High-firmness and high-blocking anti-fake packaging box

A high-barrier and packaging technology, which is applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of cardboard structural strength and poor waterproof and moisture-proof performance, reduce friction between grinding wheel and packaging box, and adversely affect the health of production workers. Achieve the effect of convenient warehouse material management, outstanding anti-counterfeiting effect, and improving structural strength and stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

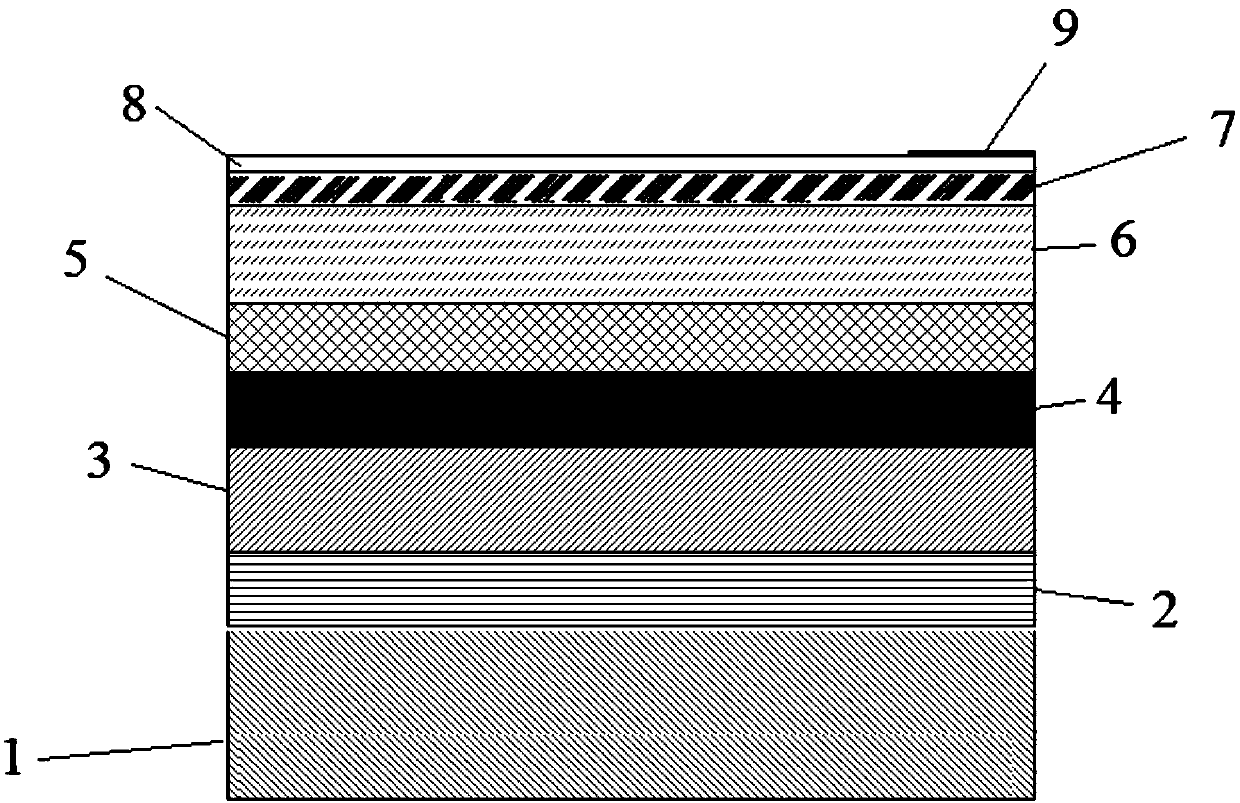

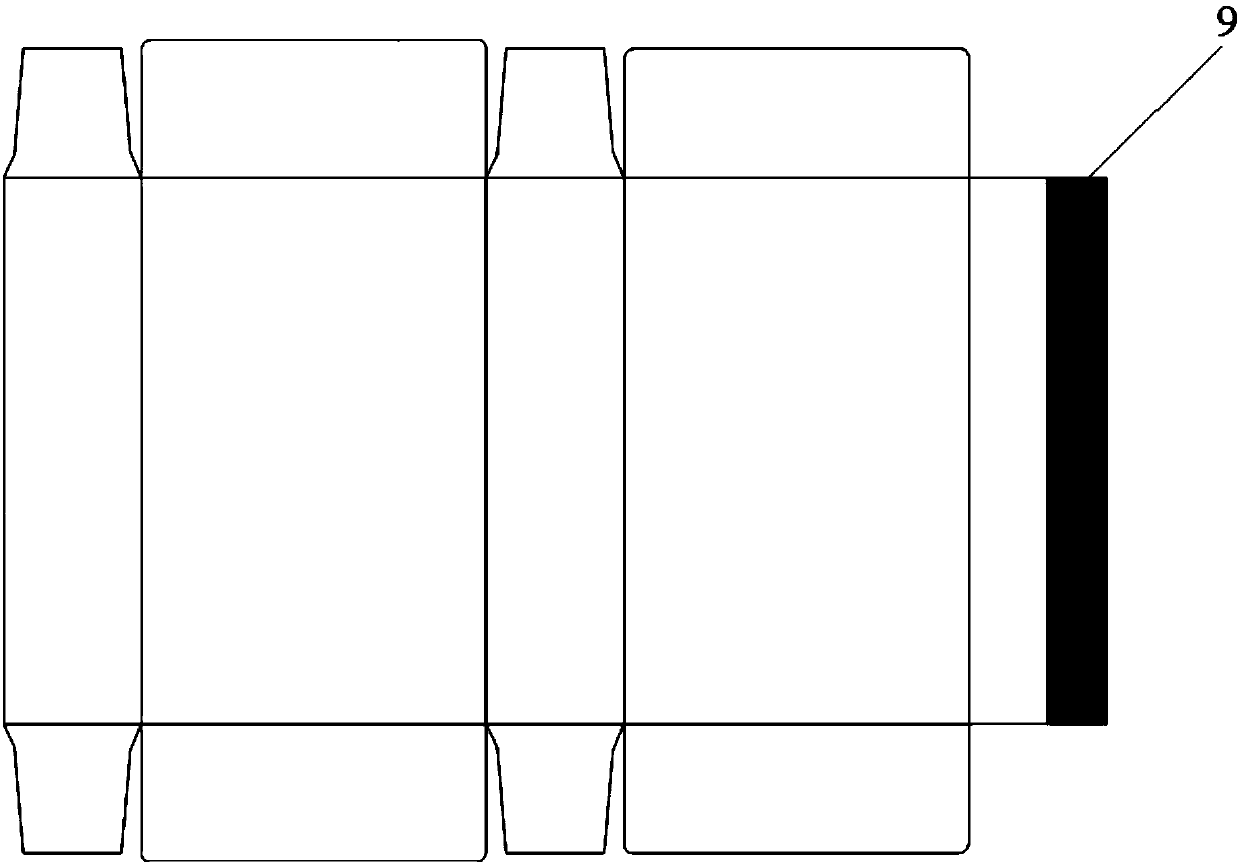

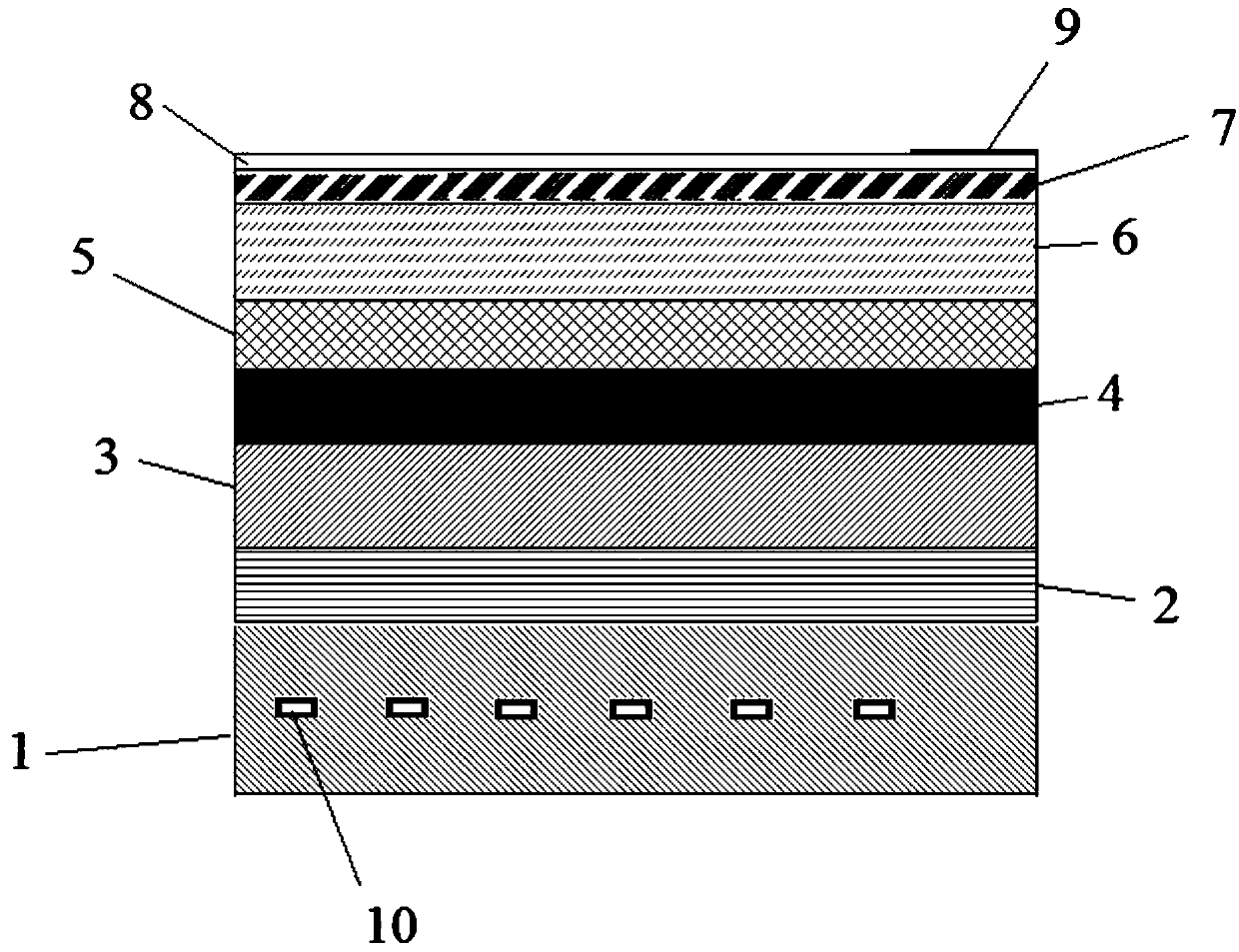

[0026] A high-fastness and high-barrier anti-counterfeiting packaging box is made of packaging cardboard pasted into the box, and the packaging cardboard structure is as follows: figure 1 and figure 2 As shown, it includes a cardboard body 1, a first adhesive layer 2, an aluminized film layer 3, a second adhesive layer 4, a holographic laser anti-counterfeiting layer 5, a BOPP film layer 6, and an acrylic glue layer sequentially compounded from bottom to top. 7 and the PET film layer 8, the outer surface (ie, the PET film layer 8) at the seal of the packaging cardboard is also plasma treated and a plasma adhesive surface 9 is formed.

[0027] In this embodiment, the thickness of the cardboard body 1 is 0.45mm, the first adhesive layer 2 is an animal adhesive layer with a thickness of 35 μm, and the second adhesive layer 4 is a solvent-free composite adhesive layer with a thickness of 30 μm.

Embodiment 2

[0029] The difference from Embodiment 1 is that in this embodiment, the thickness of the cardboard body 1 is 0.4 mm, the thickness of the first adhesive layer 2 is 25 μm, and the thickness of the second adhesive layer 4 is 25 μm.

Embodiment 3

[0031] Different from Embodiment 1, in this embodiment, the thickness of the cardboard body 1 is 0.5 mm, the thickness of the first adhesive layer 2 is 50 μm, and the thickness of the second adhesive layer 4 is 50 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com