Slit adjusting and positioning device for prestressed high-pressure die winding and preparation method

A positioning device and prestressing technology, applied in attachments, electrode manufacturing, manufacturing tools, etc., can solve problems such as shortening the service life of the mold, uneven pressure distribution in the high-pressure cavity, and fracture of the steel strip, and improve processing accuracy and efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: The machining process of the limiting unit of the present invention

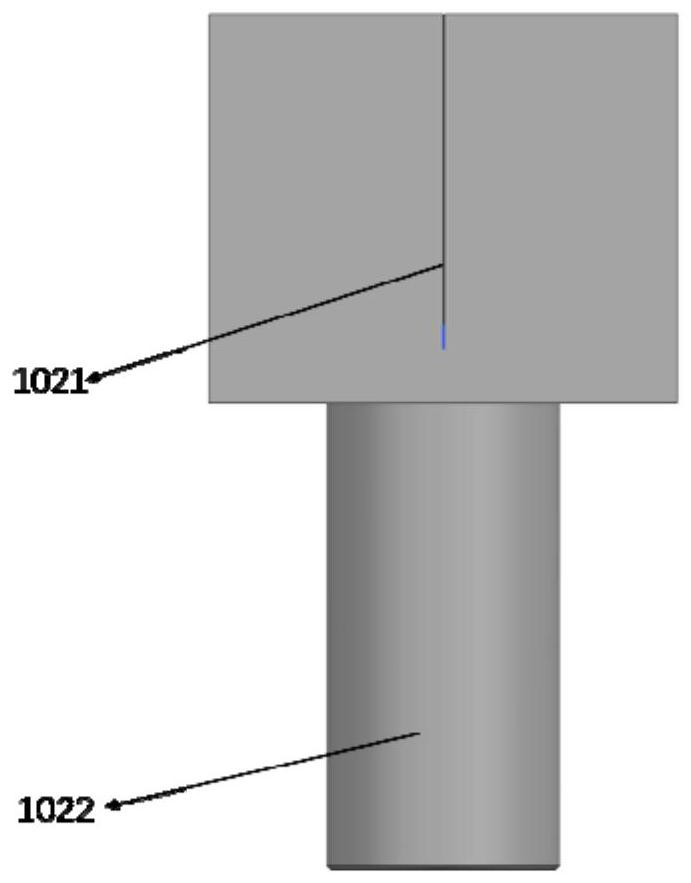

[0022] The slit limit unit is processed by wire cutting equipment. The specific processing method is as follows: firstly, the No. 45 steel is processed into a structure that connects a cuboid and a cylinder. The size of the cuboid is 80mm×60mm×50mm. In the center of a 80mm×50mm surface, the diameter of the cylinder is 30mm and the height is 60mm. Clamp the above-mentioned structure on the linear cutting indexer, and then cut it perpendicular to the surface and parallel to the long edges on another 80mm×50mm surface. A slit with a width of 0.2mm and a depth of 40mm, then adjust the angle of the indexer 30° counterclockwise, the cutting depth is 3mm, cut the chamfer at one end of the slit, and finally reverse the rotation 60° to cut the chamfer at the other end of the slit, so that A limit unit is obtained. The finished slit limit unit such as image 3 As shown, the slit dimensions are a...

Embodiment 2

[0023] Embodiment 2: overall structure of the present invention

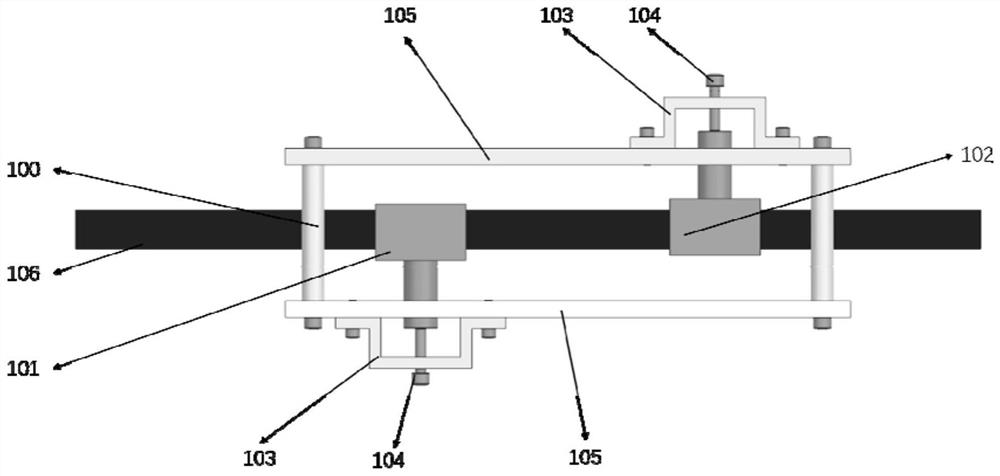

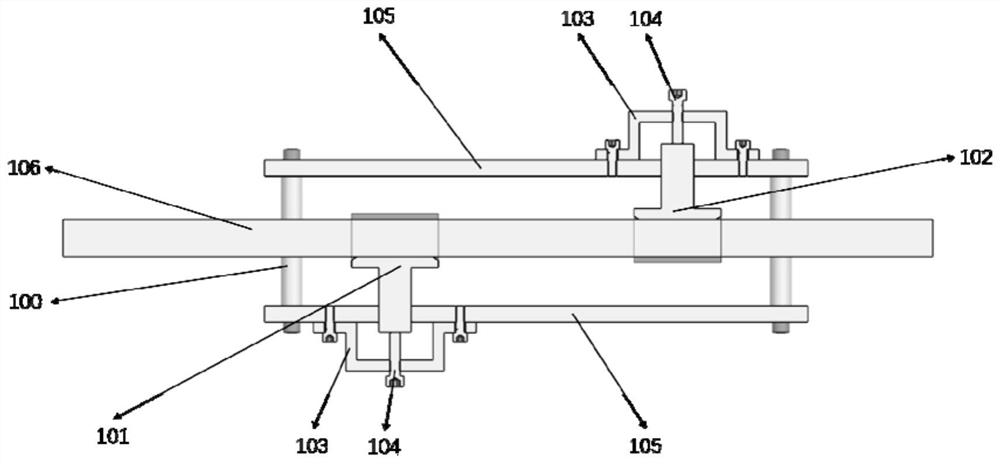

[0024] The slit adjustment and positioning device used for prestressed high-pressure mold winding in the present invention is as follows: figure 1 As shown, the present invention is used for the positioning of prestressed high-pressure mold winding steel strips. In this embodiment, the steel strip 101 to be wound is a thin 65Mn steel strip with a width of 34.5 mm and a thickness of 0.15 mm. The slit width of the limit unit is 0.2mm, which ensures that the steel strip can pass through the slits smoothly. Multiple slit limit units work together to fine-tune the height of the steel strip.

[0025] Such as figure 1 As shown, the upper and lower support base plates 105 are connected by four support columns 100 to form the supporting structure of the slit positioning adjustment device. Positioning guide holes are arranged on the upper and lower support base plates 105, and the rotating handle on the slit limit unit 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com