Novel single-phase asynchronous AC motor stator structure

A single-phase asynchronous, AC motor technology, applied in the direction of asynchronous induction motors, magnetic circuit shape/style/structure, winding conductor shape/style/structure, etc., can solve the problems of improving product competitiveness, many hidden dangers of quality, and staff operation Trouble and other problems, to achieve the effect of good motor quality and reliability, improve material utilization, and simplify the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

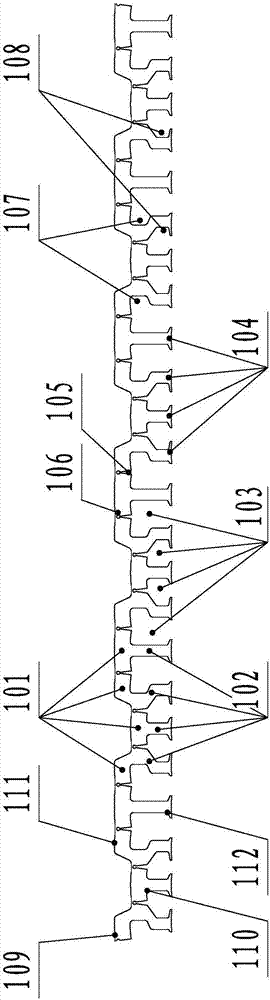

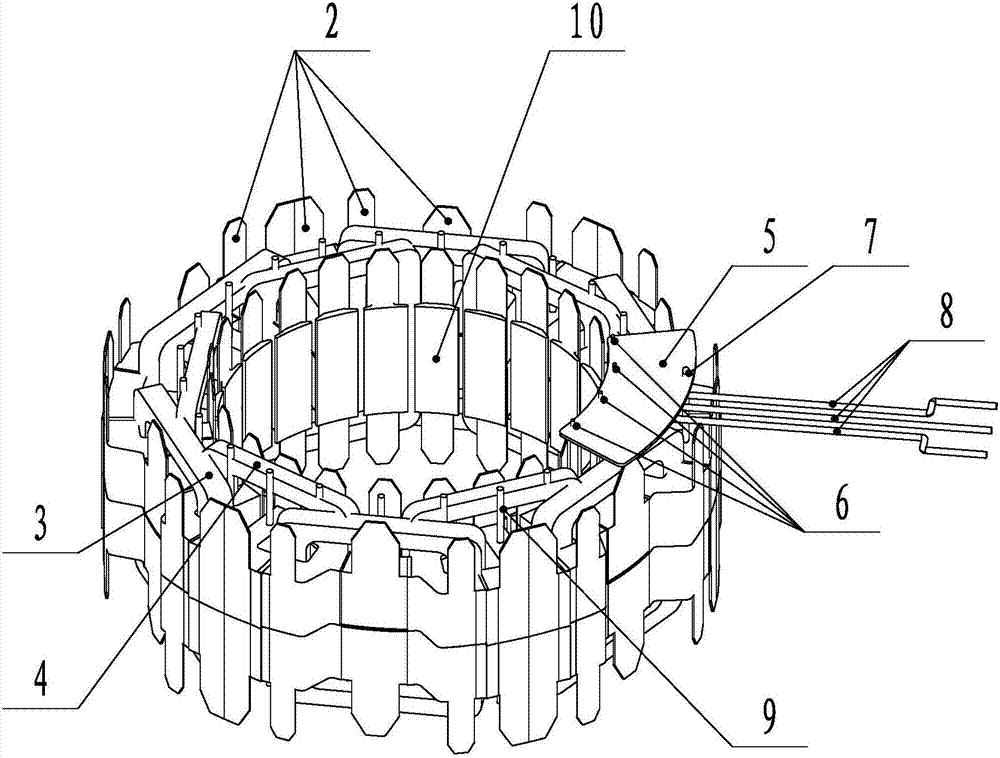

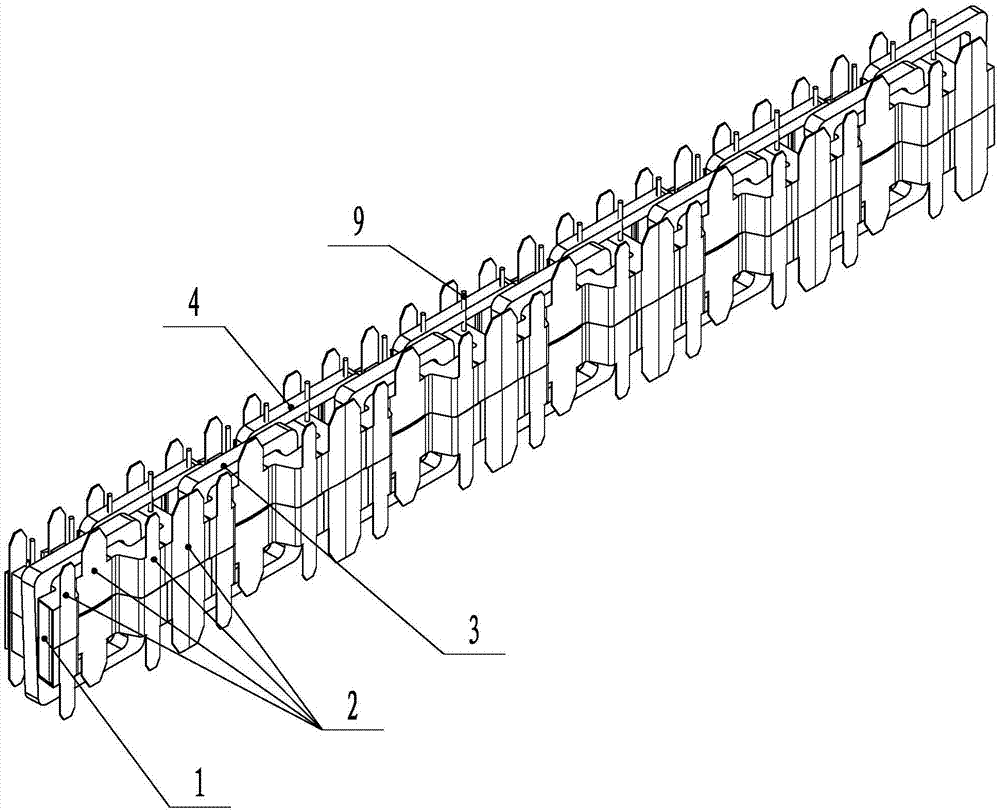

[0021] Such as Figure 1-3 As shown, a novel single-phase asynchronous AC motor stator structure includes a stator core 10, an insulating bushing 2 arranged outside the stator core 10, and a winding wound outside the insulating bushing 2. The stator core 10 consists of a linear The iron core punching sheets 1 are stacked and rolled into a circle. The stator core 10 includes a plurality of identical punching sheet groups arranged around the center of the iron core. Each punching sheet group includes the first punching sheet monomer 109, the The second punching unit 110, the third punching unit 111 and the fourth punching unit 112, each punching unit is provided with an independent insulating bushing 2, the winding includes the outer winding 3 and the outer winding 3 The radial inner inner winding 4, the outer winding 3 winds the adja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com