Cooling type ball screw device capable of being used for multi-thread opening circulation

A ball screw and cooling technology, which is applied in the direction of transmission, transmission parts, gear lubrication/cooling, etc., can solve the problem that the cooling cycle structure of multi-thread ball screw needs to be developed urgently, and achieve the effect of improving machining accuracy and machining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

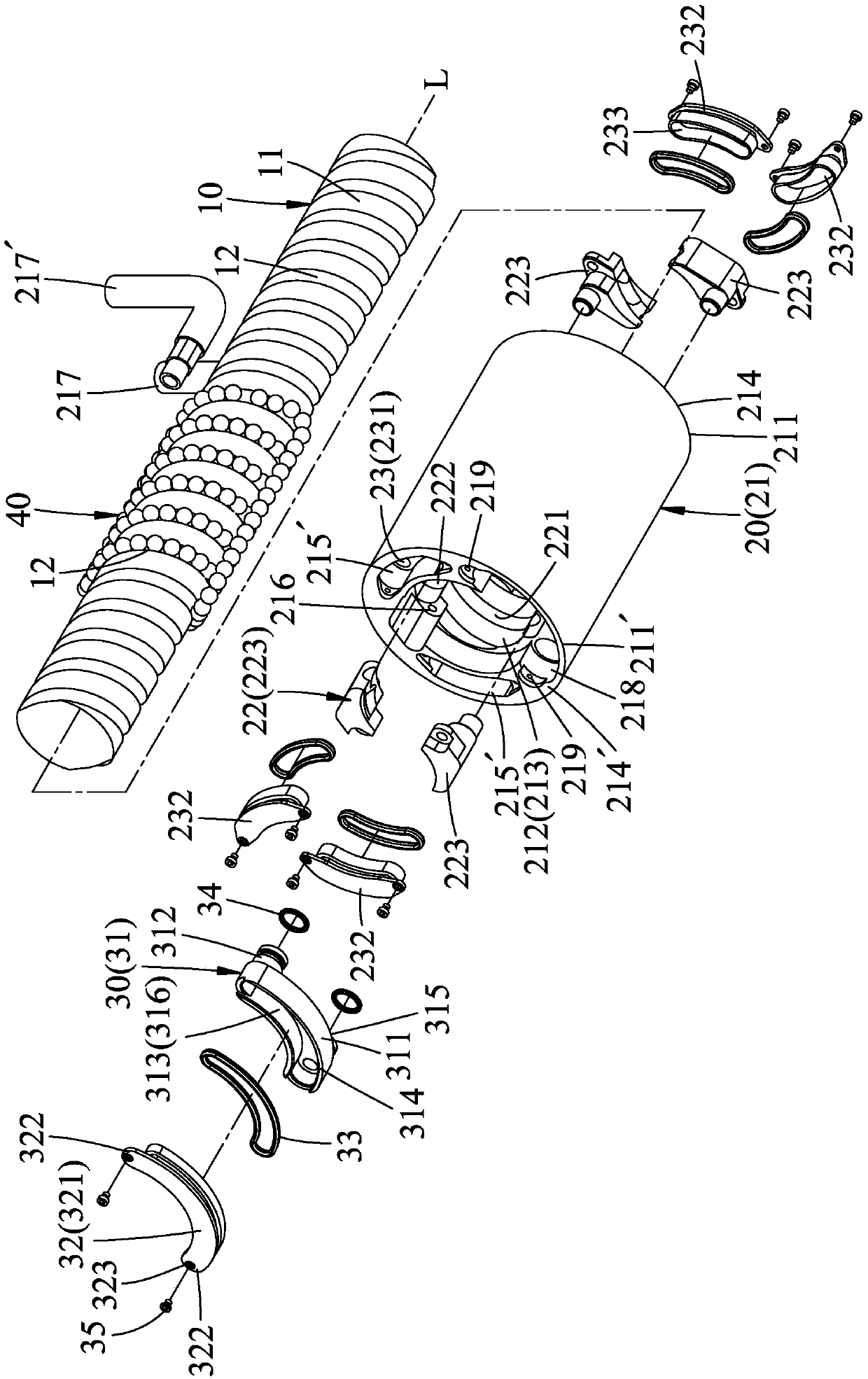

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

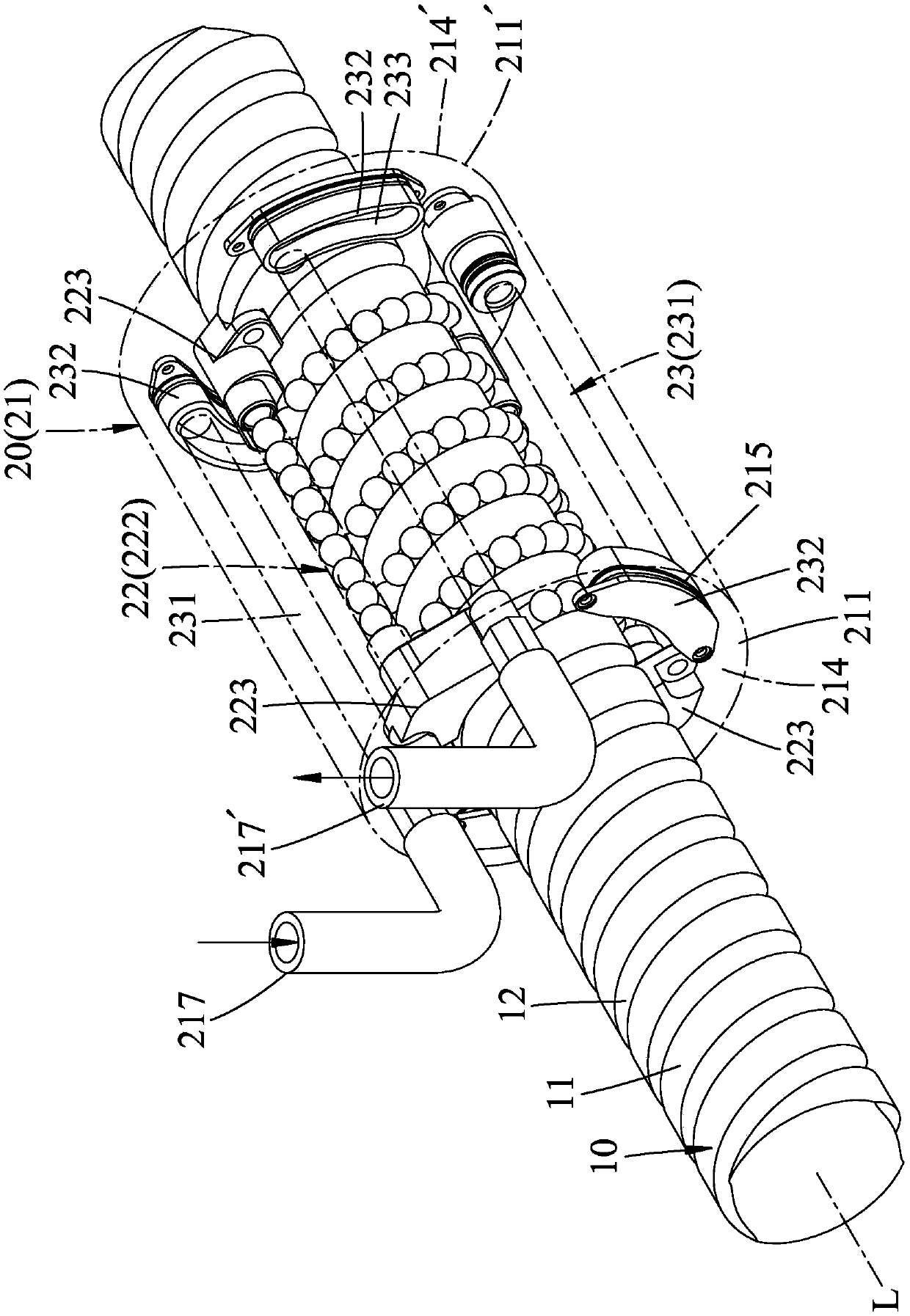

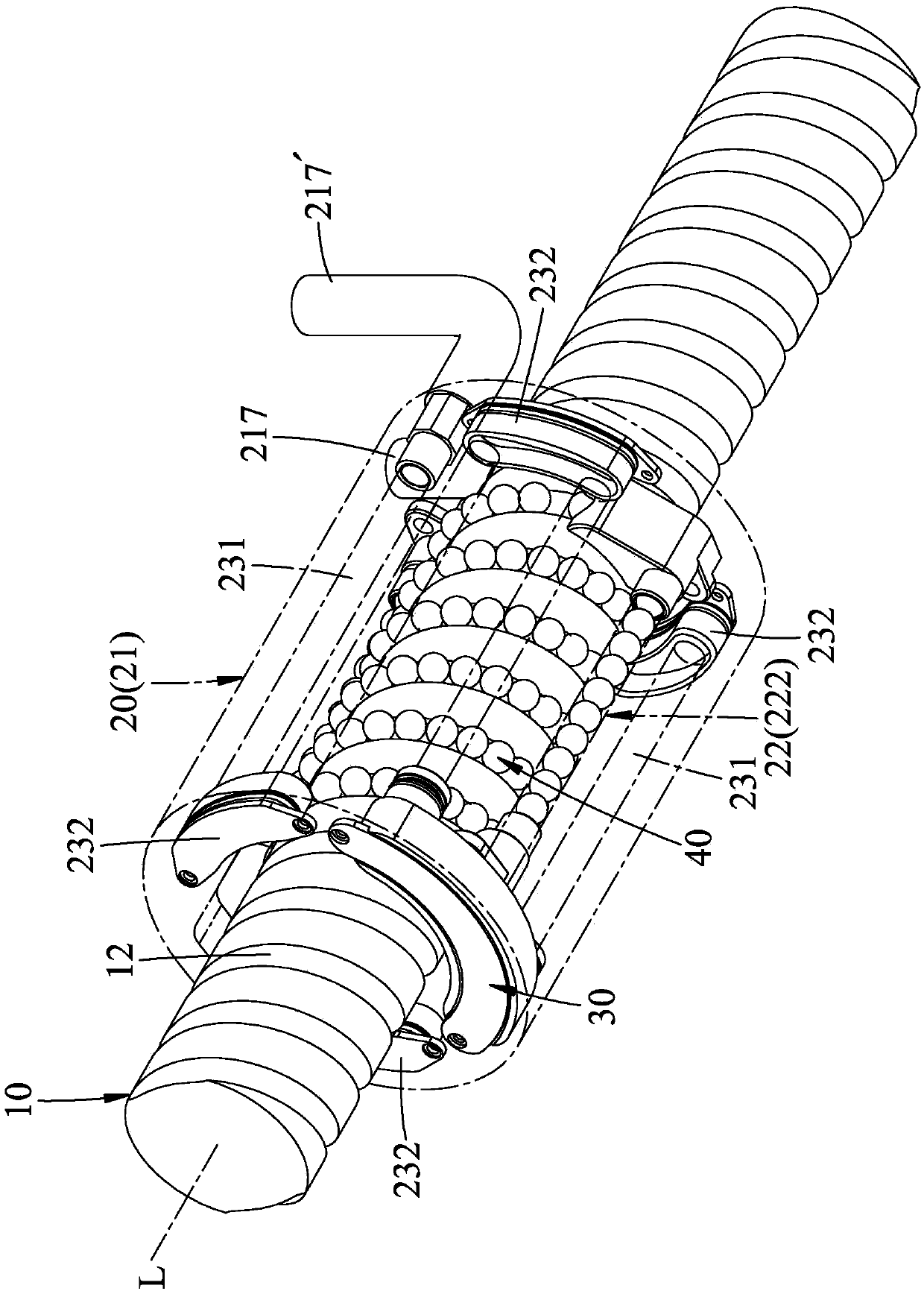

[0022] refer to Figure 1 to Figure 4 , an embodiment of the cooling ball screw device that can be used for multi-thread circulation in the present invention includes a screw 10 , a nut unit 20 and a cooling bridging unit 30 . The embodiment of the present invention is described with a ball screw device with two teeth, but it can also be three teeth or four teeth (not shown in the figure).

[0023] The screw 10 extends along an axis L and has an outer peripheral surface 11 and two external threaded portions 12 spirally wound around the outer peripheral surface 11 .

[0024] The nut unit 20 is screwed on the screw 10 through two ball sets 40 , and includes a nut body 21 , and two return channel groups arranged on the nut body 21 corresponding to the external thread portion 12 22, and a cooling passage group 23 provided on the nut body 21.

[0025] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com