Method for rapid preparation of fruit and vegetable crisp grains by three-stage atmospheric pressure microwave spouting drying

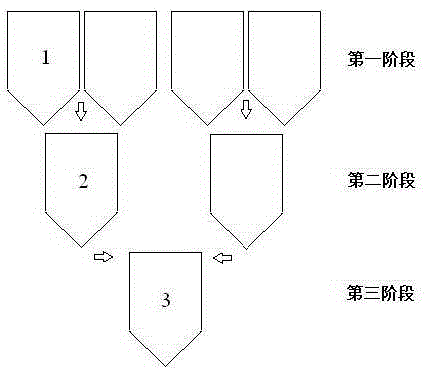

A microwave jetting, three-stage technology is applied in the field of fruit and vegetable dehydration processing and three-stage atmospheric pressure microwave jetting drying to quickly prepare fruit and vegetable crisps, which can solve problems such as difficult control, improve quality, improve crispness, and improve material loading. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: A kind of three-stage atmospheric pressure microwave jet drying method for quick preparation of potato crisps

[0035] (1) Pretreatment: The loading capacity of the equipment is 20kg in total. Fresh potatoes are used as raw materials. The potatoes are selected, cleaned, diced, and cut into 1×1×1cm 3 Potato grains, blanching, blanching temperature is 90~95°C, and blanching time is 3 minutes; the blanched potato grains are subjected to color protection treatment, and the color protection solution is a combined aqueous solution with a mass concentration of 0.1% Vc and 0.1% citric acid monohydrate ;

[0036] (2) Three-stage atmospheric pressure microwave spray drying: the potato grains after color protection are subjected to three-stage atmospheric pressure microwave spray drying:

[0037] The first stage: microwave power 2.0w / g, pulse frequency 1min, spray 3 times, each 6s intermittent spray, dry until the moisture content of the potato grains is 55%~60%, an...

Embodiment 2

[0043] Example 2: A three-stage atmospheric pressure microwave jet drying method for quickly preparing crispy carrots

[0044] (1) Pretreatment: The loading capacity of the equipment is 20kg in total. Fresh carrots are used as raw materials, and the carrots are selected, cleaned, diced, and cut into 1×1×1cm 3 Carrot grains, blanching, blanching time is 4min, blanching temperature is 90~95°C; the blanched carrot grains are subjected to color protection treatment, and the color protection solution is a combined aqueous solution with a mass concentration of 0.1% Vc and 0.1% citric acid monohydrate ;

[0045] (2) Three-stage atmospheric pressure microwave spray drying: Carrot particles after color protection are subjected to three-stage atmospheric pressure microwave spray drying:

[0046] The first stage: Microwave power 2.0w / g, pulse frequency 1min spray 3 times, each time 6s intermittent spray, dry until the moisture content of carrot grain wet basis is 55%~60%, the drying tim...

Embodiment 3

[0052] Example 3: A three-stage atmospheric pressure microwave spray drying method for rapidly preparing edamame brittle grains

[0053] (1) Pretreatment: The load capacity of the equipment is 20kg in total. Fresh edamame is used as raw material. The green edamame is depodded and granulated, cleaned and placed in boiling water for blanching. The blanching time is 1.5~2min, and the blanching temperature is 95 ~98°C; quickly cool the blanched edamame grains with cooling water until the center temperature of the material is below 10°C, then take out and drain the surface moisture.

[0054] (2) Three-stage atmospheric pressure microwave spray drying: Then the edamame grains are subjected to three-stage atmospheric pressure microwave spray drying:

[0055] The first stage: Microwave power 2.0w / g, pulse frequency 1min spray 3 times, each time 6s intermittent spray, dry until the wet base moisture content of edamame is 55%~60%, the drying time is about 15min;

[0056] The second stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com