Linkage hydraulic clamper for mining fully hydraulic rig

A hydraulic clamping and full hydraulic technology, which is applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve problems such as unreliable clamping, increased structural size of the clamper, and large external force of the clamper, so as to ensure reliability performance, ensuring the effect of operation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

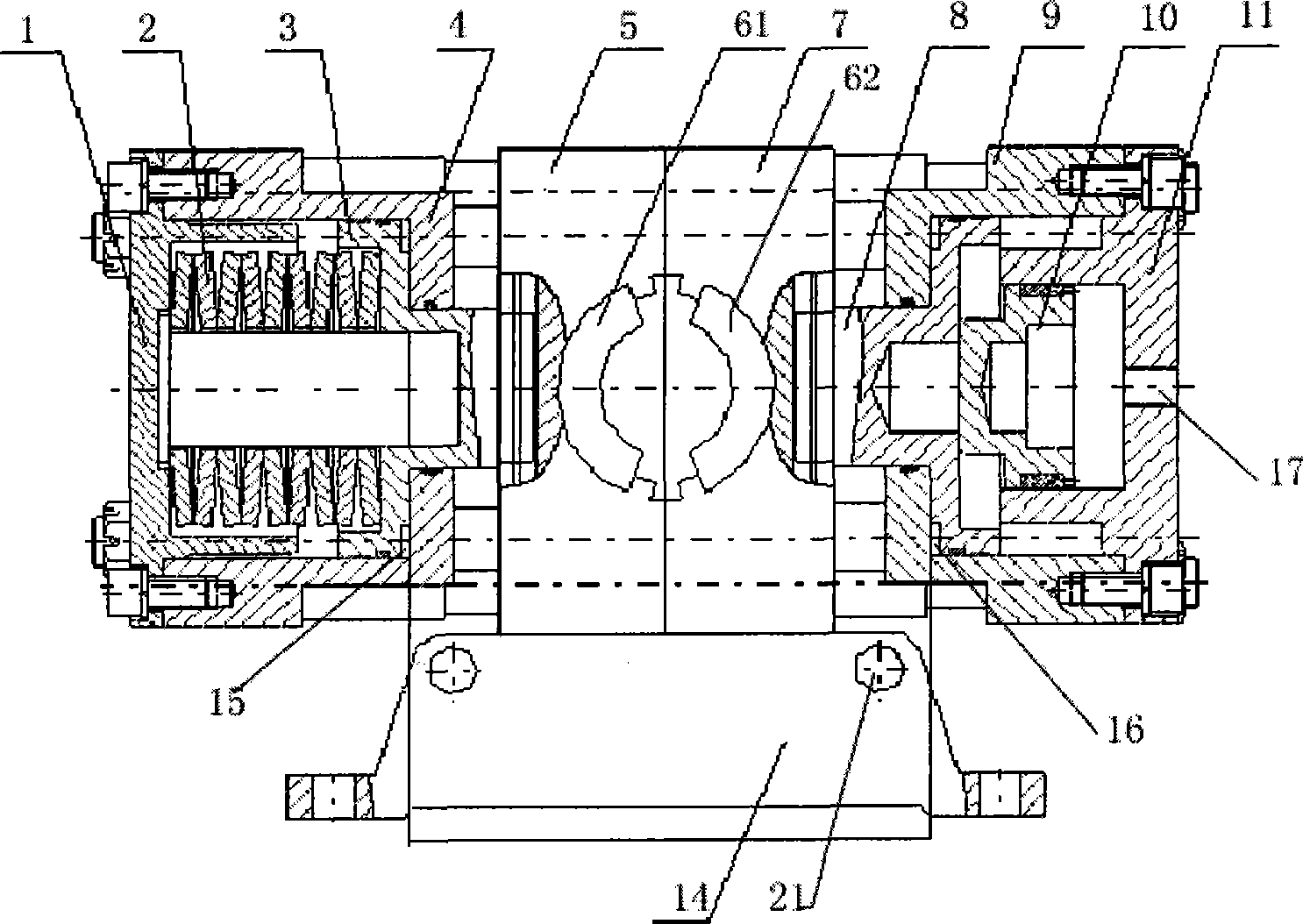

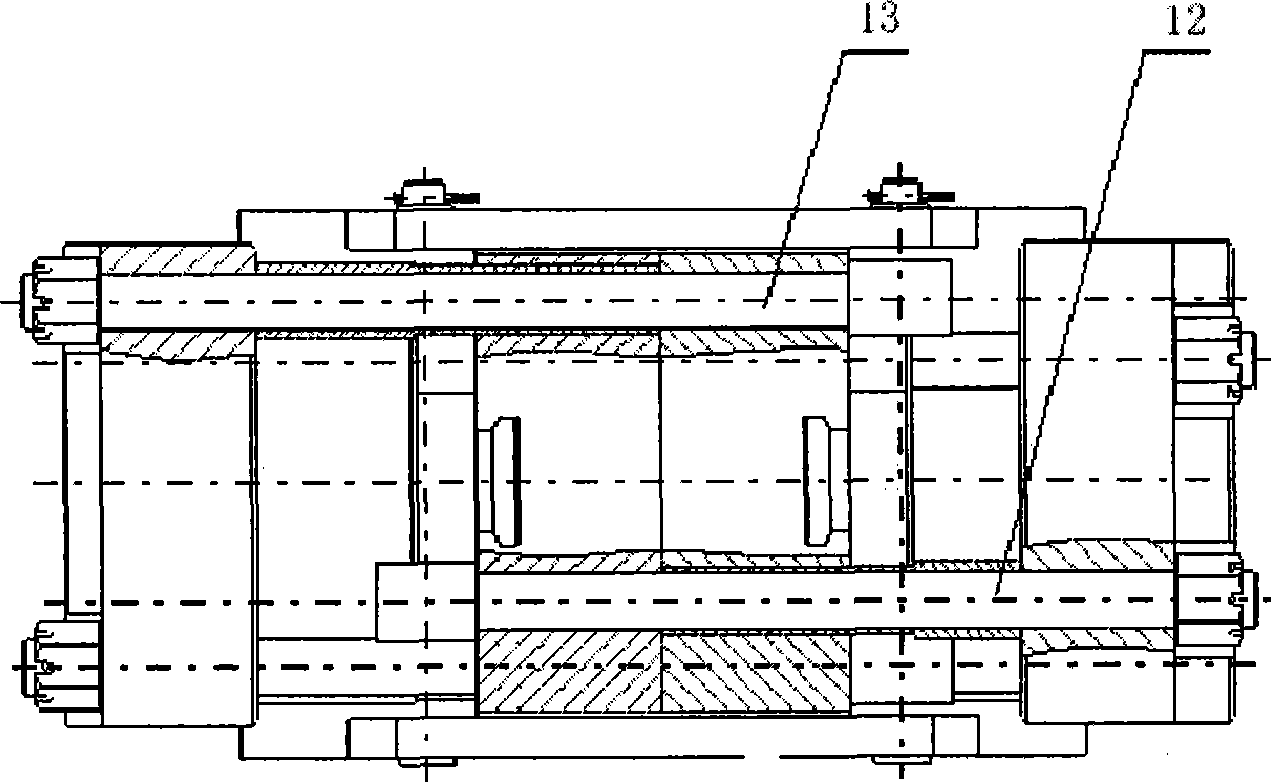

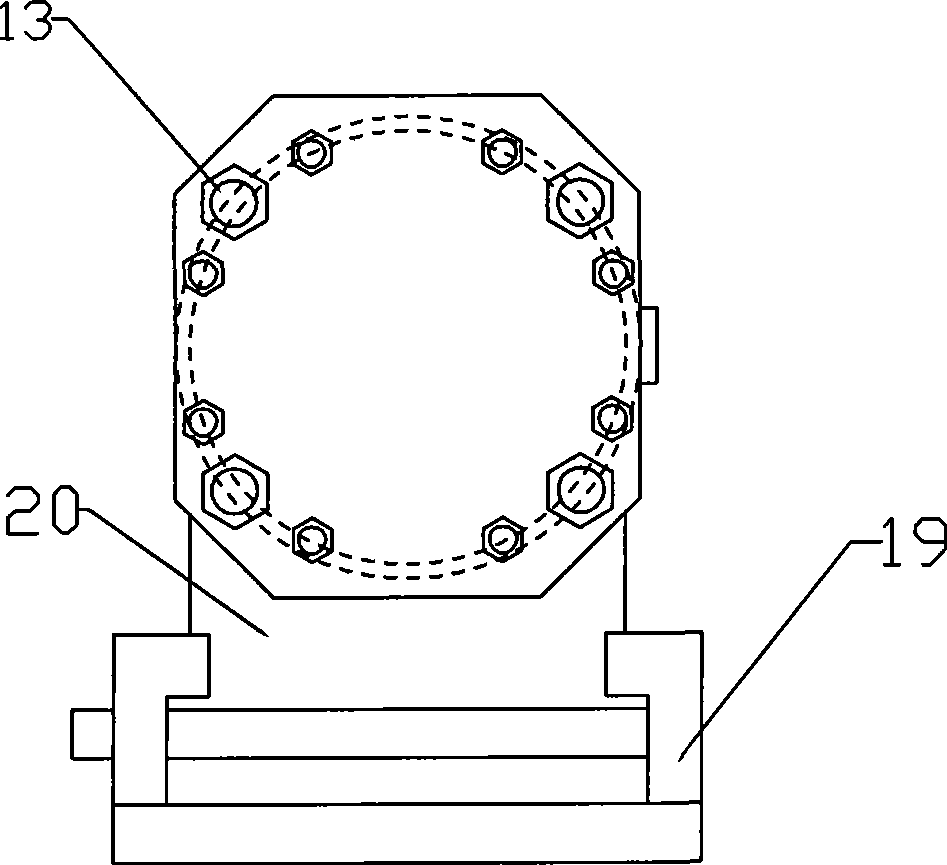

[0026] As shown in the figure, the mining full hydraulic drilling rig linkage hydraulic clamper of the present invention includes a clamper body, the clamper body includes a left clamping device and a right clamping device, and the left clamping device includes a left end cover 1, a left Loosen the oil cylinder body 4, the left loosen piston 3, the left slip 61 and the left slip seat 5, the left loose piston 3 is set inside the left loose oil cylinder body 4, and the left slip 61 is set on the left slip seat 5 And the left slip seat 5 is connected to the top of the left unclamping piston 3 through a dovetail groove, and the bottom of the left unclamping cylinder body 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com