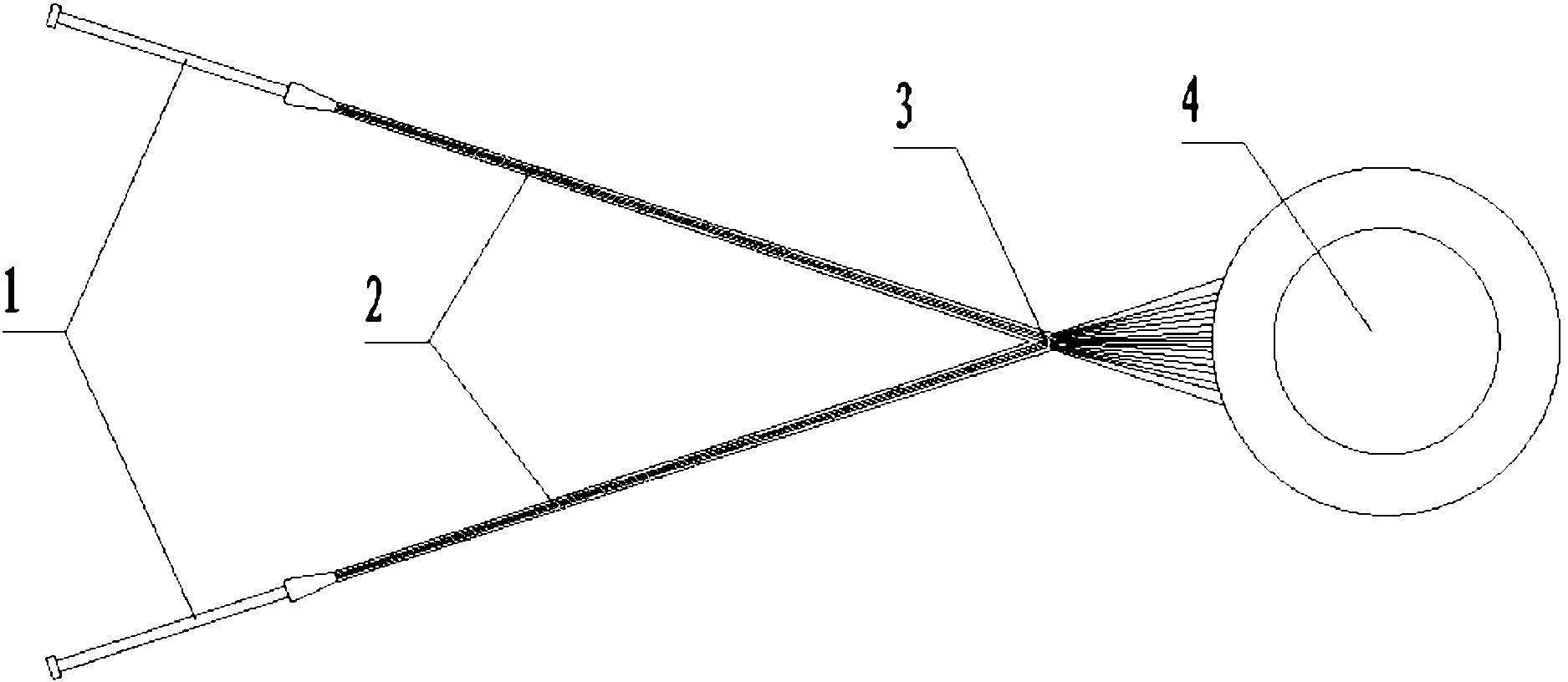

[0025] Embodiment 1, charged water flushing double water column laser flushing method and device, refer to figure 1 , the schematic diagram of the method of the present invention: two water guns 1 eject water column 2 respectively, two water columns 2 meet, and water column 2 is straight column shape, and water column is subjected to mutual extruding from intersection point 3 and is transformed into radial form by beam shape, to Radiation is carried out outside, and the radial water flow washes the charged equipment 4.

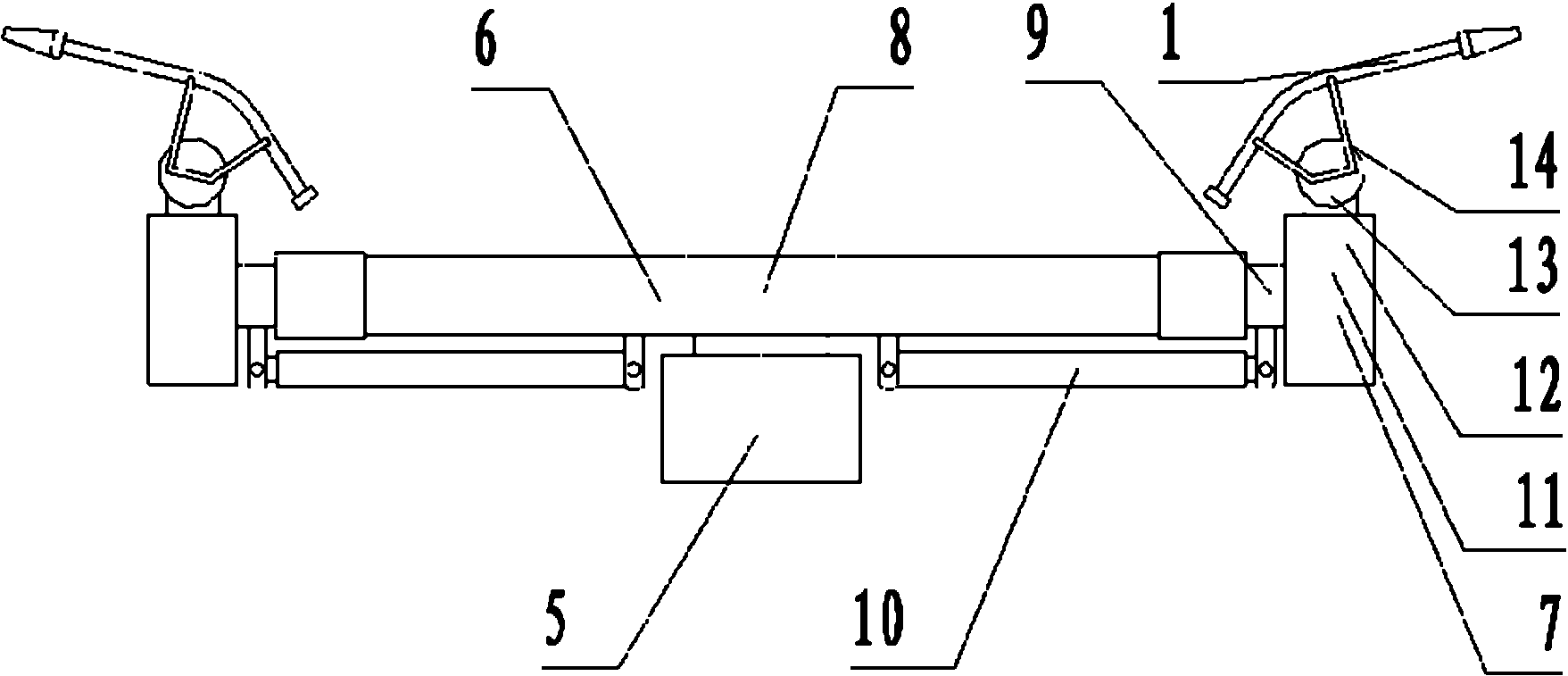

[0026] The device structure of the present invention, figure 2 , the device includes a main bracket 5, a telescopic arm 6, two sets of water gun brackets 7, and two water guns 1, the telescopic arm 6 is installed on the upper end of the main bracket 5, and a water gun bracket 7 is respectively installed at both ends of the telescopic arm 6, and the water gun 1 is installed on the On the water gun support 7.

[0027] The main support 5 includes a swivel join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com