Large shaft end keyway electrolytic machining device

A technology for machining devices and shaft parts, which is applied in the field of electrolytic machining devices, can solve the problems of no large-scale shaft part end keyway electrolytic machining devices, etc., and achieve the effects of simple structure, strong applicability, reliability and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

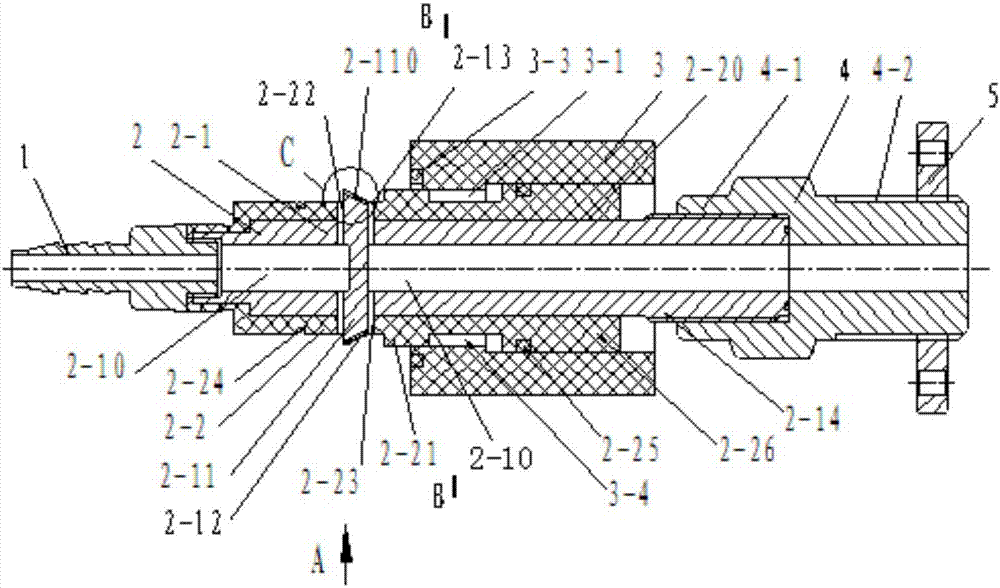

[0034] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

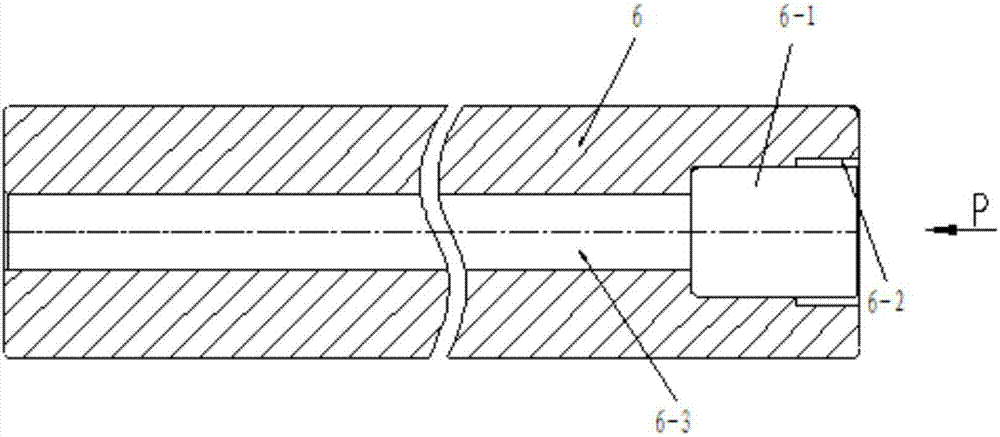

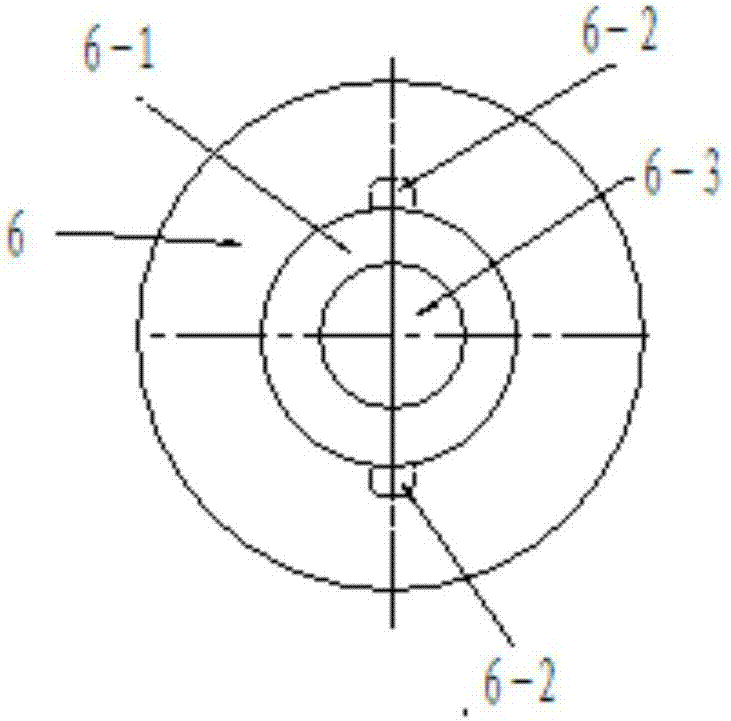

[0035] see Figure 3 to Figure 7 , the electrolytic machining device of the large shaft end keyway of the present invention includes a hose joint 1, an electrolytic cathode 2, a sealing sleeve 3, a connecting head 4 and a flange 5. Depend on Figure 3 to Figure 7It can be seen that the electrolysis cathode 2 includes a copper body 2-1 and an insulating guide body 2-2; the copper body 2-1 is provided with; the axial hole 2-10 is located in the copper body integrally with the copper body 2-1 2-1 The isolation part 2-11 on the left side that separates the axial hole 2-10, the outer surface extending symmetrically and radially outward from the isolation part 2-11 is covered with an insulating layer 2-12, and is electrolytically processed The two bosses 2-110 on the two end key grooves 6-2 on the large-scale shaft part 6 are adapted to the circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com